The Economics of Using Distiller Grains in Small-Scale Beef Operations in Indiana

December 19, 2010

PAER-2010-09

David Widmar, Graduate Student; Ken Foster, Professor and Department Head; Dennis Buckmaster, Associate Professor, Department of Agricultural and Biological Engineering; Ronald Lemenager, Professor, Department of Animal Science and Nicole Olynk, Assistant Professor

The expansion of corn-based biofuels has created an increase in the supply of distiller grain by-products, especially in Indiana and the Eastern Corn Belt. Distiller grains can be used as a corn substitute and are produced in two primary forms, wet distiller grain with solubles (WDGS) or dried distiller grain with solubles (DDGS).

Because of the energy-intensive drying process needed to convert WDGS to DDGS, WDGS are a cheaper feed source, per dry unit, for producers. Unfortunately, WDGS are especially prone to spoilage due to their high moisture content. The shelf life has been estimated to be as short as a week in the summer months.

For small-scale producers to use WDGS, they would likely need to get partial loads of the WDGS product throughout the feeding season or somehow store it. Partial loads are possible but would ultimately depend on the relationship with the WDGS supplier and hauler. Because of the high density of WDGS, storing them by themselves in an upright or bag silo is not possible as it would exceed the structural capacity of the storage facility. A possible solution is co-ensiling WDGS with silage.

Ensiling WDGS with silage requires mixing the silage and WDGS products and storing them together. The oxygen–reduced environment of the silage system discourages WDGS spoilage, and all the WDGS the producer is expected to use for the year would be hauled at the same time, so any additional cost for partial loads would be mitigated. In addition, the density of co-ensilage allows for storage in existing silage storage facilities.

Using either form of distiller grains in the feed rations is biologically feasible but poses a different set of economic implications, especially for small-scale producers who face greater risk of spoilage when using WDGS. The objective of this work is to report on different distiller grain feeding strategies for small-scale beef producers in Indiana.

Methods

Based on the biological performance observed and published on small-scale beef producers in Indiana in Arias, et al. 2008 and Arias, et al. 2009, partial budgets were created to reflect the economic impact of using the different forms of distiller grains. For each the two enterprises, bred heifer and finishing steer feeding, four different feeding trials were evaluated, DDGS, WDGS mixed at feeding, WDGS co-ensiled at silage harvest, and a control not using distiller grains. The partial budgets for each ration reflect the changes in costs from the control. Changes in costs included change in the value of production, changes in feed cost, changes in storage cost, product hauling cost, and cost associated with the change in manure value.

Feed Costs: Corn silage price was estimated at $34.10 per ton, or $5 plus 7.5 times the per bushel price of corn, as suggested by Ohio State University silage production budgets (Ward, 2008). Historic prices and value estimators were not available for hay crop silage and alfalfa silage. These values were assumed to be $35 per ton and $45 per ton respectively based on an estimated equivalent to corn silage. Mineral and ration supplements were valued based on Pur-due feed mill prices in June 2010, and beef cattle mineral prices were assumed to be $0.84 per pound. USDA’s National Agricultural Statistics Services (NASS) database was used to collect average prices for the remaining feedstuffs from 2007-2009, including an average corn price of $3.88/bu and soybean meal price of $290/ton.

Distiller grain prices were gathered from weekly Eastern Corn belt Ethanol Plant Reports published by the USDA’s Agricultural Marketing Service. Monthly averages for 2007-2009 were used to match the timing of the distiller grain purchases. Some seasonality was found to exist in distiller grains prices, and producers could realize lower cost WDGS in August and September. This timing is ideal for the co-ensiling feeding method since it is when the majority of corn silage is harvested. A conversation with a local ethanol plant provided a distiller grains transportation quote at $10/ton for 40 miles.

