Plan Today For Tomorrow’s Flood : A Flood Response Plan for Agricultural Retailers

RESOURCES - PUBLICATIONS

Plan Today For Tomorrow’s Flood : A Flood Response Plan for Agricultural Retailers

Authors

Fred Whitford

Coordinator, Purdue Pesticide Programs

Steve Cain

Project Director, Extension Disaster Education Network, Purdue University

Jim Beaty

Superintendent, Purdue Agronomy Center for Research and Education

Steve Hawkins

Assistant Director, Purdue Agriculture Centers

Jamie Southard

Safety and Regulatory Director, Effingham Equity

Cecil Henderson

Risk Manager, South Indiana, LLP

Steve Paddick

Plant Manager, Mont Eagle Mills

Jerry Bunte

Plant Manager, Crop Production Services

Jerry Boger

Safety and Risk Manager, Jackson Jennings Co-op

Bob Bellinger

Pesticide Coordinator, Clemson University

Shawn Lambert

Safety and Risk Manager, Co-Alliance, LLP

Kevin Leigh Smith

Editor, Purdue Agricultural Communication

Contents

Floods Can Occur Anywhere, Anytime . 8

Experience Is the Best Teacher . 10

Planning for Tomorrow’s Floods . 16

Putting Your Plan in Operation . 32

If All Else Fails, Evacuate . 34

Flood Recovery . 36

Rebuilding Permits . 39

Conclusion . 40

Acknowledgments . 42

The evening news showed flooded towns, displaced people, and businesses shut down — some forever. Knee-deep water submerged the early season corn, wheat, and soybeans; layers of sand and gravel washed from the river covered productive farmland; and the floodwaters carried much of the area’s livestock downriver.

The governor, and then the President of the United States, declared the flooded communities federal disaster areas. The National Guard was called in to secure the affected areas, and the Red Cross and Salvation Army quickly established shelters and food distribution centers. Soon, state and federal disaster teams began helping people regain a sense of direction in their lives. The media covered the Midwest floods story for a full week.

But soon, the newspaper headlines and television broadcasts turned to newer, more pressing events, and the flood became yesterday’s news. Outside the affected areas, the storms faded into memory. Those who experienced the floods first-hand will never forget the ordeal of the spring and summer of 2008. That flood, and others, leave their mark for many years. For the flood victims, rebuilding will take time — years in some cases — and the loss of personal mementos, family heirlooms, and pictures will be felt forever.

Before the 2008 floods were over, the Federal Emergency Management Agency (FEMA) issued 14 Federal Flood and Windstorm disaster declarations in Illinois, Indiana, Iowa, Michigan, Minnesota, and Ohio. There is no way to predict when the next flood will strike or what community will be affected, but we know with certainty that floods will strike again. The purpose of this publication is to raise the awareness of how floodwaters pose risks to both agricultural retailers and their communities. This publication includes the lessons learned from many retail managers who experienced flooding. We hope that implementing some of the practical guidelines in this publication will lessen the severity of any flood you might experience, and prepare your community to respond better.

Floods Can Occur Anywhere, Anytime

There are many possible flood scenarios. Too much debris (such as leaves, tree limbs, and trash) can clog street drains or ditches that cause flooding after a heavy rain. In such cases, water collects on paved surfaces instead of being absorbed by soil, fills water retention ponds, or goes downstream. Water rises either because the drains cannot handle the volume of water being channeled into them or the water cannot get to the ditches.

When the rain stops, the rainwater will recede from roads and parking lots within minutes, provided the drains and ditches are clear and free of debris. During the rain or shortly after, the water rapidly seeks lower ground, which floods basements or lower buildings. Floods also happen when a river’s or creek’s natural bank or levee cannot contain the water within its channel. Such floods often recede slowly, because the floodwaters cannot drain back into streams, creeks, or ditches until the water level downstream drops to pre-flood levels.

In this type of flood, waters tend to rise slowly and predictably, so emergency responders often have more time to warn the public. Flash floods develop quickly and without much warning. For instance, an area might receive 8 to 10 inches of rain in an afternoon, and quickly saturate the soil. Once this happens, water will start to run off, filling low-lying areas first.

As the water flows downhill, it eventually passes through, or concentrates on, just a few acres of ground, causing deep water in those areas. The deluge also can overwhelm the ability of creeks and streams to carry the water away. The water accumulates, and the ditches or creeks overflow their banks. Walls of water can roll across farms and towns and wreak havoc in their wakes.

To make matters worse, floods can weaken levees and cause them to fail, releasing billions of gallons of water into already flooded areas. Broken levees often produce historic 100-year floods where the water is so deep that only the rooftops of buildings are seen. Flash flooding from levee breaks happens so quickly that the only recourse may be immediate evacuation. Floods can happen even when it doesn’t rain in your area.

Let’s say an area upstream receives a heavy downpour or large amount of rain in a short time. This will cause flash flooding in that area and raises the potential for flooding in areas and communities downstream. Runoff from the area that was initially affected will eventually drain into creeks, streams, ditches, or rivers and continue downstream. As the mass of water moves downstream, flood watches and warnings are posted to alert those living along the stream. The bottom line is that flooding can and does occur anywhere — even in deserts — given the right circumstances.

Another form of flooding that plagues buildings is reverse flow flooding. This happens to buildings tied into public sewer systems. When heavy water loads on and around these public systems are too great, water pushes into sewers and works its way back into low-lying outlets in basements or into buildings with low grades. This type of flooding is often nasty because it can include sewage and all other types of foreign materials.

Sometimes, you will hear about 100-year or 500-year floods. These terms, which will be described later, are being reconsidered by the experts because flooding has been so severe in recent years. Land-use (such as a lack of retention ponds) has such an influence on flooding that experts don’t feel the 100-year and 500-year terms apply anymore. If that’s the case, you may one day see experts use different terms to describe floods, such as a 1-5 or color-coded rating scale.

Debris-clogged ditches and drains can cause floods after heavy rains.

Debris-clogged ditches and drains can cause floods after heavy rains.

