The Tractor Hitch Pin A Critical Component in Keeping Control of Implements

RESOURCES - PUBLICATIONS

The Tractor Hitch Pin

A Critical Component in Keeping Control of Implements

Authors

Fred Whitford, Coordinator, Purdue Pesticide Programs

Steve Hawkins, Assistant Director, Purdue Agricultural Centers

Keith Bowman, Head and Professor of Materials Engineering, Purdue University

Philip Walker, Superintendent, Northeast Purdue Agricultural Center

John Obermeyer, Integrated Pest Management Specialist, Purdue University

Kevin Leigh Smith, Editor, Purdue Agricultural Communication

The American Society of Agricultural and Biological Engineering (ASABE) has established standards for hitch pins under the standard ANSI/ASABE S625.

Farmers Need to Move Implements on the Road

There is a science to keeping an implement safely connected by a hitch pin to a truck or tractor. As one agricultural retailer put it, “Not using the correct pin is a serious issue that even ag retailers face. From time to time I think about how we might be held responsible for the times we hook a 1,000-gallon poly tank full of 10- 34-0 or connect 5-ton fertilizer spreader to a producer’s half-ton pick-up. I can only guess who will ultimately be held responsible in the event of an incident.”

But When the Implement Detaches, You’ve Lost Control

An implement came loose from a tractor and slammed into the windshield of an oncoming bus, killing the driver and injuring three-dozen children.

Don’t Count on Luck

A farmer recently told a story about a time when one of his wagons detached from one of his tractors: “It’s common practice to pull gravity wagons in tandem, one connected to the other,” the farmer said. “The tractor operator had just dropped off a load of corn at the elevator and was headed back to the field to get reloaded. This trip involved travel on a gravel road and, as we all know, gravel roads tend to be bumpy. “Somehow or another the pin attaching the second wagon to the first one fell out, and the second wagon went off the road into a field.

Apparently, the driver was not paying close enough attention, because he didn’t realize that he lost the wagon until he got back to the field. “Luckily, the wagon was empty and this mishap didn’t cause any damage. If the empty wagon had hit a car or utility pole it would have damaged them. But if the wagon would have been full of corn not only would you have the mess to clean up if it had tipped over, it would have been much worse to the utility pole or catastrophic to the driver of the car. Lucky for us, it didn’t cause any damage, and we found the wagon sitting in a field like it had been parked there. “After the incident, I learned that the hitch pin on the wagon was not checked for a safety pin before it was put in transport. The standard protocol should be: before you ever pull any wagons, check the condition of all the hitch pins and safety pins and be sure they are all in the correct place.”

As it turns out, what might have happened never did. Luck was on the grower’s side in this example. But for others, their luck (and the luck of people in other vehicles) ran out when their trailers or wagons came loose and crushed another vehicle.

This publication examines the factors that play critical roles in keeping implements or wagons connected to farm tractors and allow operators to maintain control of their implements and loads. Understanding how these factors work together will reduce the likelihood that a trailer may become detached during transport on busy roads or highways. This publication also is a companion to Keep the Trailer Connected to the Truck: Understanding the “Hitch” System (Purdue Extension publication PPP-92 — available from the Education Store, www.the-education-store.com).

This collision occurred when a 30-horsepower, 3,000-pound tractor tried (and failed) to pull an 8,000-pound trailer up a hill on a gravel road. The tractor lost traction and started hopping. Then, the hitch pin worked its way out and the tank took off. Luckily, the police car stopped the trailer or it would have crashed into a tent that was serving breakfast to several hundred people.

Some trailer mishaps are unavoidable — a vehicle could blow a tire after running over debris on the road, or equipment (such a weld or leaf spring) could fail. These types of incidents can happen even to those who are serious about highway safety and conscientious about what they pull on the road.

Sadly, many more trailer mishaps are attributed to human error, which means the problem could have been anticipated and avoided. Human error includes drivers who do not understand (or care to understand) what it takes to safely attach an implement’s trailer to a tractor or truck. Unfortunately, serious and avoidable incidents can result from negligent drivers who knew what to do, but failed to put in practice what they had been taught. Negligence does not excuse you from responsibility.

A loaded wagon or implement that comes loose from a tractor can cause serious injury to people, the environment, and equipment.

A negligent driver can be found at fault civilly and possibly criminally if the wagons or implements that he or she was pulling happen to injure or kill someone. And by default, the owner of the farm or business whose tractor was involved in the crash may also be brought into lawsuits and future settlements. But the reality is that it doesn’t matter whether a crash was caused by an uninformed, careless, or negligent person. No excuses can make up for people who are seriously hurt or killed when a detached implement or wagon collides with another vehicle or bystanders. Excuses cannot replace a life or soothe the pain and suffering of a victim who may face years of physical therapy, or the families who lost a loved one.

A runaway implement may not only result in damage and injuries, it can create environmental problems, too. Consider the load you are towing and what might happen if it spilled or collided with a car, a body of water, animals, or people.

The Tractor and the Hitch Pin

Whether on a farm, in a commercial garden center, at a greenhouse, or in a plant nursery, hitch pins provide the connections that keep wagons and implements attached to tractors traveling on public roads.

A typical farm or commercial business may have several implements that are pulled behind trucks or tractors on a daily basis. Each item is unique and requires operators to pay special attention to how it is attached to the truck or tractor before they drive on a public road.

A user often selects a hitch pin based on its diameter and length. The hitch pin has to be small enough to fit through the tongue of the trailer and the drawbar of the tractor, plus it has to be long enough to allow a keeper to be inserted. If diameter, length, and a keeper were the only things to consider, then making this critical connection would be straightforward and simple.

There is a lot riding on the correct grade of hitch pin that links the trailer to the tractor or truck.

In reality, the most important consideration when selecting a hitch pin is whether the hitch pin will be strong enough so that it does not bend or break when pulling a wagon or implement down the highway. When a heavily loaded wagon hits a deep pothole in the road, makes a sudden turn or stop, crosses rough railroad tracks, or drops its tires off the pavement, these things place tremendous physical stress on a hitch pin. If a hitch pin breaks because it was not correctly sized or fitted, the implement or wagon will head down the road on its own — not exactly a sight one wants to see.

Describing Hitch Pin Strength

The forces that a hitch pan can withstand are related to its design and size and can be measured by its tensile strength, yield strength, shear strength, and ductility.

The welded caps of the hitch pin sheared under pressure.

Tensile strength is measured by pulling the ends of a pin in opposite directions to see how much force it can take until it breaks or fractures. Tensile strength is typically presented as pounds per square inch. Yield strength measures the minimum load it takes to produce a permanent deformation (such as stretching or “necking”) to the hitch pin or bolt. Yield strength is typically presented as pounds per square inch.