Storage and Mixing: Costs were based on tractor fuel consumption and operating capacities figured from American Society of Agricultural Engineers Standards (ASAE) for machinery management (“Agricultural Machinery Management,” 2001; “Agricultural Machinery Management Data,” 2009). Silage and co-ensilage storage was assumed to be in AgBags (bag silos). Area custom rates were found to be $1,100 per bag for the AgBag based on conversations with dealers and includes materials and machine rental. It was assumed that dry matter storage capacity of co-ensiled products was 50% higher than silage alone because of changes in density. For these costs, only additional operating and variable costs were considered.

A critical assumption is that no logistical bottlenecks were created by the co-ensiling process. Specifically, the mixing process was assumed to not interfere with the silage harvesting or hauling processes. Second, three tractors were used, and two operators were required. The control of a normal AgBag operation required only one tractor and one operator. For the co-ensiling process, the first trac-tor is a front-end loader. Navarro, et al. 2010 found that the majority of small-scale farmers in Indiana have either a front-end loader or skid steer. The second tractor was used to power the total-mixed ration (TMR) mixer, and a third tractor was used for the AgBagger. The labor assumption of two laborers was for one person to operate the front-end loader and TMR mixer while the second operator runs the AgBagger. Additional labor was assumed at a rate of $10 per hour and fuel costs were estimated at $2.83 per gallon based the average of fuel prices in Indiana for 2007-2009, as reported in the USDA’s NASS database.

Manure: Changes in the value of manure produced and the cost of manure disposal were also considered because feeding DDGS to livestock can result in changes to the manure nutrient profile. The nutrient profiles of the rations were estimated based on the feed intake and adjusted for animal maintenance and production needs using ASAE publication D384. 2 (“Manure Production and Characteristics,” 2005). The difference between nutrient intake from the feed and the animal’s nutrient use was adjusted to reflect nutrient availability (Joern, Brad C. and Brichford, Sarah L., 1993; Christenson et al., 1992). Based on 2-year fertility needs for a corn-soybean rotation, Massey’s fertilizer application model was used to estimate the changes in application costs. The value of the manure applied was based on local commercial fertilizer prices from Miller et al. (2009).

Interest: As feed cost and feed purchasing schedules vary with the different feed rations, changes in interest cost for inventoried feeds were included. Interest charges were assumed to be 4% (Miller, et al. 2009).

Results-Bred Beef Heifers

The bred heifer analysis is based on the costs of feeding 50 head through the winter, 210 days from October 1st to May 1st and based on the results published in Arias, et al. 2008. From the study, the control diet was corn silage and soybean meal based. The test diets were a corn silage and WDGS ration co-ensiled at a dry matter ratio of 3:1 (corn silage: WDGS) (Co-Ensiled), corn silage and DDGS ration mixed at a dry matter ratio of 3:1 (corn silage: DDGS) at feeding

(CS+DDGS), and a corn silage and WDGS ration mixed at a dry matter ratio of 3:1 (corn silage: WDGS) at feeding (CS+WDGS). Diets were also supplemented with a mineral premix added at feeding time. The diets were all formulated to be isocaloric and isonitrogenous to meet the appropriate published national research council (NRC) requirements. It should be noted that the performance trial was for only 62 days, but our economic analysis has been expanded to 210 days, a better representation of what farmers are likely to experience.