Experience Is the Best Teacher

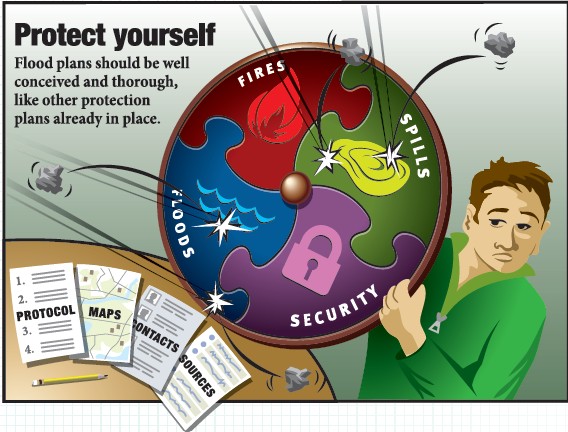

Retail agricultural outlets already should have developed and implemented emergency procedures to deal with pesticide spills, tornadoes, anhydrous ammonia releases, terrorist threats, and workplace injuries. Retailers also need to plan for the serious risks posed by floods. The following case studies recount picture-perfect responses by ag retail managers threatened by floods. These real-life examples reinforce the importance of knowing the facility, having important contacts, understanding what to protect, and having well-coordinated actions.

Agricultural retailers should have emergency plans for floods, just like they have plans for tornadoes or other disasters.

A Picture-Perfect Response

Our plant is located between two rivers, and both levees were threatened by rising water. We’ve been in the position of water threatening us before, but nothing happened or got to the point that we thought we needed to do something. As the water began to rise more and more during the last flood, we became concerned. We called our employees and put them on alert that a flood was possible. We had a levee break in 1943 and in 1959, and had a general idea of what could happen.

Some of our older customers gave us this information. I also established a pretty direct line with the levee commissioners to know when something might happen or what the odds were that something would happen. It was about 1 a.m. when we were notified that both levees broke. I told my right-hand man to meet me at the plant. When we got there, we called two other employees and got them in here to deal with the threat of flooding.

Building dikes around buildings can help protect them from floodwaters.

We had an idea of what we would do. The guys who work for me have been here for quite some time, so we didn’t have anything written down. But we verbally made a plan and knew what we were going to do and who we were going to call. The chemicals were our first focus — not only for the loss of money, but also for liability reasons. I had already contacted our distributors to line up trailers to haul our chemicals out, and I’ d been in touch with our satellite plants to help get the fertilizer and equipment out. All parties were on standby.

Even storing equipment in areas with slightly higher elevations can protect your property from flood damage.

We got hold of the distributors about 3 o’clock in the morning to send trucks down to pick up chemicals. It took a shade less than two hours for the trucks to get here. While we were waiting, we stacked and shrink-wrapped the packaged chemicals on pallets. We had time to stack, wrap, and count everything so that when the trucks arrived, all I had to do was to load the trucks. It took probably 30 minutes to load the trucks once they arrived.

One employee pumped chemicals into mini-bulks to empty the storage tanks. That took about two hours, at most. We had approximately 4,000 gallons of pesticides in storage. We put them on a flat bed trailer and hauled them to one of our other facilities. Another employee and his dad (who also is a customer of ours) came in and started moving out the rolling equipment: anhydrous tanks, Rogators, Terragators, fertilizer buggies. We already had a plan to take the equipment to an area three or four miles from the facility.

As the drivers hauled away the rolling gear, they just made trips back and forth with their pickups. They drove the equipment to the temporary storage area and then an employee’s wife picked up the drivers and brought them back to pick up more equipment. The fourth member of our team loaded out fertilizer. He ran fertilizer through the hopper into tender trucks that came from our satellite plants. Fortunately, when the flood struck, our inventory was low because it was getting late in the season. We probably had a couple hundred tons of fertilizer.

It took between three and four hours to get the fertilizer loaded onto the trucks. While all this was going on, we also built a limestone dike around our 1,000-gallon fuel tank and propane tank. We did not do anything around the buildings. We also have an anhydrous storage tank. It’s set three feet off the ground and our lot was built up a foot. Based on the worst flood in history in 1943, we were pretty certain the water would not go that high. So we were not too worried about the anhydrous tank.

We did not do anything with our 28% storage tanks. They are surrounded by a 3-foot-tall dike, and the tanks are cabled down. The tanks had product in them, but the water would have to go over the dike to get to them. And again, based on what we knew from the 1943 floods, there was really no fear of anything happening there. All members of the team finished up about the same time.

When I left that morning, I disconnected the computer system and loaded it into my truck. I took the fax machine, copy machine, and all the office equipment. I was glad I had caught up with all of the paperwork before I disconnected the system. I shut the main breakers off at the power pole for the facility before I left.

By the time everyone got there, we started moving everything at roughly at 2 o’clock in the morning, and we were out by 8 o’clock. By 10 o’clock, the water was coming up the road and we were no longer able to reach the facility. The only way to get here was with a boat. It was virtually three weeks before we were able to get back and open the place back up. It took a couple of days to bring everything back to the plant. Honestly, I really can’t see anything we would have changed. Things just went so smoothly and without a hitch.

A Job Well Done

Everybody around here knows at what water level things get serious. They say that when the river gets to 25 feet, it’s time to be concerned. The television and radio newscasts said the crest was going to get up to around 28 feet, which is up toward the top of the levee.

I also listened to the old guys who have been around here for years. They got nervous and worried, too, which confirmed what the forecasters had said. They have lived here all of their life and are the ones who know what’s really going to happen. So I started to take action.

The flood didn’t just happen, boom, all at once. We knew people working on the levees. There was a general concern that maybe it was time for people to start moving out. That’s when people in town started packing up and we started to do some things, too.

Our plant is six miles from the levee. The guy I am replacing had been here for 30 years. He’s still here and was able to give me advice. He was here through the last flood, in 1993, when the levee broke and there was 12 to 14 feet of water covering the facility. He knew what he did right and what he did wrong. We talked about it. Experience is the best teacher.

The fear of repeating what happened after the last flood was important. Everybody talked about the mess the stuff they left behind was in when they returned. It would have been so much easier, they said, if it had been moved.

This time, we had it mentally worked out what we wanted to do. We started on the things we knew would take longest. I have an advantage here because I have another plant up in the hills about 10 miles away. Early on, we hauled everything up there that we could. Then we were still able to get products and services and could operate out of the other plant. We have five people at the location that flooded, and everybody was involved.

We also hired truckers to come in and move out the dry fertilizer. We had five or six guys hauling, because at that time we decided it was fairly serious and figured the floods could reach us in a few days. We brought in a big loader (which was being stored in our company’s warehouse) that can move faster than ours to dump over the sides of the trucks. We had a lot of fertilizer on hand because we took advantage of a low price, so it took about three days to load it all.

