Can Moderate-Sized Swine Enterprises on Diversified Farms Compete with Large, Specialized Units?

June 16, 1992

PAER-1992-9

John E. Kadlec, Professor

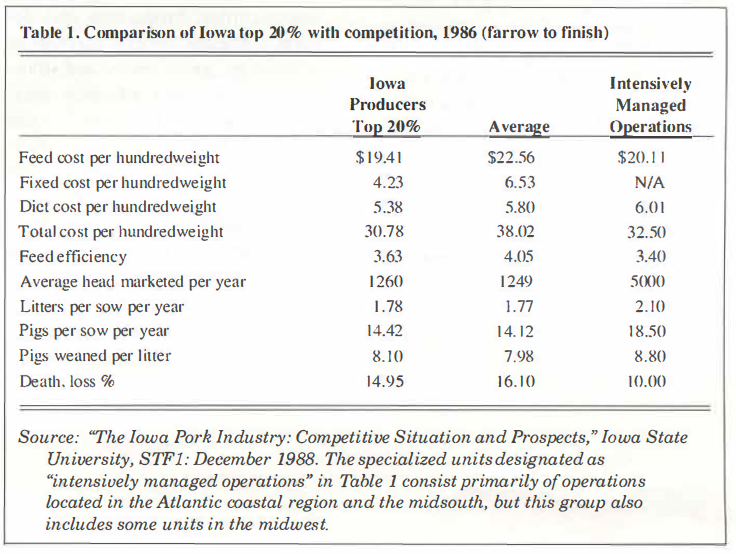

Moderate-sized swine enterprises on diversified farms can compete with large specialized units, but most must make management changes to survive. A comparison of the production costs of moderate-sized diversified Iowa farms with larger, more specialized units indicates that only the best 20-30% of Iowa farm record keepers had costs of production as low as the larger, more specialized units (Table I). Many managers of diversified farms selling 1,000 to 5,000 hogs are questioning whether they can compete with larger, more specialized units that produce over 5,000 hogs per year. Following is a discussion of five areas in which moderate-sized swine enterprises must be better than average in order to survive.

Control Feed Cost Per Pound of Gain

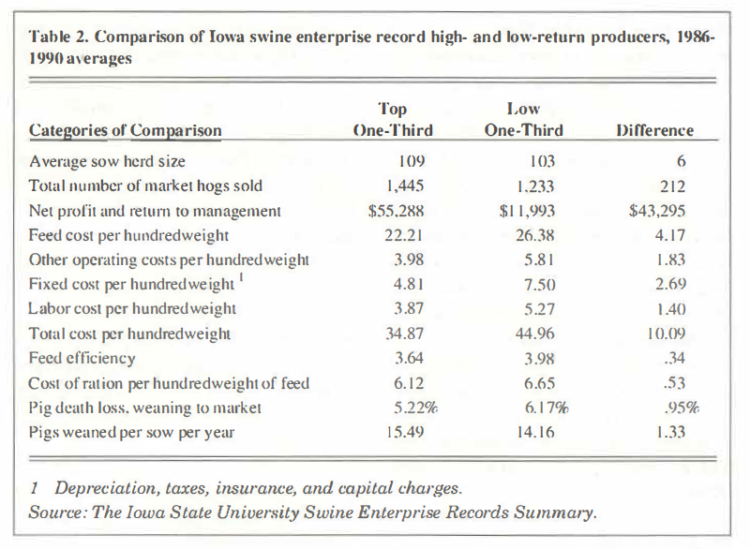

The most important cost for swine producers to monitor is feed cost per hundredweight of gain. Feed accounts for approximately 60% of the cost of pork production and can affect profit by as much as $4 per hundredweight (Table 2). The $4.00 per hundredweight difference in feed cost translates into a $30,000 yearly profit difference for a 3,000-hog enterprise. Feed cost per hundredweight of gain depends on feed conversion, feed ingredient mix, and prices paid for ingredients.

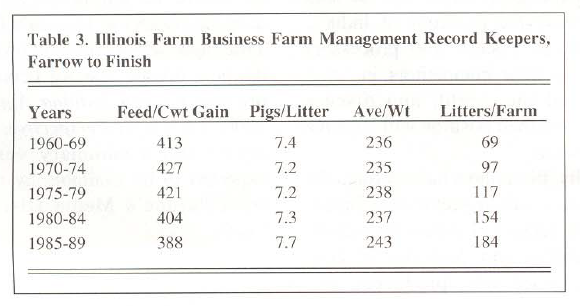

► Feed efficiency has improved dramatically during the past 10 years (Table 3). Swine producers must know the amount of feed required to produce a hundredweight of pork on their farms and must compare their feed conversion to the feed conversion of aboveaverage swine producers. At the present time, a feed conversion of 3.5 or less provides a competitive advantage, while over 4.0 is not. improvements in feed efficiency appear to be due to a variety of factors, including breeding stock selection, terminal crossbreeding systems, feeder technology and adjustment, and control of health problems through good management.

► Both price of ingredients and effect of ingredients on hog performance should be considered. It is not uncommon for swine producers to feed rations that result in high cost of production and/or poor hog perforfmance because of improperly calibrated feed mixing equipment.

