THE TRUCK-TRAILER COMBINATION VEHICLE MAKING SURE THE NUMBERS ADD UP

RESOURCES - PUBLICATIONS

THE TRUCK-TRAILER COMBINATION VEHICLE MAKING SURE THE NUMBERS ADD UP

Fred Whitford, Coordinator, Purdue Pesticide Programs

Steve Hawkins, Assistant Director, Purdue Agricultural Centers

Mark Purschwitz, Extension Agricultural Engineering, University of Kentucky

John Earnest, Jr., Collision Reconstructionist, Princeton Kentucky Police Department

David Hynes, Extension Educator, Purdue Extension-Clark County

Kevin Leigh Smith, Editor, Purdue Agricultural Communication

Using Just Your Eyes Leaves You Blind to the Facts.6

A Lot Rides on the Ratings .8

Match Components When Buying Vehicles.12

The Super Vehicle Consists of the Truck, Trailer, and Connectors.18

Analyzing Your Trucks, Trailers, and Connectors.24

Example 1. An Evenly Matched Truck, Trailer,

and Connectors.26

Example 2. Loading a Trailer Beyond Its

Gross Vehicle Weight Rating.28

Example 3. An Undersized Truck Pulling

a Gooseneck Trailer..30

Example 4. An Undersized Truck and

Overloaded Trailer .32

Decision Making Spreadsheets.34

When You Can’t Find the Numbers.35

Annual Truck and Trailer Inspections .38

Homemade Equipment .39

Conclusions — It’s All About Weights and Ratings.40

Acknowledgments .42

Disclaimer.42

Coupling a trailer to a truck is a lot like building an office,

home, or shop.A safe and functional building doesn’t materialize by luck alone.

That building comes about when there is a detailed set of plans that match the structure with dozens of individually rated systems (heating, cooling, electrical, plumbing, etc.).It then takes competent builders and craftsmen to follow those blueprints to ensure that all parts work together in the new building.

A truck has to be designed to carry its trailer and payload; a trailer has to be designed to carry the weight; and the parts that connect the trailer and truck have to be strong enough to keep them connected.

Likewise, a truck and trailer combination has thousands of individual parts that work together to keep the truck moving and the trailer operating. Truck and trailer designers develop mechanical and electrical blueprints that require parts that meet or exceed very exact specifications. Each part must work in concert with the others to allow the truck and trailer to efficiently and safely operate on and off highways .

Most often, we still consider the trailer and the truck as separate units. Actually, we attach connectors (such as hitches, inserts, balls, and chains) to meld two independently designed systems into a single “super vehicle .” The person linking the truck and trailer must understand how all the parts (including the connectors) fit together so the truck can pull the trailer safely — just like an architect must understand all the systems when designing a building .

Transportation accidents provide clear and convincing evidence that undersized or mismatched components can lead to significant mishaps with disastrous consequences to human life and the environment. This publication will help you understand how to critically analyze the ratings of your “super vehicles .” This will help you determine whether components are properly matched and to pinpoint deficiencies that need to be corrected

USING JUST YOUR EYES LEAVES YOU BLIND TO THE FACTS

Would you trust a heating and cooling professional who says, “I think this cooling unit is big enough and will work,” before measuring the size of your building or looking at the air conditioner’s cooling output? While you might get lucky, there’s a pretty good chance that air conditioner won’t be a good fit and you’ll struggle to keep your building cool in summer. Each air conditioner unit has a set of performance ratings professionals use to match the right unit to the heat load and volume of air to be cooled. Don’t match everything correctly, and you’ll learn a very expensive lesson.

This truck-mounted receiver can tow 17,000 pounds.

This ball is rated for 6,000 pounds.

What is the problem if these three components were assembled together? The amount the super vehicle can tow is based on the lowest rated component (the ball rated for 6,000 pounds), not the higher rated trailer and hitch components.

Performance ratings are also crucial when it comes to trucks, trailers, and connectors. The rating of each component must be of the appropriate capacity so it will fit together into a safe and cohesive unit. Many of the ratings are stamped or tagged on the equipment or written in the owner’s manual. Other ratings (such as the actual weights of the loads carried in the truck bed or on the trailer) you will have to determine by weighing the truck and trailer both empty and loaded.

The bottom line is that you cannot accurately gauge the adequacy and safety of a truck, trailer, or connector based on the “eye” test — not anymore than you can just look at an air conditioner and think it will be the right unit for your building. Devote a little time to understanding and examining vehicle component ratings and you will dispel the mystery and actually put the ratings to good use

A LOT RIDES ON THE RATINGS

Anyone who manages a farm or business knows there are never enough hours in the day to get the work done. So they may wonder why they should take the time to review the ratings of their super vehicles. Here’s why it’s worth your time to review the ratings of your super vehicles:

- The review gives you a detailed snapshot of the ratings associated with the truck, trailer, and connectors. It will give you a better understanding of what the super vehicle can do, and more importantly, what it cannot do. You will learn which trucks and trailers you should not combine; which equipment you must retrofit; which parts you need to scrap; and which trailers have more capacity than you thought.

- A review can reduce accidents. You don’t want to send employees out with faulty equipment that could cause a serious or fatal traffic accident. Losing a seasoned employee means being without that person’s valuable skills for an extended period of time or forever. And you don’t want to hurt or kill an innocent party.

If there ever is an incident, you want to make sure the collision reconstructionist will not report the cause was an undersized or worn out component from the truck, trailer, or connector.

And while you think that your insurance will cover you, remember that most policies state that they will not cover illegal acts. In some circumstances, using a vehicle with underrated components may be considered an illegal activity.

For example, if an overloaded trailer pushes the undersized truck pulling it through a stop sign and into another car, is the insurance company legally obligated to cover the cost of the accident, pending lawsuits, and judgments awarded by jurors? Make a habit of documenting that you use equipment safely and within manufacturer guidelines. While most accidents are preventable, they are still common enough to expose you to liability. Your attorney can better defend your actions in a lawsuit if you have documents that show your equipment was being operated safely and within the manufacturer’s guidelines. Even if you are at fault in causing the accident, your attorney can argue that the accident was not based on your negligence or a willful disregard for public safety, and that you made a good faith effort to prevent it. Winning such an argument is important when a jury considers how much to award to the accident victim

Create a permanent record of the ratings and weights of all components (see pages 24-25). Tags attached to equipment might become damaged or fall off, information stamped into metal will wear away, and owner’s manuals can be lost. Make a permanent record to capture important information before it is lost.

This is not by any stretch of the imagination a complete list of reasons why you should check the ratings of your equipment. It’s simply that there are damning, damaging, and serious repercussions from continuing to operate your super vehicles without knowing and understanding the ratings.

It’s difficult enough to keep a single vehicle operating safely. If you add a trailer to a truck without understanding how they work together, you can create serious safety issues for the public.

MATCH COMPONENTS WHEN BUYING VEHICLES

Think about the last time you bought a new truck or trailer. You found the make and model you wanted, kicked the tires, walked around the truck, breathed in the “new truck” smell, and took a test drive. With the trailer, you liked its length, the double axles, and the dealer’s reputation. Both the new truck and trailer passed the eye test.

But a successful vehicle purchase is about more than superficial considerations. We usually purchase trucks and trailers separately and seldom give much thought to whether they will work well together to haul the loads you are accustomed to towing.

Without looking at the ratings, did you really purchase a truck and trailer that maximizes the capabilities of both and do not overload either? Will the truck have to work at its upper limits to pull the trailer and load (which means it will not last as long)? Is the braking system and weight of the truck strong enough to stop your fully loaded trailers?

These are important questions you cannot answer by merely taking a test drive, being impressed with the comfortable ride, or appreciating all of the amenities that come with a new truck. You need to know what the truck is rated to pull.

Obviously, you don’t want to spend more than necessary for excess towing and payload capabilities for a truck or trailer that you don’t often use. But you don’t want to find out after the fact that the truck you bought is undersized for the daily tasks you expect it to perform — that can be dangerous

How would you answer these two questions:

- Which is better equipped to pull a heavier trailer and paylaod? A half-ton or three-quarter-ton truck?

- Does the truck’s make and model have meaning (Dodge Dakota, Ford F-150, Chevrolet Silverado 2500)?

Vehicle brand names are certainly important to manufacturers, dealers, and those in the market for a replacement truck. However, the make (such as Ford) and model (F-150, F-250, F-350) provide little information that can help you determine how suitable it is to haul and tow. While you might think a three-quarter-ton truck could tow more than a half-ton truck, or that the 3500 model could tow more than the 2500 model, the truth is that those numbers don’t really mean much.