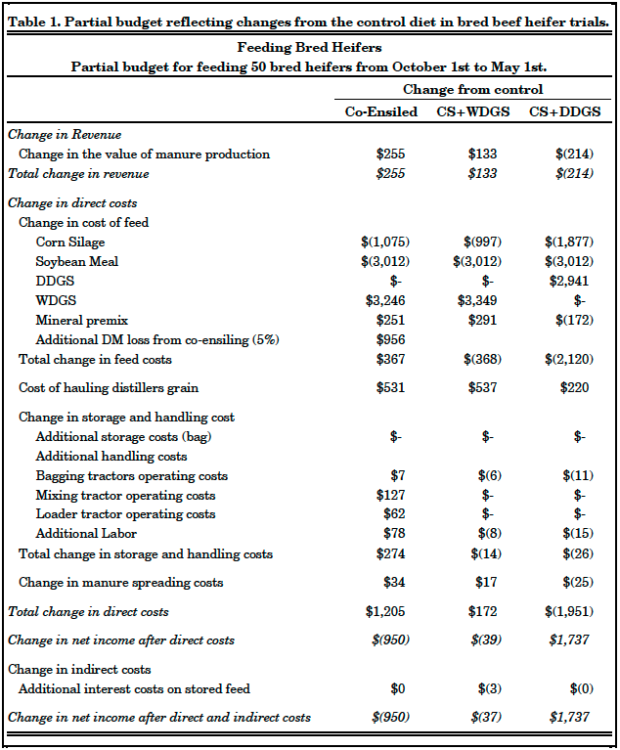

Table 1 shows the partial budget for the operation and the estimated changes in revenue, cost, and net income if the producer changed to one of the rations containing dis-tiller grains from a base ration that contained no distiller product.

From the partial budget analysis, it is clear that a producer would have the greatest estimated net income increase using the CS+DDGS ration, $1,737. The CS+WDGS resulted

in a slight change to the operation’s net income, $-37. However, the co-ensiled ration produced a negative change in net income of $-950.

Feed cost for the CS+DDGS diet is the biggest reason the largest positive change in net income. This is because DDGS replace more corn silage in the ration than WDGS. It should be noted that this ration had the lowest daily dry matter intake of the rations evaluated, 15. 41lbs/day compared to 17.26 on the control, 17.73 for co-ensiled, and 17.95 for WDGS.

The negative change in manure value in the CS+DDGS diet was a function of a decrease in the nitro-gen levels when compared to the control diet. Each of the diets had higher phosphorus levels and lower potassium levels than the control. The slight change in manure application cost is from a change in the application rates, which affected the number of acres onto which manure was applied.

Table 1. Partial budget reflecting changes from the control diet in bred beef heifer trials.

For the results presented in Table 1, distiller grain transportation costs were assumed to be $10/ton, based on a quote received June 2010 from an Indiana ethanol plant. This quote is 100% variable and does not have a fixed cost, or additional fee, to receive delivery of a partial load of distiller grains. If we assume that distiller grain transportation costs are not completely variable, but that 80% of the total cost of a full load are variable, we find that the CS+WDGS ration is adversely affected, showing a new change in net income of $829. The co-ensiled and CS+DDGS diets are only slightly affected by this because when hauling all distiller grain

in at one time and have only one partial truck load. If 76% of a full load’s total cost were to be variable, the co-ensiled and CS+WDGS ration would be indifferent, with

a new negative change of net income of $-985 for both.

It was assumed that the economic value of the bred heifers after feed-ing is based on factors outside the scope of this analysis and not affected by the observed variations in body weight. For this reason, no attempt was made to capture a dollar value for changes in animal performance across the four rations.

Results-Finishing Steers

The finishing steers study consisted of four test diets (Arias, et al. 2009). A ration based on corn silage, cracked corn, and soybean meal was used for a control to illustrate the base of a small operation not currently using distiller grains products. The other rations tested were a hay crop silage and WDGS ration co-ensiled at a dry matter ratio of 3:1 (hay crop silage: WDGS) (Co-Ensiled), a ha ycrop silage and WDGS ration mixed at a dry mat-ter ratio of 1:2. 33 (haycrop silage: WDGS) that was mixed at feeding

(H+WDGS), and a hay crop silage and DDGS ration mixed at a dry matter ration of 1:2.30 (hayc rop silage: WDGS) that was mixed at feeding H+DDGS). All the diets contained cracked corn and were iso-caloric and isonitrogenous and meet the appropriate NRC requirements.

