Providing Sustainable Post-Harvest Solutions for sub-Saharan Africa

L

ed by the U.S. Agency for International Development (USAID), Feed the Future is the U.S. Government’s initiative to end global hunger and enhance food security. More than 20 Feed the Future Innovation Labs are paired with experts from leading U.S. universities to help address grand challenges in agriculture and food security. Researchers at Purdue University power the Feed the Future Innovation Lab for Food Processing and Post-Harvest Handling (FPIL). FPIL seeks to reduce post-harvest loss, promote economic growth, improve nutrition, and enhance food security in Feed the Future target countries.

Identifying low-cost methods for controlling aflatoxin in stored maize.

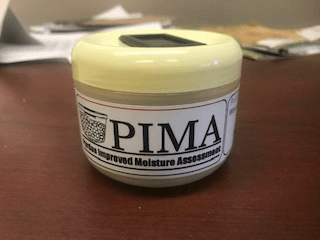

FPIL researchers have studied cost-effective ways to prevent or limit aflatoxin contamination of key crops for rural subsistence households in Sub-Saharan Africa. In collaboration with Istitut Sénégalais de Recherches Agricoles (ISRA), the premier agricultural research institution in Senegal, the research team set up a randomized intervention in the Department of Vélingara in southern Senegal. The technologies included a hygrometer to verify moisture content (developed under FPIL at Purdue); plastic sheeting as an alternative to drying on bare ground; and the Purdue Improved Crop Storage (PICS) bag as a means of preventing insect contamination and limiting fungus growth in stored maize. The results provide practical guidance to lower aflatoxins in staple crops, and suggest that strategies to reduce aflatoxins should address issues from harvest to storage comprehensively.

Partnerships & Collaborations

A partnership between the FPIL and the University of Eldoret in Kenya resulted in the establishment of the Food Processing Training and Incubation Center. Housed on the University of Eldoret’s campus, the center is fitted with basic food processing equipment and a research laboratory. It provides a space for small-scale processing, product research and development, and serves as a training facility for local entrepreneurs.

Madame Astou Gaye Mbacke first collaborated with the FPIL in 2016. This partnership led to her business, the Touba Darou Salam Cereal Processing Unit, gaining a food extruder that gave the facility the technical capacity to develop instant enriched flours. Today her instant flours are sold through a network of over 1,000 Senegalese women. The instant flour business offers a source of income, empowerment, and independence to women entrepreneurs who collaborate with Mbacke’s processing unit.

Sustainability & Scaling Up

In January 2020, FPIL researchers Dr. Cheryl O’Brien of San Diego State University and Laura Leavens, a graduate student at Purdue University, traveled to Senegal to evaluate the impact of the Touba Darou Salam Cereal Processing Unit on incomes and empowerment of the entrepreneurs. In the study, 98 percent of women surveyed reported their household incomes increased after collaborating with Mbacke. The FPIL team found average female retailer sells 50 kilograms of instant flours during a typical sales month, earning the equivalent of half the monthly household income of a typical Senegalese household. Additionally, the participants also reported that instant flour sales increase their households' ability to improve their dietary diversity, invest in their children’s education, and several other key elements.

The FPIL’s first phase contributed to strengthening institutional and human capacities. This training and capacity development is vital to the long-term sustainability of local systems. The FPIL will continue to drive the value-chain through food processing which will help to improve nutrition and increase commercialization in Sub-Saharan Africa. The Feed the Future Innovation Lab for Food Processing and Post-Harvest Handling plans to have many more success stories to tell.

This article was made possible through support provided by Feed the Future Innovation Lab for Food Processing and Postharvest Handling through the U.S. Agency for International Development, under the terms of Contract No. AID-OAA-L-14-00003 . The opinions expressed herein are those of the author(s) and do not necessarily reflect the views of the U.S. Agency for International Development.

Purdue Farmer-to-Farmer Program Switches to Virtual Assignments

In April 2020, Purdue University’s International Programs in Agriculture (IPIA) and Purdue Cooperative Extension announced the USAID John Ogonowski and Doug Bereuter Farmer-to-Farmer (F2F) program to be implemented by Purdue University in Trinidad and Tobago over the next three years. A United States Agency for International Development (USAID) funded program, F2F provides technical assistance from U.S. volunteers to farmers, farm groups, agribusinesses, and other agriculture sector institutions in developing and transitional countries.

Read Full Story >>>Purdue Extension steps in to help Hoosier fruit growers

From juicy red strawberries to sweet apples and melons, Indiana is home to many fruit growers. While each year presents its challenges in the field, this year Indiana faced an unfortunate late frost event, causing crop damage during a crucial point in the growing period. Outside of the fields, growers faced another challenge, creating a safe and healthy environment for employees and customers.

Read Full Story >>>Purdue researcher to study food safety in low-moisture food staples

Low-moisture products, such as flour, dried fruit and nuts, are often perceived as safe from food pathogens in consumer’s eyes despite recent bacteria outbreaks. Like other raw food commodities, these low-moisture food products are at risk for foodborne bacteria if there isn’t a “kill step” or heating process to eradicate bacteria during harvest or processing.

“Historically consumers don’t think about low moisture or dry foods having food safety issues. We want to raise awareness among the public about how they can properly handle these food products and reduce the risk,” said Yaohua Feng, assistant professor of food science at Purdue University.

Read Full Story >>>Purdue Farmer-to-Farmer Program Switches to Virtual Assignments

In April 2020, Purdue University’s International Programs in Agriculture (IPIA) and Purdue Cooperative Extension announced the USAID John Ogonowski and Doug Bereuter Farmer-to-Farmer (F2F) program to be implemented by Purdue University in Trinidad and Tobago over the next three years. A United States Agency for International Development (USAID) funded program, F2F provides technical assistance from U.S. volunteers to farmers, farm groups, agribusinesses, and other agriculture sector institutions in developing and transitional countries.

Read Full Story >>>Purdue Extension steps in to help Hoosier fruit growers

From juicy red strawberries to sweet apples and melons, Indiana is home to many fruit growers. While each year presents its challenges in the field, this year Indiana faced an unfortunate late frost event, causing crop damage during a crucial point in the growing period. Outside of the fields, growers faced another challenge, creating a safe and healthy environment for employees and customers.

Read Full Story >>>Purdue researcher to study food safety in low-moisture food staples

Low-moisture products, such as flour, dried fruit and nuts, are often perceived as safe from food pathogens in consumer’s eyes despite recent bacteria outbreaks. Like other raw food commodities, these low-moisture food products are at risk for foodborne bacteria if there isn’t a “kill step” or heating process to eradicate bacteria during harvest or processing.

“Historically consumers don’t think about low moisture or dry foods having food safety issues. We want to raise awareness among the public about how they can properly handle these food products and reduce the risk,” said Yaohua Feng, assistant professor of food science at Purdue University.

Read Full Story >>>