Overhead Power and Communication Lines Don’t Get Grounded

RESOURCES - PUBLICATIONS

Overhead Power and Communication Lines

Don’t Get Grounded

Fred Whitford, Director, Purdue Pesticide Programs

Ann Kline, Director, Purdue Extension-Noble County

Norman A. Blanchard, Senior Electrical Engineering Specialist, Purdue University

Sharon Cunningham, Environmental Health & Safety Manager, Alabama Farmers Cooperative

Shawn Lambert, Director of Safety, Co-Alliance Cooperative, Inc.

Kevin Leigh Smith, Continuing Lecturer and Communication Specialist, Purdue Agricultural Sciences, Education and Communication

A Tale of a Near Tragedy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Moving Electricity Across a Community . . . 8

Production and Distribution of Electricity. . . . 8

Distribution Poles. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Federal Standards Set Minimum

Clearances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

When Minimal Clearance Falls Short . . . . . . . . . . 14

When You Become the Conductor. . . . . . . . . . . . . . 16

Getting Equipment Tangled in

Overhead Lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Scenario One: First to Arrive . . . . . . . . . . . . . . . . . . . . . . 22

Scenario Two: Stay in the Equipment. . . . . . . . . 24

Scenario Three: Leaving an Unsafe Cab. . . . . 26

Who Pays to Repair Damaged Lines

and Poles?. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

All Eyes Look Up. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Conclusion—Respect the

Invisible Enemy. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Acknowledgements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Disclaimer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

A Tale of a Near Tragedy

The following account is a composite of the stories the authors heard while preparing this publication from those who had brushes with overhead lines. “Starting early and working late spraying fields, applying lime, and spreading fertilizer for weeks on end was wearing me down. I should have known better, but I stayed up the night before watching a basketball game that went into overtime. By mid-afternoon the next

day, I looked forward to getting home for some much- needed sleep.

“I finished spraying a new customer’s field and drove to where the tender truck driver waited to refill my sprayer for the next field. Due to a busy day, the driver was in a hurry to unload, so she could return to the plant to prepare for the remaining fields on the schedule. the driver quickly connected the hose from the tender truck to the sprayer, turned on the valve, and began pumping product. I decided (since I was just sitting there) it was a good time to fold the booms. That was one of the worst mistakes I’ve ever made.

“As the booms were folding, I heard a loud pop, my computer screens flickered for a few seconds, and the

sprayer shut down completely. Black smoke appeared around the sprayer as the rubber tires began burning;

the smell was so strong my eyes watered. I glanced above my cab and saw my booms tangled in the high-

voltage electric lines.

“The tender truck driver also heard the loud pop and quickly reached out her hand to turn off the valve. When she touched the valve, the electric current flowed through her into the ground. The grass showed the blackened outline of her feet where the earth was scorched by the current.

“I caught a glimpse of the tender truck driver lying motionless on the ground; I could not tell if she was alive or dead. At this point, I had to make a choice: stay in the cab and risk being burned alive or take a chance

of being electrocuted on the ground.”

What would you have chosen? Once out of the cab and on the ground, what would you have done? More

importantly, what could the sprayer operator and tender truck driver have done to prevent the problem?

We hear about retailers, farmers, and industry personnel who pull electric poles and transformers down onto equipment after guy wires get entangled in booms, about large equipment pulling down low- hanging communication wires, or about equipment getting tangled directly into high-voltage lines and knocking out power in an area. These accidents can lead to death, serious injuries, equipment replacement costs, and liability for costly repair to poles, lines, and transformers. Aside from the aggravation of not having electricity, many businesses downstream of the outage lose revenue when they are unable to carry on with business.

Concerns about entangling equipment in electrical wires heighten as the size of equipment that farmers and commercial agriculture professionals use increases.

As equipment continues to get larger, concerns about contacting electric lines will grow along with them.

It is common for such equipment to have:

• Spray booms that are 120 feet long (and getting longer)

• Augers that extend higher in the air to fill combines and fertilizer spreaders

• Dump trucks with raised beds that are taller than electric wires

• Wagons, cultivators, and combines that are increasing in size (width and height)

This publication provides an overview of three topics:

1. Understanding electrical transmission and distribution: how electricity is spread over the power grid

2. Preventing accidents: steps you should consider to prevent contact with electric lines

3. Dealing with accidents: life-saving steps to follow during an accident

This truck caught fire after connecting with an electrical line. The heat from electrical current through equipment can ignite tires.