We took what fertilizer we could to my other plant and took some to a warehouse we rented about 30 miles away. The warehouse was big enough to hold 800 tons. We had asked around, telling other people we needed space. I called one of our main chemical suppliers because the majority of what we had on hand happened to be their chemistry. We called for shuttles one day, and they had them in by the next day.

They sent about 20 shuttles. In our building, bulk chemicals are inside a dike. Just like the fertilizer, we had actually refilled some bulk chemical tanks because the prices were good at the time. It just happened that we were loaded up more than we would be under normal conditions. We had more than 4,000 gallons of bulk chemicals.

We probably spent two days pumping all of our bulk tanks into shuttles. We hauled them with our trucks to our other facility. One of the guys who worked here and one of his relatives who had a pickup with a gooseneck came and helped us. We took the pumps and meters and everything out of the chemical room. We put water into the tanks.

Where we could, we used that water when we reopened for mix water. For what was left, we contacted a guy and sprayed the water out on a wheat field. The tanks inside are bolted down. But in the last flood, flood waves destroyed buildings like ours because the doors were shut.

We knew that you have to open the doors to let the water in; otherwise the water destroys the sheds. We didn’t have too much packaged material, but what there was we put on pallets, shrink-wrapped, and hauled to our other location. We called the seed company and they picked up their seed. In this area, everybody works together. Any seed we had already delivered to farmers’ sheds we went and brought back. We picked up everything our customers had, even stuff that they hadn’t bought from us. We even picked up mini-bulks.

All we carry here is 32%. The tanks are bolted in a dike. We just weighed and transferred the product to our other location. We knew that if we got a flood like the one we got in 1993, the water would go over the dike because it’s about six feet tall. We pumped the tanks empty, and then pumped them full of water so they wouldn’t float away. During the last flood, the waves and winds moved the tanks around. There is always the risk of losing products and chemicals. We couldn’t take that risk.

We also have a 2,000-gallon fuel tank and a 1,000-gallon fuel tank. We pumped all of the fuel back into the fuel trucks. We didn’t actually move the fuel trucks, because if the levee broke, we figured we had a day to move the trucks based on the last flood.

We had plans to take off all of our electrical boxes, too. After the last flood, there was such a mess when they came back. I had just redone many of the chemical buildings and spent a fair amount of money there. The electric company was here every day. If the levee had broken, the first thing they would have done would have been to pull the three-phase meters. They would have killed the electricity so it would have been safe for us to start unbolting the electric boxes. We talked about moving the blender and mixer out. But that would have been fairly expensive, because we would have had to hire somebody to come down and do all of that.

This thing is about 18 years old, and the cost of moving it (as opposed to the cost of reconditioning or trading it off) was kind of a wash. We decided to leave it there. We emptied much of the office, including the files that were the most important to run our business. We know a guy who had a low trailer so we loaded it up. If the levee had broken, we would come in and get the remaining files, computers, copier, and electronics. We left all of that hooked up. Actually, I have a van and took all the seats out of it so if something were to happen, I was going to put all of the computers and equipment into my van. Here in the bottoms, most our customers were doing the same things.

After this had gone on for a couple of weeks, the river was still high. People thought there was a chance the levee was going to hold. We had corn to spray and beans to plant. Things started happening. We were running the business at the same time. We used the other location, because it’s where all of our supplies were. We also kept a guy down here, but there wasn’t much to do. He was here for our customers. We were away about three weeks. It then took us a couple weeks to get back to normal. Thankfully, the levees held and we never flooded.

When floods threaten, move equipment and materials (including fertilizers, pesticides, and fuel) to a safe location.

When floods threaten, move equipment and materials (including fertilizers, pesticides, and fuel) to a safe location.

Planning for Tomorrow’s Floods

Preparing a good plan that covers the steps you should take before, during, and after a flood can minimize injuries and reduce damage to your facility. Anticipating a flood allows you to:

• Protect you and your employees’ health and lives

• Have the proper insurance

• Make sure your business can recover from a flood

• Take the proper flood warning action steps

• Take further steps in the event of a flood

• Buy the items necessary to combat the flood during the emergency

• Protect your neighbors and other surrounding areas from contaminating their soil or property

Without a flood emergency plan, you may waste time, not be able to get needed resources, and be less likely to make the best decisions. The Extension Disaster Education Network (EDEN) provides useful information during all phases of floods, including planning.

In Indiana, EDEN is available at: www.extension.purdue.edu/eden

In other states, visit: eden.lsu.edu

We developed the following components of a good flood plan after interviewing agricultural retailers who have responded to floods threatening their facilities . When you make a plan:

• Designate a leader

• Determine the right mitigation steps

• Keep employees safe

• Make sure employees know their roles

• Update employee contact information

• Catalog what could be damaged

• Know what chemicals you have

• Update your inventory

• Identify your small packages

• Label your tanks

• Protect stored grain

• Understand the area’s flood history

• Know if you are located in a floodplain

• Get a NOAA radio

• Gather important supplies

• Communicate with local authorities

• Get permission to dig

• Get on the LEPC list

• Know who has practical advice

• Hide a spare office key

• Label all truck and equipment keys

• Get help from satellite facilities

• Seek help from customers

• Protect yourself from sewer backups

• Resolve electrical issues

• Protect vital records

Designate a Leader

Assign a leader to develop your company’s flood emergency plan. Designating a leader can ensure that your facility creates a flood plan before it is needed. The leader’s goals should be to get the right people in the right places who will do the right things at the right times.

Determine the Right Mitigation Steps

Determine the steps you need to reduce the impact of a flood. These mitigation steps can be:

• Physical actions, such as raising buildings above potential flood levels or moving out of highly flood-prone areas

• Personal or social actions, such as working to change land-use patterns to reduce flooding (by yourself and with your community)

• Financial actions, such as buying the appropriate flood insurance or building a contingency fund

All three actions can be effective and could be part of your pre-flood plan.

Keep Employees Safe

Emphasize personal safety over protecting equipment. Good plans should not be so chaotic that employees break speeding laws or operate equipment unsafely. Make sure your plan spells out ways to immediately care for employees or others who get injured. Be sure to provide first-aid training and supplies.

