Keep The Trailer Connected to The Truck

RESOURCES - PUBLICATIONS

Keep The Trailer Connected to The Truck : Understanding the “Hitch” System

Fred Whitford, Coordinator, Purdue Pesticide Programs

Steve Hawkins, Assistant Director, Purdue Agricultural Centers

Daniel Ess, Extension Agricultural Engineer, Agricultural and Biological Engineering

Phillip Walker, Superintendent, Northeast Purdue Ag Center

Jacob Meganck, Territory Manager, United Phosphorus, Inc.

John Obermeyer, Integrated Pest Management Specialist, Purdue University

Kevin Leigh Smith, Editor, Purdue Agricultural Communication

Content

The Story of a Serious Accident . 4

Hitch Component Ratings Matter . 8

Understand Your Truck’s Limits . 10

Select the Right Hitch Mount . 12

Choose the Proper Frame-mounted Hitch . 18

Know the Hitch Assembly’s Components . 20

Pay Attention to Trailer Ratings . 38

Safety Chains Are Important Backups . 42

Emergency Trailer Brakes Are the Last Backup System . 58

Watch Your Load Distribution and Tongue Weight . 66

Use Reflective Tape . 68

Drive Safely When Transporting Trailers . 70

Test Your Knowledge . 76

Conclusion: The Driver Is Responsible . 80

Acknowledgments . 82

Disclaimer . 83

The Story of a Serious Accident

If you’ve never thought about your trailer hitch system, consider the following scenario. “After a long and stressful day at work, I was ready to go home.

“The drive north on the interstate that evening was uneventful and traffic moved along quickly. But that changed when I saw vehicles slow down ahead and merge into the left lane. Within moments of entering the bottleneck, I saw emergency personnel removing an injured person from a van that had been hit and demolished by a trailer that separated from a pickup. It would take a miracle for anyone to survive such a horrible accident, I thought.

“I exited a mile north of the wreck and headed to the shop to detach my trailer. I forgot about the accident until I picked up the paper the next morning. This story described how the trailer was loaded with application equipment, fuel, and pesticides.

“According to the newspaper, an anonymous official at the scene said the preliminary on-site investigation found that (1) the trailer was equipped with undersized safety chains that broke when the trailer separated from the truck, (2) the trailer was carrying a heavier load than the ball hitch was rated to pull, and (3) the emergency trailer brake cable was improperly attached to the safety chain. The ball hitch sheared, the chains gave way, and the trailer struck the van, instantly killing the driver and seriously injuring two passengers.

“I felt bad for the people in the van and wondered why the driver of the pickup had been so careless. I put those thoughts aside and went about the business of attaching my own trailer to my truck, and then loaded the trailer with equipment and supplies.

“It turns out that, without thinking about it, I repeated many of the unsafe practices I had just read about in the paper. Such accidents only happen to others — or so we tell ourselves.” This account underscores an important point: just because a hitch comes with a truck that doesn’t mean the hitch can pull anything behind it. While it’s easy to load a trailer, attach the trailer to a truck, or hook a safety chain, doing them correctly is an entirely different matter.

This publication identifies the critical factors that keep trailers properly attached to trucks. Its goal is to help you understand how those factors work together and reduce your chances of losing a trailer on a busy highway. This publication isn’t the final word on trailer safety. Always consult your state and local regulations over trailer safety and requirements.

Avoid Trailer Hitch Accidents

Accidents involving detached trailers happen every day across the country. Many end tragically. Some trailer accidents may be unavoidable, as when road debris blows a tire or when a weld on part of the trailer fails. Such accidents can happen even to drivers who are serious about highway safety and conscious about what they pull down the road.

But many trailer accidents are avoidable. Human error can be involved when drivers do not understand how to safely attach a trailer to a truck, or how to load the trailer so that the truck will steer properly. Unfortunately, serious and avoidable accidents can result from drivers who fail to practice what they’ve been taught. If negligent, the driver pulling a trailer can be civilly and criminally responsible. And by default, the farm or business owner may also be brought into a lawsuit and future litigation.

More important, it doesn’t really matter whether a driver was uninformed, careless, or negligent. When people are hurt or killed in trailer accidents, excuses can’t replace lives or take away pain and suffering. Using trailers with care isn’t just about shielding yourself from liability, it’s about being safe for everybody on the road.

Runaway trailers can seriously damage other vehicles and, more importantly, injure or kill others.

Runaway trailers can seriously damage other vehicles and, more importantly, injure or kill others.

A truck was traveling 55 miles per hour when it ran a stop sign and slammed into this truck and trailer.

A truck was traveling 55 miles per hour when it ran a stop sign and slammed into this truck and trailer.  There was little the company that owns the truck and trailer could do to prevent this accident.

There was little the company that owns the truck and trailer could do to prevent this accident.  This truck is pulling a trailer without safety chains.

This truck is pulling a trailer without safety chains.  This truck is pulling a trailer without safety chains, plus the lights and brakes are disconnected.

This truck is pulling a trailer without safety chains, plus the lights and brakes are disconnected.  If this trailer were involved in an accident, a lawyer could easily argue that the owner was negligent by putting tires like these on the road.If this trailer were involved in an accident, a lawyer could easily argue that the owner was negligent by putting tires like these on the road.

If this trailer were involved in an accident, a lawyer could easily argue that the owner was negligent by putting tires like these on the road.If this trailer were involved in an accident, a lawyer could easily argue that the owner was negligent by putting tires like these on the road.  Learn the few basic concepts for attaching trailers to trucks to protect the interests of your company, your drivers, and the public.

Learn the few basic concepts for attaching trailers to trucks to protect the interests of your company, your drivers, and the public. Hitch Component Ratings Matter

In practice, a truck’s tow rating matters much less than the maximum towing capacity of the entire hitch assembly, which consists of the receiver, insert, ball, and the truck itself. The entire hitch assembly is only as strong as its weakest component. The weight of a trailer and its load should never exceed the rating of any hitch assembly component.

If a loaded trailer’s weight exceeds what the lowest rated component of the hitch assembly or truck can bear, then that trailer cannot safely be used with that towing truck. The only thing you can do if a trailer’s weight exceeds the towing capacity of the truck is to remove part of the load. However, sometimes you can upgrade the insert or ball hitch to tow more — just as long as the load does not exceed the truck’s towing capacity.

Hitch ratings beyond the truck

Consider buying a hitch and insert that exceeds your truck’s towing capacity. This can reduce the chances that one of the hitch components will malfunction. If the hitch is overbuilt beyond what the truck can tow, you can worry less worry about hitch failures.

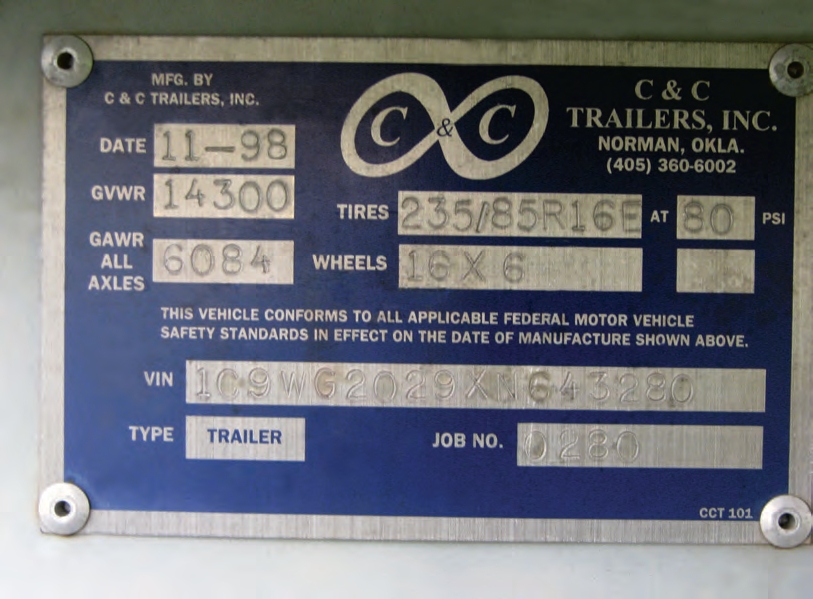

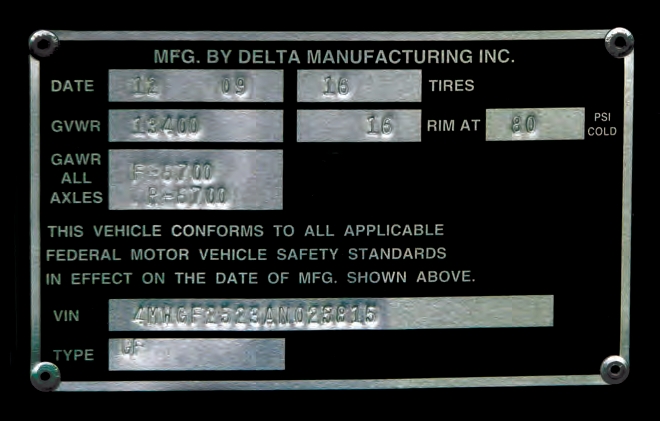

This trailer has a gross vehicle weight rating of 14,300 pounds. The total GVWR includes the maximum weight of the trailer and load it can carry.

This trailer has a gross vehicle weight rating of 14,300 pounds. The total GVWR includes the maximum weight of the trailer and load it can carry. Understand Your Truck ’s Limits

Like many, you might believe that as a truck’s size increases from half-ton, to three-quarter-ton, to one-ton, that its towing capability automatically increases. That’s not necessarily true. Descriptions like “half-ton” have limited meaning. Each truck has a specific tow rating, which depends on its design.