Moving Electricity Across a Community

We give little thought to turning on a light switch. All we want when we flip the switch is for lights to magically come on. Aside from those who work for an electrical utility, few of us understand exactly what electricity is, how it is produced, and the processes involved in its transmission. Behind the simple act of flipping a switch is an industry built around generating and delivering power without interruption to run our homes, businesses, and farms.

Voltage Is the Force that Moves Electricity

Generators produce the current that keeps the lines “full,” so end-users always have electricity available to them. Transmission lines are comparable to water lines. When you turn on a faucet, a pump creates pressure that pushes water forward that keeps the water flowing while the tap is open. With electric

transmission, instead of pressure, engineers use voltage to measure the force in a line. As the length of the electrical transmission lines increase, utilities must supply greater voltage to move electricity to the ends of the transmission lines.

In other words, it requires higher voltages to transmit electricity over long distances. When the demand for electricity is low, generators still create voltage and power, but utilities reduce the current they produce to meet demand.

Production and Distribution of Electricity

The production and movement of electricity can be divided into four distinct segments:

1. Generators to transmission lines

2. Transmission lines to substations

3. Distribution lines from substations to transformers

4. Transformers to end users

Electricity is produced by converting resources such as coal, petroleum, natural gas, and nuclear fuel into steam that spins blades in a turbine, which rotates a generator shaft. Connected to that shaft are coils of wire that create a magnetic field. As the shaft rotates, the magnetic field creates voltage in another coil of wire that surrounds the rotating shaft. When an electric load is connected to the generator, the generator pushes a current of electrons through the wire. From the power station, the electrons that make up electricity move through aluminum and copper wires. Although copper conducts electricity more efficiently, many distribution lines are made of less costly aluminum. While less costly, aluminum is also less efficient in moving electricity.

Whether the wire is made of copper or aluminum depends on the amount of power expected to flow through the line and the length of the line. There are other factors that go into that choice, too. In most cases, uninsulated overhead lines are made from aluminum because it is also lightweight. Lines inside buildings are normally copper because it is better at resisting corrosion and has a longer lifespan in an insulated wire.

Newly produced electricity enters transmission lines. They often carry 345,000 to 500,000 volts to ensure there is enough power to push the electricity to the furthest points in the utility’s grid network.

However, the high voltage that transmission lines carry cannot be used directly. Therefore, at certain points along the distribution, substations reduce this high voltage down to 7,200 volts, which feeds electricity to poles. Before electricity is delivered to users, transformers on distribution poles reduce the 7,200 volts further down to the typical 120 or 240 volts. From there, overhead lines or underground conduits carry the electricity to its final destinations.

Substations reduce the high-voltage electricity that transmission lines carry down to approximately 7,200 volts.

Large transmission lines dot the countryside and carry electricity from generators to substations.

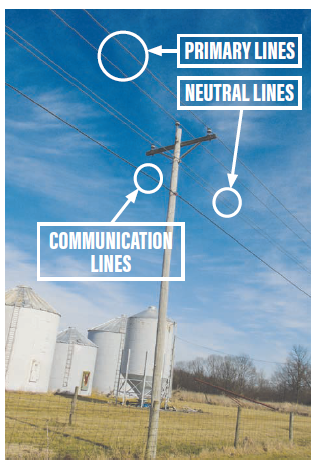

Distribution Poles

The familiar distribution poles that you see alongside highways often serve a dual purpose of carrying both electricity for power and providing communication lines for internet, phone, and cable. While each set of wires serves a separate purpose, they all function as a single unit in terms of connecting one pole to another.

(Above) Pole-mounted transformers lower electricity voltage to levels that are suitable for houses and farms. (Below) In most areas, overhead power lines carry approximately 7,200 volts.

Depending on the pole’s location and the tension placed on it from nearby poles, utility companies generally place one or more guy wires to provide additional support and stability. The top of each pole has primary power lines that carry electric current. One or more lines may each carry 7,200 volts.

About 4 feet below the primary lines is the neutral wire. Neutral wires are required for alternating current circuits to complete the circuit. The 4 feet that separates primary lines and neutral lines helps protect individuals when they are working on primary lines. The distance also allows the wires to sway normally in the wind (and even more extreme events) without making contact. However, this general configuration can vary across utilities.