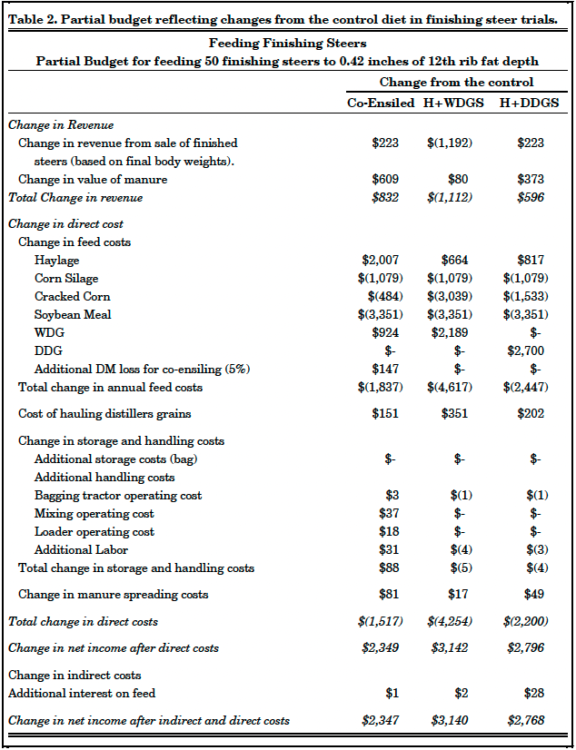

Table 2. Partial budget reflecting changes from the control diet in finishing steer trials.

The steers were placed on feed at 723 lbs. and fed until harvest, which was determined when the 12th rib’s fat depth was 0.42 +/- 0. 11 inches. Because of this, the number of days the finishing steers on feed was different for each of the feed trials. It should be noted that this economic analysis did not consider an opportunity cost for the feeding pens when cattle were kept for longer days on feed. The underlying assumption is that only one batch of cattle are fed in the facility per year and that during the intervening days between batches the facility sits idle.

Table 2 is the partial budget showing the economic changes the distiller grains diets have

on net income. The partial budget is based on the feeding of 50 head. In all three test rations, there appears to be an economic incentive to use distiller grains. The largest estimated impact on net income is for a switch to the hay crop and distiller grain rations. This is primarily caused by the hay crop and distillers being cheaper sources of feed and the greater degree of substitution for cracked corn.

The change in revenue from the sales of animals was based on an average per hundred weight price of beef cattle in Indiana from 2005-2009. Steer values were estimated as $81.08 cwt., based on the USDA NASS database. No meat quality considerations were accounted for in the revenue calculations. The revenue loss in the H+WDGS ration is due solely to the lower final body weight.

Feed cost for the H+WDGS ration is a result of the fewer days on feed and higher feed conversion efficiency.

The steers on this ration consumed less feed than the control and the other two distiller grains rations.

If we consider a fixed cost, or additional fee, to receive a partial load of distiller grains, the H+DDGS and co-ensiled rations are relatively insensitive as they receive their loads at one time with only one partial load. When the variable costs are at 82% of a full load’s total cost, producers are indifferent between H+WDGS and H+DDGS with the new change to net income for both at $2,769. Furthermore, when the transportation costs are 61% variable, there is indifference between the co-ensiled and H+WDGS rations with the new change to net income at $2,319.

Conclusion

From the rations evaluated, small-scale producers feeding bred heifers have the greatest opportunity to capture economic benefits of feeding distiller grains with the DDGS ration. Mixing WDGS at feeding resulted in a small negative change in net income but would become even more negative as the cost of a load of WDGS has a higher fixed cost component. Feeding WDGS in the co-ensiled ration was the least desired feeding option, and producers would be better off feeding the control ration with no distiller grains.

The three rations evaluated for finishing steer all provide economic incentive for the use of distiller grains products. Mixing the WDGS at feeding provided the greatest incentive but would become less favorable as the cost to haul a load of WDGS has a higher portion of fixed costs. Again, feeding WDGS in the co-ensiled ration is not the favored feeding ration but, in this case, is a more profitable feed ration than the control.