Ductility measures how much a material can “bend” before it breaks. Ductile materials will bend before they break. Metals with low ductility are usually referred to as brittle. Metals that have been bent or distorted can exhaust the available ductility and become brittle from being bent or straightened. Ductility is typically presented as a percent. Shear strength measures how much force a material can withstand before it breaks. While tensile and yield strength are important, shear stress on a hitch pin or bolt is more important in real-world transportation applications. Shear stress is a slicing action across the surface of a pin perpendicular to the axis of the pin.

A hitch pin can experience shear stress across its entire length and at different angles depending how the wagon, implement, or trailer is sitting relative to the towing vehicle. The wagon or implement tongue can move forward and backward and even side-to-side.

On one side of the hitch pin the tractor’s drawbar pulls against it toward the tractor. On the other side of the pin, the trailer pulls against the shaft of the pin. With enough pressure, the hitch pin can bend or break.

A pin can be pulled at odd angles across many different planes. Under pressure, the 3/4-inch hitch pin failed because it was too small in diameter and too soft in grade. Evidence of shear and tension both can be seen on the pin.

Shear strength is typically presented as pounds per square inch. Like, bolts, hitch pins are graded. A hitch pin’s or bolt’s shear strength is determined by its grade and diameter. Strength values for hitch pins are assumed to be equivalent to bolts of equal size and grade.

This 1 1/8-inch hitch pin made from a bolt shows deformation across the face of the bolt.

This 1 1/8-inch hitch pin made from a bolt shows deformation across the face of the bolt.  A 1-inch pin that has been used to tow a heavy load shows damage to the metal.

A 1-inch pin that has been used to tow a heavy load shows damage to the metal.

Hitch pins can experience serious stress as the metal continually works against the metal in the drawbar. The bending and unbending associated with different positions may eventually form notches that can lead to failure or exhaust the pin’s ductility, leaving it more susceptible to failure.

Hitch pins can experience serious stress as the metal continually works against the metal in the drawbar. The bending and unbending associated with different positions may eventually form notches that can lead to failure or exhaust the pin’s ductility, leaving it more susceptible to failure.

A pin that has broken under tension. The lighter gray region of the fracture indicates that the final facture was relatively brittle.

A pin that has broken under tension. The lighter gray region of the fracture indicates that the final facture was relatively brittle.

Engineers calculate shear strength using a formula based on the maximum-distortion-energy theory:

Shear strength = (Yield Strength x 0.58) x (3.14 x radius2).

The percentage of the yield strength is multiplied by the cross-sectional area of the hitch pin. Others, such as the Industrial Fastener Institute, use the same formula, substituting tensile strength for yield strength and 0.60 for 0.58.

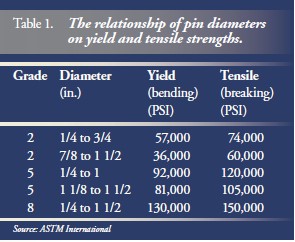

Table 2 provides the relationship between the grades and diameters of hitch pins and shear strength (following the Industrial Fastener Institute method). The table assumes that hitch pin strength is equivalent to

that of threaded fasteners of the same dimension and grade.

The hitch pin becomes more susceptible to fracture as notches on its surface get deeper.

The hitch pin becomes more susceptible to fracture as notches on its surface get deeper.  This brand new hitch pin with the label still attached broke within the first 15 minutes of its first use. Either the pin’s quality was inferior or it was rated less than the load it was pulling.

This brand new hitch pin with the label still attached broke within the first 15 minutes of its first use. Either the pin’s quality was inferior or it was rated less than the load it was pulling.

Hitch pins are often marked with important information.

Hitch pins are often marked with important information.  Hitch pins are often marked with grade 8 pin.

Hitch pins are often marked with grade 8 pin. In Table 2, note how much stronger grade 5 pins are than grade 2 pins. The larger the cross sectional area, the more force the pin or bolt can withstand. While a grade 8 pin has a greater shear value than a grade 5 pin, the increase is not as dramatic as going from a grade 2 to a grade 5.

It’s also apparent that bolts with diameters of 1/2 inch or larger have more shear strength across the grades due to greater cross-sectional area. In most cases, the connections between tractors and the trailers or the implements they pull create a double shear situation. The pin fits within three different plates. That helps, because instead of the pin experiencing force in just one plane, the force is spread across two planes, which helps to spread the force over a larger area.

One could select a hitch pin based on its double shear rating. However, with wear and tear on the hitch pin, this publication will use the single shear ratings as a means of providing extra protection when pulling implements on the highway. This margin of safety is useful because it helps account for unforeseen stresses on hitch pins that science cannot currently predict.

There was a full load of wet, moldy corn on this 275-bushel gravity wagon when it broke.

There was a full load of wet, moldy corn on this 275-bushel gravity wagon when it broke.  The only thing that held the wagon to the tractor was the keeper.

The only thing that held the wagon to the tractor was the keeper.  This shows why we use single shear ratings for the pins and bolts.

This shows why we use single shear ratings for the pins and bolts.  What started out as a double shear scenario became a single shear scenario when the wagon tongue broke.

What started out as a double shear scenario became a single shear scenario when the wagon tongue broke. Understanding the Forces at Work

It is not uncommon to see a tractor pulling a 1,500-bushel grain cart. The “dead” or stationary weight of the grain cart and its load is about 100,000 pounds that the tractor will have to put in motion in the field or on the highway. Once the tractor has the grain cart moving, it will not take 100,000 pounds of force to keep it moving down the road. But, what if the tractor has to make a sudden stop or has to swerve suddenly to miss an object in the road?

Would you trust your welding skills to hold this sprayer together? Using homemade pins and welding your own is risky when you consider the low cost of a manufactured hitch pin.

Would you trust your welding skills to hold this sprayer together? Using homemade pins and welding your own is risky when you consider the low cost of a manufactured hitch pin. As the grain cart surges forward, it exerts tremendous pressure on the pin. The pin can experience 100,000 pounds of force. This is why it is important to select a pin based on the load you will pull. In the event of such an extreme deceleration, a hitch pin will need to withstand those incredible forces without breaking. This is why you should never use homemade hitch pins because they have not been tested for strength and wear.

Using homemade pins can be very dangerous. One concern of such pins is whether the welds will hold under extreme stress. While you may be able to make a pin that shows off your blacksmithing skills, it’s important to remember that heating metal may reduce its strength. While there seem to be countless homemade designs, the one thing they all have in common is that you can never know how they will stand up to high stress until the moment of impact. You might be lucky and the pin will hold tight, or your implement might separate from the tractor.