This utility pole has a copper wire stapled to it that is driven into the ground at the pole’s base. The wire is a backup in case an insulator fails or lightning strikes the pole.

The gray cylinder on this utility pole is a distribution transformer. Notice the black plastic sleeve on the pole below it that is used to keep squirrels, racoons, and other animals from climbing to top of pole and creating short circuits.

Beneath the neutral wires, the lower lines are communication lines, which are generally constructed of fiber and may carry phone, internet, and cable signals. Sometimes, two or three communication lines are each attached to the poles separately. At other times, the communication lines are strapped together to form a single line. When strapped together, communication providers run a piece of cable (called a “messenger”) with fiber lines lashed to it. Communication lines are so strong that they almost act like a horizontal guy wire running from pole to pole.

Utility poles also have another important component: insulators. Without insulators electric current could move from the wires, through the pole, and into the ground. It is common to install polymer insulators that are rated at 15,000 volts sitting atop 7,200-volt lines. That double safety factor can help against the insulator breaking down from age, sun, weather, rain, and ice.

Federal Standards Set Minimum Clearances

The National Electrical Safety Code (NESC) establishes the minimum clearance between lines, vehicles, equipment, and people. Utility engineers must meet these requirements for every line they attach to every distribution pole. Clearance is defined as the space between the line’s lowest point and the ground.

the table and illustration below describe some of these clearances and heights.

As the illustration shows, the minimum clearance the NESC requires will be different for different locations — highways, ponds, fields, roads, or subdivisions. From an engineering perspective, clearance must account for how much engineers anticipate the line to sag based on several factors, including the distance between poles, the weight of the wires, and the degree of stretching during high temperatures. It’s important to remember that these codes can change, so it’s a good idea to consult a professional engineer to address questions about minimal clearances.

Despite the code, utility companies may not have updated all their poles, particularly in remote areas. For this reason, you should never assume that all lines meet the clearances described in the code. Always check with the utility. Distribution poles can be 40 feet tall, spaced approximately 250 feet apart, and buried 6 to 7 feet in the ground. The NESC measures clearance at the midspan between the two poles where weight has the most influence on the wires.

Utility engineers take into account that wires will react to changing temperatures. Wires sag when temperatures rise and tighten and move higher when temperatures fall. Engineers use tables to help them predict the amount of sagging that wires will experience at temperature extremes based on wire size and pole distance. For instance, a wire can sag 1 foot on an 80°F day and raise 18 inches on a 0°F winter day. To meet the NESC clearance levels, engineers must account for these and other factors.

When Minimal Clearance Falls Short

There can be problems with maintaining minimum clearance. Such problems can stem from several sources such as customers, renters, and the utilities themselves. Here are some scenarios where even the NESC minimum clearance requirements may not be enough.

New Equipment

The minimum clearance most agricultural equipment needs is 15 feet, 6 inches. This is normally enough

clearance for equipment used to cultivate, plant, spray, and harvest crops. However, ag retailers or farmers

might purchase newer equipment with flotation tires that increase the total height to 17 feet. Without

factoring height into the equation, their next visit under the wires with 15 feet, 6 inches of clearance with 17 feet equipment will not go well.

You should conduct a hazard assessment with your existing equipment and any new equipment you acquire in the future. Determine your equipment height and know what its minimum clearance must be. It would also be a good idea to post the traveling height of all equipment inside the cab so all operators will know.

If a new sprayer is more than 14 feet tall, it is classified as an oversized vehicle and requires an additional 1 foot, 6 inches of clearance. This requires raising the communication line if one exists on the poles. However, raising the lower communication line up might mean encroaching on the neutral and primary lines. In such cases, it is likely that a new set of taller poles might be required at the field entrance to ensure your equipment has adequate space to cross under the lines.

New Entry Point

On occasion, farmers might move the entry locations where they and commercial ag retailers access their fields. Very often, everyone assumes that any new field entrance lane has distribution wires and communication lines that are just as high as the old lane. Farmers and retailers seldom measure how high the wires actually are in the new lane. Consequently, utilities commonly deal with pulled wires at new entry points in fields.

