Measuring Pesticides

Measuring Pesticides: Overlooked

Steps to Getting the Correct Rate (PPP-96).

Understand effective measuring

techniques that ensure success.

Fred Whitford, Pesticide Coordinator, Purdue Pesticide Programs

Pat Hipkins, Assistant Coordinator, Virginia Tech Pesticide Programs

Dennis Nowaskie, Superintendent, Southwest Purdue Agricultural Center

Douglas Linscott, Product Development Chemist, Dow AgroSciences, LLC

Andrew Martin, Curriculum Development Specialist, Purdue Pesticide Programs

John Obermeyer, Integrated Pest Management Specialist, Purdue University

Aaron Patton, Turfgrass Extension Specialist, Purdue University

Scott Gabbard, Educator, Purdue Extension-Shelby County

George Beestman, Consultant, Beestman Formulations Consulting, LLC

Kevin Leigh Smith, Editor, Purdue Agricultural Communication

The Six Keys to Effective Applications 4

The Overlooked Step of Measuring and Mixing 10

Inaccurate Measurements Affect Performance 11

Read Product Labels for Correct Rates 14

Liquid Products and the Measuring Device 16

Liquid and Dry Ounces Are Not Created Equal 23

Factors That Affect the Accuracy of Measuring

Dry Formulations 31

Tank Size and Spray Mix Agitation 41

Conclusions 48

Acknowledgments 50

Disclaimer 50

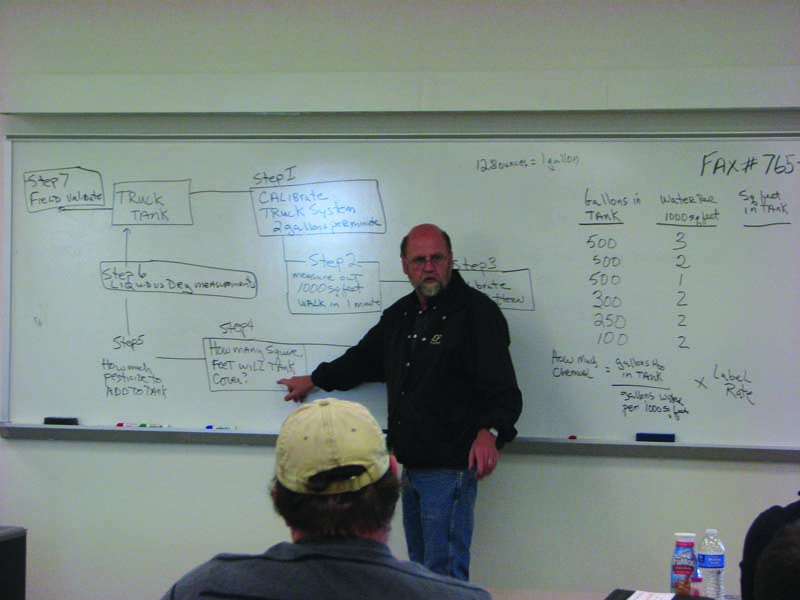

The Six Keys to Effective Applications

Safe and effective pesticide applications require six equally important steps. Applicators must:

- Identify the pest correctly.

- Select the appropriate product.

- Calibrate equipment properly.

- Measure the pesticide accurately.

- Review the treatment site before and during application.

- Monitor the results.

Recertification workshops frequently cover pest identification, product selection, equipment calibration, site awareness, and monitoring. However, workshops rarely cover properly mixing pesticides. After all, how hard can it be? You fill a measuring device with product and add it to the tank, right? How much more is there to know about measuring the right amount of a pesticide product?

It sounds simple, but it can be as complicated as it is critical. This publication describes steps that pesticide applicators can take to correctly measure and mix products to improve results, save money, and enhance safety. Specifically, it will explain some common myths about measuring pesticides, distinguish the difference between liquid ounces and dry ounces, and offer solutions to common problems associated with measuring devices for liquid and dry pesticide formulations.

Still it is important to first review the other five keys to safe and effective pesticide applications.

Identify the Pest Correctly

Before you apply any pesticide it is critical that you understand the pest’s biology and determine the current stage of its life cycle. These factors are critical because pesticides are only effective against certain pests at certain times.

Select the Appropriate Product

It’s important that any product you select is labeled for use on the target site and is a good choice for the pest. Selecting the appropriate product to use often varies depending on the state, industry, company, and customer. Product selection can be complex and vary depending on industry recommendations, a company’s philosophy, and customer needs. These decisions can also be based on marketing tactics and pricing.

- When you select which pesticide is appropriate, always consider:

- The product’s mode of action.

- The timing of the application.

- Your prior experience with the product.

- Product performance guarantees.

- The product’s use rates.

- The product’s ease-of-use.

- The product’s formulation type.

- Any residual and drift effects.

- The product’s safety to employees, customers, and the environment.

- The manufacturer’s support for its product.

- Product availability.

- Container size.

- University and distributor recommendations.

- Label flexibility.

- The application equipment required.

- Transportation requirements.

- The public’s perception of product safety.

University extension services (like Purdue Extension) offer publications with product recommendations that are based on research trials.