With manufactured pins, each grade of steel is processed under carefully chosen conditions that optimize strength and ductility. Reworking these components with uncontrolled combinations of mechanical working, heating, and cooling, can produce parts that bend too readily or worse, break without bending.

Homemade pins may work, but will they stay intact and in place?

Homemade pins may work, but will they stay intact and in place?

It is a common practice to use bolts as hitch pins. The bolt above has bent — purchase grade 8 bolts in all cases. This bolt has small head and no place for a keeper pin.

It is a common practice to use bolts as hitch pins. The bolt above has bent — purchase grade 8 bolts in all cases. This bolt has small head and no place for a keeper pin.  The operator drilled keeper holes into these bolts.

The operator drilled keeper holes into these bolts.  A larger washer holds the pin in place. The only thing holding the pin is a washer. If the washer fails, then the entire pin would fall out.

A larger washer holds the pin in place. The only thing holding the pin is a washer. If the washer fails, then the entire pin would fall out.

The threads can act as notches or stress concentrations that magnify the local stresses by three to ten times what is experienced in the smooth portions.

The threads can act as notches or stress concentrations that magnify the local stresses by three to ten times what is experienced in the smooth portions.  There are a number of novel devices that allow the tractor and wagon to be connected and disconnected without the driver having to leave the cab. Give these substitutes the same considerations for strength and size that you

would for pins.

There are a number of novel devices that allow the tractor and wagon to be connected and disconnected without the driver having to leave the cab. Give these substitutes the same considerations for strength and size that you

would for pins.

Matching the Right Hitch Pin for the Load

In many cases, the hitch pin you use is the one that’s at hand. You find a pin that’s close to the right size, drop it in, attach the keeper, and then move the load. But that approach can lead to loss of load and control. After a separation, we often say that a hitch failed. But it was not the hitch that failed, it was the connection. Selecting the right hitch pin is not complicated, but it does require doing a little homework about the pin’s diameter, length, and especially its grade.

Choose the Right Diameter

Hitch pins need to fit as tightly as possible. If a pin’s diameter is the same size as the clevis it is inserted into, then you’ll need a hammer to force it through the opening and it will be nearly impossible to remove it. The bottom line is to use a pin that can be easily inserted and taken out, but not so loose that the wagon tongue and the tractor’s drawbar beats back and forth on the hitch pin. For these reasons, it is a good practice to select a hitch pin that is one size smaller than the clevis or tongue of the tractor and wagon, trailer, or implement.

Burning a hole in the drawbar to make a pin fit weakens the drawbar. Allowing the metal to cool rapidly may also cause small fractures, so inspect it often afterwards.

Burning a hole in the drawbar to make a pin fit weakens the drawbar. Allowing the metal to cool rapidly may also cause small fractures, so inspect it often afterwards.  You can readily see this pin is too small and how, over time, the bottom of the tongue is wearing. In addition, the pin is too short, which will not allow a keeper to be easily inserted.

You can readily see this pin is too small and how, over time, the bottom of the tongue is wearing. In addition, the pin is too short, which will not allow a keeper to be easily inserted.

Select the Right Length

Measure the usable length of a hitch pin from the head of the bolt to the hole on the shaft where you insert the keeper. The hitch pin needs to be long enough so you can easily insert a keeper into the hole. Having a little space between the keeper and the clevis allows the pin to move up and down without jamming the keeper up against the tongue of the tractor or trailer, which could shear or break the keeper. A pin can also be too long. If a tractor and towed unit hit a bump that drives the connection low to the ground, it can bend a pin that is too long. You should always replace bent pins.

Select the Right Grade

Select the grade of a hitch pin based on the weight of the trailer and the load the tractor or truck will tow. The pin’s shear strength must be at least as much as the towed weight. Assume you’re pulling a 275-bushel wagon with a 1-inch clevis behind a tractor. The gross weight of the fully loaded wagon is between 18,000 and 20,000 pounds. You are using a 7/8-inch pin (one size smaller than the 1-inch clevis). If you use the conservative single shear values in Table 2, a grade 2, 7/8-inch pin would be strong enough to pull the fully loaded wagon behind a tractor.

If you have a loaded grain cart that holds 850 bushels and weighs about 58,000 pounds, what grade of 1-inch pin would you need to hold the fully loaded wagon to the tractor? You would need a grade 8 hitch pin. Is there any difference if a tractor pulls two grain wagons in tandem? Assume each fully loaded tandem wagon weighs approximately 30,000 pounds. What grade of a 1-inch hitch pin would you need to safely transport the two wagons on a highway? The second wagon that trails the first needs a pin that can accommodate 30,000 pounds. A grade 2 would almost work, but the breaking point is close to what you’re hauling. So, a grade 5 pin would be a better choice, since the single and double shear strengths are in excess of the 30,000-pound wagon.

The hitch pin that connects the tractor to the first wagon needs a shear strength that can tow 60,000 pounds — that is, both of the fully loaded wagons. Under this heavier load, the front hitch needs a grade 8 hitch pin based (once again) on a single shear (Table 2).

When determining shear strength, consider both the weight of the load and weight of the wagon.

When determining shear strength, consider both the weight of the load and weight of the wagon.

Keeping Track of the Grade Is Difficult

Going to the store and reaching into a bin of pins marked only with their usable lengths and diameters becomes a risky purchase. Unlike the markings on the head of a bolt that indicate its grade, there are no markings stamped on a hitch pin, so it is impossible to tell the grade of the pin by its appearance, weight, or color. Unless the grade is specifically indicated, always assume that the pin you are paying for is a grade 2. Ask your retailer if they offer other grades of hitch pins.

The labels on new hitch pins may include important information, including its grade (circled).

Even if the tag attached to a pin is marked, things become more complicated after the hitch pin is put in service. It won’t take long before the plastic or paper tag wears. If you store dozens of pins of different diameters and lengths all mixed together in a bin, their grades quickly become unknown and it will be nearly impossible to match the right pin with the load. And as we’ve already seen, the consequences of using the wrong grade of pin under heavy loads is significant and, at times, serious.

Potential solutions for keeping track of hitch pin grades and sizes include:

• Buy only grade 8 pins. This can be the most practical solution because the grades are all the same and you only buy the different lengths and diameters to cover your needs. If you follow this plan, first discard any existing pins you have.

• Keep grade 8 pins in a toolbox separate from other pins. You might even spray paint them to distinguish grade 8 pins from others.