When planning for cleanup, ensure that employees and volunteers are aware of the risks and provide them with appropriate protective clothing such as masks, goggles, gloves, and boots. Floodwaters and the debris they leave behind are likely to be contaminated with bacteria and other hazardous materials. Talk with health and emergency management authorities about proper protective clothing. Be sure that people helping with the cleanup have updated tetanus shots.

Make Sure Employees Know Their Roles

Train employees well. A flood is but one type of emergency you should plan, prepare, and train for. Use your new or updated flood plan as part of your emergency response training. Conduct a walkthrough of the facility, use photographs, and show your step-by-step list to instruct employees. It’s important to go over written plans to keep them fresh in people’s minds.

Training is the one time to bring all employees up-to-date on what is expected of them during an emergency. Hopefully, when the crisis starts, they can put into practice what they learned in the past training programs. It is important to periodically repeat these exercises to account for employee turnover.

Update Employee Contact Information

Always be sure you can contact your employees and volunteers. A major difference between floods and most other emergencies is the need to bring to the site as many employees as possible. It takes people to sandbag, move equipment, drive forklifts, collect customer records, set up pumps, or shut down equipment in an orderly manner. There is always room for people with and without special skills in flood prevention or recovery activities. Remember that relatives, spouses, and others can help at any site when floods threaten.

Use the same updated call list that you have developed for other emergency plans. Make sure you have each employee’s home landline, cell, and pager numbers. Be sure to list the names and numbers of other company employees who work at different facilities that you will call on. Put critical contact names and information on dated, wallet-sized cards, laminate them, and give them to your employees.

Catalog What Could Be Damaged

Be sure to note the property that could be damaged in a flood. As you make your list, be sure to answer these questions:

• Is the facility’s property above the surrounding land?

• What could be affected if two or six feet of water flooded the area?

• What damage would this level of water cause to the property, buildings, inventory, and operations?

• What inventory and equipment should be saved first in an emergency?

Know What Chemicals You Have

Keep an up-to-date list of the chemicals you have on hand. The sizes of modern agricultural warehouses, the diversity of chemicals they have in inventory, and the large quantities of products stored on-site pose major challenges for retailers planning for and reacting to floods. On-site and off-site pollution caused by spilled fuels, pesticides, oils, propane, and fertilizers can become real contamination issues when products are released into floodwaters.

Even after floodwaters have receded, spilled product might require expensive remediation. This is why agricultural retailers are nearly unanimous in agreeing that their first concern when confronted by flooding is to deal with the chemical inventory first — fuel, lubricants, oils, fertilizers, and pesticides.

Update Your Inventory

Be certain your inventory is up-to-date. A complete inventory becomes particularly important when cleaning up after floodwaters have receded. If the inventory list includes the general location, it can help identify inventory that has been destroyed or is difficult to identify. A good inventory also helps with insurance negotiations. The inventory precisely tells you how many tanks and other supplies are missing.

Make sure to account for small packages and to keep them out of reach of floodwaters.

Good Records Aid Recovery

Consider this retailer’s story that demonstrates the value of keeping your inventory up to date. Everything we had was picked up, destroyed, or broken loose by the water. We had cases and cases of oil and 2.5-gallon jugs. The boxes disintegrated. The jugs were scattered everywhere. The high water took the propane and fuel tanks away. Propane tanks were really big issues, because two-thirds of them left the lot. We had sixty-two tanks out there, and we got all but one of them back. Without the good records and inventory to prove what we had, we would have had a hard time making sure we found it all after the flood.

Identify Your Small Packages

Don’t forget small packages in your flood plan. Often, our first thoughts are for 2.5-gallon plastic pesticide containers or water-soluble bags. However, don’t forget caulking-type lube products; hydraulic oils; and quart cans of oil, transmission fluids, and other products.

One option during a flood is to place these small containers on high, secured, storage racks in the warehouse. In some cases, warehouses may be four to five feet higher than the attached chemical buildings, allowing these pallets to be stored on higher ground. Pallets of these smaller products also can be trucked off-site.

Label Your Tanks

Label all tanks with your name and location. In a recent flood, an agricultural retailer lost 35 fuel tanks that were washed downstream. The dealer was able to find all but one of his tanks, because each had a sticker with the company’s name and phone number. Sticker all tanks, large and small, at initial installation. You may even want to label 55-gallon drums.

Labeling tanks with your name and location makes them easier to recover if they get washed away by a flood.

Wet Grain Can Damage Bins

The following story describes why it’s important to dike around grain bins, or at least, to closely inspect them if it floods around the base:

We’ve got two 90,000-bushel-grain bins sitting down lower than the others. When the levee broke, the water reached four feet deep around them. The corn absorbed water and swelled.

One of the bins had roughly 80,000 bushels in it. The other had about 50,000 bushels. When the corn in the one with fewer bushels swelled, it lifted the corn upward instead of pushing outward. But the one with 80,000 bushels couldn’t lift the corn, because it was so heavy. It swelled and pushed out the sides. We discovered it early Sunday morning, around 7 o’clock. Corn was dribbling out the side of the bin.

Protect stored grain. Even a little water can make grain swell enough to rupture storage bins.

When we got closer, we could see that the swollen corn split the bin six inches. By 11 o’clock that day, the split was four rings up, and then the corn had started pushing out the split. We had maybe about half a foot of water — low enough so that we could get to the bins. We were concerned about the bin taking out electric poles. The electricity supply for the elevator and main office was no more than 10 feet from the side of the leaking bin.

We were concerned that if the bin gave way, it could take out those poles with their transformers. We called the energy company and had them disconnect the lines and kill all the power. We called a contractor who works on grain bins. They drilled two, eight-inch holes on all sides of the bins across from one another. They inserted 21-foot augers with motors in each hole and started unloading the bins. We saved a lot of the corn.

Protect Stored Grain

In the event of a flood, it’s important to protect any grain stored on your site. Floodwaters not only spoil the grain by getting it wet, the soaked grain also can expand, damaging or destroying storage bins. Build dikes around grain bins or closely inspect them around their bases if flooding occurs.

Building dikes around grain bins can help to keep stored grain dry.

Understand the Area’s Flood History

Know the flood history of your facility. When you live and work in an area long enough, you can frequently predict how much rain it takes to cause flooding, what areas along a creek flood first, and where water goes as it spills over the banks. If you don’t know, ask current and retired employees, growers, or neighbors if they remember the property ever flooding. Everybody remembers the “big” floods and how deep the water got.