Trucks with larger tow ratings usually have high-performance features such as heavy-duty engines, springs, transmissions, frames, U-joints, rear axles, and brakes. These features have nothing to do with whether the truck is called a three-quarter-ton or half-ton.

Pay attention to the tow rating in a truck’s manual and don’t exceed that rating. When a truck tows more weight than it is designed to pull, drivers can lose control of the truck and trailer. For example, if a car suddenly stops in front of a truck pulling too much weight, the truck’s driver may slam on his brakes, but the trailer’s momentum can push the truck forward and into the stopped car because the loaded trailer exceeds the truck’s brake ratings.

Before towing, you also need to consider how much weight the truck can carry and tow at the same time. The tag located in the truck’s doorjamb or behind its seat provides its gross combination weight rating (GCWR) — the GCWR is also provided in the truck manual. A truck’s GCWR is the maximum weight it can haul and pull. GCWR includes the weight of the truck, the trailer it’s towing, and the total cargo carried in the truck and on the trailer. Exceeding a truck’s GCWR can have consequences similar to towing more than what the truck is designed to pull.

You also need to consider that you can shorten a truck’s useful life if it tows loads beyond its limitations. When you purchase a new or used truck, make sure you choose one that has a rating that exceeds the normal weights you typically will carry or tow.

For example, you might find a truck with a maximum towing rating of 9,150 pounds. That doesn’t mean you should haul or tow the maximum weight every day — don’t operate your truck on the extreme end of what it was designed to do. Instead, select a truck with a higher maximum towing rating so you are not always maximizing the load capacity. This ensures the truck has a longer service life and makes driving it safer.

A truck’s towing capacity isn’t necessarily higher because it is called a “half-ton” or “three-quarter-ton.” Always refer to your truck’s owner manual for tow ratings.

Select the Right Hitch Mount

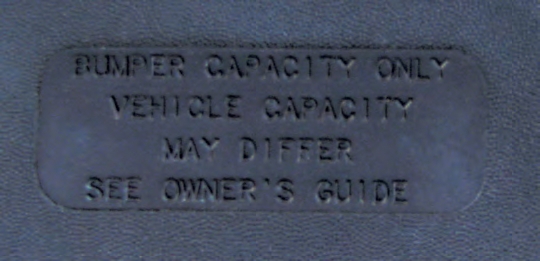

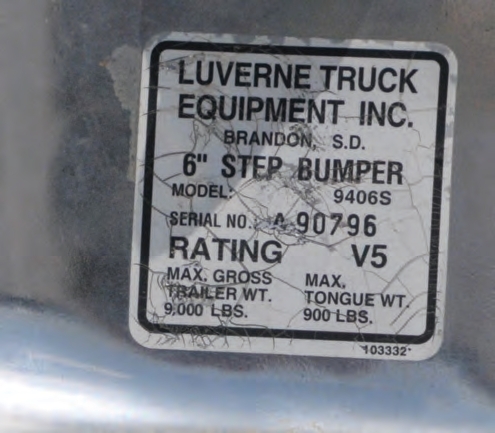

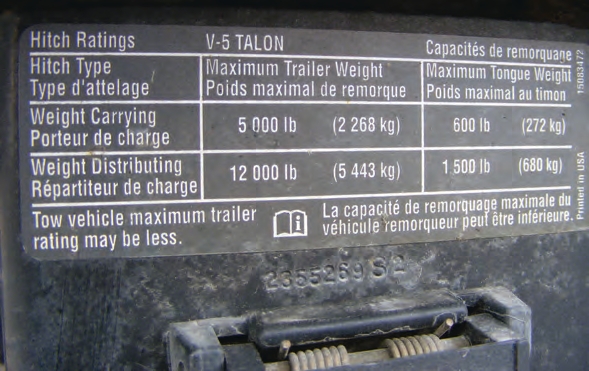

You can attach a hitch assembly to a truck’s bumper or frame. Most rear bumpers are made from stamped sheet metal and are attached to trucks by four to eight bolts. For that reason, a bumper hitch can safely tow only a limited weight. Each bumper is normally stamped with the amount it can safely tow. Typically, a mini-truck’s bumper can tow less weight than a full-size truck bumper. However, it’s important to remember that a bumper-mounted hitch will always tow significantly less weight than a properly designed frame-mounted hitch can.

Some trucks may have customized bumpers that have been added on post-purchase. Some bumpers may be designed to tow more weight, but you should never tow more than the truck’s GCWR, regardless of the bumper’s rating.

When a truck pulls a trailer that exceeds the bumper’s rating, the bumper can bend, twist, or even pull off. Trailers that are too heavy can pull bumpers off accelerating trucks. Overloaded trailers can also push trucks forward when drivers quickly brake.

Growers and commercial industries should not use bumper hitches to tow their equipment unless their trucks have customized, reinforced bumpers. When a truck has both a bumper hitch and a frame-mounted hitch, you should always use the hitch attached to the frame. A framemounted hitch allows you to carry larger loads, because it’s stronger and it reduces the risk of the trailer detaching from the truck.

These ball hitches are mounted directly to the bumpers. Notice the bumper in the top left photo can support a load of 2,000 pounds, the bottom left one 3,500 pounds, and the above photo 5,000 pounds. These values are independent of what the truck can tow bottom).

These ball hitches are mounted directly to the bumpers. Notice the bumper in the top left photo can support a load of 2,000 pounds, the bottom left one 3,500 pounds, and the above photo 5,000 pounds. These values are independent of what the truck can tow bottom).

Customized bumpers are often designed to tow more weight than bumpers installed by truck manufacturers

Customized bumpers are often designed to tow more weight than bumpers installed by truck manufacturers  These bumpers have been twisted from towing excess weight.

These bumpers have been twisted from towing excess weight.

Pulling a trailer that is too heavy can pull the bumper and ball back toward the trailer.

Pulling a trailer that is too heavy can pull the bumper and ball back toward the trailer.

When this fertilizer trailer crossed railroad tracks it pulled the bumper off the truck.

When this fertilizer trailer crossed railroad tracks it pulled the bumper off the truck.  The trailer tongue hit the tracks, causing the fertilizer to push forward, and the front of the poly tank collapsed.

The trailer tongue hit the tracks, causing the fertilizer to push forward, and the front of the poly tank collapsed.  Never modify a bumper by cutting a larger opening. It weakens the bumper and reduces the weight it can tow.

Never modify a bumper by cutting a larger opening. It weakens the bumper and reduces the weight it can tow.

When a bumper is damaged or corroded, the amount it can safely tow is significantly reduced.

When a bumper is damaged or corroded, the amount it can safely tow is significantly reduced.  Notice how little metal is left between the ball and the outside edge of the bumper.

Notice how little metal is left between the ball and the outside edge of the bumper.  Pulling with a patched bumper is not advised.

Pulling with a patched bumper is not advised. Choose the Proper Frame-mounted Hitch

Farms and commercial businesses use many different frame-mounted hitches. Generally, frame-mounted hitches can be placed in one of three main groups, depending on how the trailer’s tongue weight (sometimes called dead weight) is distributed:

• Weight-carrying hitches. These hitches carry the tongue weight on the hitch at the back of the truck.

• Gooseneck hitches. These hitches are mounted in the center of a truck bed. This allows the truck’s frame, springs, and axles, to support the trailer’s tongue weight.

• Weight-distributing hitches. These hitches are actually accessories that are often used for extremely heavy trailers. A weight-distributing hitch does not bear all the vertical load from trailer tongue weight. Instead, it uses springs, levers, bars, or chains to distribute the vertical load from the rear of the truck to the front of the truck and to the rear of the trailer. When a driver adjusts and tightens the support bars on the hitch, that lifts up the back of the truck.

Weight-carrying hitches

Weight-carrying hitches

Gooseneck hitches

Gooseneck hitches  Weight-distributing hitches

Weight-distributing hitches

A weight-distributing hitch can greatly increase what the truck can safely tow by redistributing the trailer’s tongue weight

A weight-distributing hitch can greatly increase what the truck can safely tow by redistributing the trailer’s tongue weight Know the Hitch Assembly’s Components

Each component of a hitch assembly is individually rated for the maximum load it can tow. This is an important safeguard that can reduce the risk of trailers detaching on the road. Just as a chain is only as strong as its weakest link, so a hitch assembly is only as strong as its weakest component.

Operating safely means working within maximum load limits for each component of the hitch assembly. The components of a hitch assembly are:

- Receivers

- Inserts

- Hitch pins

- Hitch balls

Receivers

It is common for trucks to have factory- or professionally-installed receivers attached to their frames. A receiver forms the base into which you can place attachments and pins to hold them in place. Convenience and flexibility have made these types of hitches quite popular among users. In contrast to bumper hitches, hitches mounted to frames are made of heavy-duty steel and have many more attachment points. Each receiver has a permanent label attached to it that is marked with the maximum trailer weight that it can tow.

The way a receiver is constructed and mounted also determines how much weight it can carry. Exceeding more than the maximum tongue weight can bend or break a receiver. The bottom line: when the tongue weight exceeds the limits of the receiver, bad things happen.

It’s important to remember that receivers can rust. When not in use, cover receivers to keep water and salt from accumulating and degrading the metal. If you leave the attachments in the receiver year round, be sure to lubricate the pins and receivers.