• Buy the correct size and grade of pin for the heaviest loads each implement will pull and attach the pin to that implement.

• Put a chain or tag on a pin and attach it to the implement. Take a small chain and attach the pin to a wagon tongue.

When equipment matches, it may be possible to keep track of high-quality pins even if the information tag has disappeared. A chain is fastened to the hitch pin and the implement and attached to a tractor or truck.

When equipment matches, it may be possible to keep track of high-quality pins even if the information tag has disappeared. A chain is fastened to the hitch pin and the implement and attached to a tractor or truck.

Some growers have expressed concern that placing rubber covers over hitch pins does not allow visual inspection of the pins.

Some growers have expressed concern that placing rubber covers over hitch pins does not allow visual inspection of the pins.

A Bent Pin Is a Victory

When a pin bends but doesn’t break, it means you are living a charmed life. If the pin had experienced just a little more force, the trailer, wagon, or implement could have been on its own.

If you see a bent pin, then you definitely must switch to using higher grades of hitch pins before you use that tractor and implement combination again. Don’t push your luck; see the bent pin as an early warning that you need something stronger!

The Hitch Pin Keeper

Note the lack of keepers in these pins

Note the lack of keepers in these pins  The pin under most circumstances will work, but corn stubble or a large bump in the road can push the pin out when working over a field or moving down the highway.

The pin under most circumstances will work, but corn stubble or a large bump in the road can push the pin out when working over a field or moving down the highway.

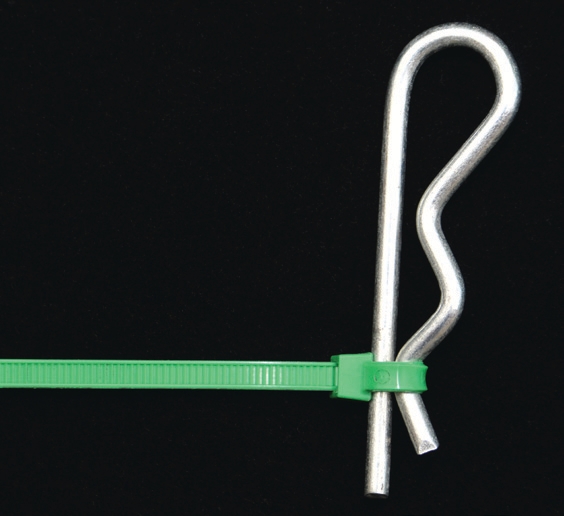

Using a wire or a field flag as a keeper is not a good idea.

Using a wire or a field flag as a keeper is not a good idea.  Some growers insert hitch pins from the bottom side up with the keeper on top of the tongue as another method of helping to retain the keeper pin. A washer that fits the hitch pin is used to take some of the stress off the keeper. This is a bad idea, because if the keeper fails for any reason, the hitch will disconnect.

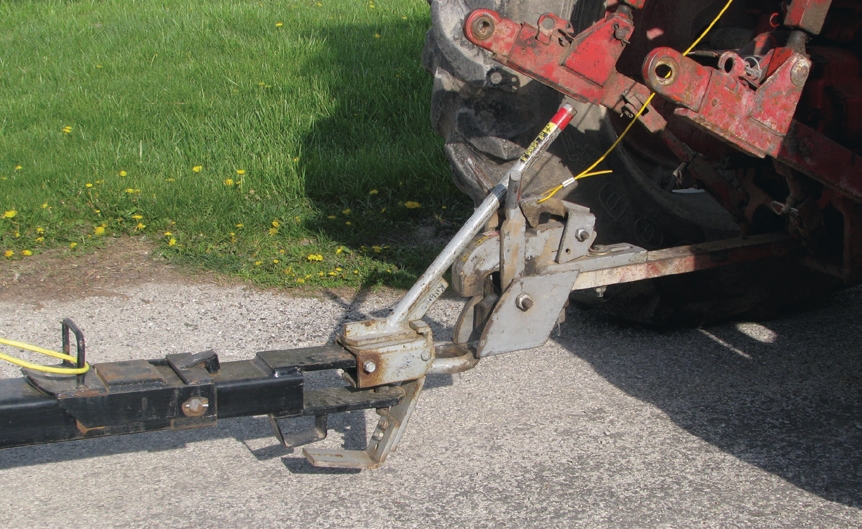

Some growers insert hitch pins from the bottom side up with the keeper on top of the tongue as another method of helping to retain the keeper pin. A washer that fits the hitch pin is used to take some of the stress off the keeper. This is a bad idea, because if the keeper fails for any reason, the hitch will disconnect.  The clip is attached to the hitch pin, which allows the pin to be reinserted if it is pulled out.

The clip is attached to the hitch pin, which allows the pin to be reinserted if it is pulled out.  Attaching locks to hitch pins

Attaching locks to hitch pins  Other examples pertaining to the keeper include using locking pins

Other examples pertaining to the keeper include using locking pins  A zip tie is an easy way to keep the keeper in place

A zip tie is an easy way to keep the keeper in place  A more robust clip in a hitch pin that has less chance to fail.

A more robust clip in a hitch pin that has less chance to fail.  A cotter pin can be bent into the hitch pin opening when the tractor and wagon will be hooked for longer periods of time. However, this cotter pin is softer than this safety clip and would fail sooner

A cotter pin can be bent into the hitch pin opening when the tractor and wagon will be hooked for longer periods of time. However, this cotter pin is softer than this safety clip and would fail sooner The keeper prevents the pin from popping out of the hitch. While there are many different kinds of keepers, their importance is critical for safe trailer operation.

Consider the following story that illustrates how this relatively simple mechanism plays an important role in safe transportation. “I had an incident when I was hauling two empty grain wagons back to the field down a county road. I didn’t bother to check that the keepers were in place.

“Driving down the road at 25 miles an hour, I looked in the rearview mirror and saw that the rear wagon had detached and was heading toward the ditch. It crossed the opposite lane of traffic. Fortunately, no one was coming the other way. It made me think of what could have happened. Now I always check to make sure the keeper is in place.”

Imagine how different things would have been if others were traveling on the same road at the same time. And that’s why you should always secure hitch pins with appropriate keepers. Of course, this is easier said than done.

There are no grades assigned to keepers because there is little force placed against them. So you should select keepers that look sturdy enough for the job at hand. Install the keeper so it is as far away from the bottom tongue as practically possible. This will prevent the keeper from banging against the metal in the event the pin is forced up. Before you pull any load, check to see that the keeper is in place.

It would be very difficult to put a keeper in this pin because it is too short for this operation.