Sagging communication lines can be snagged and pull other distribution pole components into contact with equipment.

Advise the Utility Before Problems Occur

Not enough room to pass your equipment under a power line? Simply communicate to the utility that you purchased a taller tractor, wagon, sprayer, combine, augur, or other piece of equipment. The utility will come out and work with you one-on-one. The utility wants to ensure poles and wires are high enough for the farmer or ag retailer to get their job done and to keep power flowing to their customers.

Renters of Pole Space

Multiple companies have rental agreements with utility companies that allow them to attach their communication lines to distribution poles. While utilities rent pole spaces to others, the poles still belong to the utilities and the utilities are ultimately responsible for maintaining ground clearance. If communication lines are not up to code, utilities contact the companies renting the poles to inform them they need to meet minimum clearances for their lines.

Lack of Maintenance

As poles, electrical wires, and guy wires age, they may not maintain minimum clearances. If you see a problem with poles or wires due to maintenance issues, contact the utility immediately.

When You Become the Conductor

To understand how to respond when equipment tangles with the overhead lines, it is necessary to understand how you become the path for electricity that moves from the wires, through you, and to the ground. This means we need to discuss an electrical concept called potential difference. A simplified definition of potential difference includes the idea that electrical current flows from higher elevation to lower

elevation.

We also know that electricity seeks the shortest path with the least resistance to ground. Assume a charged primary line is lying on the ground. While the ground is a poor conductor of electricity, it can absorb the 7,200 volts. Then, visualize an imaginary concentric circle surrounding that point of contact with 7,200 volts as the bullseye of a dart board. Continue to draw concentric circles as you move further away with the number of volts within that circle getting smaller the farther you move from the contact point. Electricity can only go so far.

A DEADLY COMBINATION FOR HUMANS

Of course, you cannot see those imaginary concentric circles. If you were to stand within one circle with both feet close together, it’s likely that the most direct path to ground for the electricity is still directly into the soil. However, if you were to step in two separate circles, that means there is a higher electrical potential in one circle than in the other. In such cases, the electricity will flow from one leg into the other, because your legs represent a better path to ground.

When one foot is in the 7,200-volt circle and the other is in a 4,000-volt circle, then the electrical current will flow “downhill” from the foot in the 7,200-volt circle, through your body, and down to the foot in the 4,000- volt foot circle. As a result, you can be electrocuted. Imagine a sprayer boom lying on an energized line or a line laying across the cab. The entire sprayer will have 7,200 volts passing through it, including the sprayer, engine, steering wheel, and most importantly, you. The electrical potential difference between you, the wires, and equipment is the same, and the current has no reason to flow, because rubber tires insulate the charged system.

What happens if you step off the ladder onto the ground while your hand holds the railing? As you step off the bottom ladder of the sprayer, one hand holds the railing as your foot gently touches the ground because you are worried about getting shocked or twisting your ankle. As you hold the ladder’s handrail, the current travels through your body from your hands on the metal to your feet planted on the ground.

The higher voltage passing through the sprayer flows to the lower voltage of the ground, and you (the person) receive the full force of the current now flowing from the equipment to the ground. You become the connection between 7,200 volts on the sprayer and ground. This can destroy your body in a split second.

Power To Burn and Destroy

This loader was handling lime when it contacted electrical lines. It was so hot that the cab and glass melted.

Getting Equipment Tangled in Overhead Lines

Extended augers, spray booms, and dump truck beds can put you in harm’s way if they contact power lines. Here are a few ways equipment can get tangled in overhead lines.

Getting ‘Juiced’ by Primary Lines

Putting equipment directly in contact with or within a short distance of overhead primary wires is a disaster waiting to happen.

Placing a ‘Call’ with Communication Lines

While communication lines do not carry electricity, pulling them down creates additional problems. When a communication line is pulled down, it often brings down nearby poles and primary wires, too. When this happens, primary lines energize communication lines with 7,200 volts or more.

Wrapping Your ‘Arms’ Around a Guy Wire

Entangling a sprayer boom with a guy wire can lead to snapped poles, thrown breakers, and downed lines. Pulling a pole is like hitting the first in a long line of standing dominoes — one follows another. The distribution system is tied in so well together that what you do to one section affects poles and wires up and down the system, which can cause the power grid to go off-line.