Also, be aware of the receiver sleeve within a receiver. Some larger pickup trucks (such as three-quarter-ton trucks) come equipped with two different sizes of receivers. The larger and stronger 2.5-inch receiver is for towing larger loads. However, the more commonly used 2-inch inserts are too small for the 2.5-inch receiver. You can use a 2-inch adaptor sleeve to downsize the receiver. If you do this, be aware that the only thing holding the sleeve into the larger receiver is a pin. Whenever you use the 2-inch sleeve, replace the pin. If not, the smaller 2-inch sleeve can fall out onto the highway.

This receiver bent after being sideswiped by another truck.

This receiver bent after being sideswiped by another truck.  Each receiver has a maximum force that it can tolerate before it bends or breaks.

Each receiver has a maximum force that it can tolerate before it bends or breaks.

A bent receiver prevents the ball and coupler from properly attaching, which increases the odds that the trailer will dislodge from the ball.

A bent receiver prevents the ball and coupler from properly attaching, which increases the odds that the trailer will dislodge from the ball.  This insert has rusted inside the receiver.

This insert has rusted inside the receiver.  Receiver covers can help prevent corrosion.

Receiver covers can help prevent corrosion.

Inserts

Inserts may be hollow in the center or made with solid cores. Solid inserts have a number of holes that allow you to insert pins depending on which ball you use as you rotate and place it in the receiver.

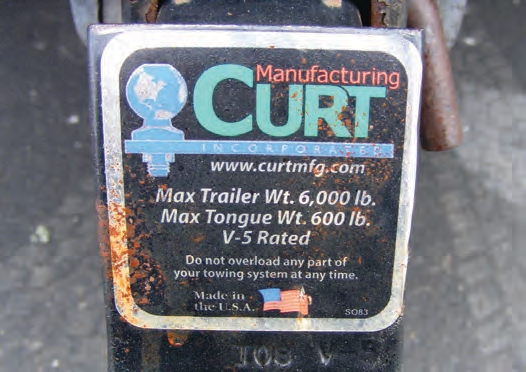

Each insert has a rating stamped into the metal or written on a permanent sticker. The ratings provide the maximum towing and tongue weights it can support. Without a tag, you will not be able to know how much the insert is rated for. Like receivers, do not exceed the limits for what a hitch insert can safely tow. Using an unmarked insert is dangerous.

Some companies make hitch ball mounts that have the same rating whether they are mounted in a rise or drop position. The instructions that come with a hitch ball mount should state if it can only be inserted one way.

Watch for wear

Hitch balls wear down over time just like the insides of couplings do. When is a ball worn? A general rule of thumb is to replace a ball when it has lost 1/8 inch from its original diameter.

Inserts have ratings just like other hitch components. Never use homemade inserts or inserts rewelded by someone other than a certified welder or a manufacturer.

Inserts have ratings just like other hitch components. Never use homemade inserts or inserts rewelded by someone other than a certified welder or a manufacturer.  Note that the labels on these hitches always warn users that operators should never exceed the weight the vehicle was designed to pull. A truck’s lower towing rating always takes precedence over a hitch’s higher rating.

Note that the labels on these hitches always warn users that operators should never exceed the weight the vehicle was designed to pull. A truck’s lower towing rating always takes precedence over a hitch’s higher rating.

Inserts can break when stressed beyond their manufacturer’s rating.

Inserts can break when stressed beyond their manufacturer’s rating.  This truck has an extra insert that allows the truck to turn without the trailer hitting the truck. However, the extended hitch is too long to be supported.

This truck has an extra insert that allows the truck to turn without the trailer hitting the truck. However, the extended hitch is too long to be supported.  In addition to ball attachments, you can use inserts equipped with a pintle hook

In addition to ball attachments, you can use inserts equipped with a pintle hook  In addition to ball attachments, you can use inserts equipped with a Hitch pin. In all cases, a pin holds an insert in place.

In addition to ball attachments, you can use inserts equipped with a Hitch pin. In all cases, a pin holds an insert in place.  This pintle hook is not an insert, but it will be stamped with towing and tongue weight ratings.

This pintle hook is not an insert, but it will be stamped with towing and tongue weight ratings.  If you have a ball insert that is designed to move up or down, you can use it to help level the truck and trailer.

If you have a ball insert that is designed to move up or down, you can use it to help level the truck and trailer.  Cushion bumpers lessen the shock of braking and taking off. Like other components, they also have maximum towing capacity and trailer tongue weight ratings.

Cushion bumpers lessen the shock of braking and taking off. Like other components, they also have maximum towing capacity and trailer tongue weight ratings.

An insert bouncing on the highway is a flying missile looking for a target! Remove inserts when not in use.

An insert bouncing on the highway is a flying missile looking for a target! Remove inserts when not in use.  This insert could easily fall out of the receiver and bounce on a highway.

This insert could easily fall out of the receiver and bounce on a highway.  The simple solution is to remove the insert when not in use.

The simple solution is to remove the insert when not in use.  Leaving inserts in the truck bed causes three problems. First, they are exposed to the elements, which accelerates corrosion.

Leaving inserts in the truck bed causes three problems. First, they are exposed to the elements, which accelerates corrosion.  Second, they can be easily stolen.

Second, they can be easily stolen.  Third, they can be dangerous missiles in an accident. If you remove inserts, put then behind a seat or in a locked workbox.

Third, they can be dangerous missiles in an accident. If you remove inserts, put then behind a seat or in a locked workbox. There are many types of inserts that allow for the proper connection between the trailer and the truck. Inserts are equipped with various attachments. You should purchase inserts so that you can keep the ball height and trailer coupler height level when attached.

You should pull inserts out of the receivers when you’re not using them (pages 28-29). There are many instances when inserts have fallen out on the highway and led to serious injuries because they went through the windshields of trailing vehicles. Taking them out will also help reduce the risk that someone will steal them when the truck is parked and unattended.

Even stationary inserts can pose a hazard. You do not want a hitch to cause someone’s death or injury — “A friend’s father died after he tripped and fell on the hitch. The ball broke a rib, which pierced his heart. It was a freak accident that could probably have happened with a tool in the barnyard but many others, myself included, have banged my knee or fell over an insert.” By removing the insert, you can eliminate these types of accidents. Even making the inserts easier to spot (such as painting them) can help prevent mishaps.

Painting inserts make them easier to spot and can prevent accidents.

Hitch Pins

Manufacturers have designed different types of hitch pins that lock inserts to receivers. Most hitch pins do not have ratings. Notice that most hitch pins are solid steel with a place to insert the keeper. Some designs even include a lock within the hitch to prevent the insert from being stolen. All pins are subject to corrosion and can be difficult to remove if you do not lubricate or remove them when you’re not using the hitch.

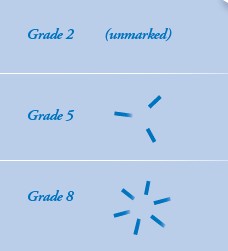

Hitch pins will wear down as you pull the insert forward and backward during pulling and stopping. Pins can bend or break. You should replace any pin that is bent (see photo on the right), worn, or badly rusted. Ideally, you should replace a worn hitch pin with one that is identical to what came with the original equipment. Be careful about making your own makeshift hitch pins from bolts. If you must use a bolt in an emergency, make sure the bolt is a grade 5 or 8. Also, make sure the bolt that goes though the receiver and insert is solid all the way through. Many hardware store bolts are grade 2 or unrated.

These bolts are extremely soft and can shear very easily during a panic stop. Attaching a nut to a threaded bolt can create unexpected problems. Securing a bolt with a single nut is not the best choice, because the bolt can easily loosen over time. Double nut the bolt or use a self-locking nut to help prevent the nut from falling off the bolt. But remember, once corroded, a nut can be nearly impossible to remove.

A hitch pin that has rusted designed to be locked

A hitch pin that has rusted designed to be locked  A hitch pin that has rusted in place

A hitch pin that has rusted in place  A pin needs to fit in a hole in a way that minimizes play and prevents breaking.

A pin needs to fit in a hole in a way that minimizes play and prevents breaking.

You should remove uncovered locks when they’re dusty, during the winter, or when not is use.

You should remove uncovered locks when they’re dusty, during the winter, or when not is use.  Some locks have covers over the keyhole that will offer some protection of the locking mechanism.

Some locks have covers over the keyhole that will offer some protection of the locking mechanism.  It is acceptable to use a tractor hitch pin, such as a grade 5 or 8 5/8-inch pin.

It is acceptable to use a tractor hitch pin, such as a grade 5 or 8 5/8-inch pin.  This photo shows good and bad practices. A single nut can easily come loose. However, the bolt is solid and the weaker threads are away from the stress.

This photo shows good and bad practices. A single nut can easily come loose. However, the bolt is solid and the weaker threads are away from the stress.  A good example of double nutting to keep the bolt secure.

A good example of double nutting to keep the bolt secure.  Never invent your own solutions, as this driver who used a tie-strap around the pin to secure it in place.

Never invent your own solutions, as this driver who used a tie-strap around the pin to secure it in place.  Use a grade 5 or 8 bolt to hold an insert into a receiver.

Use a grade 5 or 8 bolt to hold an insert into a receiver.  Frequently check nuts to ensure they are tightly secured because they can loosen over time.

Frequently check nuts to ensure they are tightly secured because they can loosen over time.

Drilling through a bolt to create a hole for a locking pin is a bad idea. It weakens the bolt and makes the assembly less safe.

Drilling through a bolt to create a hole for a locking pin is a bad idea. It weakens the bolt and makes the assembly less safe. Hitch Balls

The most common hitch ball sizes are 1 7/8 inches, 2 inches, and 2 5/16 inches. Lighter trailers often take the 1 7/8-inch ball and trailers more than 7,000 pounds often require the 2 5/16-inch ball. Don’t assume that balls of the same diameter have the same towing ratings. Each ball has its own rating regardless of its diameter. Often, the shank diameter and length determine the ball’s tow rating.