In many respects, every individual vehicle is uniquely built and equipped even if they carry the same designation. In other words, not every Chevrolet Silverado 2500 is built exactly the same. In fact, each manufactured truck is part of a larger series, meaning that two different Chevrolet Silverado 2500 trucks may be able to tow or haul considerably different weights, even though they look exactly the same.

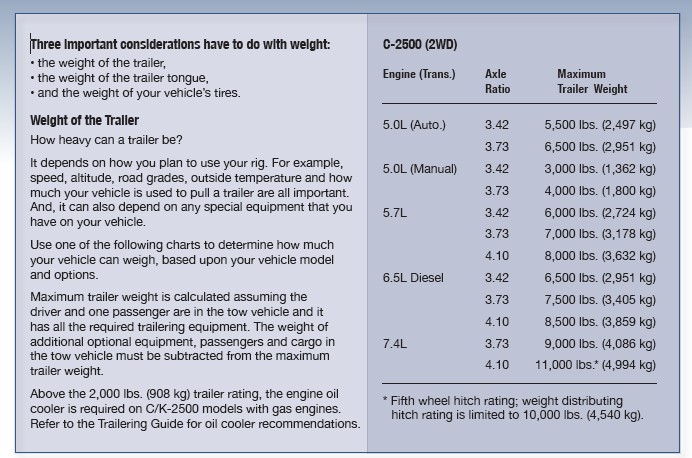

The vehicle owner’s manual can provide you with important information about how much it can tow. This one is reproduced from the manual for a Chevrolet C-2500.

How much payload a truck can carry or tow cannot be defined by simple words, brands, or even numbers. For example, if you use the Dodge Ram 1500, 2500, or 3500 designations as the sole criterion for judging towing strength, you do not have enough information.

The capability of a truck to haul and tow is directly related to several components, including the spring ratings, axle ratio, engine size, engine type (gas, diesel), transmission, frame strength, tire size, tire road rating, and brakes. All of these features can be drastically different within and between truck series such as the F-150 and F-250. Some might find it hard to believe that trucks designated as half-ton can have more towing power than those designated as three-quarter-ton trucks. It all depends on the truck.

How much a truck can tow or a trailer can haul depends on its design. Automotive engineers have calculated payloads and towing capacities based on the ratings of the components they put into the truck and trailer. This is why basing your decision to buy by simply kicking the tires and taking a test drive will tell you little about what you really need or should need to know about that specific truck.

Once you find the truck or trailer brand you believe is priced within your budget and possibly sized to meet the needs of your business or farm, take a few moments to see if, in fact, the truck or trailer is strong enough or sized properly to deal with your operation.

Before you make a decision, be sure you know the answers to these questions:

- What will you be hauling for your business or farm?

- Do you know how much weight you need to tow?

- Is it possible to obtain the weights and sizes of the items you will haul?

Remember that utility trailers, whether open or enclosed, provide you flexibility when handling loads. However, just because something fits on a trailer doesn’t mean the trailer is the correct size.

A truck has to be designed to safely pull, stop, and control the trailer attached to it. If a truck is too small, you will be unable to control the trailer and its load.

A truck has to be designed to safely pull, stop, and control the trailer attached to it. If a truck is too small, you will be unable to control the trailer and its load.

Accidents can happen when the truck and trailer’s towing capacities are mismatched.

Accidents can happen when the truck and trailer’s towing capacities are mismatched.

Keep the Trailer Connected to the Truck: Understanding the ‘Hitch’ System (Purdue Extension publication PPP-92) can help you find many of the ratings that are talked about in this publication. It is available from the Purdue Extension Education Store, www. the-education-store.com.

Ball 3,500

Ball 3,500  Insert 5,000

Insert 5,000  Receiver 7,500

Receiver 7,500  Truck 12,400

Truck 12,400 Find the component with the weakest capacity and base the super vehicle’s towing capacity on that. A truck and trailer may look large enough to get the job done, but notice how this 20-foot trailer can only have 1,100 pounds loaded on it. Can you see why? While the truck is rated to pull 12,400 pounds, the ball has only a 3,500-pound rating. If the trailer weighs 2,400 pounds, that only leaves only 1,100 pounds load capacity. This is why it is important to know ratings.

THE SUPER VEHICLE CONSISTS OF THE TRUCK, TRAILER, AND CONNECTORS

When your truck pulls a trailer, you actually create one super vehicle from three distinct systems. The ratings of these three systems (the truck, trailer, and connectors) must be coordinated to create a single unit that can operate safely on the highway. Having those ratings in front of you will allow you to objectively compare and empirically contrast your super vehicle to observe potential problems that could lead to missteps, miscues, or mishaps.

Potential problems means you have time to assess and modify before something bad happens. By changing some things in your operation or equipment, you can turn potential miscues and mishaps into unlikely events.

Find the Ratings for Your Specific Super Vehicle

There are several ratings you should know when analyzing your super vehicle:

- Combined gross vehicle weight

- Curb weight

- Gross axle weight rating

- Receiver rating

- Insert rating

- Ball hitch rating

- Coupler rating

- Tire ratings

- Combined Gross Vehicle Weight Rating (also called Gross Combined Weight Rating and Gross Combined Vehicle Weight Rating). This number represents the maximum total weight of the super vehicle system. It includes the tow vehicle, trailer, passengers, load on the trailer, load on the tow vehicle, tools, fuel, etc. Find this rating in the owner’s manual.

- Curb Weight. This is the weight of an empty truck with a full tank of fuel. To get this number, weigh the truck or ask the dealer who sold you the vehicle for assistance.