Overall, small-scale beef producers do have economic opportunities to use distiller grains with their bred heifer and finishing steer operations. On-farm retrofitting of equipment could make this co-ensiling process more efficient and lower some of the added handling cost. Finally, producers should carefully evaluate their unique storage, equipment, and feeding systems before switch-ng their beef feeding strategies to include a distiller grains product.

Editor’s note: For a full-length version of these results, contact the co-author at dwidmar@purdue.edu Citations “Agricultural Machinery Management.”

Citations

“Agricultural Machinery Management.” American Society of Agricultural and Biological Engineer Standard. Publication: ASAE EP496. 2. Feb. 2003. http://www3.abe.iastate.edu/ast330/ Project/AESE496.2.pdf.

“Agricultural Machinery Management Data.” American Society of Agricultural and Biological Engineers Standard. Publication: ASAE D497. 6. June 2009. http://asae.frymulti.com/azdez.asp?JID =2&AID=27762&CID=s2000&T=2.

Arias, R. P.; Lemenager, R. P.; Snyder, L. J.; Lake, S. L. “The Effects of Co-Ensiling Wet Distiller’s Grains Plus Solubles with Corn Silage on Growth Performance of Bred Beef Heifers During Late Pregnancy.” Proceedings from the Western Section of the American Society of Animal Science. Vol. 59. 2008. http://www.asas.org/ western08/proceedings/08W0350. pdf.

Arias, R. P.; Snyder, L. J.; Lemenager, R. P.; Lake, S. L. “The Effects of Co-Ensiling Wet Distiller’s Grain Plus Solubles with Haylage on Feedlot Performance and Carcass Characteristics of Finishing Steers.” Proceedings from the Western Section of the American Society of Animal Science. Vol. 60. 2009. http://www.asas. org/westernsection/2009/proceedings/ 09WS0382.pdf.

Christenson, D. R.; Warncke, D. D.; Vitosh, L. M.; Jacobs, L. W.; Dahl, J. G. “Soil Testing Procedures” Fertilizer Recommendations for Field Crops in Michigan. Publica-tion: Extension Bulletin E-550A, March 1992. http://web1.msue.msu.edu/imp/modf1/06029704.html.

Joern, Brad C. and Brichford, Sarah L. “Calculating Manure and Manure Nutrient Application Rates.” Agronomy Guide. Purdue University Cooperative Extension Service. Publication: AY-277. Sept. 1993. http://www.extension.purdue.edu/extmedia/AY/AY-277-W.html.

“Manure Production and Characteristics.” American Society of Agricultural Engineers Standard. Publication: ASAE D384. 2. March 2005. http://asae.frymulti.com/ azdez. asp JID=2&AID=32018&CID =s2000&T=2.

Massey, Ray. “Manure Distribution Cost Analyzer.” August 2008. http://agebb. missouri.edu/commag/crops/massey/ downloads/index.htm.

Miller, W. Alan; Dobbins, Craig L.; Erickson, Bruce; Nielsen, Bob; Vyn, Tony J.; Johnson, Bill; Wise, Kiersten. “2010 Purdue Crop Costs & Return Guide.” Purdue Extension. Publication: ID-166-W. September 2009.http://www.agecon.purdue.edu/extension/pubs/id166_2010_Sept09.pdf.

Navarro, Julia I.; Lake, Scott L.; Lemenager, Ronald P.; Marshall, Maria. “Inventory Resources for the Utilization of Bio-Fuel Co-products by Small and Medium Sized Beef and Dairy Producers in the State of Indiana.” Working paper. 2010.

Ward, Barry. “Small Scale Corn Silage Production Budget-2009. Conservation Tillage Practices: N-Source-NH3.” The Ohio State University Extension, 2008. http://aede. osu.edu/programs/farmmanagement/ Budgets/crops-2008/silage2008.pdf.