1 7/8 inches

1 7/8 inches  2 inches

2 inches  2 5/16 inches

2 5/16 inches  Unless the manufacturer has welded the hitch ball to the insert, be sure to torque the nut on the shank of the ball according to the manufacturer’s recommendations.

Unless the manufacturer has welded the hitch ball to the insert, be sure to torque the nut on the shank of the ball according to the manufacturer’s recommendations.

When a trailer is too heavy for the ball and insert, that weight can bend the ball and insert toward the truck if the load is thrust forward

When a trailer is too heavy for the ball and insert, that weight can bend the ball and insert toward the truck if the load is thrust forward  When a trailer is too heavy the weight can bend the hitch ball and shank back toward the trailer

When a trailer is too heavy the weight can bend the hitch ball and shank back toward the trailer  You can buy unrated hitch balls from a bulk bin or you can buy them with instructions that specify the torque the nut requires, the amount of acceptable wear, and the weight it can tow.

You can buy unrated hitch balls from a bulk bin or you can buy them with instructions that specify the torque the nut requires, the amount of acceptable wear, and the weight it can tow.  Try to eliminate 2,000- and 3,500-pound balls and replace them with higher rated balls. This helps reduce the chance that you will pull a trailer with an undersized ball.

Try to eliminate 2,000- and 3,500-pound balls and replace them with higher rated balls. This helps reduce the chance that you will pull a trailer with an undersized ball.  Balls for gooseneck hitches also have specific load ratings and must be attached according to manufacturer’s specifications.

Balls for gooseneck hitches also have specific load ratings and must be attached according to manufacturer’s specifications.  The ball on a gooseneck hitch depends heavily on what the ball is attached to.

The ball on a gooseneck hitch depends heavily on what the ball is attached to.  The attachment assembly can be a manufactured kit or custom-made by a certified welder.

The attachment assembly can be a manufactured kit or custom-made by a certified welder.  Never use a hitch to hold down a load.

Never use a hitch to hold down a load. Pay Attention to Trailer

Trailers, like trucks and hitches, have various ratings associated with how the trailer was manufactured. Metal or plastic plates on the fronts of trailer tongues indicate:

• How much tongue load is expected when the trailer is fully loaded

• The maximum weight the trailer can carry based on the design of the trailer, its axles, and tire size

• The size of the ball to be used with the coupler

• Warning statements

Trailers also have two main parts that you should pay attention to: trailer couplers and trailer coupler latch pins.

Your fleet you may have light- to heavy-weight trailers that require different hitch components to safely pull on the road.

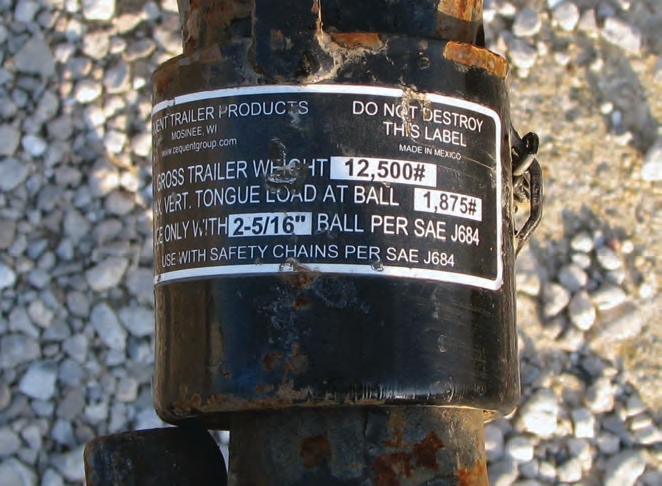

Your fleet you may have light- to heavy-weight trailers that require different hitch components to safely pull on the road.  When fully loaded, the tongue weight on the truck’s hitch is 1,875 pounds. It also requires a 2 5/16-inch ball. Compare the gross and tongue weights to the ratings of the truck, receiver, and insert.

When fully loaded, the tongue weight on the truck’s hitch is 1,875 pounds. It also requires a 2 5/16-inch ball. Compare the gross and tongue weights to the ratings of the truck, receiver, and insert. Trailer Couplers

A trailer has a gross vehicle weight rating, but the trailer coupler may have a separate set of ratings stamped on the metal or on a tag. Trailer couplers are important components that are often overlooked.

In addition to the ratings, make sure to keep couplers in good working condition. Be sure to prevent dirt and grime from accumulating on the inside of couplers.

Inspect couplers for corrosion and other damage.

Inspect couplers for corrosion and other damage.  Weak couplers can cause the entire hitch system to fail.

Weak couplers can cause the entire hitch system to fail. Trailer Coupler Latch Pin

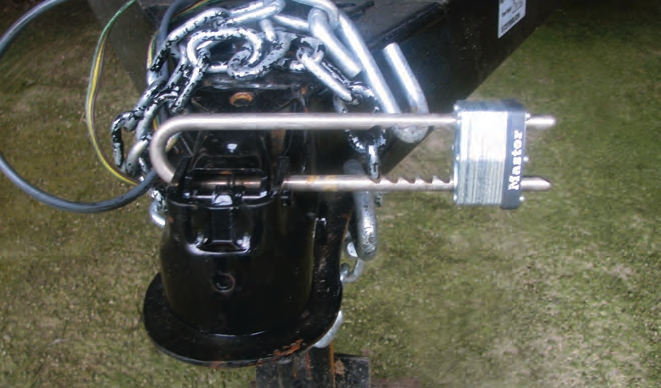

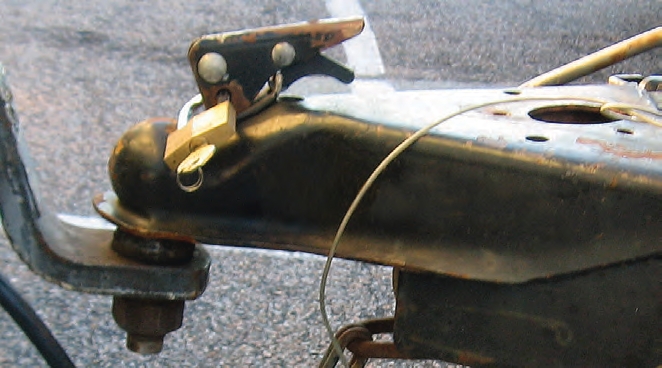

Although there are several styles of trailer hitches and couplers, all of them need to be secured with safety pins to ensure the hitch stays securely attached to the ball hitch.

You need to safely secure the trailer’s coupler to prevent the trailer from disconnecting from the truck. While the trailer’s tongue weight can keep the coupler and hitch attached, potholes and loads distributed too far to the back may cause the trailer tongue to pull upward and off the ball. That’s where the safety pin, bolt, or padlock provide added protection. They keep the trailer and hitch from disengaging.

One mechanic recommends an easy test to make sure your trailer coupler is safely connected to the ball. Jack up the trailer. If it pulls up the truck’s bumper, the trailer is secure. If the trailer pops off, you need to reconnect.

When possible, use coupler latch pins that don’t require tools to remove. Keep extra latch pins in the truck in case one gets broken, bent, or lost.

When possible, use coupler latch pins that don’t require tools to remove. Keep extra latch pins in the truck in case one gets broken, bent, or lost.  Don’t improvise safety equipment. The coupler on the left is secured with a bent metal flag, which can be very dangerous on the road.

Don’t improvise safety equipment. The coupler on the left is secured with a bent metal flag, which can be very dangerous on the road.  There is a little pressure on the coupler latch pin, but there is a chance it will come loose.

There is a little pressure on the coupler latch pin, but there is a chance it will come loose.  Always use high-quality locking pins.

Always use high-quality locking pins.  If you use bolts, check them frequently for loose nuts and wear.

If you use bolts, check them frequently for loose nuts and wear.  Trailers are easy targets for thieves. Locking the coupler to the hitch can at least make it more difficult to steal the trailer.

Trailers are easy targets for thieves. Locking the coupler to the hitch can at least make it more difficult to steal the trailer.  If you use a padlock to prevent theft, don’t forget to remove the key.

If you use a padlock to prevent theft, don’t forget to remove the key.  Don’t forget the details. This coupler latch does not have a pin to keep it attached to the ball.

Don’t forget the details. This coupler latch does not have a pin to keep it attached to the ball. Safety Chains Are Important Back ups

Safety chains provide secondary protection if a trailer detaches from a truck’s hitch system. If your trailer has safety chains with a suitable size and grade, they can keep the trailer and towing truck attached long enough for the driver to pull over. Without properly attached safety chains, a detached trailer can skid off into the road, and then could strike another vehicle.