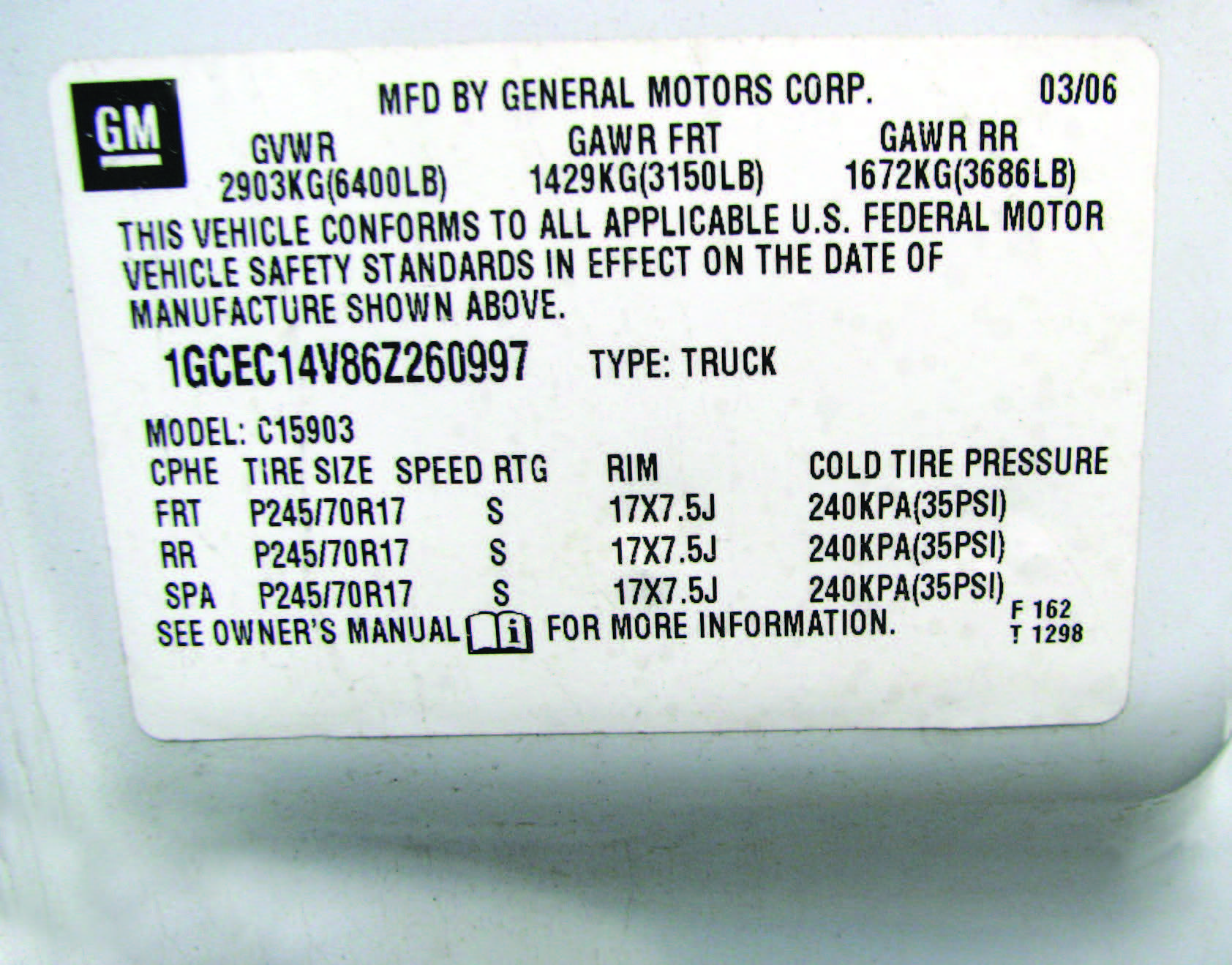

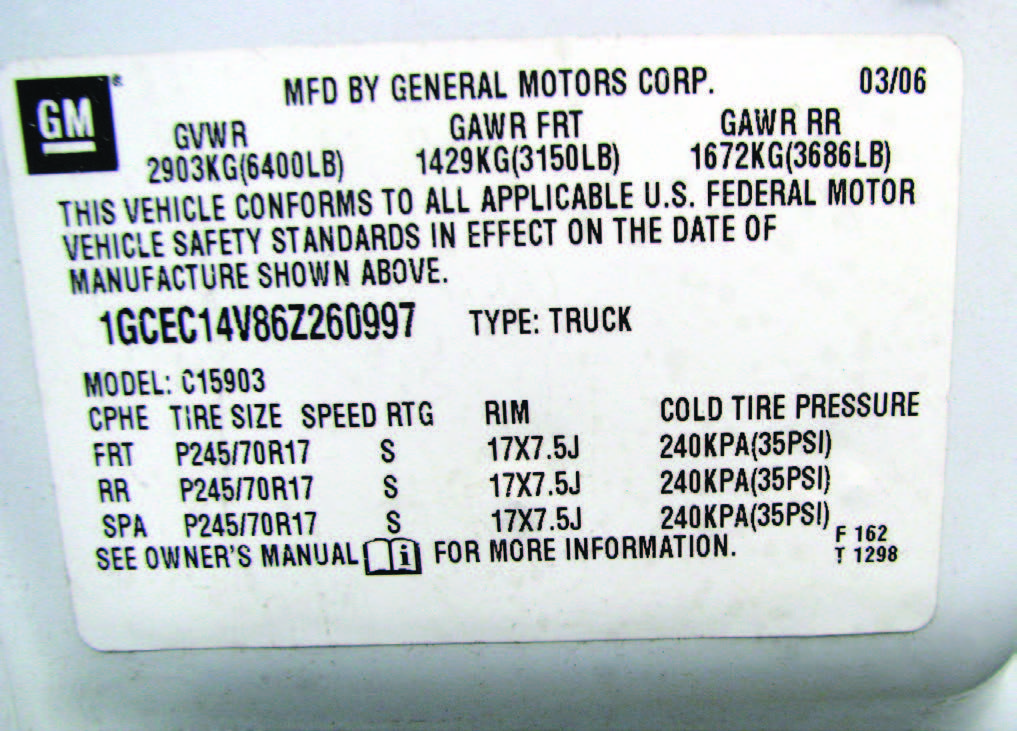

- Gross Axle Weight Rating (GAWR). This is the maximum weight the axle is manufactured to carry. Find these ratings on the vehicle door jamb. In the examples shown here, the front axle GAWR is 3,150 pounds and the rear is 3,686 pounds .