While there are many ways to find yourself in these predicaments, the bottom line is they all can seriously hurt or kill you. Before entering a field, take a moment to observe your surroundings and ensure that you have the correct clearances before entering.

This tree was cut but fell toward the truck carrying electric lines with it.

Snagging a guy wire can pull down poles.

When you decide to extend a sprayer boom, always check your surroundings. Make sure you are not near electric lines but are in the field with room to work.

Even though this equipment is short, it still caught a guy wire, broke the pole, and pulled down the transformer on top of it.

3 DON’TS FOR STAYING CLEAR OF OVERHEAD ENTANGLEMENTS

All the wires on a utility pole have dangers associated with them. Here’s our best advice is to avoid those dangers.

The Shock of Your Life

Since the human body is largely composed of water, it easily conducts electric current. The heart and other muscles work by electrical stimulation. How much current will flow from the wires depends on the electrical resistance of the path through the body and how much voltage is between the two contact points. Ohm’s law (which states that current equals voltage divided by resistance) can help predict current flow. At a current level of about 20 milliamps (0.002 amps) most people cannot let go of an energized wire, which extends the duration of a shock. At higher currents, the heart muscles lose their rhythm. This rhythm loss is called “fibrillation” and can occur at levels as low as 50 volts. Sometimes, leg and hip muscles will violently extend, throwing a person far from the point of contact. Electric current also heats up conductors, which means that electricity can burn tissues and organs and destroy the central nervous system at the same time the heart stops.

Can you imagine 7,200 volts coursing through your body? Using Ohm’s law, at 7,200 volts with a resistance of 5,000 ohms we can estimate more than 1,000 milliamps will flow through the body. This is more than 10 times the voltage that can stop a beating heart muscle. The initial current can also damage skin and lower the body’s resistance to allow even more current to flow. Knowing what to do if your equipment gets tangled in the wires might save your life. Taking the wrong course of action might be the last thing you do.

Consider these three scenarios and the lessons they offer about avoiding risk from power lines.

SCENARIO ONE: First to Arrive

You are sent out to deal with company equipment that hit a utility pole. As the first one at the scene, you must fight your impulse to immediately help your friend out of the entanglement. If you put one foot on the ground while holding the vehicle, you may be electrocuted. Instead, drive up next to the equipment and roll down your window. Tell the trapped operator to not get out of the vehicle and that you will call 911. When

you call 911, inform the dispatcher you are at the scene of an electrical emergency and ask that they contact the power company to have them on-site as soon as possible.

Meanwhile, keep bystanders 30 feet from the scene. Whatever you do, stay inside your vehicle. Never rush in to help without ensuring that the utility company has deenergized the lines. As previously discussed, you don’t know whether the power is still on or what area of the ground is charged with electricity. Everyone remains safe as long as they stay inside their vehicles. You can also call the power company and let them know the pole number involved at the accident.

A Tragic Mistake

“DEKALB COUNTY, Ind. (WANE) — The DeKalb County Sheriff’s Department is investigating a man’s death following a crash Thursday evening. According to authorities, a truck was traveling north in the 2200 block of County Road 61 when the driver, 20-year-old [name removed], lost control and hit a utility pole. The impact caused the pole to snap in half and live wires fell across the road.

A release from the sheriff’s department says [name removed] got out of the truck to walk back toward the road when he stepped on the live wires. He was pronounced dead at the scene by first responders.”

Source: wane.com, January 27, 2023

Electric utility crews have the specialized training and equipment to repair pole and line damage safely. When you see work on the lines take the long way around. If you are in any agricultural equipment, the size of it already may take up the open space when utility workers are present. Stay clear to give them the space they need to move and raise the lines.

This truck sliding off the road could lead to a major shock. It looks like a simple truck crash, but is the scene safe? Are there any lines down? With ice possible on the lines, ensuring that this line is supported needs to be a priority.

SCENARIO ONE: The first to arrive

You’re sent out in response to a coworker who hit a utility pole with company equipment.

SCENARIO TWO:Stay in the Equipment

It is critical to stay in the cab until the utility company sends linemen to deenergize the lines. Tires provide

insulation against electricity moving from the wires to the ground. An active power line can be lying on the hood of the cab, but you are protected as long as you stay in the cab.