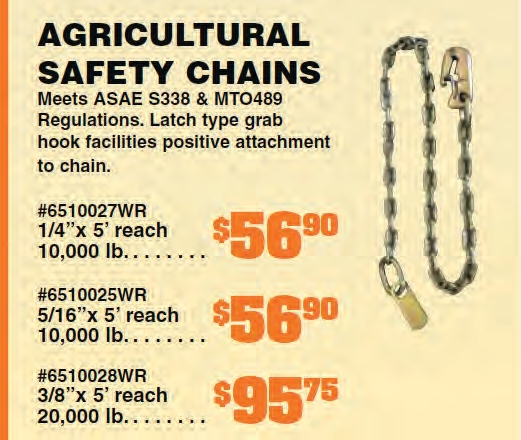

Safety Chains Are Important Back ups 42 When selecting safety chains:

• Know the chain’s breaking strength

• Use the proper chain length

• Connect chains to the right part of the truck

• Attach chains to the trailer frame properly

• Understand the concept of the weakest link

• Replace, don’t repair, worn chains

• Use the right bolts, nuts, and spacers

Know the Chain’s Breaking Strength

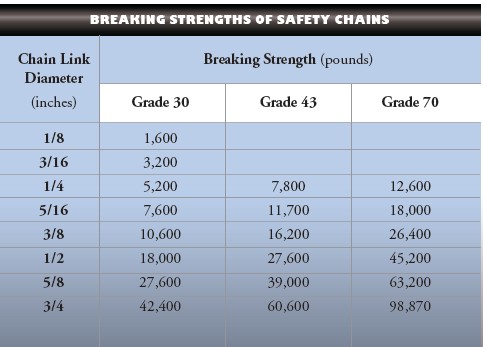

Safety chains must be able to withstand the sudden jerk that occurs when a trailer falls away from a towing unit. That jerk places tremendous tensile and shear stress on chains, hooks, and attachment points such as bolts or welds. You need to make sure that the safety chain you use is strong enough to withstand the initial shock without snapping a link, breaking a hook, or shearing a bolt.

Chain manufacturers assign breaking strengths to chains based on specific diameters and grades. The following table provides the breaking strength of safety chains based on grade and diameter.

Remember that an unmarked chain is no better than a grade 30 when it comes to calculating its breaking strength.

At a minimum, the combined breaking strength of your safety chains must be equal to the weight of the load the truck is towing. To calculate this value, add the breaking strength of each chain together. Under most uses, two grade 30 5/16-inch or 3/8-inch chains will suffice. However, if you desire smaller diameter chains, select ones that have higher grades, which have higher breaking strengths at lower diameters.

However, experienced mechanics suggest a higher standard. They say that a single chain should be strong enough to carry the trailer and load. This is an inexpensive way to improve your safety on the road.

Remember that states often have guidelines about the number and strength of safety chains required on trailers. Always follow your state’s rules.

Use the Proper Chain Length

Safety chains need to be long enough to allow normal pivoting between truck and trailer on wide turns. If it is too short, a safety chain can be ripped from a trailer. But safety chains shouldn’t be so long that they drag across the pavement and get worn quickly. Make sure safety chains are about halfway down between the road and the equipment.

If you have chains that are too long, use an intermediate support. Do not shorten a chain by twisting it. Most manufacturers even provide warnings against twisting chains. That’s because a chain’s breaking rating is determined in a straight-line pull. When you twist chains, you place additional stresses on the chain that can alter how the chain breaks — in effect, you’ve changed its breaking strength.

Your safety chains should be strong enough so that they can hold the trailer until a driver can safely pull over in case of an emergency.

Your safety chains should be strong enough so that they can hold the trailer until a driver can safely pull over in case of an emergency.  When sizing safety chains make sure they are rated to at least hold the maximum gross truck weight rating of the largest trailer and load you will tow.

When sizing safety chains make sure they are rated to at least hold the maximum gross truck weight rating of the largest trailer and load you will tow.  Make sure that safety chains are in good condition. This chain is so corroded that there is a good chance it could break if the trailer came loose.

Make sure that safety chains are in good condition. This chain is so corroded that there is a good chance it could break if the trailer came loose.

A chain that is too long will drag on the pavement, which weakens the chain.

A chain that is too long will drag on the pavement, which weakens the chain.  Inspect safety chains and replace them before the links get as thin or worn as the ones shown here.

Inspect safety chains and replace them before the links get as thin or worn as the ones shown here.  Tangled up safety chains can place additional stresses on them and actually lower their breaking strength.

Tangled up safety chains can place additional stresses on them and actually lower their breaking strength.

Connect Chains to the Right Part of the Truck

If you have a frame-mounted hitch, attach the safety chains to the loops designed for that purpose.

Hooking up safety chains to a weak part of the truck (such as the bumper) means that if the weaker part breaks lose first, the chain will not engage during an emergency separation.

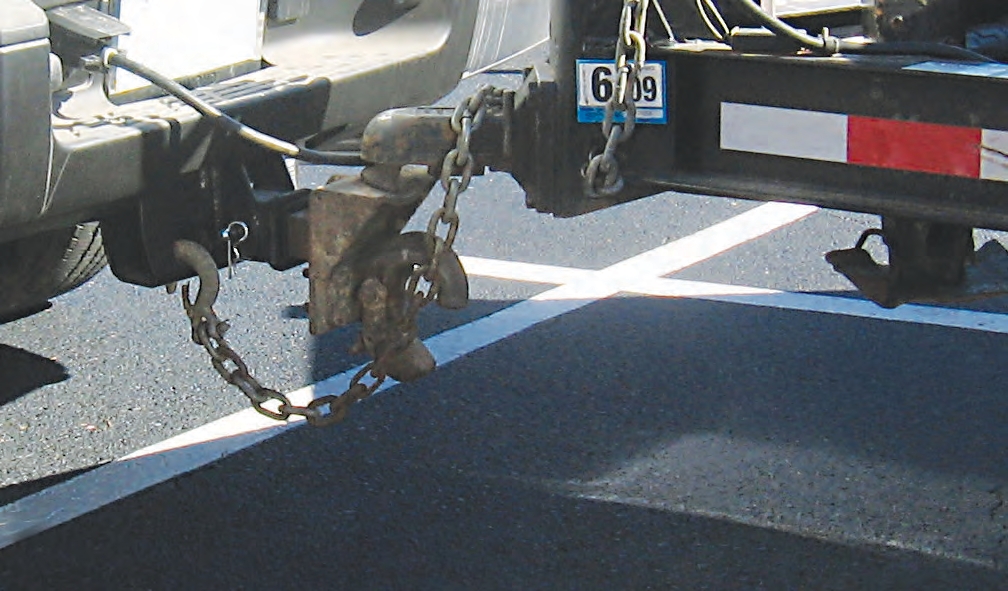

The preferred way to attach chains to weight-carrying hitches is to criss-cross the chains and attach them to opposite sides of the truck. Crossing chains over and underneath the trailer tongue like this forms a cradle in case of a detachment. The cradle will minimize the trailer’s side-to-side movement during a detachment and help to keep the tongue from planting into the pavement.

Of course, attaching safety chains to a hitch can be difficult when the connections are underneath the truck. Although tempting, do not install a hook via a link to the hitch unless it is your only option. While the new hook makes it easier to hook the safety chain, this type of connection is not nearly as strong and secure as it would be if attached directly to the connection point on the receiver.

Connectors are often not rated for transportation use. While links are often made for use in transportation, you must be certain they are in good condition and have a rating that is strong enough to secure your load. If you use a connector, it is critical that it is not the weak link and that it has a load rating that meets your specific specifications.

This truck has safety chains that have been properly criss-crossed.

This truck has safety chains that have been properly criss-crossed.  On the left side of this bumper, you can see that the driver broke off the spring-loaded backs of the hooks on the safety chain.

On the left side of this bumper, you can see that the driver broke off the spring-loaded backs of the hooks on the safety chain.  Safety chains on a gooseneck trailer do not have to be crossed, because they are just the right length to keep the trailer from exiting the bed of the truck.

Safety chains on a gooseneck trailer do not have to be crossed, because they are just the right length to keep the trailer from exiting the bed of the truck.  When a truck has no dedicated points to attach safety chains, be safe. Do not attach chains with bolts. Instead, attach a certified D-ring to the frame on the back of the truck.

When a truck has no dedicated points to attach safety chains, be safe. Do not attach chains with bolts. Instead, attach a certified D-ring to the frame on the back of the truck.  Make sure that spring-loaded latches can completely close or they become ineffective.

Make sure that spring-loaded latches can completely close or they become ineffective.

Just because a link can hold a hook that does not mean that it will withstand the pressure when a trailer detaches from a hitch. Read the instructions to see what limitations the manufacturer places on hooks and attachments.

Just because a link can hold a hook that does not mean that it will withstand the pressure when a trailer detaches from a hitch. Read the instructions to see what limitations the manufacturer places on hooks and attachments.  Notice that the loop that the connector is attached to is a homemade attachment point. It could easily be the weakest point.

Notice that the loop that the connector is attached to is a homemade attachment point. It could easily be the weakest point.  This trailer has only one chain attached when it should have two. In addition, the chain is hooked on by a link instead of the hook that is provided. Use hooks that fit the attachment points on the towing truck, and that match the chain’s breaking strength.

This trailer has only one chain attached when it should have two. In addition, the chain is hooked on by a link instead of the hook that is provided. Use hooks that fit the attachment points on the towing truck, and that match the chain’s breaking strength.  When you buy a receiver, make sure that the places you hook safety chains are big enough to accommodate large hooks. If not, you’ll have to add attachments for safety chain hooks.

When you buy a receiver, make sure that the places you hook safety chains are big enough to accommodate large hooks. If not, you’ll have to add attachments for safety chain hooks.

Make sure that all attachment points are intended for use in transportation.

Make sure that all attachment points are intended for use in transportation.  An example of a grossly inadequate “ fix.”

An example of a grossly inadequate “ fix.”  This is a great attachment point, but that benefit is negated by using a hook that has been stretched to the point that it serves no useful function.

This is a great attachment point, but that benefit is negated by using a hook that has been stretched to the point that it serves no useful function.  This connector is not made to withstand the pressure of a safety chain pulling against it. Notice that the open area between the two posts has little metal, which makes it a weak link at that point.