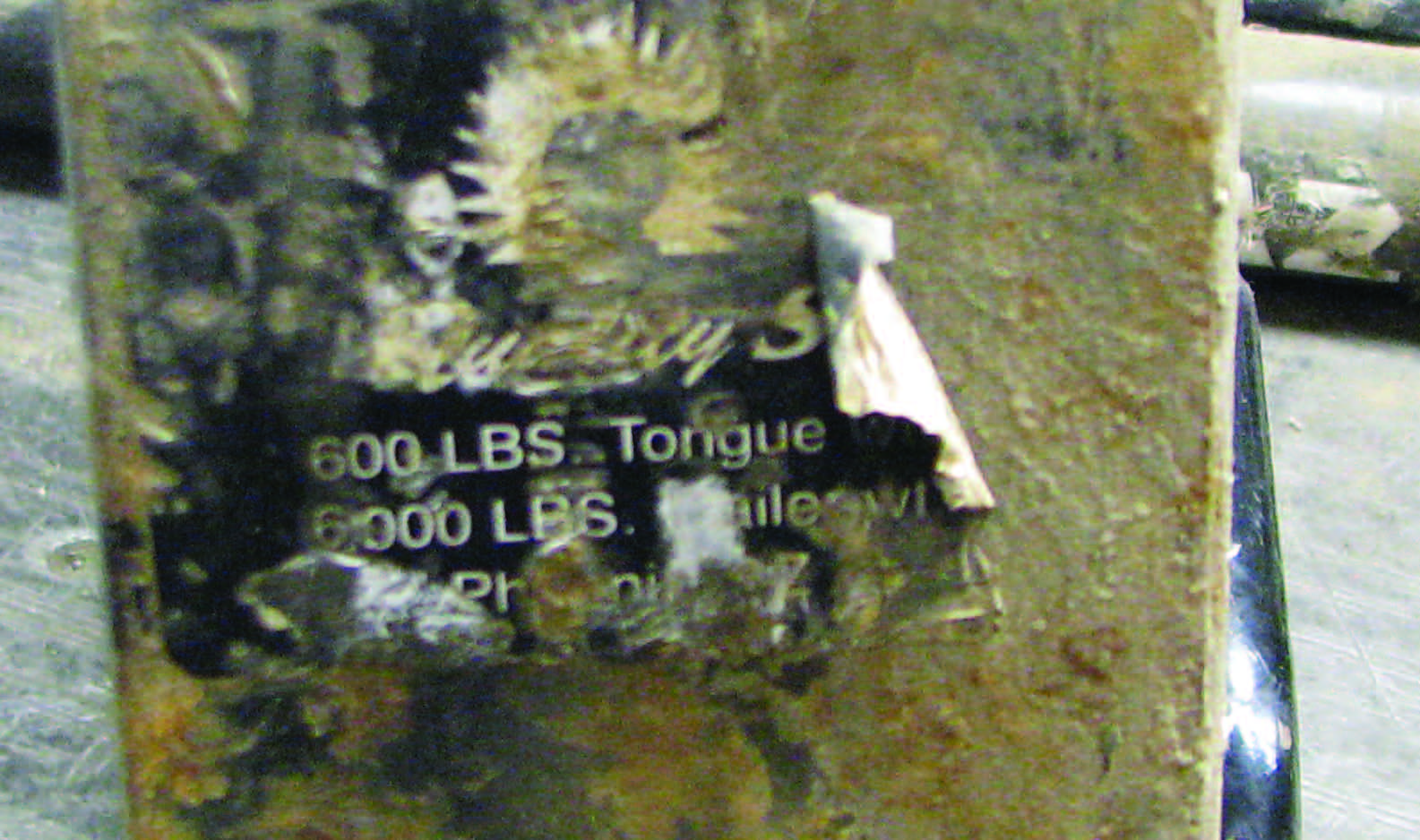

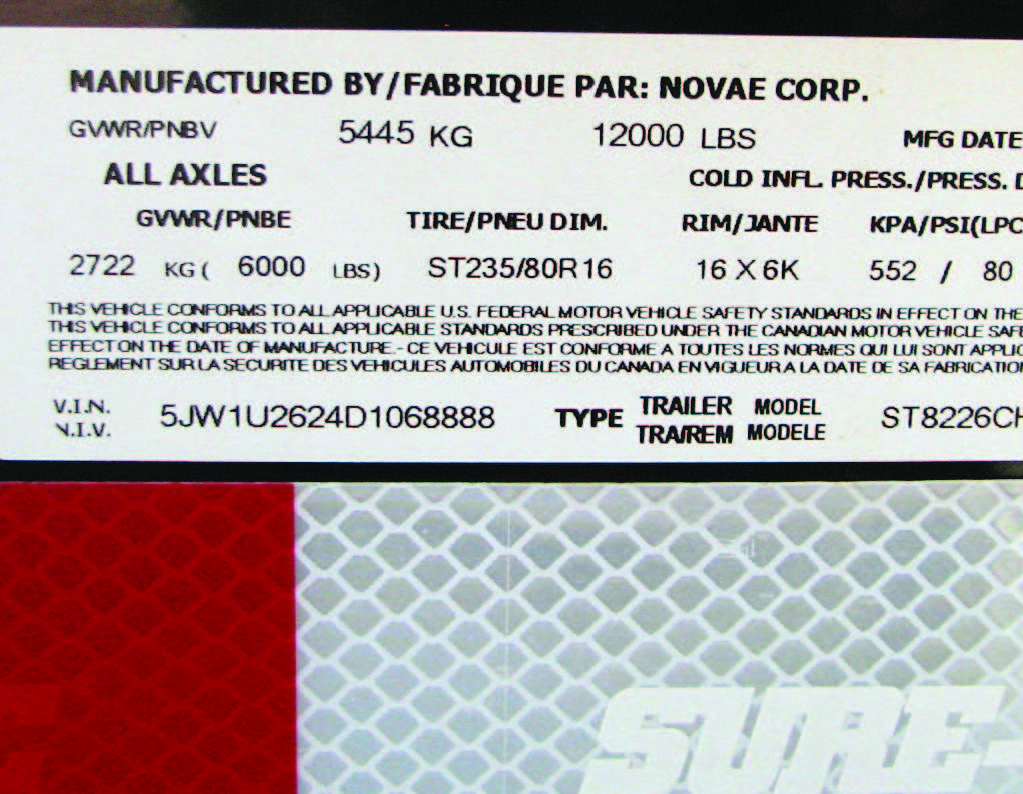

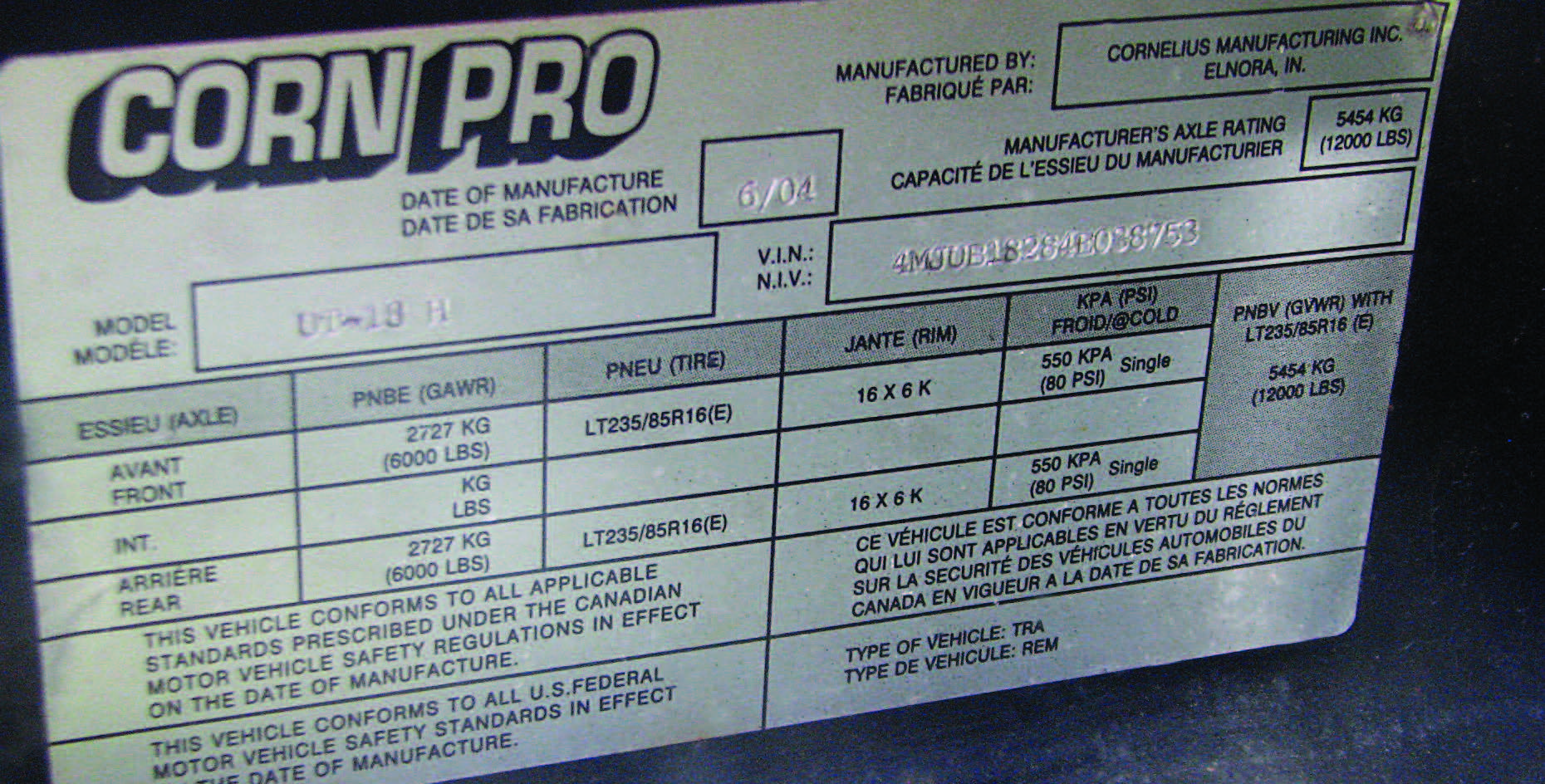

Most newer trailers have the axle rating on a tag mounted near the trailer’s tongue. If there is no tag on the tongue, check the axle for a tag or stamp. In the example shown here, each axle on the trailer is rated for 6,000 pounds. If you cannot find the axle ratings, contact the trailer manufacturer to get the exact number.

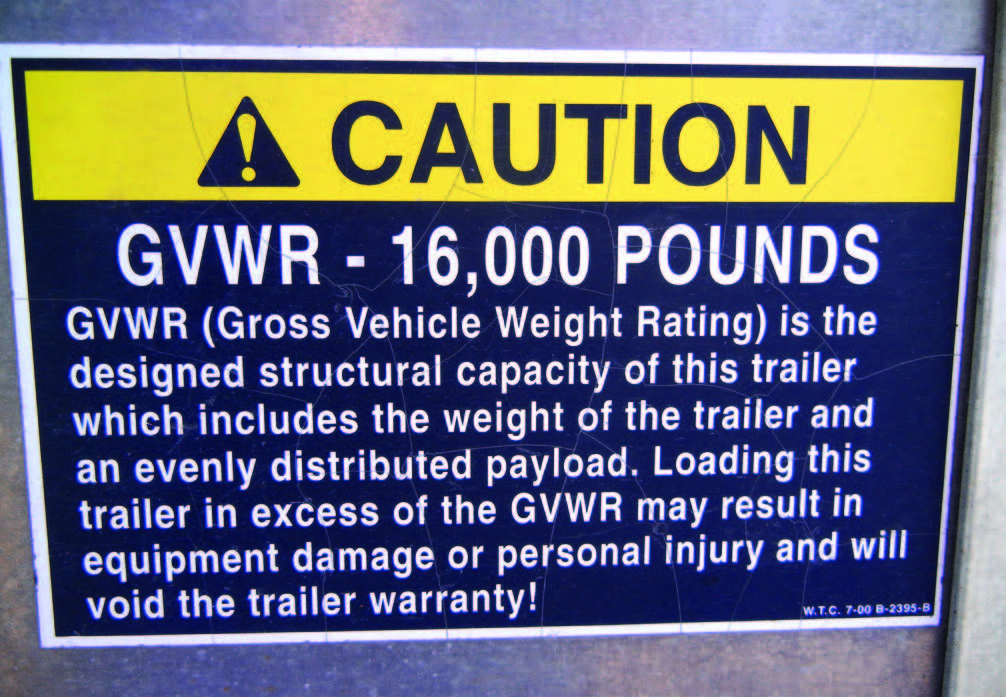

- Gross Vehicle Weight Rating (GVWR). This rating represents the maximum loaded weight an individual truck or trailer can safely carry. The GVWR for a truck or trailer always includes the weight of the truck or trailer itself. The GVWR includes the suspension, tires, frame, and overall manufactured design strength of the vehicle and trailer.