It would be very difficult to put a keeper in this pin because it is too short for this operation.  The hitch pin is the first defense against highway mishaps. The outcome of a crash that releases anhydrous ammonia or pesticides can lead to years of litigation.

The hitch pin is the first defense against highway mishaps. The outcome of a crash that releases anhydrous ammonia or pesticides can lead to years of litigation.

Today’s heavier and wider equipment means that hitch pins need to be stronger. Whenever an implement becomes detached from the tractor or truck, people can be seriously injured if the implement collides with oncoming or trailing passenger vehicles.

Today’s heavier and wider equipment means that hitch pins need to be stronger. Whenever an implement becomes detached from the tractor or truck, people can be seriously injured if the implement collides with oncoming or trailing passenger vehicles.

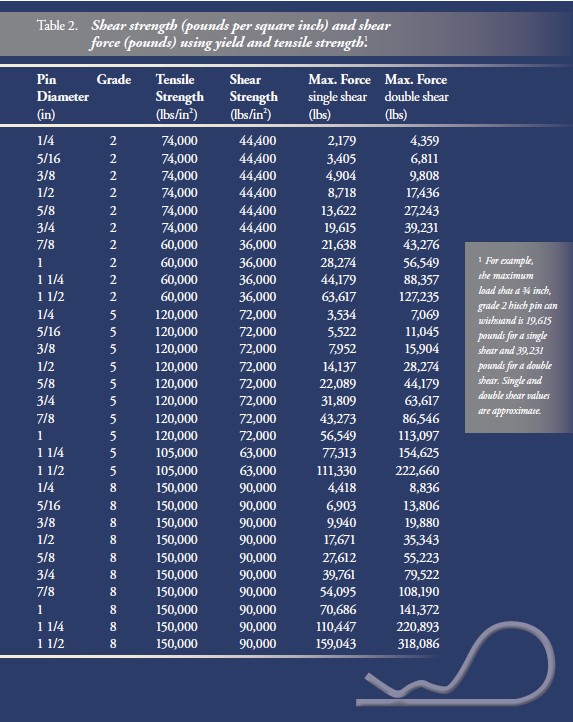

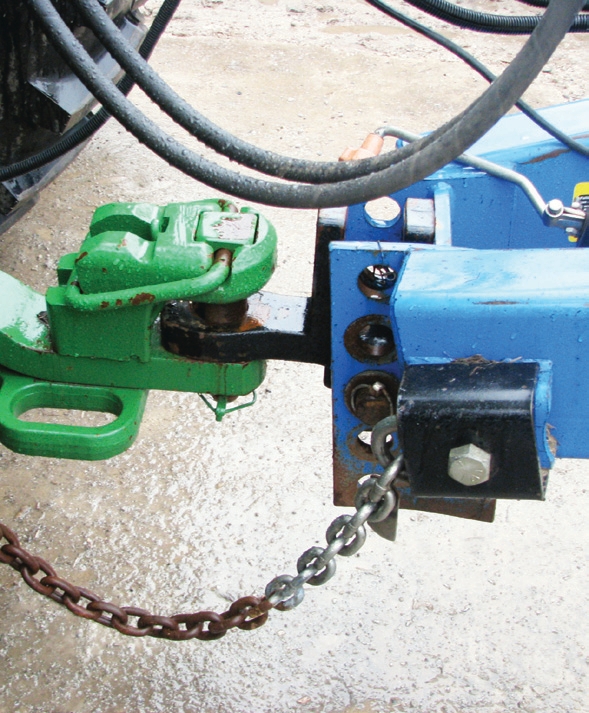

These photos show a pintle hook with a properly sized hitch pin and that is well secured with safety chains. A drawbar and hammer strap hitch pin system will drop the pin automatically when backing up to an implement.

These photos show a pintle hook with a properly sized hitch pin and that is well secured with safety chains. A drawbar and hammer strap hitch pin system will drop the pin automatically when backing up to an implement.  The pins fit very snugly in the drawbar hammer strap and operators often overlook this pin. In most cases, it is not even with the tractor.

The pins fit very snugly in the drawbar hammer strap and operators often overlook this pin. In most cases, it is not even with the tractor.

While we have focused on tractors, trucks also have inserts that use hitch pins to pull trailers, wagons, and other agricultural implements. The same information we’ve used to discuss tractors applies to trucks. See Keep the Trailer Connected to the Truck: Understanding the “Hitch” System (Purdue Extension publication PPP-92) available from the Education Store (www.the-education-store.com).

While we have focused on tractors, trucks also have inserts that use hitch pins to pull trailers, wagons, and other agricultural implements. The same information we’ve used to discuss tractors applies to trucks. See Keep the Trailer Connected to the Truck: Understanding the “Hitch” System (Purdue Extension publication PPP-92) available from the Education Store (www.the-education-store.com).  Follow warnings on implements about towing with tractors only. With heavier implements and trailers, trucks do not have the bulk or breaking power to stop quickly enough in case of an emergency.

Follow warnings on implements about towing with tractors only. With heavier implements and trailers, trucks do not have the bulk or breaking power to stop quickly enough in case of an emergency.  This truck hitch has a hitch pin that does not have a keeper. One good bump and the pin would bounce out on the highway, which could collide with oncoming traffic.

This truck hitch has a hitch pin that does not have a keeper. One good bump and the pin would bounce out on the highway, which could collide with oncoming traffic. Safety Chains as a Backup Attachment

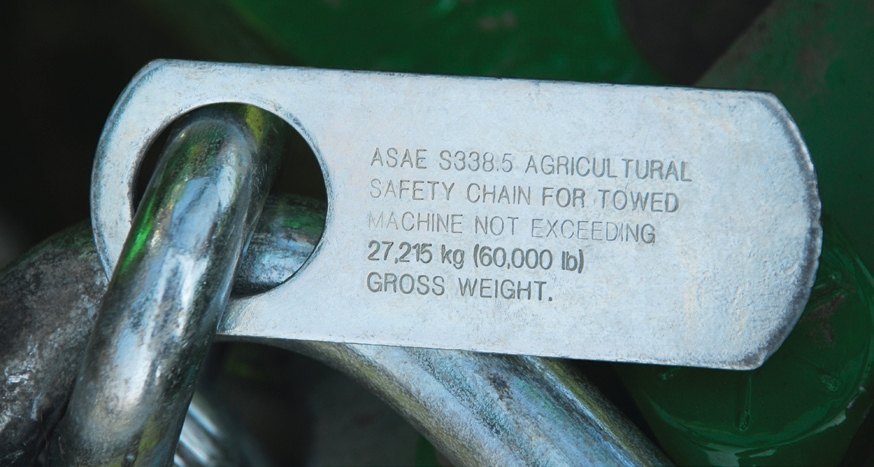

Safety chains are backup measures that can keep a trailer attached to a truck or tractor if the hitch system fails. But like hitch pins, you need to install safety chains correctly. Safety chains, in some cases, are just as important as the hitch or hitch pin. Without a properly attached safety chain, a detached wagon or implement can skid into an oncoming vehicle when a pin shears or comes out. Use a suitable size and grade of safety chain to keep the towed and towing vehicles together long enough for the operator to pull onto the shoulder of the road. Unfortunately, some safety chains are not strong enough.