Know if You Are Located in a Floodplain

Find out if your facility is located in a floodplain. Areas along rivers and creeks prone to flooding are called floodplains. The Federal Emergency Management Agency (FEMA) creates flood maps using floodplain delineations, flooding frequency, historical evidence, and scientific studies. FEMA uses these maps to price flood insurance policies. Flood maps are available at: www.fema.gov

Flood maps designate areas that are at a high, moderate, or low risk of flooding. The zones delineate flood boundaries:

• High Risk (Zone A) areas are expected to flood once every 100 years

• Moderate Risk (Zone B) areas are expected to flood once every 100 to 500 years

• Low Risk (Zone C) areas are expected to flood once every 500 years or more

Look at the flood map for your area to see in what zone your business is located. Determine the approximate elevation of your facility’s buildings by placing a GPS receiver at ground level. You can compare that elevation with FEMA zone elevations on the flood map. Doing this allows you to estimate how many feet above or below the flood map elevations your buildings are.

If you are not in a Zone A, don’t automatically assume you are completely safe. Local flash floods can still occur. In fact, 25 percent of all paid insurance claims come from damaged areas outside of Zone A flood zones.

To be sure, facilities in Zones B or C are at less risk than facilities in Zone A. However, as flash floods have shown, a large ditch near your facility might be the source of major flooding on your property. If the creek is running full, then there is nowhere for the water in the ditch to go. In fact, creek water will actually run back into the ditch 23 Building dikes around grain bins can help to keep stored grain dry. and force water to back out onto surrounding land. Flood maps are just one of many information sources that will help define your risk of flooding at the facility.

Flash floods also have shown that large amounts of rainfall focused on one area can cause a wall of water to rush toward lower ground. This can flood areas no one anticipated. In 2008, multiple storms dumped 10 or more inches of rain in areas not designated as floodplains. Thousands of people who lived and worked in those areas never thought it would flood.

Large ditches near your facility are enough to cause flooding. If high enough, floodwaters can even run back into the drainage pipes shown in the photos above.

Ultimately, 89 percent of the people who experienced flood damage from these storms lacked flood insurance. You may not be able to do much about unexpected floods, but you can carry flood insurance and build smart by raising some critical equipment a few feet off the ground to avoid flood damage. Don’t let someone tell you that you can’t buy flood insurance. No matter where your business is located, you should be able to buy some protection. If you have flood insurance, find out how much coverage you have before the flood. A number of standard insurers provide some flood coverage in their package property policies. These usually range from $50,000 to $100,000. This may be adequate, but you need to be familiar with the coverage to avoid surprises and a false sense of security.

Get a NOAA Radio

Get and use a radio from the National Oceanic and Atmospheric Administration (NOAA). A NOAA radio is a special device that should be plugged in at the homes of your facility’s first responders. The radio gives advanced warnings for floods and storms. It is silent except when a flood or tornado warning sets off an alarm. NOAA radios are especially useful for receiving warnings about severe weather that might lead to flash flooding. Remember, each area of the country has its own radio setting.

A NOAA radio gives advanced warnings for floods and storms.

Gather Important Supplies

Compile a list of contractors who can help with emergency supplies and their 24-hour phone numbers. During the emergency, you will be competing for resources. Without working out a plan ahead of time, the items you need may not be available when you need them. Specifically, know where you can rent or buy:

• Large-volume “trash” pumps

• Large-capacity generators to run lights and pumps

• Sand and sandbags

• Clear or black plastic sheeting

• Tractor-trailers

• Warehouse space

• Rain gear to keep employees dry

• Garden hoses (about 600 feet) and nozzles for cleaning, flushing, and washing

• Flat shovels for removing muck

Communicate with Local Authorities

Request that county and city authorities, street departments, and highway garages to walk through your facility before a flood. Make sure authorities understand that you are concerned about the potential release of chemicals into floodwaters.

Your Local Emergency Planning Committee (LEPC) needs to understand that your facility is part of the community’s critical infrastructure that needs protection during an emergency. Make it clear that you will reimburse them for any products they return to your site. The message is that they can protect the community during a flood by bringing sand or loaning heavy-duty pumps.

Cooperation allows all parties to work together . Consider that all floods are costly. Flood damage to roads and buildings can cost towns and counties millions of dollars . When a flood strikes, community response and recovery assets may be scarce . Negotiating the use of and the cost of those assets before flooding may benefit your facility.

Another critical issue in preparing for unexpected floods is to look at land-use planning around your facility. Pay attention to your surroundings and ask yourself some questions . Has development taken over large areas around your facility? Is your facility between a development on higher ground and a ditch or river at lower ground?

If you answer yes to these questions, you might be prone to flooding that never occurred in your area before . At that point, you might take steps to work with the community to develop water holding areas, levees, or better drainage . You could also work with local authorities to keep debris from accumulating at bridges and clearing debris from streams and ditches .

It’s also important to consider levees and drainage . For levees, it is not a matter of if they will fail, but of when they will fail . Almost all levees can fail at a certain level of flooding . Either water will wash over them or erode them to the point of breaking down and washing away. Levees can help, but they are not the first choice for flood control . In fact, they may be the last resort because levees pass the problem downstream to others where lives and property can be lost .

Ditches and improved drainage can help, but these practices also pass the problem downstream . The wisest choice in flood preparation is proper planning up- and downstream . Overall, finding proper ways to retain water so it is allowed to drain away slowly is important . This takes community planning and action . Work with your community to develop retention basins, levees, or better drainage .

Cooperating Pays Off

The following testimonial shows that officials were convinced that it was in the community’s best interest to safeguard one retailer’s facility: We kept in touch throughout the day with the fire department and the LEPC. The LEPC contacted the county and asked them to get sand and sandbags to our facility after realizing that we were in jeopardy of having floodwaters come into our facility. When it was dropped off at our facility, the truck operator said the load of sand was free, but that we would have to purchase the sandbags.

Get Permission to Dig

Open ground lies around many agricultural facilities. The soil from those areas could be useful to fill sandbags or to build a temporary dike to protect buildings. But you should always receive written permission from the landowner before a flood that will allow you to use the field if it ever becomes necessary. Before any flooding, negotiate compensation and identify any buried utilities or tile in the area.