Calibrate Equipment Properly

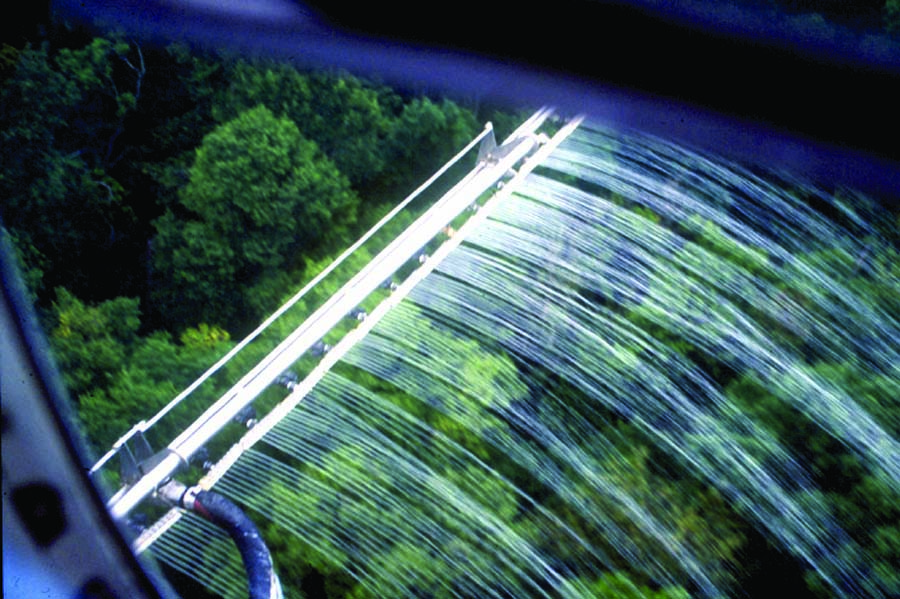

Another key step to successful pesticide application is to calibrate the equipment. Calibration involves getting the individual application equipment components to deliver a predetermined amount of spray solution — uniformly and with minimal drift — to the target you will treat.

For liquid applications, calibration includes choosing the correct nozzle types and orifice sizes, pumps, hoses, pressures, and travel speeds. Each component supports a part of the spraying system and must be configured to deliver the proper volume and rate to the treatment site.

Because his equipment is properly calibrated, this technician knows how long to apply insecticide in each injection hole to protect this home from termites.

Because his equipment is properly calibrated, this technician knows how long to apply insecticide in each injection hole to protect this home from termites. Review the Treatment Site Before and During Application

Being aware of the treatment site elevates the application beyond just spraying the product on an agricultural field, cemetery, park, lake, right-of-way, home interior, hospital, or school. Site awareness takes into account that each application site is unique.

Site awareness involves actions that promote stewardship of the property and the environment, and protects people and pets. Turning over birdbaths, using pesticide baits at daycare centers, and keeping pesticides out of drains help ensure safe applications.

When conditions warrant (high winds, rain, soil conditions), applicators are expected to change application techniques, postpone applications, or adapt procedures to accommodate unusual features of the property — that includes a careful consideration of adjacent properties and the environment.

Monitor the Results

Monitoring the results of any pesticide application will affirm whether it was made properly and achieved the results you expected. This follow up allows you to create a library of experiences for future reference.

By combining your personal “book knowledge” and on-the-job experiences, you should make sure that the pesticide and application are:

- Applied correctly every time.

- Applied in a professional manner.

- Appropriate for the site and itssurroundings.

- Applied safely.

The Overlooked Step of Measuring and Mixing

Applicators generally assume that getting the right amount of product in the tank is the easiest of the six steps of pesticide application. While it’s true that adding a product to a specific level in a measuring device is simple, there are a number of overlooked problems that you must address during the measuring and mixing process.

Mixing and measuring problems can undermine an effective application. If you do not accurately measure product — and use too little or too much — you can negate the reasons why you purchased the product, offset your calibration efforts, and create problems at the job site. It can cause customers to complain, tarnish your reputation, lose business opportunities, affect your bottom line, and even violate the label or the law.

Inaccurate Measurements Affect Performance

Adding too much or too little pesticide to the tank both can create problems. Imagine the problems that occur when an herbicide treatment fails to control miles of brush under a power line. In such a case, the company may be expected to redo the treatment. This will cost the company additional expenses for manpower, fuel, wear and tear of equipment, and additional herbicide just to do what should have been done right the first time.

The extra cost doesn’t even factor in the possibility that poor performance can cause the customer to seek another service provider, meaning lost revenue and a damaged reputation.

Applying a product at lower than labeled rates can fail to control the pest. This, in turn, can lead to costly insurance claims, protracted lawsuits, and customer dissatisfaction.

If you fail to control a pest — such as failing to control weeds —you can lose customers to the competition.

If you fail to control a pest — such as failing to control weeds —you can lose customers to the competition. For instance, an insecticide applied at lower than labeled rates to control termites can lead to extensive structural repairs.

Assuming that the application method, placement, and timing are correct, under-applying a fungicide or insecticide may cause fruit or vegetable producers to lose all or portions of their crops if the fungicide fails to control diseases or the insecticide fails to control insects.

Algae and plant growth can become so thick on a pond or lake that it can make it unusable for boating, swimming, or fishing. These are just some examples of what can happen when products are not applied at the proper concentration.

Comparable problems can occur when products are applied at rates greater than stated on the label. Any application that exceeds the labeled rate violates state and federal laws and regulations, which can lead to significant fines being assessed against the individuals and companies involved in such applications. What’s more, high rates can injure crops or leave residues that exceed federal tolerance standards. In some cases, over application can lead to carryover problems, which means a new crop planted the next season could be injured. High rates are also more likely to move off-site, potentially harming nontarget organisms and the environment.

All these problems are detrimental to your professionalism, credibility, safety, and profitability. And yet, you can avoid these problems simply by following product labels and applying the proper amount of product each time.

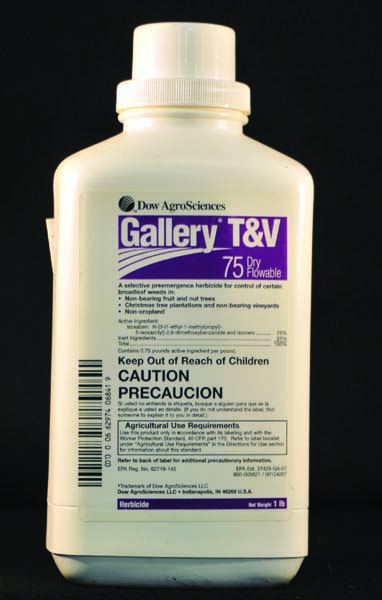

Each product has specific uses, rates, and precautions that applicators must follow. Measuring the proper amount of product is a key step in the application process.

