9.Drone Maintenance and Winterization

RESOURCES - PUBLICATIONS

The Evolution of Spray Drones, Their Capabilities and Challenges for Pesticide Applications

9. Drone Maintenance and Winterization

End-of-season maintenance on drones ensures quick startups in the spring. Winterizing drones is straightforward, since most of the time, they will be stored in temperaturecontrolled rooms like heated shops.

Perform a visual inspection that focuses on looking for cracking and splits in the frame, because there is a lot of torque when drones take off and impact force when they land. Check all the parts to see if anything needs tightening or replacing. Make sure to replenish your spare parts inventory so you are not surprised the next time you need that part in the field.

There is really no inspection you can perform with the drone’s software. The software is designed to check the functionality of the electronic components. Drones will go through self-check diagnoses when they are first powered on. The propellers move a little, the cameras will move, and lights will flash. If any part fails the self-diagnosis, the controller will tell you there is a problem. A message will appear on the controller saying the drone can’t take off because the following issue x, y, or z needs to be addressed.

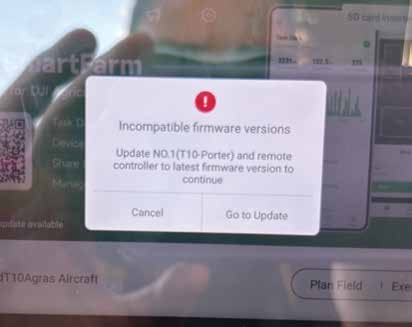

It is important to ensure that you are using current firmware for your drone’s software. Manufacturers may send software updates to fix bugs or other issues. It is also important to ensure drones and battery firmware are compatible, otherwise a pilot may show up to the field and not be able to fly until the software is updated with current software patches. If you have not flown for a while, power up the drone and controller at the shop where you have a consistent internet connection to help avoid any untimely firmware updates at jobsites.

It is important to observe and inspect drones before and after operations to detect any damage that may have occurred.

What Is My Dadgum Password?

Make sure you have carefully noted your username and password to log into drone software and keep it where you have easy access to it when you want to use the drone next season.

Make sure to keep a battery in place to help protect the copper connection when you wash a drone and even when not in use. Use a paper towel or cloth to wipe any water from the copper connectors. Do not take out the battery because this exposes terminals and can short if water is present.

Before storing batteries, examine each battery for signs of swelling on the top and sides of the unit. It is always a good practice to label your batteries 1, 2, 3, etc. The labels help ensure that you use each battery regularly instead of charging and using the same battery over and over again.

The owner’s manual should provide directions on how you should store batteries. Triple rinsing drone tanks, flushing out lines and pumps with clean water, and using tank cleaners overnight are good practices to help remove any unwanted chemical residues. Replace hoses that appear to be checkered from sunlight damage or appear to be stained or colored from absorbing chemicals.

Software errors, like this one, are often displayed when starting up a drone. It is important to keep software up to date to ensure best performance.

Software errors, like this one, are often displayed when starting up a drone. It is important to keep software up to date to ensure best performance.  When batteries are not in place, electrical components are exposed and are at risk for damage.

When batteries are not in place, electrical components are exposed and are at risk for damage. DRONE FACT

When cleaning drones, do not pressure wash them or remove any components (such as batteries) to avoid getting water into the drones.

If your drones will be subjected to freezing temperatures, then you should flush their systems with RV antifreeze after cleaning them. This will help prevent any remaining water from freezing. Remove as much water as possible by emptying tanks, open any valves to release any trapped water, and blow air through the systems. Fill drone tanks with enough RV antifreeze to flush the entire drone.

At first, the color of the antifreeze coming out of the nozzles will be lighter, because it has been diluted with any remaining water left in the drone. Continue to flush until the antifreeze coming out of the nozzle is the same color as the antifreeze you put in.

Batteries can swell if they overheat, which in turn decreases performance or causes permanent damage

Batteries can swell if they overheat, which in turn decreases performance or causes permanent damage  Drones should not be stored in freezing temperatures. However, rinsing drone lines with RV antifreeze helps prevent damage that may occur from cold environments and extends the life of such components.

Drones should not be stored in freezing temperatures. However, rinsing drone lines with RV antifreeze helps prevent damage that may occur from cold environments and extends the life of such components.