► Swine producers must be competitive in the prices paid for corn, soybean meal, and other purchased feed. Enterprise size, storage facilities, and geographic location affect prices paid per unit of feed.

Farms that produce and store their own corn have a 20 cents per bushel or $2.50 per hog advantage over units that purchase corn. Also, corn prices in geographic areas where much of the specialized-unit expansion is taking place, such as North Carolina, are an additional 20 cents per bushel higher. Therefore, midwest farms that produce their own corn have a $2.50 per hog advantage over specialized units in the same area, and as much as a $5.00 per hog advantage over specialized units in corn deficit areas.

Control Building and Equipment Costs

Building and equipment costs (depreciation, interest, taxes, insurance, and repairs) account for 15-20% of total costs of production. Four ways to attain low building costs per hundredweight of gain are:

► Keep construction costs as low as possible without sacrificing building quality. The investment in buildings and equipment reported by some large, specialized units is less than$100 per farrow-to-finish hog produced. These large operations often receive discounts because of size and duplication of the construction of particular types of buildings, and some even have their own building construction crew. Also, building requirements in warm climates may be less costly than in cold climates.

Table 1. Comparison of Iowa top 20% with competition, 1986 (farrow to finish)

Building investments of moderate-sized diversified farms often are $120 or more per hog produced. Each $10 increment in building investment per hog produced results of about $ l.50 higher production cost per hog during the entire life of the building, assuming hog performance and labor requirements are unaffected by the building investment. Large, specialized units have a per-hog cost advantage of about $5.00 over moderate-sized diversified farms. The diversified farm may be able to reduce building investments by doing part or all of the construction work and/or by serving as the general contractor.

► Keep buildings fully utilized. If building ownership costs for a fully utilized building average $7 per hundredweight of pork produced, each 10% below full utilization results in increased costs of approximately 70 cents per hundredweight of pork produced. This is because total building costs remain almost the same regardless of the number of hogs produced.

► Increase the life of buildings and equipment. Some managers extend the life of buildings and equipment through good maintenance. Assuming a $100 investment per hog in buildings and equipment and a normal life of I0 years. one “extra year” decreases cost per hog by $1.00 for the entire life of the building. Arrangements for continuity of the business also affect the length of time that buildings and equipment are used.

Table 2. Comparison of Iowa swine enterprise record high- and low-return producers, 1986-1990 averages

► Shop for interest rates. Each 1% difference in interest rates affects building and equipment costs about 60 cents per hog produced. Operators can attain significant savings by borrowing at favorable rates or by financing with a larger percentage of equity capital.

Improve People Management

Labor costs represent I 0-15% of the cost of production. The most important challenge is to follow sound procedures in recruiting, hiring, training, evaluating, motivating, and compensating employees. In order to hire and keep good employees, managers must become “masters of labor management.”

Table 3. Illinois Farm Business Farm Management Record Keepers, Farrow to Finish

Merchandise Your Hogs

Some producers receive $1 or more per hundredweight of hogs sold than do other producers. This price advantage can most likely be attributed to location; the type, weight, and volume of hogs sold; and the arrangement between the buyer and the producer. Hogs from larger units are likely to be more attractive to buyers than smaller units. It is extremely important for all producers, but especially smaller producers, to monitor price received relative to other farms and to take necessary steps to ensure competitive prices. These steps may include:

► Developing specific arrangements with buyers regarding the type, size, and number of hogs to be delivered at particular times.

► Coordinating with other producers in the same area to provide the type and number of hogs needed at specific times and bargaining with buyers for compensation for volume and quality

► Identifying and maintaining good markets will be one of the greatest challenges for swine producers in the decade ahead.

Grow to a Suitable Size

Be large enough to gain economies of size and to generate your desired income. Profit margins per hog will likely narrow in the decade ahead due to greater competition from large specialized units. In order to have the same income provided from the swine enterprise as in the past, it will be necessary to produce more hogs. Also, it will be necessary to gain economies of size for labor use, in feed equipment use, in purchase prices, on building prices, and market prices. For most operators, a 3,000-head-per-year farrow-to-finish hog unit will be needed. Smaller enterprises may gain economies by making group purchases and sales with other producers.

How to Excel

Diversified, moderate-sized swine farms in the Midwest have some cost advantages over larger, more specialized units due to lower costs for corn waste disposal, and overhead. Yet in a study of lowa farms, only about 20-30% of the Iowa State University record keepers had lower costs of production than large, specialized swine production units. The average Iowa record keeper had $5.50 higher costs per hundredweight than the specialized units. To be competitive, the moderate sized, diversified farms in the Midwest must:

► Keep good swine enterprise records and know such key management factors as feed cost, building cost, and price received per hundredweight of pork produced

► Compare key management factors to similar farms and to large specialized units

► Be at the cutting edge of practices that lead to improved feed efficiency, especially in the selection of breeding stock and use of terminal crosses

► Purchase feed at below-average prices

► Keep building costs at a m1111mum with low-cost construction, full utilization, good maintenance, and low interest rates

► Understand labor management practices that will ensure hiring, motivating, and keeping good employees

► Produce the type of hog that best fits consumer demand and take steps to assure good markets

► Be large enough to be competitive in purchasing inputs and securing good markets. For small producers, group purchasing and selling may be required.