Each product has specific uses, rates, and precautions that applicators must follow. Measuring the proper amount of product is a key step in the application process.

The importance of having the correct amount of product in the tank cannot be overstated when you consider what could go wrong if you use the wrong rate on an apple orchard, ditch bank, pond, utility line, golf course, or corn field.

The importance of having the correct amount of product in the tank cannot be overstated when you consider what could go wrong if you use the wrong rate on an apple orchard, ditch bank, pond, utility line, golf course, or corn field.

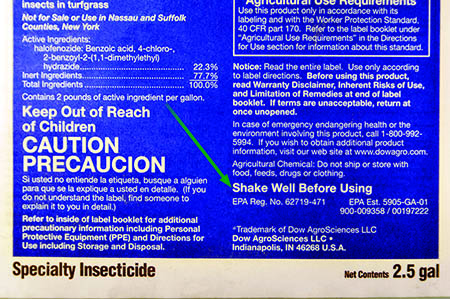

Read Product Labels for Correct Rates

Pesticide labels provide guidance for both practical and legal (EPA-approved) product use. Product labels state use rates as well as directions for diluting the products to make the finished spray mixtures.

Putting the right amount of product in a tank requires following the instructions on the label. While reading a label seems simple enough, some labels can be difficult to read. Sometimes, that’s because small package sizes require ultra-fine type. If that’s the case, consider viewing or printing the product labels online; however, you must remember that the label on the container is the “official” (legal) label that counts.

It may take more than just a few minutes as you read through the label to find the correct rates for a specific pest and location. The first step to reading a label is to locate the section that describes the site or type of application you want to make. Rates depend on the crop, environment, target, or type of application. For example, herbicide rates to control brush depend on whether the method is a foliar spray, or a basal bark, dormant, or cut stump application.

Labels may provide a single rate for specific uses. However, labels can also state a rate range. In such cases, the actual rate you choose may depend on factors such as the predominant pest, pest density, soil type, temperature, crop stage, carrier, and application method. For example, if the pest density is low, you might apply at the lower end of the range; if the soil is high in organic matter, you might apply at the higher end of the range.

Rates may also vary by state or region. And different crops sometimes have different use rates for the same product. You must select the most appropriate legal rate within a given label range and determine the best precautions for a site and situation.

Liquid Products and the Measuring Device

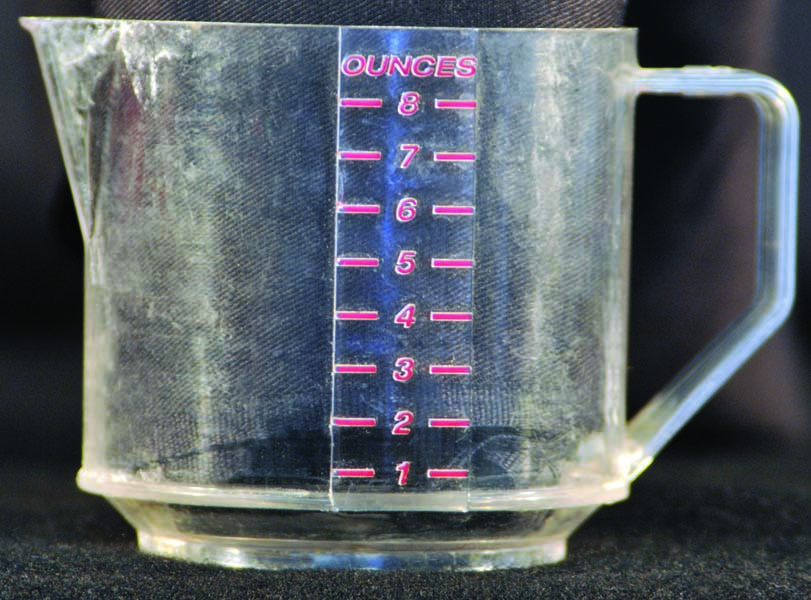

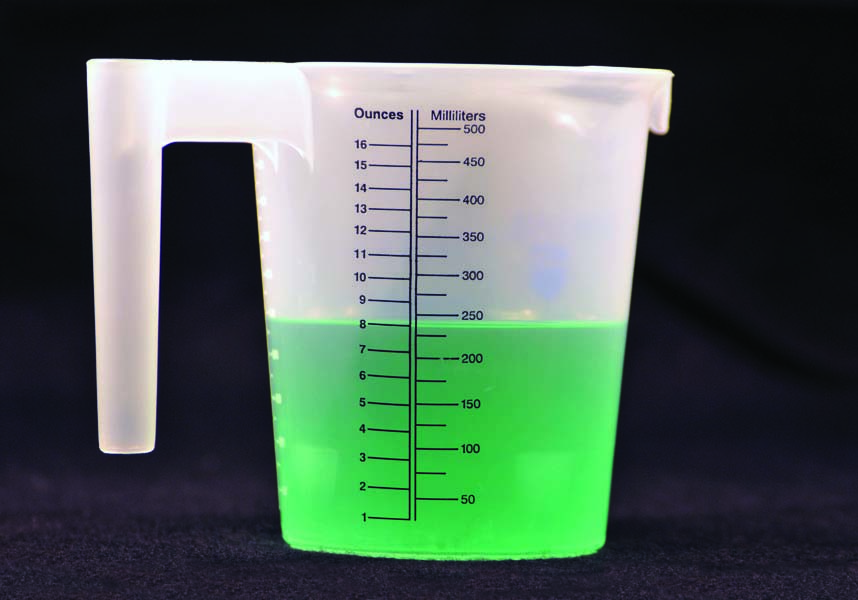

Pouring the right amount of a liquid into a measuring container is a straightforward procedure. All you have to do is calculate how much product you need (based on the label rate and your equipment output), measure to the appropriate line in the measuring container, and pour the contents into the tank.