Get on the LEPC List

Place your name on the LEPC e-mail emergency notification list. The list keeps you informed and up-to-date on where flooding is anticipated or already taking place. Ask LEPC officials for their cell phone numbers. Be diligent in asking, because you don’t want to be buried in voicemail in an emergency. Make sure that you also are working with whoever controls and maintains the levees that help protect your property. Having a better idea about whether or not the levee will hold back floodwaters is critical for making the right decisions at the right time.

Know Who Has Practical Advice

In every fertilizer, chemical, or fuel plant there are personnel who are relied upon to operate the facility. These individuals understand the everyday operations — from when and how the product is brought on-site, off-loaded, stored, and then dispensed — and provide the framework for developing a realistic and practical flood response plan. Ask each of these individuals what steps they would take and what resources they think need to be protected if the property is under a flood warning. They should be able to readily list a number of steps they would take to protect the interest of the facility. Have each person review shutdown and reaction procedures. Ask them to prioritize the list so that anyone working in the area will know what to do first when a flood threatens.

The list of procedures you compile from your key personnel across the plant’s operations will form the blueprint of your flood emergency plan. Part of your flood-training program should be to take pictures of people doing the listed procedures. Show the photos to employees and discuss why they are important. This process will help those less familiar with the operation successfully put the plan in motion when the person responsible for that work is not available.

Hide a Spare Office Key

Knowing where the key to the main building is located is critical when it is time to react to flooding. But if you tell everyone where the hidden key is, it’s no longer hidden. Part of your plan should be to identify and notify personnel who need to know where the keys to each building are located. Depending on who arrives first, knowing where the keys to the important buildings are hidden allows for an earlier response as others are called to the facility. And when you leave a facility before a flood, be sure to leave the doors to all buildings open. Although this may sound counterintuitive to business owners, leaving the doors open can help prevent floodwaters from causing structural damage.

Labeling Keys Saves Time and Property

Consider the story of one ag retailer who made sure his keys and equipment were properly labeled before a flood:

We can handle a 2- or 3-inch rain. If we hear there is a flood warning, or we hear there is a 2- to 3-inch rain coming, we touch base with everybody and put everybody on alert. We were on our way down to the plant when we heard we were getting heavy rains. If the plant starts to fill up with water, we go down and turn one valve and force the water into the city sewers. We have three pumps in the ground and they help to keep water levels down.

The pumps can handle a 3- to 4-inch rain. When I came down here Saturday I knew exactly where to find the keys to the trucks. All the keys are brought in every night and locked in the office. All of the main people have keys to get into that office. Each key has a number and a name. For instance, our propane truck is a Kenworth and it’s number 47. We tried to get the equipment out Saturday night. We moved our propane trucks, three fuel trucks, and a couple of service trucks. We were in a pretty good size loader with an extended bucket.

There were three of us in the bucket taking us back to move more equipment once we dropped off the others. By that time there were 18 inches of water down there. When the levee next to the facility broke, we had just enough time to get back into the bucket to save ourselves. The facility was totally submerged with eight to nine feet of water within 15 minutes. We would have saved all of the equipment, but the levee right next to our facility broke. That was the end of what we could do.

Label All Truck and Equipment Keys

When floods threaten, fuel delivery trucks, tender trucks, fertilizer spreaders, and pesticide application equipment need to be moved off-site to higher elevations. An often-overlooked detail is access to vehicle keys. With some floods, there is little time to react. When minutes count, moving vehicles quickly without searching for keys will lessen the potential for flood damage. Label keys with the names of the equipment and identification numbers that correspond to the trucks or equipment. Someone will need to shuttle drivers back to the facility once they have moved the equipment to safer ground.

Fuel trucks can get trapped by floodwaters

Fuel trucks can get trapped by floodwaters Get Help from Satellite Facilities

Consider what equipment, personnel, and storage space satellite branches can provide. Most facilities today are no longer stand-alone operations. They are part of larger organizations with multiple satellite branches. Different branches should consider coordinating their plans, particularly for when they may all be under some degree of risk.

Seek Help from Customers

Consider buying lunch once a year for growers or other people who can help you or have equipment you might need in a flood. If they are willing, arrange for specific help or equipment that you might need. Growers have backhoes, front-end loaders, and other equipment that you might need in a flood emergency. You can even make use of heavy-duty pickup trucks and trailers that can be quickly loaded and hauled off-site. The good news is that growers already know how to operate their own equipment.

Include willing growers and others in your emergency management plan. Of course, be clear that their operations come first and build that into your expectations. Make sure you talk with your insurance company about any liability issues regarding these volunteers being injured or damaging equipment while helping you.

Protect Yourself from Sewer Backups

Be prepared for sewer backups. When rivers rise, pipes carrying treated sewage back up. In fact, river or creek water can flow back into sewer pipes, causing the contents of the pipes to flow backward into toilets and out into buildings. One option for avoiding backups is to install shut-off valves that prevent sewage and water from back flowing onto the property. Before installing a shut-off valve, always obtain the appropriate permission and permits to retrofit the plumbing.

Resolve Electrical Issues

Deal with as many electrical equipment issues as possible before any flooding. Some of the more expensive items to repair and replace are three-phase boxes. It’s cheaper to hire an electrician to move each converter up eight feet than let floodwaters and the debris they carry wash inside of them.

Protect Vital Records

Remove vital records, including computer hard drives, before floodwaters threaten your facility. Lost customer and supplier records can make it very difficult to get your business running again after a flood.

Always hire a professional electrician to work on your electrical equipment before floodwaters threaten.

Always hire a professional electrician to work on your electrical equipment before floodwaters threaten.

Putting Your Plan in Operation

Understanding the differences between a flood watch and flood warning is essential for reacting to impending floods.

Authorities issue a flood watch after the first signs that water in the creeks is rising or the potential for accumulation in low-lying areas is possible. When a flood watch is issued, pay close attention to local weather broadcasts. Know if the watch turns into a warning.

A flood warning is more serious. Officials issue a flood warning when flooding is already happening or will soon be occurring. When a flood warning is issued, call your local emergency responder contacts to ask where flooding is anticipated. A flood warning that includes your area means you need to think seriously about getting to your facility and implementing your flood response plan. With or without a flood warning, you can get a jump on issues by watching stream flow levels around you and upriver from you. A massive rainfall upriver today may be your flood tomorrow.