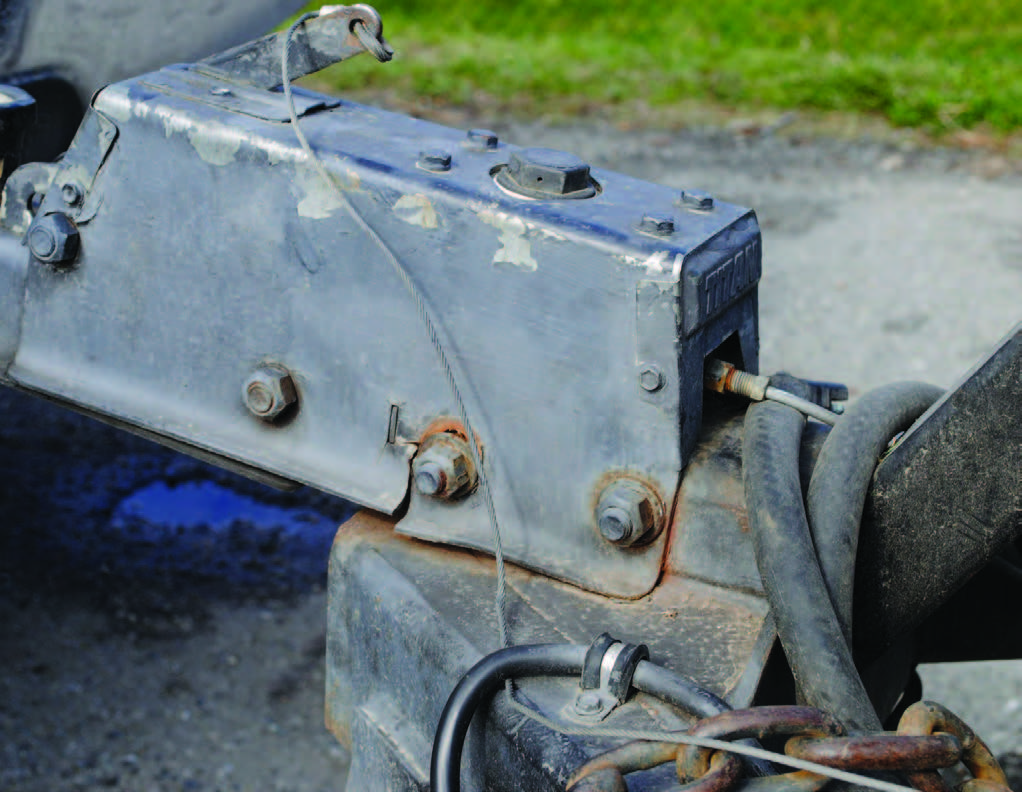

- Receiver Rating. The receiver is mounted to the truck and it should state the maximum trailer weight based on whether a weight-carrying or weight-distributing type of hitch is used. This tag is normally attached on the receiver. If it is not there, contact the truck manufacturer to see what the receiver is rated for.

This is a weight-carrying hitch.

This is a weight-distributing hitch type. Crossing chains allow the trailer tongue to be cradled by the chains instead of going into the pavement in the event the trailer detaches.

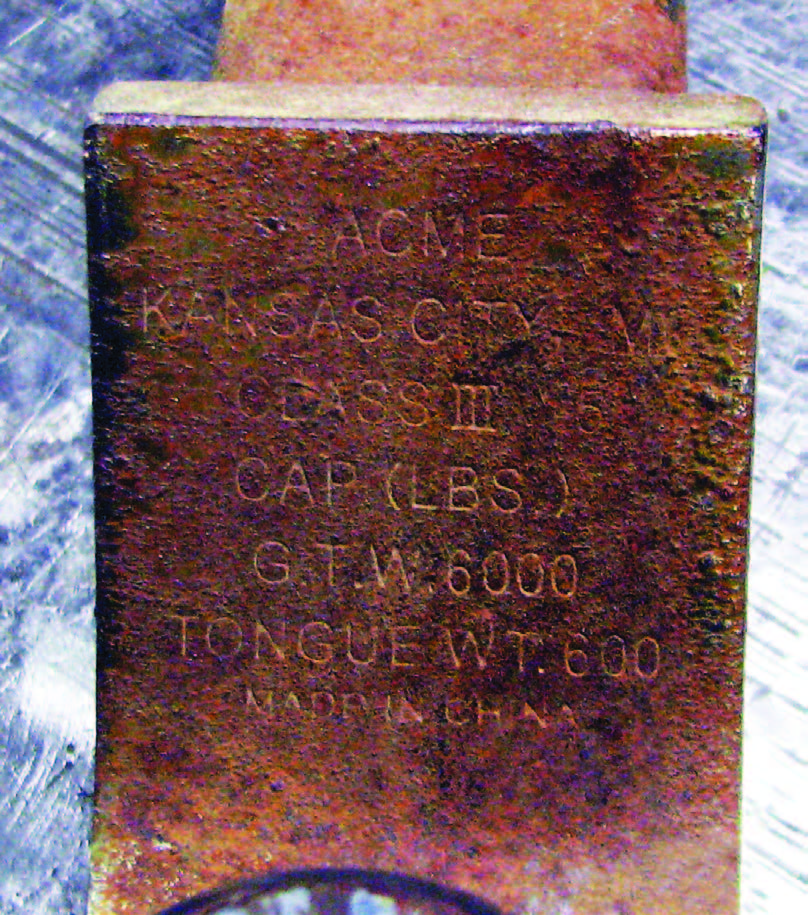

- Insert Rating. The rating on an insert may be on a tag or engraved into the steel. In both cases, the receivers shown here are designed to pull up to 6,000 pounds.

- Ball Hitch Rating. The rating for a ball hitch is etched into the top of the ball. In this case, the 2-inch ball is built to pull 10,000 pounds (top left). The 2 5/16-inch ball is built to pull up to 6,000 pounds (top right). This illustrates that you cannot assume that a larger ball can tow more.

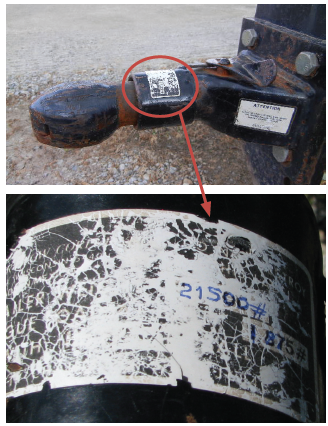

- Coupler Rating. One of the more important ratings is the latch mechanism for the coupler. Sometimes the coupler is rated less than the GVWR of the trailer. The coupler rating shown here is 21,500 pounds.

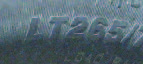

- Tire Ratings. Tires are stamped with many ratings that are useful in calculating loads that the truck or trailer can carry. The tire above is a light truck tire that is 265 millimeters wide with a sidewall height that is 70 percent of its width. It is a radial that fits on a 17-inch rim. The load range E means it is equivalent to a 10-ply rating and can hold up to 80 pounds of pressure.

Detailed information about tires, is available in Tires For the Road and Field: A Guide to Getting the Best Value and Performance (Purdue Extension publication PPP-99), available from www. the-education-store.com.

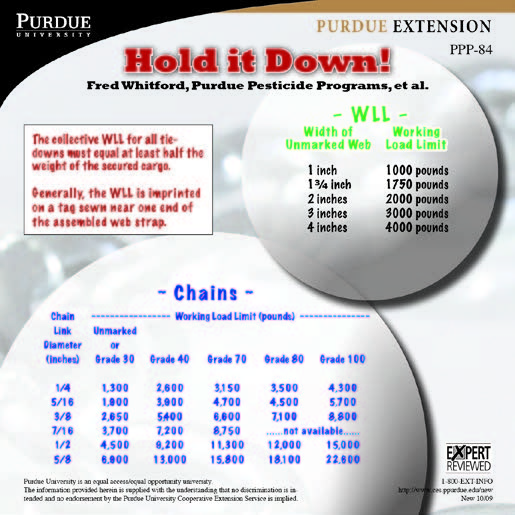

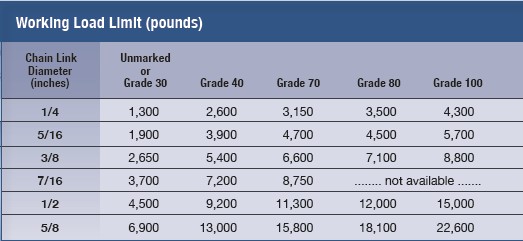

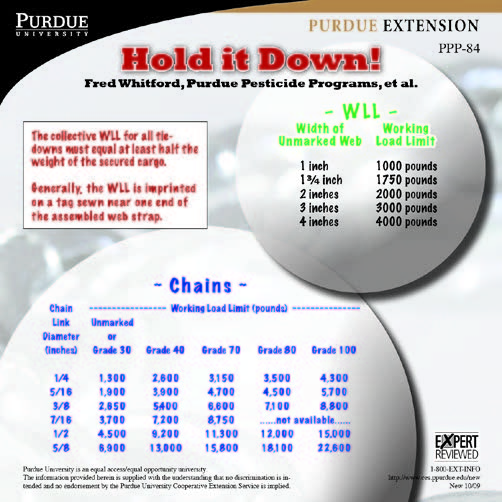

The chain, binder, and hook all have ratings, which are normally stamped on them. More information about tension ratings for straps and chains is available in Securing The Load: A Guide to Safe and Legal Transportation of Cargo and Equipment (Purdue Extension publication PPP-75) and Hold it Down! pocket guide (PPP-84), available from the Education Store, www.the-education-store.com.