Inside the cab, you are like a bird perched on a fully energized primary wire. You might feel a slight tingle that lets you know there is a current flowing. Don’t panic and stay put! Staying inside the cab, keeps you alive.

If you find yourself in this scenario, call 911 and/ or the utility company to inform them of the situation. Tell them you cannot confirm the downed line has been deenergized. The 911 operator should pass along this information to law enforcement, fire, ambulance personnel, and other first responders who arrive at the scene to ensure they do not become victims. Remain in the cab until power lines are deenergized and the utility company gives you the all-clear signal that it is safe to leave the cab. Make sure it is the utility that says power is off. Never attempt to remediate a power line problem until the utility indicates power has been deactivated.

With the system de-energized, a utility worker can begin inspecting the damage.

Make sure the person who tells you the power is off works for the utility. You should always assume the power is on if anyone other than the utility is providing the response.

SCENARIO TWO

Stay in the vehicle

You collided with a utility pole but see no threats to your safety in the vehicle.

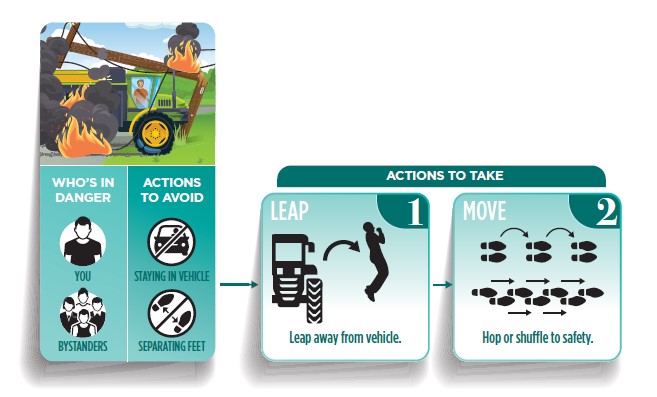

SCENARIO THREE:Leaving an Unsafe Cab

If your equipment strikes power lines and the tires and other parts of the equipment are burning, you have little choice but to exit the cab. However, making one mistake when exiting can lead to tragic consequences. If you must leave the cab, leap off and get clear of the machine.

Aim for a spot where you can comfortably jump without getting hung up on the equipment or falling backward into the equipment once your feet touch the ground. Falling back into energized equipment allows electricity to flow through the person into the ground.

You do not have to make an Olympic jump, but make the jump away from the downed power line. Get as low as you can to help maintain your balance as your feet hit the ground. Cross your hands over your body to make sure you are not touching any metal during the jump. Hit the ground with your feet close together to try to keep them in the same “circle” of voltage.

Can You Safely Drive Off?

If you can drive away from the immediate area, do so. Be aware about pulling poles and more wires on your equipment. This might be the last resort before having to jump out of the burning equipment.

Proper balance is critical. If you fall forward, your feet and hands may contact the ground at different voltage circles; the voltage difference would cause current to flow through your body. With your feet firmly on the ground, you have two choices to move forward: You can bunny-hop or you can shuffle both feet. Make sure to rub your shoes together as you move forward. Don’t separate your feet. By keeping your feet close together, you are more likely to remain in a single voltage zone.

Deadly Consequences if You Do this

Stepping down off the tractor by putting one foot on the ground while touching the equipment might be the last thing you remember. You might as well have one foot on the ground while holding the live wire in your hands. Electricity will flow through your body, causing burns to organs, muscle spasms, cardiac arrest, and death.

The comment we often hear about this advice is: “Keeping your feet together will take you forever.” Instead, you should be thinking, “I have nothing better to do with my time right now.” Because forever might have a fatal definition. The terrain you are on might require blending both techniques. For instance, corn stalks might make it impossible for you to shuffle your feet. If it is a that field with few obstacles, shuffling might get you out of the area quicker.

In any case, do not let your guard down. Don’t assume safety because you do not feel a tingle. As you slowly move away from the scene, assume everything around you is electrified (including the fence, guy wires, equipment debris, trucks, gates, and so on). The fact that you are still alive and trying to move away from the accident means luck is on your side. Go as far as you can until the linemen show up and give the all-clear.

ELECTRICITY ON THE GROUND

Know how to move. Voltage reduces consistently from where live wires touch the ground. When moving to safety, always keep your feet touching, and shuffle or hop to safety to keep the voltage uniform in your body. Never separate your feet — that can cause a deadly voltage difference in your body.