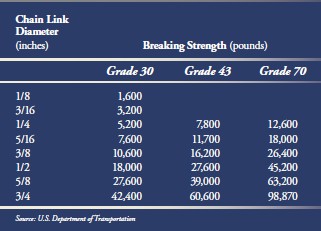

Breaking Strength

Safety chains must be able to withstand the sudden jerk that occurs when a trailer falls away from a towing unit. That jerk places tremendous tensile and shear stress on chains, hooks, and attachment points such as bolts or welds. You need to make sure that the safety chain you use is strong enough to withstand the initial shock without snapping a link, breaking a hook, or shearing a bolt. Chain manufacturers assign breaking strengths to chains based on specific diameters and grades. Table 3 provides the breaking strength of safety chains based on grade and diameter.

Implement and tractor drawbars do fail. One way to prevent catastrophic consequences is to attach safety chains in the event of an unlikely drawbar failure.

Some manufacturers attach diagrams to their implements that describe how to best attach safety chains.

Some manufacturers attach diagrams to their implements that describe how to best attach safety chains.  If a primary hitch pin breaks or falls out, there should be a sufficiently strong transport safety chain that will keep the tractor and trailer or implement connected long enough to allow the operator to pull over.

If a primary hitch pin breaks or falls out, there should be a sufficiently strong transport safety chain that will keep the tractor and trailer or implement connected long enough to allow the operator to pull over.  Table 3. Breaking strengths of chains based on grade and diameter.

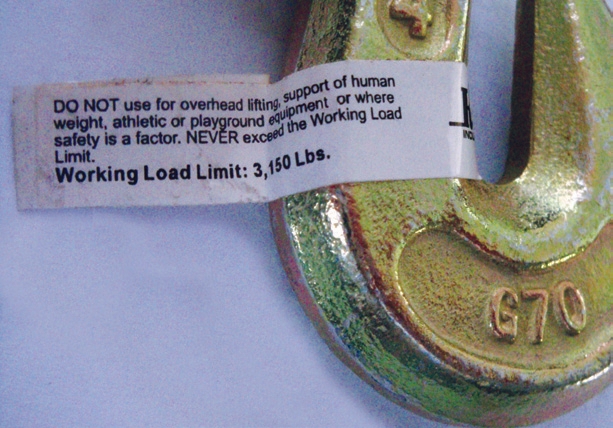

Table 3. Breaking strengths of chains based on grade and diameter.  The higher the grade and larger the diameter of the chain, the greater the breaking strength of individual links. Not all chains have grade markings on them. The chain in the lower left is a grade 70.

The higher the grade and larger the diameter of the chain, the greater the breaking strength of individual links. Not all chains have grade markings on them. The chain in the lower left is a grade 70.

At a minimum, a chain’s breaking strength must be equal to the weight of the trailer and load the tractor or truck is hauling. If you use more than one chain, add the breaking strengths of both chains to calculate this value. However, experienced mechanics suggest a higher standard. They say that a single chain should be strong enough to carry the trailer and load. This is an inexpensive way to improve your safety when towing a trailer.

Remember that states often have guidelines about the number and strength of safety chains required for trailers or implements. Always follow your state’s rules as a minimum. Large farm implements often come with safety chains permanently fastened to them, which indicate that the towed implement should not exceed a specific gross weight. Be aware that if you alter your equipment, you may need to upgrade the safety chains.

The Concept of the Weakest Link

The safety chain’s grade and diameter aren’t the only important considerations. All chain components (hooks, latches, repair links) need to have the same or higher grade than the chain itself.

If this grade 43 hook were put on a grade 70 chain, then the breaking strength would be calculated by the hook’s assigned value based on a 3/8-inch hook.

If this grade 43 hook were put on a grade 70 chain, then the breaking strength would be calculated by the hook’s assigned value based on a 3/8-inch hook.

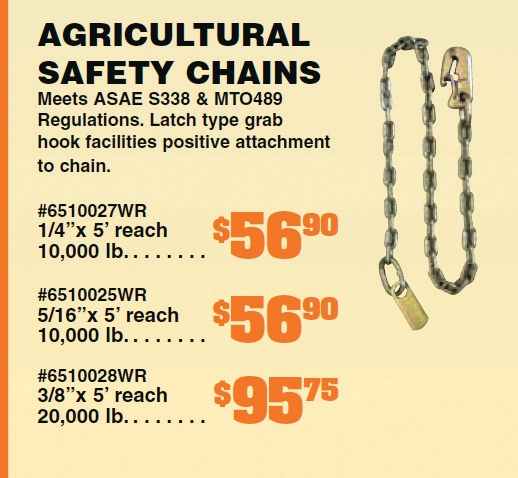

This advertisement provides an important lesson about chain attachments. It says that the breaking strength of the ¼-inch and 5/16-inch 5-foot chain is 10,000 pounds. Normally, the larger diameter chain has a greater breaking strength. In this example, the grab hooks on the 5/16-inch” chain must have a breaking strength less than that of the chain. (Photo used with permission.)

This advertisement provides an important lesson about chain attachments. It says that the breaking strength of the ¼-inch and 5/16-inch 5-foot chain is 10,000 pounds. Normally, the larger diameter chain has a greater breaking strength. In this example, the grab hooks on the 5/16-inch” chain must have a breaking strength less than that of the chain. (Photo used with permission.) Chain Length

Safety chains need to be long enough to allow normal pivoting between the truck and trailer on wide turns. If they are too short, safety chains can be ripped from a trailer. But safety chains shouldn’t be so long that they drag across the pavement and get worn quickly.

Make sure safety chains hang about halfway between the ground and the equipment hitch. If you have chains that are too long, use an intermediate support. Do not shorten a chain by twisting it. Most manufacturers specifically warn against twisting chains. That’s because a chain’s breaking rating is determined in a straight-

line pull. When you twist a chain, you place additional stresses on it that can alter how it breaks — in effect, you’ve changed its breaking strength.

A proper use of the intermediate support, which keeps the chain from dragging.