However, not all measuring devices are accurate. While the lines marked on the container say one thing (such as ounces), the actual measurement in the container may be off by as much as 15 percent, according to the article “Which Cup Measures Up?” from the May-June 2011 issue of Cook’s Illustrated.

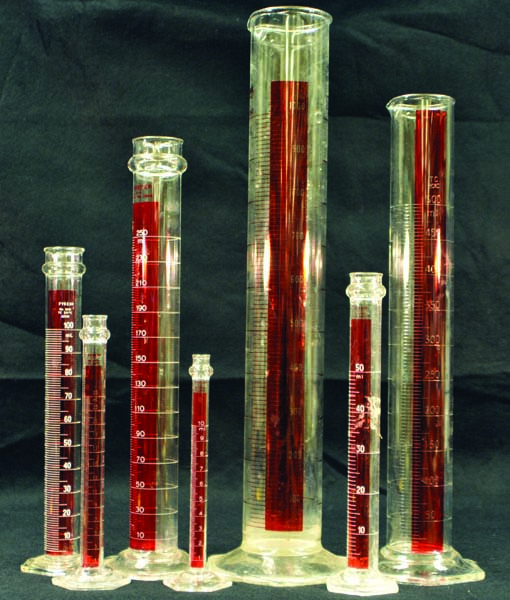

It’s easy to check the accuracy of any measuring container. For a few dollars, you can buy an accurate graduated cylinder from a science supply store. Because research is usually conducted in metric units, the measurement lines on graduated cylinders are usually in metric units (such as milliliters).

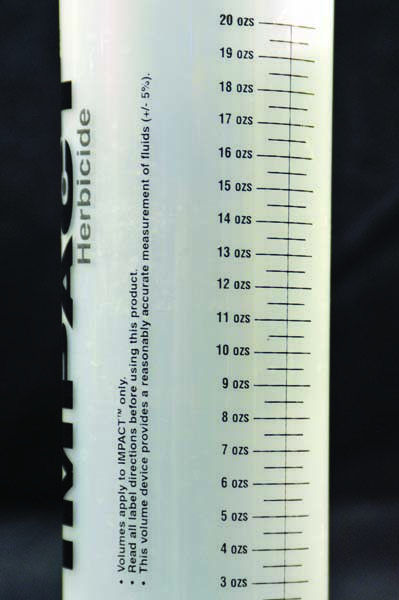

As pesticide manufacturers develop products that require smaller weights or volumes to treat larger areas, the importance of accurate measurement tools is essential.

You’re not actually using the metric cylinder to measure the product. Instead, you’re going to use it to check the accuracy of your measuring device. For that, it’s important to know the following equivalents:

8 fluid ounces = 1 cup = 236.5882 milliliters

Collect 237 milliliters of water in the graduated cylinder, and pour that into the measuring device you want to evaluate. Read the measurement at the water line. If the water level is at 8 ounces or the 1-cup line, then you know your container is accurate.

Here are several suggestions to make it easier to measure pesticides accurately:

- Don’t answer phones or talk to people when you’re mixing products.

Keep distractions to a minimum until you have finished the job.

