Farmer sentiment rebounds, but future expectations continue to slide

Farmer sentiment improved modestly in February, as the Purdue University/CME Group Ag Economy Barometer rose by 3 points from January to a reading...

There are a few constants in human life. Sleeping. Breathing. Using the bathroom. But the constant that captures the most of our time and attention, the one that’s central to our cultures, our families, our memories, is eating. From a baby’s first bite of banana to a child’s birthday cake to college pizza parties to anniversary boxes of chocolate, food is how we mark time, bond and show love. Increasingly, it’s clear that food is also the key to our health, in ways both obvious (candy rots your teeth) and less obvious (how certain fibers affect the microbiome).

There are a few constants in human life. Sleeping. Breathing. Using the bathroom. But the constant that captures the most of our time and attention, the one that’s central to our cultures, our families, our memories, is eating. From a baby’s first bite of banana to a child’s birthday cake to college pizza parties to anniversary boxes of chocolate, food is how we mark time, bond and show love. Increasingly, it’s clear that food is also the key to our health, in ways both obvious (candy rots your teeth) and less obvious (how certain fibers affect the microbiome).

READ MORE

Farmer sentiment improved modestly in February, as the Purdue University/CME Group Ag Economy Barometer rose by 3 points from January to a reading...

Karthik Sankaranarayanan trained in two quite different scientific subfields as a graduate student and as a postdoctoral researcher. Now at Purdue...

“This might sound very weird,” Binayak Kunwar says, “but my first impression of the United States was that the sky here was too...

For Hayvn Meihls, studying abroad started with a leap of faith and turned into a passion for seeing agriculture through a global lens. As a...

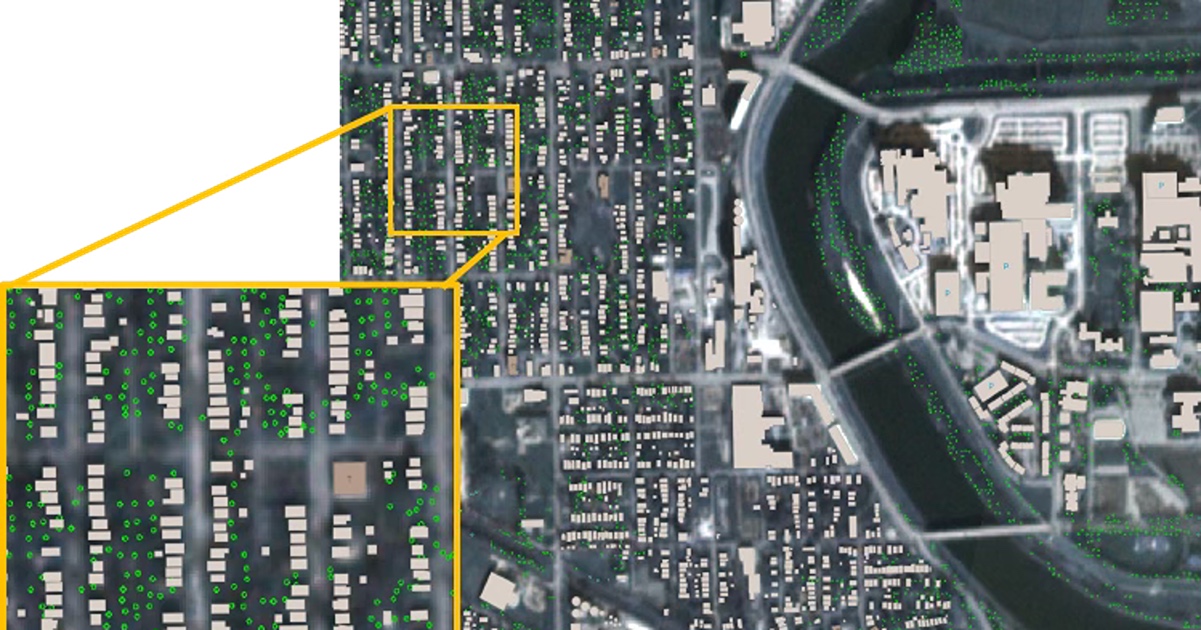

A Purdue University digital forestry team has created a computational tool to obtain and analyze urban tree inventories on public and private lands...

Kendall Cottingham is a graduate student in Purdue University's Department of Biochemistry. Cottingham works with fruit flies — which at the cellular level are remarkably similar to humans — to understand how specific RNA modifications might affect neurological function. The goal is to identify where problems in neurogenerative diseases come from and create solutions that could ultimately benefit humans.

From floods to fall drought to 20-foot icicles, the Midwest experienced some record-breaking weather events in 2025. Climatologists with the Midwestern Regional Climate Center, a partnership between the National Centers for Environmental Information and Purdue University, identified ten of the most memorable and impactful of the year.

After picking, pressing and processing apples, Purdue University Food Science students saw the fruits of their labor at the campus Farmers Market, where their Purdue apple cider is sold. Try the student-made cider this Thursday, October 30th at the last Farmers Market of the season!