A proper use of the intermediate support, which keeps the chain from dragging.  This chain is properly hooked, but needs to have the slack adjusted. One way to do this is to wrap the chain around the drawbar support.

This chain is properly hooked, but needs to have the slack adjusted. One way to do this is to wrap the chain around the drawbar support. Connecting the Chain to the Tractor

Attach safety chains to the loops designed for that purpose. When it comes to tractors, safety chains should always be hooked to a structural member, not the drawbar. When you use two chains, cross them so they will support the hitch. Hooking chains to a weak part of the tractor will only allow the weaker part to break first, and the chain will not engage during an emergency separation.

An improperly attached hook cancels out everything else that was done to keep the equipment attached to the tractor. Also notice that the intermediate support is being used improperly as part of the attachment point. Most tractor manuals give clear instructions about the use of intermediate support brackets.

An improperly attached hook cancels out everything else that was done to keep the equipment attached to the tractor. Also notice that the intermediate support is being used improperly as part of the attachment point. Most tractor manuals give clear instructions about the use of intermediate support brackets.  Using two chains is always a better choice to ensure an implement or wagon will stay attached to the tractor in the event the hitch pin fails.

Using two chains is always a better choice to ensure an implement or wagon will stay attached to the tractor in the event the hitch pin fails.  Some growers suggest that it is better to have a chain hooked to the right side of the tractor than the left side. Their idea is that if the hitch pin fails, an implement attached to the right side of the tractor will be pulled toward the shoulder rather than into the opposite lane. The chain attached to the implement is attached to a chain that is looped in the center, which would give more stability in the event of a detachment.

Some growers suggest that it is better to have a chain hooked to the right side of the tractor than the left side. Their idea is that if the hitch pin fails, an implement attached to the right side of the tractor will be pulled toward the shoulder rather than into the opposite lane. The chain attached to the implement is attached to a chain that is looped in the center, which would give more stability in the event of a detachment.  Some growers suggest that it is better to have a chain hooked to the right side of the tractor than the left side.

Some growers suggest that it is better to have a chain hooked to the right side of the tractor than the left side.  Using two chains is always a better choice to ensure an implement or wagon will stay attached to the tractor in the event the hitch pin fails.

Using two chains is always a better choice to ensure an implement or wagon will stay attached to the tractor in the event the hitch pin fails.  Many hooks have spring-loaded latches for a more permanent attachment. Make sure that the spring-loaded latch can completely close or it becomes ineffective.

Many hooks have spring-loaded latches for a more permanent attachment. Make sure that the spring-loaded latch can completely close or it becomes ineffective.  This photo shows multiple pieces of equipment attached together. A safety chain is attached from an anhydrous applicator to the wagon. The applicator’s design has an area to capture the link of the chain to make it easier to hook up the safety chain.

This photo shows multiple pieces of equipment attached together. A safety chain is attached from an anhydrous applicator to the wagon. The applicator’s design has an area to capture the link of the chain to make it easier to hook up the safety chain.  Connecting the second wagon to the first wagon needs some consideration. Is the hitch with the first wagon equipped to deal with the weight it will pull? The answer depends on how well the attachment point is welded to the main frame of the wagon. This is why safety chains become an important means of keeping the two units attached in the event the hitch or frame fails.

Connecting the second wagon to the first wagon needs some consideration. Is the hitch with the first wagon equipped to deal with the weight it will pull? The answer depends on how well the attachment point is welded to the main frame of the wagon. This is why safety chains become an important means of keeping the two units attached in the event the hitch or frame fails.

Risk is greater when a tractor pulls multiple implements and trailers. One important question to ask is whether the frame and attachment point of the implement in front of the anhydrous ammonia tank is strong enough to pull the wagon. A mistake here can be costly if the anhydrous tank pulls away from the tractor and ruptures during transport.

Risk is greater when a tractor pulls multiple implements and trailers. One important question to ask is whether the frame and attachment point of the implement in front of the anhydrous ammonia tank is strong enough to pull the wagon. A mistake here can be costly if the anhydrous tank pulls away from the tractor and ruptures during transport.  Why should you consider the weights being pulled? As one agricultural retailer manager indicated, “The gentleman that was using the toolbar actually saw the problem before it broke off completely. It could have turned out much worse if he had not caught it.”

Why should you consider the weights being pulled? As one agricultural retailer manager indicated, “The gentleman that was using the toolbar actually saw the problem before it broke off completely. It could have turned out much worse if he had not caught it.”  There are many cases when safety chains for the second wagon or implement cannot be attached to the first unit. While welding is not generally recommended unless performed by a certified welder, in this case it might be better than nothing. For instance, the picture illustrates that the trailer has a welded handle and the hooks can be attached when not in use.

There are many cases when safety chains for the second wagon or implement cannot be attached to the first unit. While welding is not generally recommended unless performed by a certified welder, in this case it might be better than nothing. For instance, the picture illustrates that the trailer has a welded handle and the hooks can be attached when not in use.  The welded frames on the front trailer allow a place to attach the safety chains from the trailing unit.

The welded frames on the front trailer allow a place to attach the safety chains from the trailing unit. Repairing a Safety Chain Assembly

Knowledgeable people argue whether it’s a good idea to repair a safety chain. Some view putting a repaired safety chain back into service as a risky liability. To them, it’s just as simple to unbolt the old one and put a new one on for peace of mind. Others disagree, believing that a properly repaired safety chain is just as good as a new one. But even they agree that their reasoning is based on the assumption that the connectors they use to make any repair are rated for highway use and that they are of comparable or greater strength of the original chain.

Another common disagreement is whether one should ever weld a safety chain to a trailer. If you decide to weld any safety chains, a general rule of thumb is that you should only allow certified welders to do the job. This is especially true when dealing with a hardened steel chain. If not heated and cooled correctly, the chain can be made brittle and have less strength. Certified welders know they have to take a second step to bring that piece of metal back into condition. A welder who is uncertified may unknowingly damage the chain’s

integrity and tensile strength.

Bringing metal back into condition is less of a concern with grade 30 and 43 proof coil chains. In any case, make sure that the grade is stamped on the chain links and on any attachments. If not, then you should treat the grade of the chain and its attachments as 30 grade.

While easy to install, these repair links are not rated for road use.

While easy to install, these repair links are not rated for road use.

Safety Chain Bolts, Nuts, and Spacers

The bolts, nuts, and spacers that attach safety chains to trailer frames are some of the least appreciated attachment points. But it pays to give attention to these components. If a trailer comes loose, the bolts are going to experience tremendous pressure.