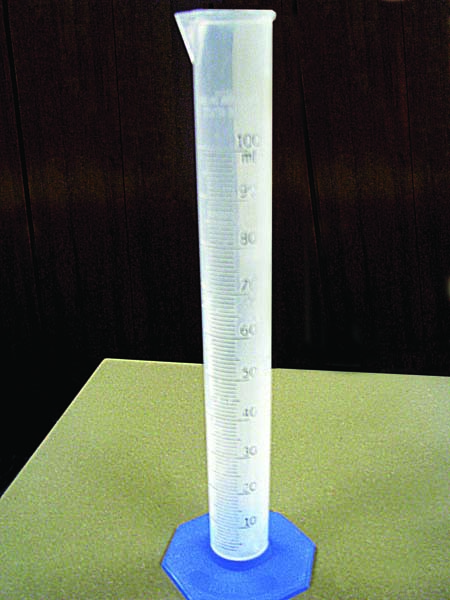

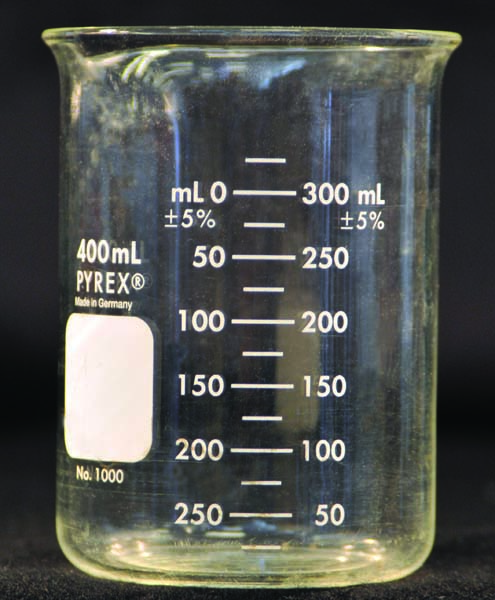

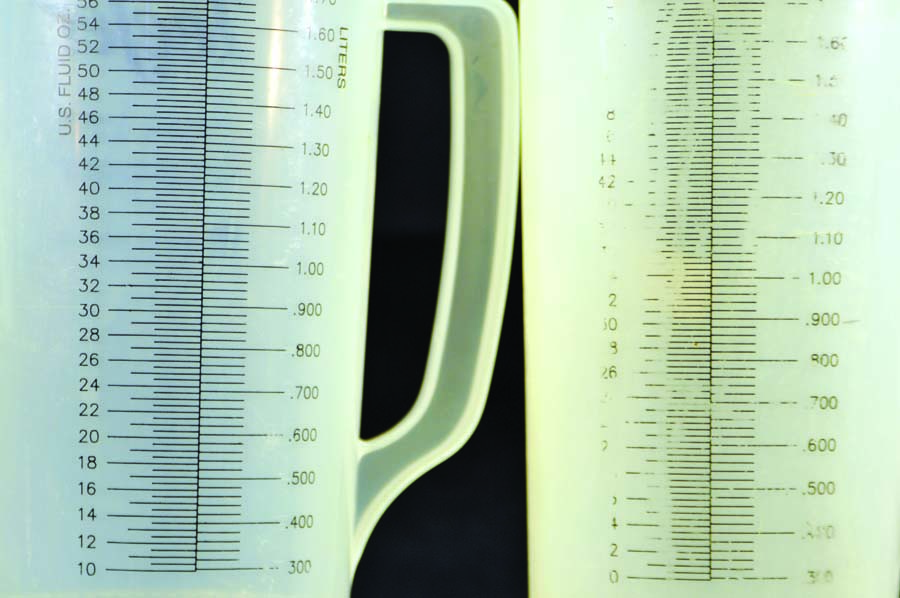

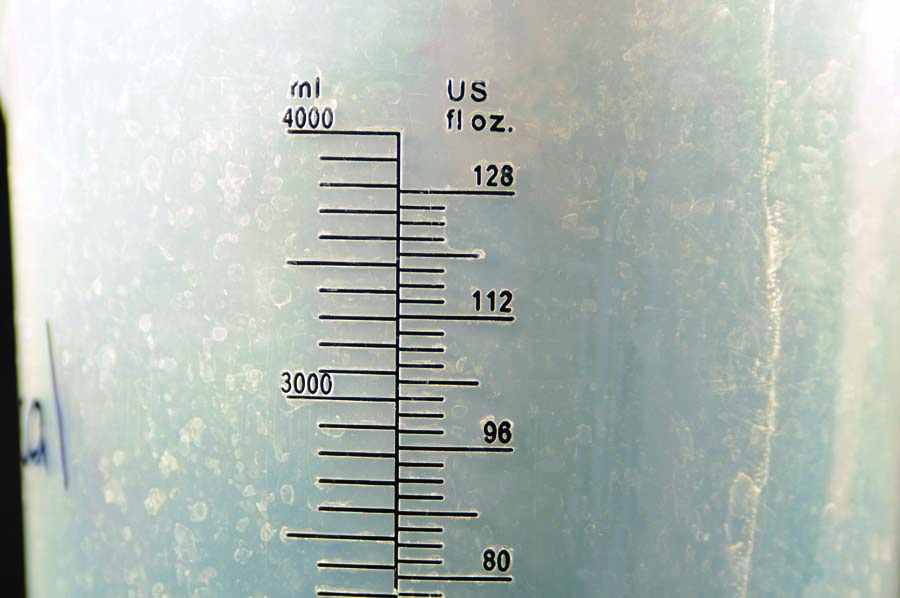

(Left and far left) Use graduated glass or plastic cylinders that allow for precise measurements. (Left) The units on this cylinder are 1 milliliter apart. (Below left) It is impossible to accurately measure 236 milliliters with this glass beaker below, since there is no mark for this amount.

(Left and far left) Use graduated glass or plastic cylinders that allow for precise measurements. (Left) The units on this cylinder are 1 milliliter apart. (Below left) It is impossible to accurately measure 236 milliliters with this glass beaker below, since there is no mark for this amount.

- Try not to use measuring containers that include both metric and English units. Such containers can be hard to find, but product labels in the

The United States generally does not use metric units, so having those markings only clutters the measuring cup and causes confusion. - Look for liquid measuring containers with pour spouts and handles.This minimizes the risk that you’ll spill any of the product you carefully measured.

- Buy measuring containers with graduations that are easy to read.Select ones with large, well-spaced lines and numbers that are etched (not painted) and highlighted with color.

This will make it easier to read the units on the container. Painted lines on measuring containers can wear off or be dissolved by some products such as surfactants and organic solvent-based formulations.

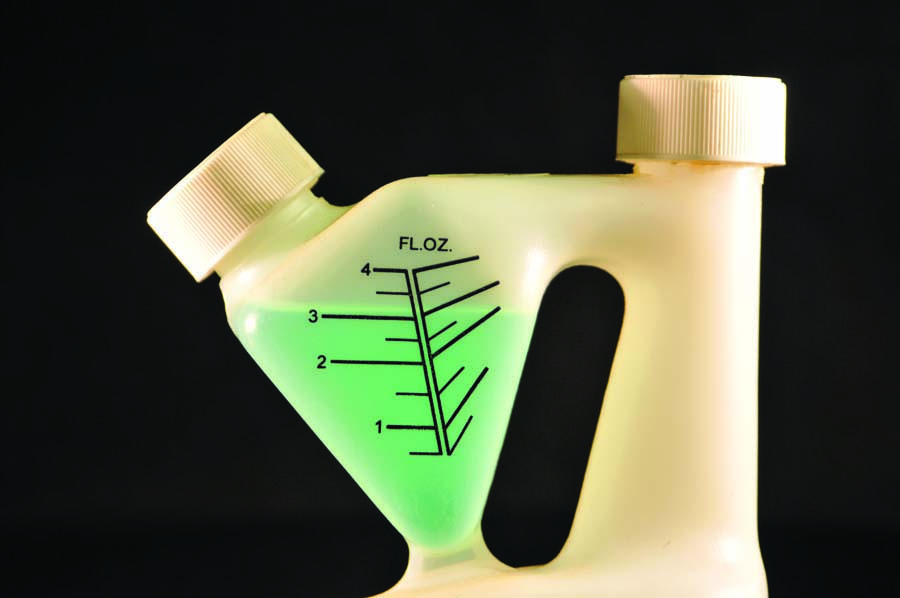

“Tip and pour” products are easy to measure and can be safer to use.

- Replace measurement containers when numbers and markings become difficult to read.