The United States Geological Survey (USGS) provides extremely useful daily stream flow maps at: water.usgs.gov

When a flood threatens, there are general steps ag retailers should take:

• Activate your call list

• Turn on your NOAA radio

• Think of people’s safety first

• Have an exit strategy

• Call suppliers to remove their products

• Move rolling stock to higher ground

• Move all outdoor mini-bulk and 55-gallon containers indoors or off-site

• Move small packaging to higher ground

• Make sure tank lids are secured

• Sweep and clean up contaminants within containment areas

• Place pumps indoors and within outdoor containment areas

• Start barricading openings around doors before lower ground floods

• Dike around grain bins

• Empty fuel tanks into fuel trucks

• Empty liquid fertilizer tanks and move product off-site

• Empty bulk pesticide containment tanks and move product off-site

• Empty dry fertilizer from bins and move product off-site

• Remove all pumps and meters

• Fill liquid fertilizer and bulk pesticide tanks with water so they won’t float away

• Retrieve important records (customer invoices, farm maps, etc.)

• Remove computer hard drives off-site

• Place computer equipment and files on top of desks or move them off-site

• Open all doors to avoid structural damage

• Turn off all electricity

• Remove as much electrical equipment as possible

• Fuel and turn on generators to activate pumps

• Account for everyone when evacuating the site

• Always think about people first

Before leaving a facility, make sure to open doors to prevent structural damage that floodwaters can cause.

Before leaving a facility, make sure to open doors to prevent structural damage that floodwaters can cause.  You can also build temporary dikes around buildings to help protect them.

You can also build temporary dikes around buildings to help protect them. If All Else Fails, Evacuate

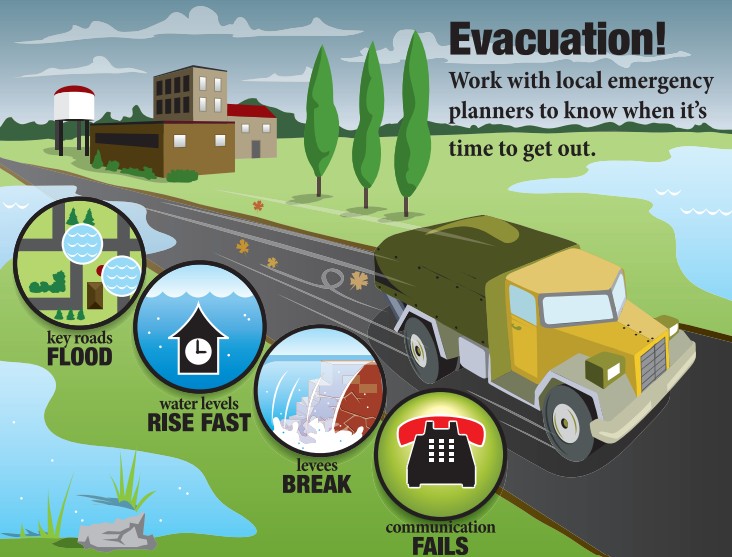

Protecting lives is number one. In flash floods or when waters are rapidly rising, the best and only plan may be to evacuate people safely. Local emergency managers and planners must be involved in these types of plans, especially if evacuation routes go through flood-prone areas and jeopardize evacuees. Work with local emergency managers to develop guidelines to determine when it’s time to move people out.

Develop plans for rescuing workers who may be trapped in the facility. People often become trapped in their homes or other buildings because they keep going to higher floors to avoid floodwaters. Make sure employees know how to stay safe. Provide communication equipment that will work when power is out, so employees can call for help if they become trapped.

Don’t allow employees to risk their lives rushing to the rescue. Constantly remind employees that safety is first. During flash floods, once-gentle creeks can sweep people away. The force of water is very powerful and can move tons of soil. Don’t ever try to drive through floodwaters. Only a foot of water can float most vehicles and two feet of moving water can sweep a truck off the road.

In a recent flood, an employee drove across a flooded road to take the shortest route to work. Water less than six inches deep swept his pickup off the road and into a raging creek. His body was found under a bridge after the floodwaters receded. No equipment is worth a life.

Avoid the situation that one policeman found himself in:

We tried to rescue a person who was swept into a fast flowing, flooded creek. We formed a human rescue line by grabbing hands, but we were still a few feet too short to reach him as he went by. Who would have thought, in our flat little town, that a flotation device on a rope would have saved a life?

Flood Recovery

While floods make immediate headlines, the real work comes after, when communities turn their attention to cleaning up. In many ways, the risks to people during the recovery may be greater than the flood itself. Take extreme care when reentering areas that were flooded.

One danger after any flood is the drive back to your facility. Never return to your facility until authorities give approval. Flowing water may have washed out parts of roads or weakened them.

Other flood recovery considerations include:

• Practice safe sanitation

• Get tetanus shots

• Keep the power off

• Don’t overload septic systems

• Supply your own water

• Retrieve your tanks

• Check for spills

• Pump out water safely, slowly

First Steps to Flood Recovery

(Purdue Extension publication ACS-101) provides more information about what to do after a flood. It is available at: www.extension.purdue.edu/floodpub Multiple copies may be ordered from the Purdue Extension Education Store: www.extension.purdue.edu/store

The publication is a joint effort of Purdue Extension and the Extension Disaster Education Network.

Practice Safe Sanitation

Assume that all standing water inside buildings or in low-lying areas is contaminated by raw sewage, bacteria, and chemicals. There is no telling what the floodwaters picked up prior to reaching your facility. Sanitation is extremely critical. Wear rubber shoes or hip boots and gloves when doing flood recovery work. Keep floodwater from your skin, mouth, and eyes. Provide hand cleaners for sanitation where clean, running water might not be available. Insist that employees use the cleaners before eating or smoking.

Get Tetanus Shots

Employees working on the cleanup effort should be up-to-date on their tetanus shots. A good rule of thumb: if you can’t remember when received your last tetanus shot, you probably need one.

Keep the Power Off

Keep power off until an electrician reviews your situation.

Electrical equipment such as motors will be full of floodwater, trash, and mud. Turning on the power prematurely can damage motors and other equipment and result in expensive repairs. A general rule of thumb: if you are not a certified electrician, you’re not qualified to make the call. Depending on the depth of the flood, electricians may need to remove, clean, and replace all connectors, electric motors, light switches, lights, and other items that were under water.

Don’t Overload Septic Systems

Consider bringing in portable toilets if your facility has a septic system. After a flood, the water table will be too high for septic systems to work properly.