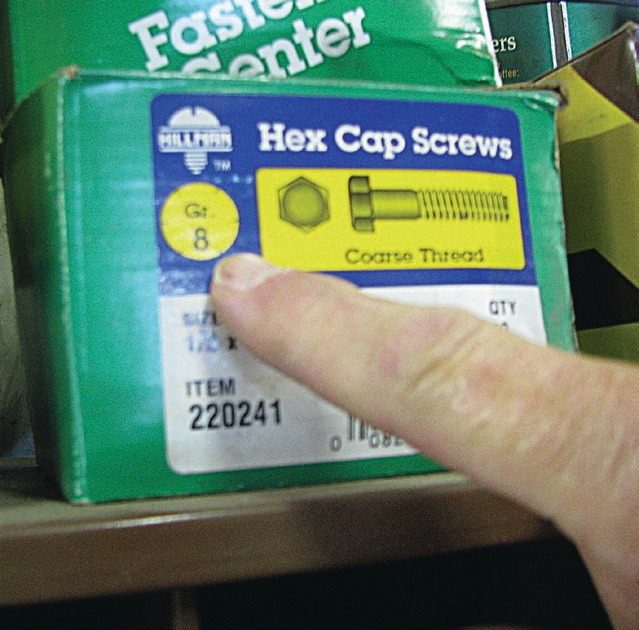

There is a recognized system of markings on bolt heads — the grades are 2, 5, or 8. A grade 5 bolt has three diagonal lines on the bolt head, a grade 8 has six, and a grade 2 is unmarked. Hitch pins do not have such markings stamped on them.

Make sure that the bolt you use has a grade that equals or exceeds the breaking strength of the chain and its components. You don’t want to be holding a 5,000-pound load with a safety chain that’s attached to the trailer with a grade 2 bolt. Protect yourself and invest in a grade 8 bolt and nut where a safety chain is bolted to a trailer’s frame. The bolt must be strong enough to withstand the shear force it will experience if the trailer detaches from the truck.

Nuts and washers are also graded, but they don’t have marks on them to distinguish one grade from another. Ask for grade 5 or grade 8 nuts and washers when you replace safety chains. Inspect and replace high-stress bolts frequently.

For more information about safety chains and trailer safety, see Keep the Trailer Connected to the Truck: Understanding the Hitch System (Purdue Extension publication PPP-92), available from the Education Store (www.the-education-store.com).

This grower has color-coded trays to organize his bolts and nuts: yellow for grade 8. Keeping washers and bolts of different grades separate is very important because they are not marked like the bolts.

This grower has color-coded trays to organize his bolts and nuts: yellow for grade 8. Keeping washers and bolts of different grades separate is very important because they are not marked like the bolts.  Larger pieces of equipment have chains attached to bolts. A sudden jerk of the chain will require that bolt to hold a tremendous stress.

Larger pieces of equipment have chains attached to bolts. A sudden jerk of the chain will require that bolt to hold a tremendous stress.

Mirrors

When towing an implement or trailer behind a tractor, it is important to see what’s going on behind you. Mirrors allow you to judge what evasive actions to take when highway traffic and emergency vehicles try to pass. By having and using mirrors, you might be able to avoid accidents or mishaps.

Using your mirrors allows you to glance back and observe how the units being towed are operating. If you see the wagons and trailers bouncing, you might have to slow down. Excessive movement stresses hitch pins, hitch clips, and safety chains. On rough roads (where trailers bounce up, down, and sideways), you should make certain the keeper holding the hitch pin in place is still present and that the safety chains are still attached.

Reflective Tape, Flashers, Slow Moving Signs, and Reflectors

Anything you can do to make your equipment more visible on highways, is not only smart, it is advisable. If your equipment is easier to see, it is less likely to be involved in a crash. This is especially true at dusk and dawn when it is difficult to see moving equipment on the road.

It’s always wise to place reflectors, flashers, and/or reflective tape on the extreme edges of machinery. In some cases, an escort with flashing lights may be appropriate.

When other drivers cannot easily see the widths and lengths of implements and wagons, bad things can happen.

When other drivers cannot easily see the widths and lengths of implements and wagons, bad things can happen.

Conclusion

What are the grades and conditions of the pins hanging in the shop, in the back of the truck and tractor, or under the workbench? Evaluate your pins because you have a lot riding on them — and so does everyone else.

Remember that connecting a trailer or implement to a tractor creates a “single” vehicle through a hitch pin and safety chains. If a trailer comes unhitched from a tractor on the highway, the results can be catastrophic: a spill can damage the environment, or worse, people can be injured or killed. Nobody wants to be that person whose trailer or implement slammed into a van carrying a family or that spilled pesticides or fertilizers into a pristine creek.

Take the time to connect your trailers properly. Otherwise, you might just experience that gruesome feeling when your implement or trailer comes loose at the moment a school bus is coming by.

Acknowledgments

Thanks to Dawn Minns for graphic design. Thanks to Ron Melancon for the photos on page 5, and to the York Daily Record for the two photos on page 9. Thanks also to those who offered constructive comments during the development of this publication:

Jim Beaty

Purdue University Agronomy Center for Research and Education

Don Biehle

Southeast-Purdue Agricultural Center

Jamie Bultemeier

John Deere

Todd Hinen

Northeast-Purdue Agricultural Center

Bob Klein

University of Nebraska

Shawn Lambert

Co-Alliance

Dennis Nowaskie

Southwest-Purdue Agricultural Center

Steve Queen

Trupointe Cooperative

Jason Tower

Southern Indiana Purdue Agricultural Center

Jake Trahan

Winfield Solutions

Terry West

Purdue University

Disclaimer

This publication is intended for educational purposes only. The authors’ views have not been approved by any government agency or business. The publication is distributed with the understanding that the authors are not engaged in rendering legal or other professional advice, and that the information contained herein should not be regarded or relied upon as a substitute for professional consultation. The use of information contained herein constitutes an agreement to hold the authors harmless for liability, damage, or expense incurred as a result of reference to or reliance upon the information provided. Mention of a proprietary product or service does not constitute an endorsement by the authors or their employers.

Find Out More

Purdue Pesticide Programs offer a number of publications on related topics to help you manage your

operations better. All publications are available from the Purdue Extension Education Store:

www.the-education-store.com

(888) EXT-INFO (496-4636)

PURDUE AGRICULTURE

It is the policy of the Purdue University Cooperative Extension Service that all persons have equal opportunity and access to its educational programs, services, activities, and facilities without regard to race, religion, color, sex, age, national origin or ancestry, marital status, parental status, sexual orientation, disability or status as a veteran. Purdue University is an affirmative action institution. This material may be available in alternative formats.