ANALYZING YOUR TRUCKS, TRAILERS, AND CONNECTORS

When connecting a truck to a trailer, it is useful to analyze your truck, trailer, and all of the connecting devices. Below are five useful tables to assist you in this process. In this section, we describe a completed report for a 2011 Ford F-150 towing a 2011 Featherlite trailer with a truck-mounted hitch. As you can readily see, there are many ratings involved when towing a trailer with a truck that can be used to see if the components of a super vehicle match.

Component 1. Truck System

- Year: 2011

- Make: Ford

- Model: F-150

- Cab: supercab

- Bed: 8 feet

- Wheelbase: 163 inches

- Engine: 5.0 liter

- Fuel: unleaded gasoline

- Transmission: 5-speedautomatic

- Gross axle weight rating (rear): 4,200 pounds

- Rearaxleratio: 3.73

- Tire size: LT245/70R17

- Tireloadingrating: 3,120 pounds

- Tire pressure: 60 psi

- Gross vehicle weight rating: 8,200 pounds

- Curb/empty weight: 5,780 pounds

- Load capacity: 2,420 pounds

- Towing capacity: 9,600 pounds

Component 2. Connector System

Truck-Mounted Hitch

- Hitch rating for weight carrying: 5,000 pounds

- Hitch tongue weight: 500 pounds

- Hitch rating for weight distribution hitch: 10,500 pounds

- Insert size: 2 inches

- Insert rating: 5,000 pounds

- Ball size: 2 inches

- Ball rating: 5,000

- Coupler size: 2 inches

- Coupler rating: 5,000 pounds

- Coupler tongue weight rating: not indicated

- Safety chain grade: 43

- Safety chain size: 0.25

- Safety chain breaking strength: 2,600 pounds

- Safety chain hook grade: unknown

- Safety chain hook: grade 30, 1/4 diameter

Gooseneck Hitch System

- Not Available

Component 3. Trailer System

- Year: 2011

- Make: Featherlite

- Model: 6.7 x 10 feet

- Type: conventional

- Electric emergency brake: none

- Axles: single

- Axle rating: 3,500 pounds

- Single/dual tires: single

- Gross vehicle weight rating: 2,990 pounds

- Curb weight: 1,590 pounds

- Payload weight: 1,400 pounds

- Tire size: ST 205/75R15

- Tire loading rating: 1,820 pounds

- Tire pressure: 50 psi

Component 4. Combination System

- Combination gross vehicle weight rating: 15,300 pounds (from owner’s truck manual)

Component 5. Actual Weights of Payloads

- Payload in truck: one person, no load in bed: 180 pounds

- Actual load carried on trailer: Polaris ATV: 1,170 pounds

Example 1. An Evenly Matched Truck, Trailer, and Connection

The Facts: In this example, we have a 2011 Ford F-150 truck pulling a Featherlite trailer loaded with a Polaris Ranger.

Payload on Trailer

1,170 pounds

Truck Information (pounds)

GVWR 8,200

Curb Weight -5781

Max Payload Weight 2,240

Towing 9,600

Each tire 3,120

Rear axle 4,200

Weight-carrying Hitch Connectors (pounds)

Hitch 5,000

Insert 5,000

Ball 5,000

Coupler 5,000

Safety chains (2) 5,200

Trailer Information (pounds)

GVWR 2,990

Curb Weight -1,590

Max Payload Weight 1,400

Axle 3.500

Each tire 1,820

WHAT DO THE NUMBERS TELL US?

The payload capacity of the vehicle in this example is 2,420 pounds — calculated by subtracting the curb (empty) weight from the gross vehicle weight rating (GVWR). The GVWR is the maximum rated weight of a truck including its own weight, passengers, and payload. Since the only load we are carrying is a single driver, the GVWR, the tires, or the rear axle ratings are not exceeded. The two trailer tires have a combined rating of 3,640 pounds (1,820 x 2 tires) and if properly inflated and maintained, this is more than sufficient for the designed 2,990-pound GVWR of the trailer.

The truck in this example is rated to tow a trailer and payload up to 9,600 pounds. The empty trailer weighs 1,590 pounds, which means the trailer can safely carry a payload up to 1,400 pounds. Curb weight alone cannot dictate payload weight. The weight of the trailer and load added together accounts for a 2,760-pound payload, which is well below the 9,600 pounds the truck is designed to tow. However, it is only 230 pounds short of the trailer’s 2,990-pound GVWR.

The tongue weight of the loaded trailer was approximately 330 pounds. Most truck and trailer manufacturers recommend 10 percent to 15 percent of the total trailer weight plus its load to be transferred to the weight-carrying hitch of the truck. You don’t want to overload the rear axle (GAWR) or the carrying capacity or tongue load ratings of the other components. In this case, 10 percent to 15 percent of 2,790 pounds is 279 to 418 pounds. The tongue weight in this example is within recommended limits.

The lowest rating for the connectors was 5,000 pounds. This means that the hitch, insert, ball, chain, and trailer coupler are well within their specifications to safely tow the weight of the 2,760-pound trailer .

The last analysis is to compare the weight of the super vehicle to the Combined Gross Vehicle Weight Rating (CGVWR) listed in the truck manual. The CGVWR rates how much total weight the truck designed to carry, pull, and stop. For this Ford truck, the owner’s manual indicates that the CGVWR is 15,300 pounds. To calculate the total weight of the super vehicle, add up the following weights to come up with the total.

(pounds)

- the curb (empty) weight of the truck 5,780

- Payload in the truck bed 0

- The weight of one person 200

- The empty weight of the trailer 1,590

- The payload on the trailer 1,170

Actual Combined Gross Vehicle Weight Rating 8,740

The super vehicle’s total weight is 8,740 pounds, which is significantly less than the 15,300-pound CGVWR listed in the truck manual. The conclusion is that the truck is equipped to safety handle, brake, and steer itself and the trailer. It also means that the truck has built-in capacity to carry payloads in the bed and pull a heavier trailer. It’s also important to note the truck is not working at the upper range of its capacity, which means with proper maintenance it should last longer.

WHAT DO WE NEED TO DO?

In this example, there is no deficiency. The more salient point is that the GVWR of the Featherlite trailer is nearly maxed out carrying the Polaris ATV. Because of this, operators must be cautious about carrying tools or other supplies on the trailer. In this example, you should carry tools and other supplies in the truck bed.

Example 2. Loading a Trailer Beyond Its Gross Vehicle Weight Rating

The Facts: In this example, we have a 2000 Chevy 2500 pulling a CornPro trailer, a Ford tractor, and wheat drill (not shown).

Payload on Trailer

5,000 pounds — 3,000 pounds for the Ford tractor plus 2,000 pounds for the wheat drill

Payload in Truck Bed

400 pounds of supplies

CornPro (pounds)

GVWR 10,000

Curb Weight -2,900

Max Payload Weight 7,100

Each axle 5,000

Each tire 2,820

2000 Chevy 2500 (pounds)

GVWR 8,600

Curb Weight -5,8555

Max Payload Weight 2,745

Towing (manual) 7,000

Each tire 1,874

Rear axle not available

Weight-carrying Hitch Connectors (pounds)

Hitch: A-5,000 B-5,000 C-5,000

Insert: A-5,000 B-10,000 C-10,000

Ball: A-5,000 B-6,000 C-3,500

Coupler: A-10,000 B-10,000 C-10,000

Chain: no grade markings

WHAT DO THE NUMBERS TELL US?

This Chevy truck has an empty payload rating of 2,745 pounds. If it carries a payload of 400 pounds and a 200-pound driver, it is well within the GVWR. The Chevy 2500 truck has a 7,000-pound towing rating, which is exceeded by the 7,900 (empty CornPro trailer plus the 5,000 payload).