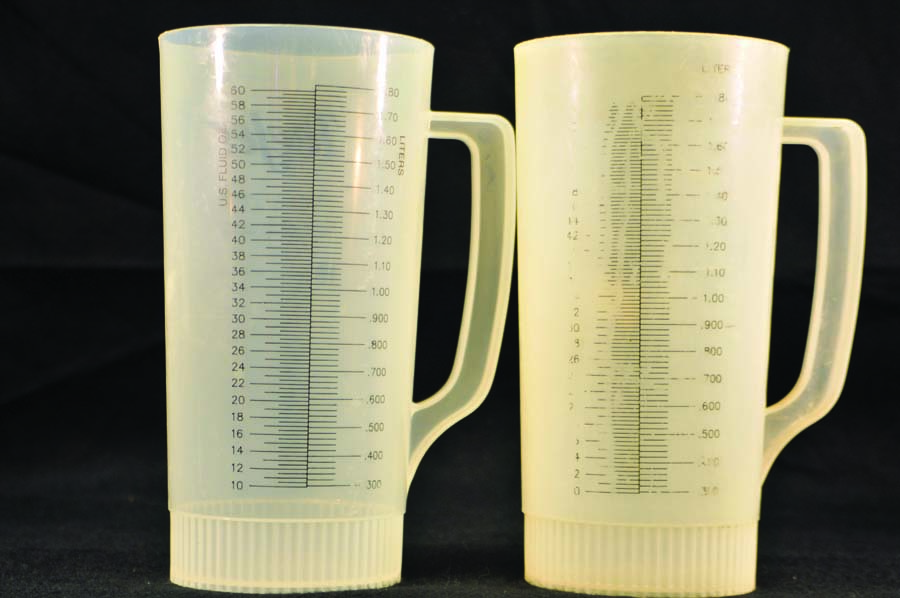

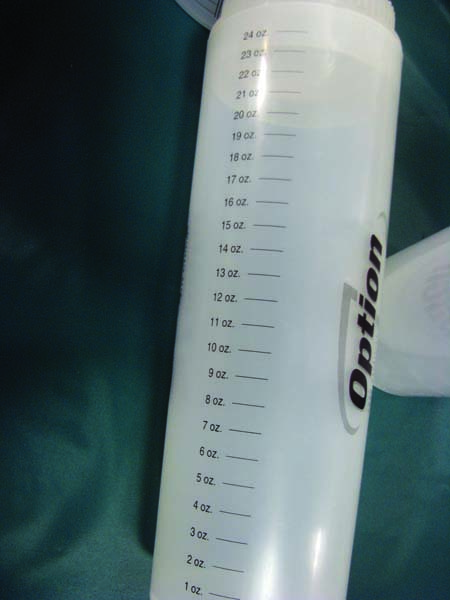

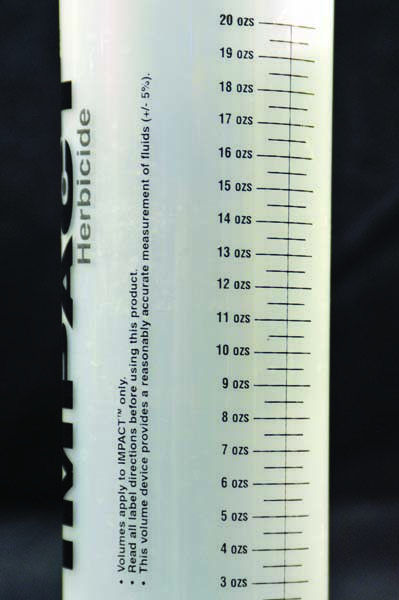

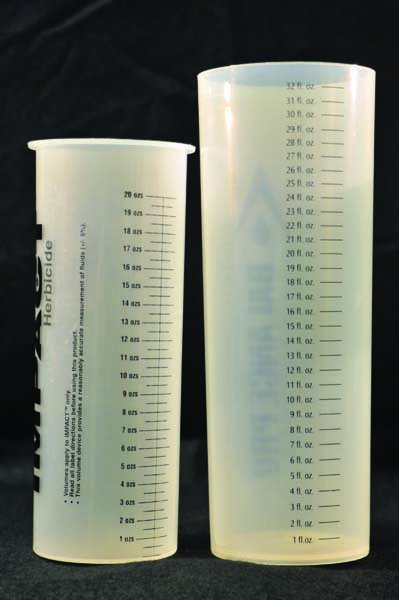

- Consider using taller and narrower measuring containers.Taller, narrower measuring containers typically have more graduation marks and more space between lines on the container compared to shorter, wider ones. Your measurements will be more precise when you use a properly calibrated measurement device that contains more markings.

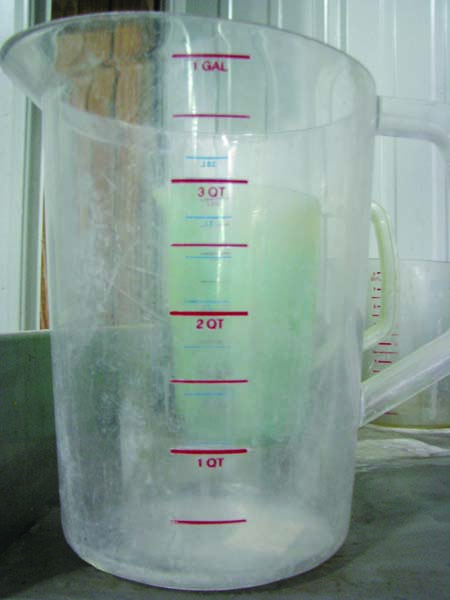

This container only has marks for quarts and half quarts and is unsuitable for measuring ounces.

This container only has marks for quarts and half quarts and is unsuitable for measuring ounces. • Read measuring containers only when placed on flat, level surfaces and at eye level in a well-lighted place.

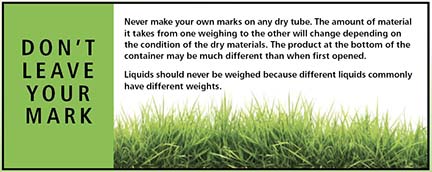

• Never write or add marks on your measuring device. Always use a graduated device that measures accurately

with manufacturer-applied measurement marks instead of adding your own.