This connector is not made to withstand the pressure of a safety chain pulling against it. Notice that the open area between the two posts has little metal, which makes it a weak link at that point.  These safety chains are not actually attached to the trailer, which makes them less effective in case of an accident.

These safety chains are not actually attached to the trailer, which makes them less effective in case of an accident. Attach Chains to the Trailer Frame Properly

A common debate is whether to weld a safety chain onto a trailer. If you do weld chains, a general rule of thumb is that you should only allow a certified welder to do the job. This is especially true when dealing with a hardened steel chain. Heating up the chain can make it brittle. Certified welders know they have to take a second step to bring that piece of metal back into condition. A welder who is uncertified may unknowingly damage the integrity and tensile strength of the chain.

Bringing metal back into condition is less of a concern with grade 30 and 43 proof coil chains. In any case, make sure that the grade is stamped on the chain links and on any attachments. If not, then you should treat the grade of the chain and its attachments as 30 grade.

Use grade 5 or 8 bolts to attach safety chains to frames. Note the six lines on the bolt head that signify this is a grade 8 bolt.

Use grade 5 or 8 bolts to attach safety chains to frames. Note the six lines on the bolt head that signify this is a grade 8 bolt. Understand the Concept of the Weakest Link

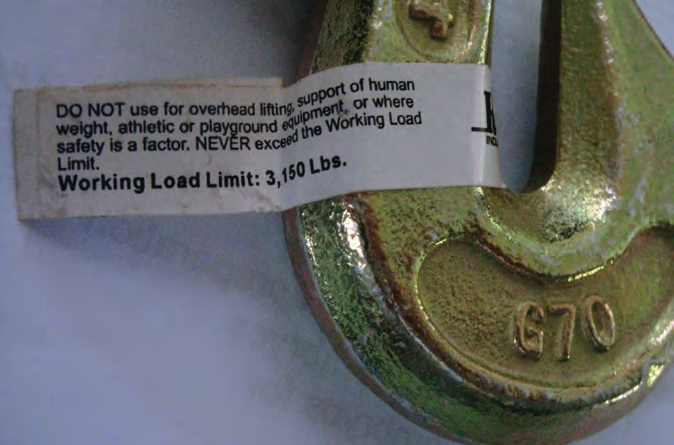

It’s not just the chain’s grade and diameter that are important when towing. All chain components (hooks, latches, repair links) need to have the same grade or higher than the chain itself.

The chains and attachments shown on this page are each rated grade 70, which means that all parts are of equal strength.

The chains and attachments shown on this page are each rated grade 70, which means that all parts are of equal strength.

This advertisement provides an important lesson about chain attachments. The ad says that the breaking strength of the 1/4-inch and 5/16-inch 5-foot chain is 10,000 pounds. Normally, larger diameter chains have greater breaking strengths. The grab hooks on the 5/16-inch chain must have a breaking strength less than that of the chain.

This advertisement provides an important lesson about chain attachments. The ad says that the breaking strength of the 1/4-inch and 5/16-inch 5-foot chain is 10,000 pounds. Normally, larger diameter chains have greater breaking strengths. The grab hooks on the 5/16-inch chain must have a breaking strength less than that of the chain.  This driver is placing a risky bet that the connectors will hold these two chains together in case of an accident. It is important to make sure the connectors are rated for transportation.

This driver is placing a risky bet that the connectors will hold these two chains together in case of an accident. It is important to make sure the connectors are rated for transportation. Replace, Don’t Repair, Worn Chains

Under most conditions, it is not a good idea to repair safety chains. It is better to replace a worn chain than to repair it. For many operators, the liability of putting a repaired safety chain back into service is too risky — it’s just as simple to unbolt the old chain and put on a new one (or in some cases, have a certified welder reattach a new chain).

Still, some operators believe they are qualified to repair safety chains. To operate properly, a repaired safety chain must contain connectors that are just as good as new ones. Furthermore, the connectors should be rated for highway use and all of the chain’s components must be of comparable or greater strength than a new chain.

While easy to install, replacement links may not be rated for road use, which makes them unsafe for hauling trailers.

While easy to install, replacement links may not be rated for road use, which makes them unsafe for hauling trailers.  If you repair a chain, use links rated for transportation, such as the grade 43 repair link

If you repair a chain, use links rated for transportation, such as the grade 43 repair link  Always read the warnings that come with chains hooks. Some warn against using them where shock load or abrasive conditions exist. Make sure the components you buy are designed for over-the-road use.

Always read the warnings that come with chains hooks. Some warn against using them where shock load or abrasive conditions exist. Make sure the components you buy are designed for over-the-road use.  Attaching pieces of chains together with nuts and bolts is not a safe way of creating an attachment point for safety chains to the towing truck.

Attaching pieces of chains together with nuts and bolts is not a safe way of creating an attachment point for safety chains to the towing truck.  The benefits of properly criss-crossing a quality chain can be negated by having flimsy clips attached to the chain and bumper.

The benefits of properly criss-crossing a quality chain can be negated by having flimsy clips attached to the chain and bumper.

Use the Right Bolts, Nuts, and Spacers

The bolts, nuts, and spacers that attach safety chains to trailer frames are some of the least appreciated attachment points. But it is important to pay attention to these components. If a trailer comes loose, the bolts are going to experience tremendous pressure, too.

There is a recognized system of markings to grade bolts — the grades are 2, 5, or 8. A grade 5 bolt has three diagonal lines on its head, a grade 8 has six, and a grade 2 is unmarked.

Make sure the bolt you use has a grade that equals or exceeds the breaking strength of the chain and its components. You don’t want to be holding a 5,000-pound load with a safety chain hooked that’s attached to the trailer with a grade 2 bolt. Protect yourself and invest in a grade 8 bolt and nut where a safety chain is bolted to a trailer’s frame. The bolt must be strong enough to withstand the shear force it will experience if the trailer detaches from the truck.

Nuts and washers are also graded, but they don’t have marks on them to distinguish one grade from another. Ask for grade 5 or grade 8 nuts and washers when you replace safety chains. Inspect and replace high-stress bolts frequently.

Use the proper bolts when replacing a safety chain.

Use the proper bolts when replacing a safety chain.  bolt grades

bolt grades  Note the marks on the bolt heads. What is the grade of each bolt?

Note the marks on the bolt heads. What is the grade of each bolt?

Emergency Trailer Brakes Are the Last Back up System

Most states require trailers of certain gross weights to have both trailer brakes and a breakaway switch mounted on the tongue of the trailer. A breakaway emergency brake helps a trailer stop itself if it separates from a towing truck.

The way breakaway switches work is fairly simple. A short cable goes from the trailer to the truck. If the trailer breaks loose, the trailer pulls the cable, which engages the trailer brakes. Working together with safety chains, the emergency brake will help stop the detached trailer. Batteries, which are often recharged by the truck, power the emergency brakes.

It’s important to remember that the breakaway switch only works if the brake cable is attached to the towing truck’s frame, not the safety chains. If the cable were attached to the safety chain, the cable would not be pulled when the chain is pulled. When no other attachments are available, the attachment point for the cable might be on the hitch.

You must maintain the emergency brake cable in good condition if you expect it to do its job. If the cable snaps before it can engage the brakes, then it doesn’t do you any good. When you attach an emergency brake cable, unhook the trailer but leave the safety chains on. Then, drive the truck forward just until the chains are tight. At this point, opinions diverge on how long the cable must be.

Should the cable be just a few inches shorter or longer than the safety chain?

Those who say that the brake cable needs to be longer than the safety chains point out that, when engaged, the brake system is a panic emergency stop, not a controlled application of the brakes.

If the trailer is lost at the hitch and the brake safety system engages before the chains come off, (which would happen if the cable is shorter than the safety chains) the trailer’s brakes will lock. When that happens, the driver will no longer have control of the trailer’s brakes, and the sudden stopping of the trailer may cause the driver to loose control of the truck — the sudden jerk may even pull the trailer loose from the truck.

If the brake cable is longer than the safety chains, then the chains may hold the trailer in the event of a breakaway. When that happens, the driver is still in control of the trailer’s brake system. Although the trailer may be slamming back and forth, the driver has a chance to bring the truck and trailer to a controlled stop.

A trailer sales technician who says the cable should be longer than the chains said, “If the chains do not hold, setting the brakes is a last resort. You do not want the trailer brakes coming on at full force at 60 miles per hour.”

Those who say the brake cable needs to be shorter than the safety chains argue that the emergency brake is there to help you when a trailer uncouples. If the cable is long, the brake will only assist the driver if the trailer has come completely free of the towing truck — in which case, the driver has no control over the trailer.

If the emergency brake cable is slightly shorter than the safety chains, then the brakes will engage while the trailer is still tethered to the truck by the chains. In that case, (with the brake on and the trailer still attached) the driver still has some control. If the chain has to come off before the emergency brake engages, the driver has lost control of the trailer and it is on the road doing and going where it wants to go.

Those who argue for shorter emergency brake cables say, “I would rather keep the trailer attached to the towing truck.” This difference of opinion means that there is no one-size-fits-all answer that will apply to everyone and every situation. These are choices that you must make for yourself.

However, no matter what option you follow, always make sure the emergency brake system functions. And whatever the length of the cable, it must be free to pull. If the cable gets entangled in the safety chains and doesn’t work when it needs to, that negates the back up brake system. You need to be sure the brake cable goes from the trailer to the truck without any obstructions.

This emergency cable is improperly attached to the safety chain.