The truck-mounted receiver hitch is rated at 5,000 pounds as a weight-carrying hitch, which means that the empty trailer, tractor, and wheat drill at 7,900 pounds exceeds the rated capacity of the truck-mounted hitch.

There are three different insert and ball combinations in the truck bed . Note that in combination C, the ball (3,500 pounds) is underrated for what the hitch (5,000 pounds) can pull.

This example is for a weight-carrying application . The towing capacity of the truck and receiver hitch has been exceeded as it is currently outfitted.

The Combined Gross Vehicle Weight Rating is:

(pounds)

- The curb (empty) weight of the truck 5,855

- Payload weight 400

- The weight of one person 200

- The empty weight of the trailer 2,100

- The payload on the trailer 5,000

Actual Combined Gross Vehicle Weight Rating 13,555

The truck has a CGVWR of 17,500 pounds, indicating that the truck is equipped to handle the weights being hauled and towed if the operator uses the proper components.

WHAT DO WE NEED TO DO?

If you are going to use a 7,900-pound trailer, then you must replace the insert and ball. The receiver must have a capacity greater than 7,900 pounds. And if you might tow a heavier load in the future, the capacities should be higher yet. For example, since the GVWR of the trailer is 10,000 pounds, it would make sense that all your hitch components have a 10,000-pound capacity to use the trailer’s full capacity.

A weight-distributing hitch system, properly sized, would have the capacity to tow this trailer and load. The Chevy 2500 manual indicates that the maximum trailer weight with a weight-distributing hitch is 10,000 pounds.

Example 3. An Undersized Truck Pulling a Gooseneck Trailer

The Facts: In this example, a 2006 Ford F-350 pulling a LoadMax trailer that is carrying a 7130 John Deere tractor with loader.

Payload on Trailer

14,450 pounds

Trailer Information (pounds)

GVWR 24,000

Curb Weight -9,100

Max Payload Weight 14,900

Each tire 2,920

Each axle 10,000

Gooseneck Connectors (pounds)

Hitch 25,000

Ball 25,000

Coupler 25,000

Truck Information (pounds)

GVWR 13,000

Curb Weight -8,600

Max Payload Weight 4,400

Towing (manual) 17,500

Each tire 2,910

Rear axle 9,500

WHAT DO THE NUMBERS TELL US?

The truck is rated to tow 17,500 pounds. The trailer’s curb weight is 9,100 pounds and the tractor weighs 14,450 pounds, which means the total load is 23,550 pounds. Operators need to be aware that this is 50 pounds short of the trailer’s 24,000-pound GVWR. This load is 6,050 pounds more than the truck’s towing capacity. The tractor on the trailer nearly exhausts the trailer’s payload capacity. The hitch, ball, and coupler in the truck barely can accommodate the gooseneck trailer and tractor.

The CGVWR is calculated:

(pounds)

- The curb (empty) weight of the truck 8,600

- The empty weight of the trailer 9,100

- The weight of one person 200

- The payload on the trailer 14,450

Actual Combined Gross Vehicle Weight Rating 32,350

This Ford F-350 Crew Cab has a CGVWR of 23,500 pounds, so the current total weight of 32,350 pounds exceeds the CGVWR by 8,850 pounds.

Although we do not know the gooseneck tongue weight on the truck, we can see that the combined capacity of the eight trailer tires are right at their limit (2,910 pounds x 8 tires = 23,280 pounds). Thus, even with the proper truck, you must pay attention to the condition and inflation pressure of the trailer tires.

WHAT DO WE NEED TO DO?

This is a dangerous situation! The truck is grossly undersized, which means braking, steering, and control will be serious problems. To pull this trailer and load, you must hook it to a truck with a larger towing capacity.

Adding to the problem is that the trailer and hitch components are near the maximum of their ratings. It would be wise to use different trailer and hitch components that are better matched to the load being carried by the trailer and towed by the truck. The bottom line: this load needs a bigger truck.

Example 4. An Undersized Truck and Overloaded Trailer

The Facts: In this example, a 2010 Ford F-350 is pulling a 2010 Featherlite 8121 gooseneck livestock trailer.

Payload in Trailer

14,400 pounds

(12 dairy cows at 1,200 pounds each)

Truck Information (pounds)

GVWR 9,800

Curb Weight -6,655

Max Payload Weight 3,145

Towing (manual) 15,300

Each tire 3,120

Rear axle 6,150

Gooseneck Connectors (pounds)

Hitch 20,000

Ball 20,000

Coupler 20,000

Trailer Information (pounds)

GVWR 16,000

Curb Weight -4300

Max Payload Weight 11,700

Each axle 7,000

Each tire 3,250

WHAT DO THE NUMBERS TELL US?

The truck’s manual indicates that its maximum towing rating is 15,300 pounds. The total load is 18,700 pounds, which includes the empty trailer weight (4,300 pounds) and its load (12 dairy cows at 14,400 pounds). The load exceeds the truck’s maximum towing rating by 3,400 pounds. The hitch, ball, and coupler ratings at 20,000 pounds means they are adequate for keeping the livestock trailer attached to the truck. The 14,400 pounds of payload on the trailer also exceeds the trailer’s payload capacity of 11,700 pounds.

The combined gross vehicle weight rating established by the truck manufacturer is 19,000 pounds. The actual gross combined weight being carried is 25,555 pounds.

(pounds)

- The curb (empty) weight of the truck 6,655

- The payload weight 0

- The weight of one person 200

- The empty weight of the trailer 4,300

- The payload on the trailer 14,400

Actual Combined Gross Vehicle Weight Rating 25,555

Featherlite trailer GVWR

This example exceeds the truck’s CGVWR rating by 6,555 pounds or 35 percent.

WHAT DO WE NEED TO DO?

The easiest and safest (but probably least practical) fix is to carry just half of the dairy cows at a time. Both the trailer and truck are not rated to carry the full load. The owner should have first checked the ratings before purchasing this truck and trailer combination. Had he or she done so, it would have been evident that a heavier rated truck and trailer were required.

DECISION MAKING SPREADSHEETS

For this publication, three Excel spreadsheets were developed to help operators determine if their vehicles can safely tow a trailer with or without a load. The spreadsheets are available on the Purdue Pesticide Programs website: www.ppp.purdue.edu.

Use the conventional hitch spreadsheet for lightweight and medium-weight drawbar-type hookups with both weight-carrying and weight-distributing hitches.

Use the gooseneck spreadsheet for hookups that use a gooseneck configuration.

Use the fifth wheel spreadsheet for fifth wheel configurations.

You can enter the information into the spreadsheet’s corresponding entry boxes. The spreadsheet will then compare the information and display if the tow vehicle and trailer combination is safe to operate or what limits are exceeded.

Download the spreadsheets from the Purdue Pesticide Programs Publications page: ppp.purdue.edu

Conventional Hitch

Truck-Trailer Calculator

Gooseneck Hitch

Truck-trailer calculator

Fifth Wheel

Truck-Trailer Calculator

WHEN YOU CAN’T FIND THE NUMBERS

This image shows the Vehicle Identification Number (VIN) on a truck dash.

If you cannot find the specific information for a truck, you can find most of the information you need online at www.decodethis.com. The site can provide your vehicle’s GCWR, towing capacity, etc ., as long as you have the Vehicle Identification Number (VIN) and the vehicle has not been modified.

Trailer manufacturers can go out of business. However, if you can determine the trailer brand and the manufacturer is still in business, they may be able to help you determine the trailer’s rating. You will need to provide the VIN to identify your specific trailer. If the trailer manufacturer is out of business, but you have a valid registration, the GVWR may be noted on the registration.

You should always replace worn hitch components and missing labels. Why guess when so much is at stake?

Always assume that unmarked safety chains and hooks are grade 30 and capacity is then based on the chain’s diameter.

There is no excuse for not knowing the weight of a load. You can obtain the weight of a truck, trailer, or a load at a certified truck scale, grain elevator, or fertilizer outlet.

Consider weighing the heaviest loads that the truck and trailer can carry. If you are within the various rating specifications, then any lighter load will also be within the tolerance set by the truck, trailer, and connection manufacturers.

Just because it fits doesn’t mean it is correct or legal!

Determining Individual Numbers

Here are simple was to determine the individual numbers that make up the ratings in a super vehicle.

- Truck Curb Weight. Empty the truck of all cargo and fill up the fuel tank. Park the truck on the scale, exit the cab, and get an accurate reading of the weight of the empty truck.