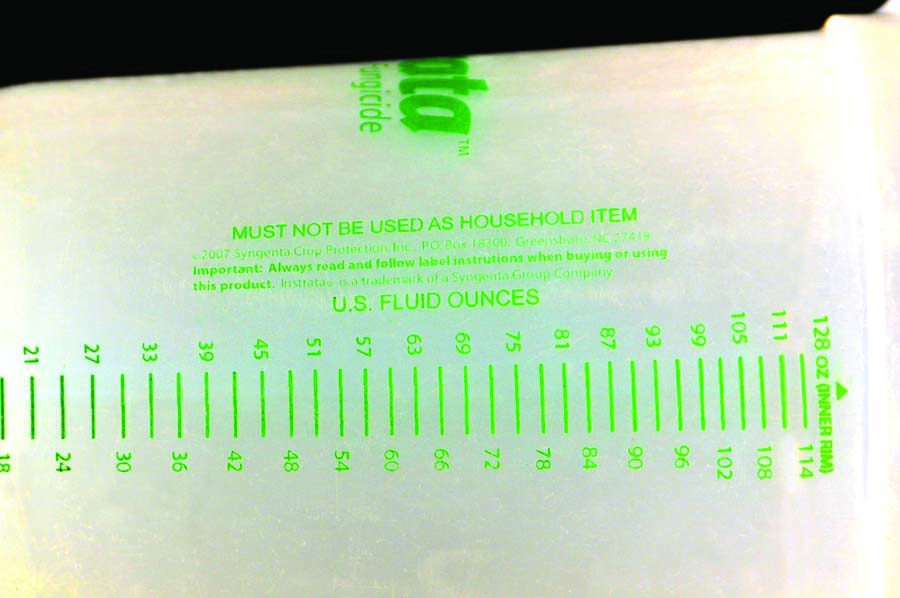

Notice that this measuring cup starts at 10 ounces, so you should not use it to measure smaller amounts of products.

Notice that this measuring cup starts at 10 ounces, so you should not use it to measure smaller amounts of products.  Notice that the 128-ounce mark on this measuring cup is defined as the inner rim.

Notice that the 128-ounce mark on this measuring cup is defined as the inner rim.

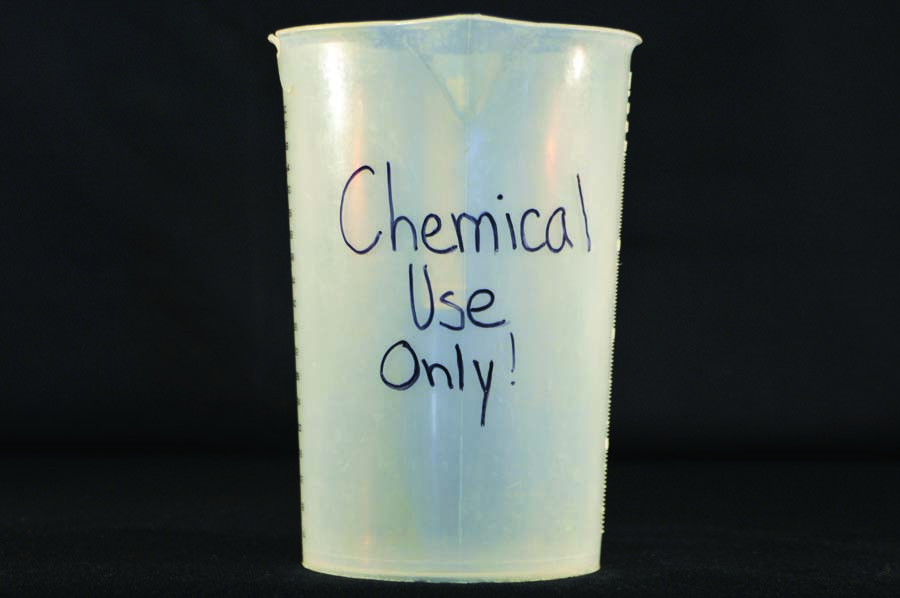

Never use pesticide measuring devices for any other purpose.

Never use pesticide measuring devices for any other purpose.

Liquid and Dry Ounces Are Not Created Equal

We’re accustomed to measuring liquid formulations in ounces. An important fact you may have forgotten is that a liquid ounce is a volume measurement, while a dry ounce is a measure of weight.

This is a significant distinction that directly influences the accuracy of a measurement. If you measure 3 ounces of salt by volume, you have more material than if you measure 3 ounces of the salt by dry weight (see photo below). If you use a device to measure liquid volume when you should be using a device to measure dry formulations you will change the intended application rate drastically.

All applicators are familiar with pouring a liquid into a measuring cup. When you pour a liquid ounce into a measuring container, it always represents 1/128 of a gallon. This is called a volumetric measurement because one ounce of any liquid always fills the same volume — it takes up the same amount of space.

A dry ounce is equal to 1/16 of a pound.The amount of a material it takes to get 1 dry ounce depends on the density of the material. For instance, weighing out 4 ounces of different products shows the differences in their densities (see photo below). Four dry ounces of coffee creamer weigh the same as 4 dry ounces of salt. However, because salt is denser than the coffee creamer, 4 dry ounces of coffee creamer takes up more space. The volume occupied by a given weight of dry material depends directly on the density and particle size of the product.

The specific volume of a dry wettable granule (WG) pesticide product depends on its density. The volumes of WG products vary by their ingredients and the size and shape of their granules.