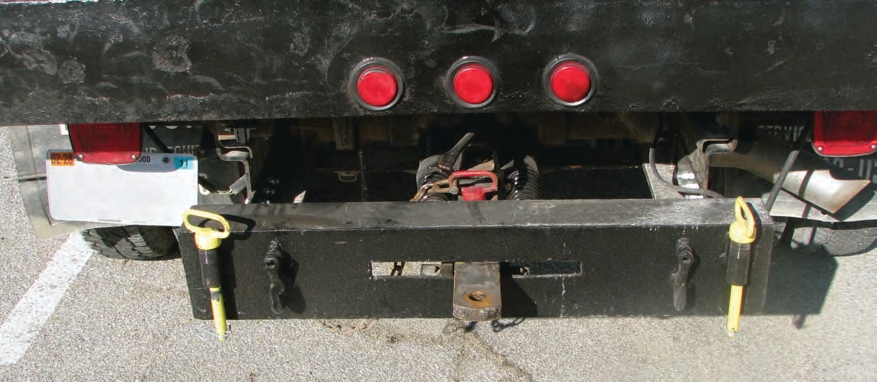

This emergency cable is improperly attached to the safety chain.  This truck has an attachment point dedicated to the emergency brake cable.

This truck has an attachment point dedicated to the emergency brake cable.  This emergency brake cable is in good working condition.

This emergency brake cable is in good working condition.  This emergency trailer brake cable is improperly hooked to the chain.

This emergency trailer brake cable is improperly hooked to the chain.  The wire is so rusted that it would pull apart before it could activate the emergency brake.

The wire is so rusted that it would pull apart before it could activate the emergency brake.  This bumper has a special, secure attachment just for the emergency brake cable.

This bumper has a special, secure attachment just for the emergency brake cable.  Do not tie two parts of a broken cable together. If a cable breaks, replace it.

Do not tie two parts of a broken cable together. If a cable breaks, replace it.

This emergency brake cable has too much slack, which means the brakes will not engage as quickly if the safety chains fail.

This emergency brake cable has too much slack, which means the brakes will not engage as quickly if the safety chains fail.  Always connect the emergency brake cable directly to the towing vehicle. Always connect the emergency brake cable directly to the towing vehicle.

Always connect the emergency brake cable directly to the towing vehicle. Always connect the emergency brake cable directly to the towing vehicle.  Make sure to occasionally inspect the control box to ensure that the wiring is intact.

Make sure to occasionally inspect the control box to ensure that the wiring is intact.

Replaceable, rechargeable batteries power emergency trailer brakes.

Replaceable, rechargeable batteries power emergency trailer brakes.  They recharge off the towing truck. Extend the life of the battery by bringing them inside during freezing weather to charge.

They recharge off the towing truck. Extend the life of the battery by bringing them inside during freezing weather to charge.  Electric trailer brakes can only work if you properly maintain the wires and plug-ins.

Electric trailer brakes can only work if you properly maintain the wires and plug-ins.  Broken covers or split wire housings can lead to brake and light failures.

Broken covers or split wire housings can lead to brake and light failures.

Periodically check the emergency trailer brake system to be sure it is working. The check is rather straightforward. Before you check emergency brakes, disconnect the trailer plug. This will prevent feedback from going into the emergency brake controller in the cab of truck.

Remove the safety chains and pull the emergency trailer brake cable. You should be able to hear the brakes engage. Then drive the towing truck slowly. If you can feel the resistance of the trailer dragging, then the battery and system are working. If the trailer brakes don’t lock, then the battery is not charged, the system is no longer functional, or the battery wires are disconnected. When completed, replace the pin back into the brake box.

In addition to checking emergency brakes, you also need to maintain them. Periodically lubricate the brake switches inside the box through the year to keep the springs inside them operational — you want everything to work if you need the brakes to activate. Use a lubricant that will not damage the brake’s plastic components.

If you leave a trailer unconnected from a truck for a few hours, consider pulling the emergency pin. This will lock up the brakes, which makes it very difficult for someone to steal the trailer.

If you leave a trailer unconnected from a truck for a few hours, consider pulling the emergency pin. This will lock up the brakes, which makes it very difficult for someone to steal the trailer.  Avoid excess risks. Do not attach an emergency brake to a trailer without a cable

Avoid excess risks. Do not attach an emergency brake to a trailer without a cable  Do not hook up an operational brake and cable to the trailer’s coupler

Do not hook up an operational brake and cable to the trailer’s coupler  do not tape up the emergency brake box

do not tape up the emergency brake box Watch Your Load Distribution and Tongue Weight

It’s important to make sure the weight of any load is less than the gross vehicle weight rating of the trailer. When you load supplies and equipment on a trailer, you should place part of the weight over the trailer’s springs and axles. How you place a load directly influences the amount of tongue weight you place on the hitch.

Follow owner’s manual recommendations for the maximum tongue weight allowed. Tongue weight is a function of how you distribute the load on the trailer. If the load is too far forward, there will be too much weight on the tongue at the hitch. The risk is going over the rating of the ball, insert, and receiver, which can damage the hitch, the coupler, or bend the trailer’s tongue.

Too much weight on the trailer’s tongue and rear hitch can also affect how the truck handles. That weight can push down the towing truck’s back end, which takes weight off the front wheels and makes steering more difficult. The towing truck may tend to wander to the right or left, and have less stopping power in the front brakes.

If you’re driving at night, other drivers will quickly tell you when there is too much tongue weight is on the hitch. Your headlights will shine directly into oncoming vehicles and the other drivers will flash their lights, thinking that you have your high beams on.

Placing too little weight on the tongue of the trailer can be extremely dangerous. If you place the load behind the axle, the trailer tongue can actually lift up on the hitch and prevent the rear tires from getting proper traction. When this happens, the trailer will sway back and forth at increased speeds. This is very dangerous because you can easily lose control of the truck.

It’s best to center loads over the trailer’s axle and slightly forward to get some tongue weight on the hitch. A general recommendation is to get about 65 percent of the trailer’s gross weight forward of the midpoint. After you load a trailer, look at the hitch.

The back of the truck and front of the trailer should be level or slightly pushed down a few inches. This creates a slight downward angle, a very shallow “V” at the hitch. The space in the wheel well should be pushed down a little.

If the hitch is near the ground, safety chains are dragging, or truck tires are in the wheel wells, you have too much tongue weight on the hitch. Before driving off, you will need to readjust the load by pushing it back on the trailer. You might have to reposition your load with more weight in the front of the trailer if, when loaded, the hitch has not been pushed down an inch or two.

Make sure your truck and hitch system are capable of towing a load before you get on the road.

Make sure your truck and hitch system are capable of towing a load before you get on the road.

Use Reflective Tape

While most drivers should be able to see you easily during the day, towing a trailer at night adds additional risks. It can be quite difficult for other drivers to see how wide your trailer is or even where the rear of the trailer is. Consider placing reflective tape on the sides and rear of your trailer to mark the extreme widths and to define the rear of the trailer. Adding reflective tape is one of the most cost-effective steps you can take to make sure those driving behind you know the space you occupy.

Adding reflective tape to trailers is one of the best investments you can make. Trailers with reflective tape are much easier to see than those without.

Adding reflective tape to trailers is one of the best investments you can make. Trailers with reflective tape are much easier to see than those without.

Drive Safely When Transporting Trailers

Trailers are designed to follow tow vehicles, which means they will follow the erratic paths of malfunctioning trucks just as they will follow the straight paths of properly functioning trucks. Improper tire pressure, poor alignment, faulty steering adjustment, or bad suspension affect a truck’s drivability, which affects the drivability of the truck-trailer combination.

Before towing a trailer, it is important that your truck is in good operating condition. If your insurance company or state transportation regulations require you to have your towing trucks annually inspected, that mandatory inspection is a good time to inspect all of the hitch components, too. Experienced drivers are important for towing trailers. You should never assume that an employee knows how to tow and back up the trailer. You should provide an annual basic refresher course on towing for all of your employees. Going to the parking lot and reviewing the steps of hitching, loading, securing, backing, and moving a trailer is important for every business.

Spend a few minutes inspecting trailers and reviewing procedures to lower the risk that your trucks will be ticketed or cause accidents — a ticket is the least of your worries.

Any new employee that you expect to tow a trailer should go through hands-on training. It’s important that new employees are not only told how to handle the trailer, but that they actually practice what they have been taught. A person with towing experience can help novices learn how to back up in the parking lot and answer any questions the driver has on the highway.

When you train new employees, consider covering the points about loading the trailer, inspecting the truck, and driving on the highway described below.

Loading the Trailer

• Hook the trailer and truck together so they are nearly level with each other.

• Load trailers so that 65 percent of the cargo weight is in the front half of the trailer (nearest the truck).

• Keep all cargo within the trailer. Never let cargo hang over the sides or extend beyond the trailer.

• Never allow employees to ride in trailers, not even on the lot.

• After connecting a trailer, make sure its jack stand is high enough so that it won’t be ripped off the trailer during transport.

• Ensure that the gross weight of the trailer and its load never exceeds the towing capacity of the truck or any of the hitch attachments.

• Follow the towing truck and hitch component manufacturers’ recommendations for the required tongue weight.

• Always attach trailers to hitches before loading. Loading the trailer before attaching the hitch will force the tongue of the trailer to swing up.

• Balance loads from side to side.

• Know the loaded trailer height and follow roadway height limits.

Secure Loads Properly

More information about securing loads is available in Securing the Load: A Guide to Safe and Legal Transportation of Cargo and Equipment (Purdue Extension publication PPP-75), available from the Purdue Extension Education Store, www.the-education-store.com.