Having the discipline to stay inside the equipment is critical. If the emergency requires you to get out, you need to know how you can make the jump to safety without hesitation.

SCENARIO THREE

Leave an unsafe cab

You collided with a utility pole but see a fire outside the vehicle.

Who Pays to Repair Damaged Lines and Poles?

Who picks up the tab for repairing powerlines and replacing utility poles? the answer depends on the situation and is decided after the utility restores power and an investigation concludes.

Here are two examples of who would pay for the damages.

1. An operator hits a guy wire with a sprayer boom, pulling down two poles and their lines. In this example, the operator was at fault, so the operator or the operator’s company might be required to pay the repair bill.

2. A sprayer pulls into a lane toward a customer’s field. As it passes under the communication lines, the sprayer pulls them down along with several poles and electric wires. Investigations show the communication lines along the spans do not meet minimum clearance heights. In this example, the utility assumes the cost of repairs because the lines were not at the right height.

If a loose anhydrous ammonia tank hits and damages a line, the driver may be responsible for paying for repairs.

All Eyes Look Up

Equipment operators must continually focus on the clearance between lines and equipment, where guy wires are in fields, and locations to safely lift beds and fold booms. We get so used to poles and lines that they become an invisible part of the background. Like most safety issues, the best approach is prevention.

Consider these seven recommendations for being safe around power lines.

Recommendation 1:

Notify Everyone of Line Locations Crop producers and salespeople should notify applicators of locations of power lines and guy wires. Problematic lines should be entered in the sprayer’s mapping program along with the utility’s phone number.

Uneven terrain can increase the height of equipment.

Like most safety issues, the best approach is prevention.

Recommendation 2:

Look Up

If a field’s entry changes, drivers should look up to determine if there is enough clearance between equipment and lines. Just because the new entrance is close to the previous one does not mean the lines are at the same height.

These photos show the same field, but two different entrances off the highway. The top photograph shows a much higher clearance than the second field entrance.

Recommendation 3:

Find the Lines

A new field can mean trouble for applicators if they do not consider power line heights. This is especially

problematic when entering a new field or making farm deliveries at dusk or dawn. You should always ask yourself, “Where are the lines?”, “Where are the guy wires?”, and “Where are the poles?”

Recommendation 4:

Work Away from Lines

Plan your work so you are well away from lines. Power lines and poles are placed in easements that allow

utilities access to their equipment. Whenever possible, pull into a field rather than working within or close to

the easement.

An impeded view inside your equipment could make seeing the lines impossible. Give yourself plenty of space. GPS and computer systems can be used to track lines and show safe field entrances.

Recommendation 5:

Know Your Equipment

Know the height and turning radius of your equipment, including the boom, augur, and dump beds. Post the

overall height of your equipment in the cab, so it is always handy. You should always ask yourself two

questions when operating near power lines.

• Can you safely swing the boom arm around the power equipment?

• How many feet does your machine require for sharp turns?

Even the lines that run from the last pole to the farm can pull down larger poles. These lines aren’t always as high as main lines.

A Costly Mistake

This chain and hook were meant to go over harvested trees. Instead, it was intercepted by a primary line. This workplace mistake was very costly when the entire truck, trailer, and timber were destroyed.

All eyes look up — clearance is a top concern. These lines could have become entangled in the equipment if not for care taken by the operator.

Recommendation 6:

Use Tenders as Spotters

Out in the field, use tender drivers as spotters. While waiting to refill, tender drivers can look around for potential issues relative to overhead lines. Tender drivers must pay attention to where they load and ensure they do so well away from any lines.

Recommendation 7:

Lower Booms in the Field

Lower and retract booms, beds, and augers in the field before moving toward the highway. Always make sure you are far enough away from wires whenever you fold or extend equipment. Ensure you complete the process and that all booms, augurs, and beds are in closed positions ready for travel before you approach anywhere near power lines.

Constant Reminders Are a Good thing

It never hurts to make sure equipment operators are always working safely. Here are some ways you can help.

• Put pop-up messages on work tablets that remind applicators and tender truck drivers to “Keep Your Eyes Open for Power Lines.”

• Place electric shock warning stickers next to the boom, augur, and dump switches.