- Trailer Curb Weight. Drive the empty trailer over the scale and record its weight.

Weighing a trailer in the way shown here will produce a figure that includes tongue weight of trailer.

Weighing a trailer in the way shown here will produce a figure that excludes the trailer’s tongue weight.

- Load Weight. Place the heaviest load (including tools, supplies, and other items) on the trailer and reweigh the trailer. Get the load weight by subtracting the trailer curb weight from the total loaded weight.

- Tongue Weight. Be sure the scale does not have sloped ramps, or the tongue weight will shift to the trailer. Pull the truck on the scale with only the tongue of the loaded trailer still on the scale. Take that weight. Subtract the weight of the truck from this reading to get your tongue weight.

ANNUAL TRUCK AND TRAILER INSPECTIONS

Each super vehicle should be thoroughly inspected each year using the criteria established by the Department of Transportation (DOT) . The form can be found at www.fmcsa.dot.gov/documents/ eta/part-396form6.pdf.

We recommend an annual inspection even if you or your company is not regulated by the DOT. Keep records of your inspections to show a history of care in the event of an accident — that can help protect you in the case of a lawsuit.

The inspection’s purpose is to find any problems that need to be corrected to prevent highway accidents. In addition, if you regularly perform annual inspections that will greatly assist your attorney if there is ever the threat of a lawsuit after an accident .

Note, the DOT walk-around inspection is required daily for commercial motor vehicles. Before getting in the vehicle each day, walk around the vehicle and trailer and conduct a thorough visual inspection. At the end of the shift, a documented (written) inspection is required to list any defects noted during the day’s work. List any defects and, if any are serious enough, have a mechanic make the repairs before that truck or trailer is allowed to leave.

Homemade Equipment

CONCLUSIONS — IT’S ALL ABOUT WEIGHTS AND RATINGS

Today, businesses and farms use their trucks as rolling offices, well-stocked and equipped to tackle any and all jobs that day. The truck is linked to the home base, connected to computerized systems to access accounts, and carries a full complement of sprayers, mowers, fuel, pesticides, water, and fertilizers on a trailer. Today’s trucks and trailers are nothing short of an efficient office moving from site to site. But the combination of the truck and trailer has serious implications — accidents involving the combination can have major repercussions. The question addressed in this publication was whether the components creating a super vehicle — truck, trailer, and connectors — have ratings that match and are rated high enough to get the job done safely.

Before you put any equipment on the road, you need to be able to answer such questions as the capacity of the truck to tow a trailer loaded with spray equipment, whether the trailer can support heavy equipment or pesticide minibulks, or whether the connectors are properly rated to keep the truck and trailer attached. This publication provided you a way to think about how to analyze individual ratings and how to look at the three components as a whole system.

Why You Should Question the System

A question from a seed dealer illustrates why you should always question the super vehicle system.

“The axles are rated at 14,000 pounds. Here is the kicker: they say at capacity it will carry 275 units. Well, a unit of beans is roughly 48 pounds. So, 275 units at 48 pounds is 13,200 pounds, plus the empty weight of the trailer (6,100 pounds) comes to 19,300 pounds. That is a ton of weight on a bumper pull truck. This weight is now over the gross combined weight rating and the tow capacity of the truck.

“So my question is: how do farmers use these without a ton of liability? And what truck can pull 19,300 pounds pulled on a bumper down the road? A Ford F-250, like the one being used to pull, is rated to pull 12,000 pounds!”

The bottom line is that each major part on the truck and trailer has been through a design, evaluation, and quality control process that defines what each of those parts can and can’t do. From the headlights on the front of the truck to the brake lights on the trailer, the super vehicle is made up of a set of ratings that will determine the vehicle’s safety.

If you ignore ratings and an accident occurs, it can lead to injury and expensive lawsuits that you will not have a chance of winning. If deemed grossly negligent or flagrant, a district attorney could decide to file criminal charges.

ACKNOWLEDGMENTS

Adam Allgeier, Indiana farmer

Bob Avenius, TruGreen

Keith Baylor, Cummins

Jim Beaty, Purdue University

Sharon Drescher, Syngenta Crop Protection

Harold Enger, Spring-Green

Dennis Nowaskie, Purdue University

Jud Scott, Jud Scott Consulting Arborist

Brad Shelton, Purdue University

Mike Titus, Co-Alliance

Jason Tower, Purdue University

Phil Walker, Purdue University

Gary Yunker, Spring-Green

Photographs on pages 5 (bottom), 9, 11 (top right, bottom), and 41 (right side) used by permission of Ron Melancon.

Disclaimer

This publication is intended for educational purposes only. The authors’ views have not been approved by any government agency or business. The publication is distributed with the understanding that the authors are not rendering legal or other professional advice to the reader, and that the information contained herein should not be regarded or relied upon as a substitute for professional consultation. The use of information contained herein constitutes an agreement to hold the authors, companies or reviewers harmless for liability, damage, or expense incurred as a result of reference to or reliance upon the information provided. Mention of a proprietary product or service does not constitute an endorsement by the authors or their employers. Descriptions of specific situations are included only as hypothetical case studies to assist readers of this publication, and are not intended to represent any actual person, business entity or situation. Reference in this publication to any specific commercial product, process, or service, or the use of any trade, firm, or corporation name is for general informational purposes only and does not constitute an endorsement, recommendation, or certification of any kind by Purdue University. Individuals using such products assume responsibility for their use in accordance with current directions of the manufacturer. Any picture of a product used in a way not intended by the manufacturer is neither endorsed nor condoned by the authors or the manufacturer.

FIND OUT MORE

Purdue Pesticide Programs offer a number of publications on related topics to help you manage your operations better. All publications are available from The Purdue Extension Education Store:

www.the-education-store.com

(888) EXT-INFO (496-4636)

Keep the Trailer Connected to the Truck: Understanding the ‘Hitch’ System (PPP-92). Reduce your risks of losing a trailer or other equipment on a busy highway.

Keep the Trailer Connected to the Truck: Understanding the ‘Hitch’ System (PPP-92). Reduce your risks of losing a trailer or other equipment on a busy highway.  Tires For the Road and Field: A Guide to Getting the Best Value and Performance (PPP-99). Find the right replacement tires for your vehicles and operations.

Tires For the Road and Field: A Guide to Getting the Best Value and Performance (PPP-99). Find the right replacement tires for your vehicles and operations.  Securing the Load: A Guide to Safe and Legal Transportation of Cargo and Equipment (PPP-75). Keep gear safely secured to prevent accidents andstay legal.

Securing the Load: A Guide to Safe and Legal Transportation of Cargo and Equipment (PPP-75). Keep gear safely secured to prevent accidents andstay legal.  Hold it Down! pocket guide (PPP-84). This laminated pocket guide is a companion to Securing the Load (PPP-75).

Hold it Down! pocket guide (PPP-84). This laminated pocket guide is a companion to Securing the Load (PPP-75).  The Tractor Hitch Pin: A Critical Component in Keeping Control of Implements

(PPP 94). Understand the critical role these often-overlooked pieces of equipment play.

The Tractor Hitch Pin: A Critical Component in Keeping Control of Implements

(PPP 94). Understand the critical role these often-overlooked pieces of equipment play.  Extracting Stuck Equipment Safely: How to Avoid Expensive and Painful Incidents (PPP-98). Know when it’s safe to extract equipment on your own and when it’s better to call a pro.

Extracting Stuck Equipment Safely: How to Avoid Expensive and Painful Incidents (PPP-98). Know when it’s safe to extract equipment on your own and when it’s better to call a pro.  Transporting Farm Equipment: What Growers Need to Know (PPP-83). Learn safe practices and your legal obligations for transporting equipment.

Transporting Farm Equipment: What Growers Need to Know (PPP-83). Learn safe practices and your legal obligations for transporting equipment.  DOT Rules of the Road: Putting Responsible Drivers and Safe Vehicles on the Highway (PPP-65). Safeguard your drivers, reduce your liabilities, and protect the public and environment.

DOT Rules of the Road: Putting Responsible Drivers and Safe Vehicles on the Highway (PPP-65). Safeguard your drivers, reduce your liabilities, and protect the public and environment. It is the policy of Purdue University Cooperative Extension Service that all persons have equal opportunities and access to its educational programs, services, activities, and facilities without regard to race, religion, color, sex, age, national origin or ancestry, marital status, parental status, sexual orientation, disability or status as a veteran. Purdue University is an Affirmative Action institution. This material may be available in alternative formats.

Order or download materials from

Purdue Extension · The Education Store

www.the-education-store.com