A trailer that detaches on a busy highway is a disaster in the making.

A trailer that detaches on a busy highway is a disaster in the making.

Managers and supervisors should occasionally check trailers to ensure that all of the company’s safety guidelines are being followed. It is critical to make sure that employees are doing what they have been taught and ensure that unsafe trucks never leave the lot.

Managers and supervisors should occasionally check trailers to ensure that all of the company’s safety guidelines are being followed. It is critical to make sure that employees are doing what they have been taught and ensure that unsafe trucks never leave the lot.  Consider purchasing a hitch that allows right-to-left and back-to-front movement, which will help when you hook the trailer to the truck.

Consider purchasing a hitch that allows right-to-left and back-to-front movement, which will help when you hook the trailer to the truck.

Inspecting the Truck

• Check for anything that could blow or fall off a trailer such as a piece of equipment or supplies. Make sure that there are no wrenches, other tools, or any debris on the trailer deck that could fall off and hit another vehicle.

• Check tires for wear and proper inflation. One of the easiest ways to loose a tire is to run on low pressure. Improperly inflated tires will heat up, which can cause the belts inside them to separate, and lead to a blowout. Make sure to use tires with ply ratings that can carry the loads being towed.

• Adjust mirrors to see the full length of the trailer. Consider installing wider mirrors on both sides of the towing truck as well as wide-angle (convex) mirrors to help drivers see what is around them more easily. While these mirrors provide an excellent wide-angle view of the trailer and driving lane, remember that items in these mirrors are closer than they appear.

• Properly secure the pin and hitch coupler.

• Fasten safety chains. • Install the electric plug.

• Make sure to adjust electric brakes when the trailer is empty and readjust them after it is loaded. A 5,000-pound trailer needs more braking power than one that weighs 3,000, and requires less power when it is empty.

The yellow markings on this trailer wheel are lug nut indicators. If an arrow is not facing the same direction as the others, that indicates the nut is loose.

The yellow markings on this trailer wheel are lug nut indicators. If an arrow is not facing the same direction as the others, that indicates the nut is loose.  Notice anything wrong with this jack?

Notice anything wrong with this jack?  What’s on top of the gooseneck trailer?

What’s on top of the gooseneck trailer?  If you use worn tires on a fully loaded trailer, you are playing a dangerous game. A tire that blows on the highway seldom has a positive outcome for the driver or those sharing the highway.

If you use worn tires on a fully loaded trailer, you are playing a dangerous game. A tire that blows on the highway seldom has a positive outcome for the driver or those sharing the highway.

On this trailer the coupler latch pin is not in place.

On this trailer the coupler latch pin is not in place.  Keep instruction manuals for the truck and trailer components in two locations: the office and the truck. You never know when you might have to fix something on the road.

Keep instruction manuals for the truck and trailer components in two locations: the office and the truck. You never know when you might have to fix something on the road. Driving on the Highway

• Don’t be distracted with a cell phone.

• Stay centered in your lane. • Never exceed speed limits.

• Drive slightly slower than the posted speed limit, but not so slowly that you back up traffic.

• Slow down when going over railroad crossings, bumpy roads, and in construction zones.

• Maintain a safe stopping distance behind other vehicles that you will need to slow the truck and trailer. Give yourself plenty of time, especially when handling heavier trailer loads.

• Avoid sudden maneuvers when towing a trailer.

• Go slightly wide on right turns. The trailer will go slightly inside of the right side of the truck.

• Pay attention to where you are going and what is behind you.

• Signal well in advance before passing another vehicle, changing lanes, or turning.

• Don’t forget about blind spots. Mirrors that are adjusted for trailers create a blind spot that makes small cars between the trailer and truck difficult to see.

• Allow extra distance after passing a vehicle before pulling back into the driving lane.

• Pay special attention not to get on soft shoulders that can cause the trailer and truck to go out of control.

• Keep lights on at all times.

• Learn to back a trailer with mirrors. Get out of the truck and look around the load first before backing a covered trailer.

Slow down when road conditions become dangerous. Drivers can lose control of trucks when trailers start sliding on ice and snow.

Slow down when road conditions become dangerous. Drivers can lose control of trucks when trailers start sliding on ice and snow.

Putting Your Knowledge To Work on Real Problems

The truck pulling this trailer was rated to pull 18,000 pounds. The trailer was pulled on a ball hitch rated at 7,500 pounds. In addition to the skid steer with its attachments, a grapple bucket was placed on the front of the trailer. It all fit very nicely on the trailer, but on the way home, two tires came off when the driver turned a corner and the rear brake calipers on the truck broke from the strain. Luckily, no one was hurt.

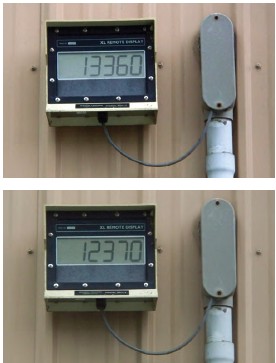

So what happened? The gross vehicle weight rating of the trailer is listed at 12,000 pounds. The weight of the trailer is 5,060 pounds, which leaves a useable payload capacity of 6,940 pounds. The loads were weighed after the fact. The weight of the empty trailer (5,060 pounds) and the skid steer (8,300 pounds) made a total weight carried at 13,360. An additional 990 pounds for the grapple bucket made the total weight 14,350 pounds.

The trailer and the skid steer without the grapple bucket were weighed when attached to the truck. The weight came in at 12,370 pounds, meaning that 990 pounds of the weight was transferred to the tongue. By adding 900 pounds for the bucket to the trailer load provides about 90 pounds, which is transferred to the hitch. The load that the trailer was built to carry was exceeded as was the ball hitch. It was lucky that no one was hurt when the tires came off.

The moral of the story: Just because it fits on a trailer does not mean it is safe or legal. For a small fee, most agricultural retailers will weigh units for owners to have exact weight information.

Looks Can Be Deceiving

A truck and trailer might look like a perfect fit for each other. However, a closer inspection of the hitch components and the gross vehicle weight rating of the trailer may show that the hitch system is inadequate to tow the trailer safely on the highway.

Conclusion: The Driver is Responsible

Never view your hitches as simple mechanical devices. Instead, you should view them as a complex integration of components that work together to keep the trailer connected to the truck.

Hooking a trailer to a truck creates a “single” truck through a hitch mechanism, safety chains, emergency trailer brakes, and load distribution and securement. Experienced drivers understand that the ways a truck steers, brakes, and turns can be altered when a trailer is attached.

The consequences of a trailer unhitching from a truck on the highway can be catastrophic. People are killed or injured each day from these types of accidents and the environment damaged. Nobody wants to be that person whose trailer slams into a van carrying a family or spills chemicals into a creek. Read and follow the ratings of the truck, hitch, and trailer when towing so that accidents are prevented.

Understand that connecting a trailer to a truck is a system of ratings. During annual inspections, make sure mechanics check the hitch system for loose bolts, worn balls, or faulty equipment.

Understand that connecting a trailer to a truck is a system of ratings. During annual inspections, make sure mechanics check the hitch system for loose bolts, worn balls, or faulty equipment.  Just ask yourself what would happen if any of these trailers came loose from the truck. Where would it go? Who would be injured or killed? There are serious repercussions when trailers and trucks are not properly matched and properly secured.

Just ask yourself what would happen if any of these trailers came loose from the truck. Where would it go? Who would be injured or killed? There are serious repercussions when trailers and trucks are not properly matched and properly secured.

Never forget that unsafe practices can have real, tragic consequences. The man in this photo was killed and the woman was severely injured after a trailer broke loose from its hitch and struck their vehicle.

Never forget that unsafe practices can have real, tragic consequences. The man in this photo was killed and the woman was severely injured after a trailer broke loose from its hitch and struck their vehicle. Thanks to Dawn Minns for graphic design. Thanks also to those who offered constructive comments during the development of this publication:

Bob Avenius, Trugreen-Chemlawn

Jim Beatty, Purdue University

Gerry Blase, Asplundth

Jim Colias, Matt’s Lawncare and Landscaping

Robert DeVore, Great Lakes Four Wheel Drive Association

Paul Hardy, Orkin

Brenda Hoffman, United States Department of Agriculture

Andrew Landers, Cornell

Kip Landwehr, Winfield Solutions

Ron Melancon, Dangeroustrailers.org

Jim Milazzo, Safe Tow

John Nellis, Nellis Landscape Service

Dennis Nowaskie, Purdue University

Steve Queen, Advanced Agri-Solutions

George Saxton, Office of Indiana State Chemist

Brad Shelton, Purdue University

David Trotter, Purdue University

Larry Wilks, Oak Lawn Farm

Jim Wilson, South Dakota State University

Steve Zachary, Purdue University

Phil Zimmerman, Fertilizer Dealer Supply

This publication was partially supported with funding from: the Indiana Nursery and Landscape Association, Indiana Professional Lawn and Landscape Association, and Indiana Water Resources Research Center at Purdue University.

Disclaimer This publication is intended for educational purposes only. The authors’ views have not been approved by a government agency or business. The publication is distributed with the understanding that the authors are not engaged in rendering legal or other professional advice, and that the information contained herein should not be regarded or relied upon as a substitute for professional consultation. The use of information contained herein constitutes an agreement to hold the authors harmless for liability, damage, or expense incurred as a result of reference to or reliance upon the information provided. Mention of a proprietary product or service does not constitute an endorsement by the authors or their employers. Images that show the misuse of any trucks, trailers, hitch components, or any other equipment are for educational purposes only. Always read and follow manufacturers’ instructions before operating any equipment.