Supply Your Own Water

You will need to supply your own drinking water. Never assume that drinking water from the city or a well is safe. Just because the water looks crystal clear doesn’t mean it is safe to drink.

Retrieve Your Tanks

Retrieve any tanks that were washed away as quickly as possible. This not only gets you back in business sooner, it is the good-neighbor thing to do and will keep you in good standing with your community.

Check for Spills

Review indoor and outdoor areas that are diked and check for ruptured tanks or crushed packages.

One retailer explains why this practice is important: We lost a bulk oil tank that floated in the indoor chemical dike. It was a 3,000-gallon tank and held about 1,600 gallons of 32-weight hydraulic oil, which is a light material. The tank turned over inside the building, although three 4,500-gallon tanks didn’t move. The reason the tank with the hydraulic oil floated is it didn’t have enough product inside to hold it down. We probably lost between 100 and 200 gallons of oil inside the dike. Some of the 2.5-gallon jugs floated up to the ceiling. When the water went down they busted when the 55-gallon drums landed on them.

If there is no apparent pesticide, oil, or fertilizer spill, pump water inside dikes, back out over the dike walls. If there is evidence of a spill, pump the material into a poly tank, clean the concrete, and place the cleaning water into the same poly tank. Work with authorities to determine the appropriate place to dispose of contaminated water.

Pump Out Water Safely, Slowly

Quickly pumping water out of a building will not restore the items or prevent damage, so be sure to pump water out safely and correctly. Removing all the water at once may cause serious structural damage to buildings by causing the floors and foundation to collapse.

Pumping water from within buildings is an art and a science. Unfortunately, items damaged by floodwaters are more than likely destroyed. Don’t forget that gas-powered sump pumps produce carbon monoxide, so be sure all areas where indoor pumps are running are well ventilated.

Drain water slowly to equalize pressure on both sides of the walls. Once the flood has receded, water still in the ground outside may be pushing hard against basement walls. The water in your basement is pushing back. If you drain your basement faster than the water in the ground is draining, the outside pressure will be greater than the inside pressure and may cause the foundation, basement walls, or floor to crack or rupture.

When removing water from a basement, consider these additional steps:

• Wait to pump until floodwaters are no longer covering the ground outside.

• Pump water away from the structure to avoid back pressure. If you just put the hose outside a door or window, the water can make its way back into the building and add pressure to the basement wall.

• Pump out one foot of water, mark the water level, wait overnight, and then check the water level the next day. If the level went back up and covered your mark, it is still too early to drain your basement. If that’s the case, wait 24 hours and then pump the water down one foot again and check the level the next day. When the water in the basement stops returning to the mark, pump out two to three feet and wait overnight. Continue pumping two or three feet at a time, and then waiting overnight until all water is out of the basement.

Floods can easily carry tanks away. Make sure to label your tanks so you can retrieve them after floodwaters recede.

Floods can easily carry tanks away. Make sure to label your tanks so you can retrieve them after floodwaters recede.  Don’t return to a facility until officials give you the all clear. Floods can weaken or wash away roads.

Don’t return to a facility until officials give you the all clear. Floods can weaken or wash away roads.

Rebuilding Permits

After an area is flooded, local authorities may restrict or limit rebuilding. In some cases, authorities may consider a buy-out plan to avoid future rebuilding in an area. A general rule of thumb is that property that has (1) flooded three times, or (2) has experienced more than 50 percent damage in one flood or multiple floods may be prevented from rebuilding.

Whether or not authorities restrict rebuilding, you should consider your options before you rebuild. Also, consider the facility itself. Disaster victims often want to rebuild just the way it was before as a way to get life back to normal. But after a flood may be the best time to change damaged buildings or reconsider site layout to better suit your future needs — and flood proofing is one of those needs.

Conclusion

We’ve all seen creek levels rise and water pond around buildings after a steady, two-hour rain. Farmers delay planting productive “bottom land” until late spring to miss heavy spring rains. People who live along rivers expect flooding, so they elevate their homes many feet above known flood levels.

Experience teaches us to take floods seriously in these areas and to plan for the occasional flood. Floods are similar to spills, fires, tornadoes, or any other emergency. But, floods often take longer to recover from, because of hidden damages, and often, lack of insurance. Floods are a real risk that ag retailers need to consider and plan for as part of doing business. While we can’t necessarily predict who the next flood will affect, we can think about contingency plans to deal with floods.

Each flood has its own unique footprint over an area and the lives of its people. How deep the water will be depends on the amount of water falling in that area, the terrain, the facility’s elevation, how long it rains, how deep the river channel is, the width of the flood plain, the saturation level of rivers and creeks, and the ratio of impervious surfaces to soil surfaces.

While each flood is different, plant managers know how their facilities operate, and where chemicals are located in the warehouse. They know how water sheds off the property, how small rains affect the facility, and what roads are susceptible to flooding.

Relying on Lady Luck to get through a flood (or any emergency) is a sure plan for disaster. Those who plan and give some thought about what to do in case of a flood usually can get back in business more quickly than those who did not put a plan in place. How much you can accomplish will depend on how soon you start the process and how quickly the water is rising. The facts are clear: advanced-planning limits the damage caused by rising water.

The facts are clear: advanced-planning limits the damage caused by rising water.

Thanks to Steve and Paula Adduci for the original illustrations used in this publication, and to Dawn Minns for graphic design. Thanks to Farm Journal for the flooded farm photo on page 7. Thanks also to those who offered constructive comments during the development of this publication:

James Belt, Ohio Department of Agriculture

Barry Brennan, University of Hawaii

Dan Childs, Heritage Seeds

William Hoffman, United States Department of Agriculture

Steve Leer, Purdue Agricultural Communication

Dennis Nowaskie, Purdue University

Steve Pritchard, Daseke Insurance

Charlie Sayler, Nationwide Agribusiness Insurance Company

Work on this publication was partially supported with outreach funding from the Indiana Water Resources Research Center at Purdue University.

The content of this publication is for educational purposes only. The authors’ views have not been approved by any governmental agency or business. This publication is distributed with the understanding that the authors are not engaged in rendering legal or other professional advice, and that the information contained herein should not be regarded or relied upon as a substitute for professional or legal consultation. The use of information contained herein, by any person, constitutes an agreement to hold the authors harmless for any liability, claims, damages, or expenses incurred as a result of reference to or reliance on the information provided.