Conclusion — Respect the Invisible Enemy

It seems dangerous situations around power lines are repeated each year around the country as ag retailers and growers rush to get crops planted or harvested. The agricultural industry works long hours, and it can be too easy to forget about the dangers overhead lines pose. Power lines are inherently dangerous, which is why utilities spend thousands of dollars each year training linemen to work safely. In fact, newly hired linemen are put through an intensive school before working on power lines. Linemen are repeatedly told never to underestimate the deadly power in power lines. Neither should you. If those working every day with electric lines take their work seriously, why would we not do the same?

It’s not that we do not understand the risks of 7,200 volts passing through our bodies, but we take it for granted that we will not interact with those lines. Remember to take precautions when working near power lines. Remain calm if you find yourself with a primary electrical line draped over your equipment or wires entangled with the boom. Do not panic! Stay in the cab and wait for help to arrive.

If you need to jump out of the cab because the equipment catches fire (or something similar), keep your arms crossed over your chest, then jump safely out and plant both feet on the ground as close together as possible. Take your time as you move slowly away from the accident. Remember, the power in power lines can kill!

Electric power is wonderful, but it is a force with no conscience and has no respect for humans. If you treat electricity with respect, you will enjoy its benefits. If you don’t treat it with respect, it will injure or kill you without hesitation. It is up to you to respect electricity.

Aboveground electric lines in rural areas are everywhere. Pay close attention when working fields near these lines.

The Rest of the Story for Tale of a Near Tragedy

The broadcaster Paul Harvey was famous providing, “the rest of the story.” The incident that we used at the start of this publication had a good ending, but only by luck. After the operator folded the booms under the power lines, the sprayer’s tires, rims, and two airbags were destroyed and had to be replaced. All the hydraulic hoses going to the rear tires and some wiring along the frame were melted from the heat generated by the burning tires.

In addition, all the tires on the tender truck tires had to be replaced because they had blown after the power surge. One of the blown tires damaged the rear shocks and air bags and had to be replaced. Aside from what had to be replaced, there was no further damage to the equipment. And the sprayer driver? He returned to work with no medical issues. The tender truck driver received a significant shock when she tried to shut off the valve. She had to undergo medical treatment but was later cleared to return to work.

Acknowledgements

Thanks to Dawn Minns for graphic design and Adduci Studios for illustrations. Thanks also to the following individuals who provided valuable comments and suggestions that improved this publication:

Walt Black, Alabama Farmers Cooperative

Randy Brumfield, Bartholomew County REMC

Kevin Burch, Consultant

Robbie Collins, Lockton Companies

Julie Lamberson, Co-Alliance Cooperative

Russell Lassiter, Andalusia Farmers Cooperative

Victor Lenkaitis, Nationwide Insurance

Dan Mekkes, Safety Specialist, Townsend Tree Service

Craig Trowbridge, Entrust Solutions Group

Bob York, BASF

Disclaimer

This publication is intended for educational purposes only. The authors’ views have not been approved by any government agency, business, or individual and cannot be construed as representing a perspective other than that of the authors. The publication is distributed with the understanding that the authors are not rendering legal or other professional advice to the reader, and that the information contained herein should not be regarded or relied upon as a substitute for professional consultation. The use of the information contained herein constitutes an agreement to hold the authors, companies, or reviewers harmless for liability, damage, or expense incurred as a result of reference to or reliance upon the information provided. Mention of a proprietary product or service does not constitute an endorsement by the authors or their

employers. Descriptions of specific situations are included only as hypothetical case studies to assist readers of this publication and are not intended to represent any actual person, business entity, or situation. Reference in this publication to any specific commercial product, process, or service, or the use of any trade, firm, or corporation name is for general informational purposes only and does not constitute an endorsement, recommendation, or certification of any kind by Purdue University. Individuals using such products assume responsibility that the product is used in a way intended by the manufacturer and misuse is neither endorsed nor condoned by the authors nor the manufacturer.

Reference in this publication to any specific commercial product, process, or service, or the use of any trade, firm, or corporation name is for general informational purposes only and does not constitute an endorsement, recommendation, or certification of any kind by Purdue Extension. Individuals using such products assume responsibility for their use in accordance with current directions of the manufacturer.

Find out more at

THE EDUCATION STORE

edustore.purdue.edu