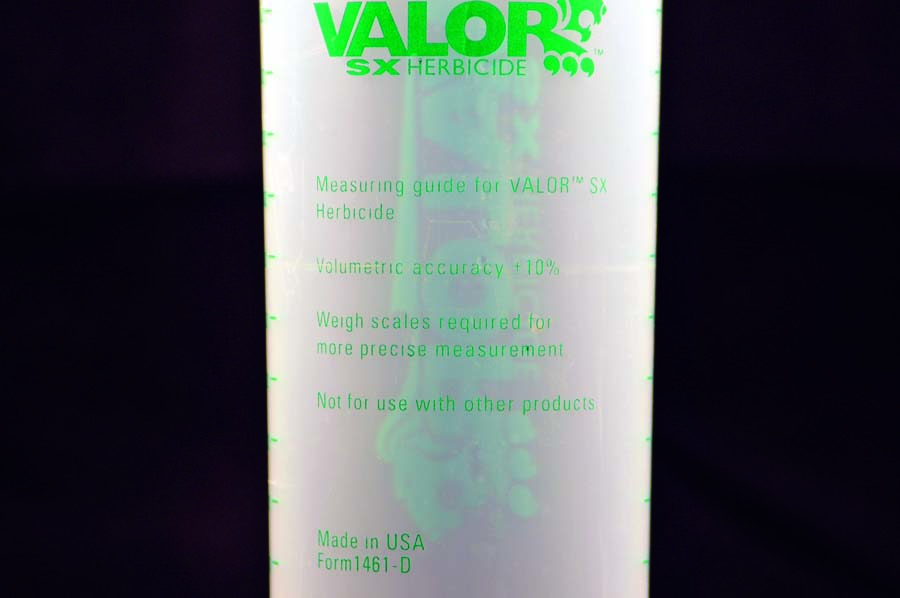

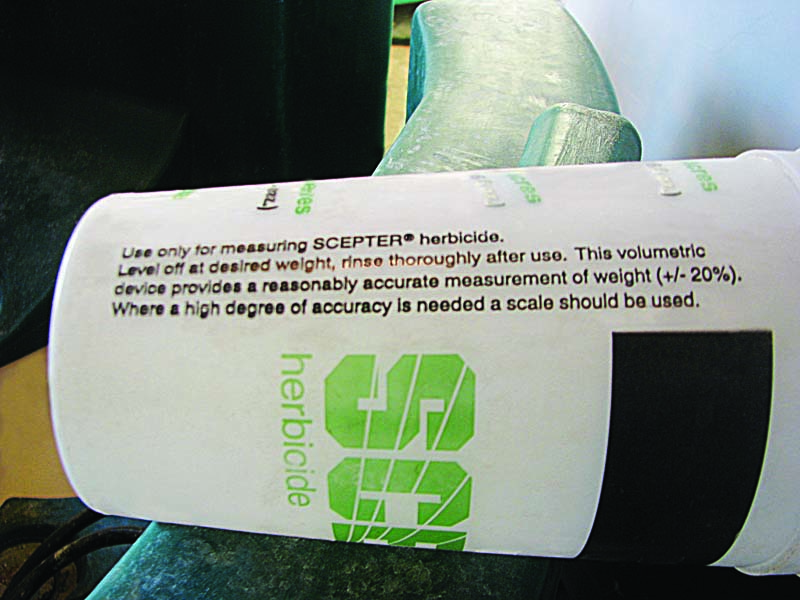

Instead of having to weigh dry products on a scale, manufacturers have designed volumetric tubes that are made specifically for their products that make measuring their products easier for their users. This is the norm for dry flowable (DF) and water-dispersible granule (WDG) formulations.

There are several designations used commercially for water-dispersible granule formulations. These include WG (wettable granule), WDG, and DF. These are all granulated products that are designed to be diluted and dispersed in water. WG has become the most common designation within the global crop protection industry and will be used here to represent the broader group of formulations.

The manufacturer weighs an ounce of the product, and then places it into the measuring tube. The manufacturer then places marks on the side of the tube that correspond to the number of dry ounces. This procedure is used for all graduations on these dry containers. The marks and lines represent the number of dry ounces — not fluid ounces.

There are some things you need to know about retail-supplied measuring devices:

• Before you measure, make sure you know whether a measuring device is meant for fluid ounces or dry ounces. If it is for liquid ounces, the measuring device should clearly say liquid ounces, fluid ounces, fl. oz., or liq. oz. Many measuring tubes look similar, so be sure that you identify which ones measure fluid ounces and which ones measure dry ounces.

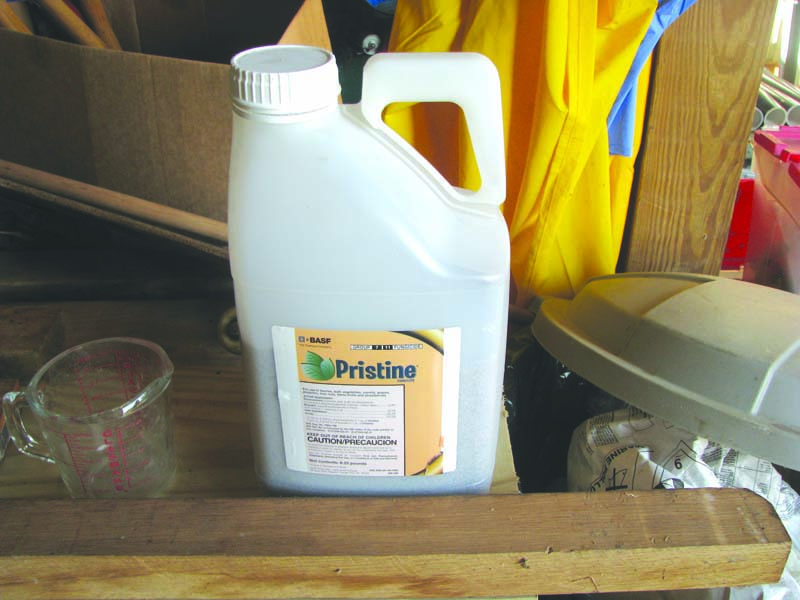

Can you explain why measuring this dry fungicide product in a volumetric container is inaccurate? The answer: the dry product is being measured with a container that measures liquids. For safety, never use kitchen measuring devices to measure pesticides.

Can you explain why measuring this dry fungicide product in a volumetric container is inaccurate? The answer: the dry product is being measured with a container that measures liquids. For safety, never use kitchen measuring devices to measure pesticides.

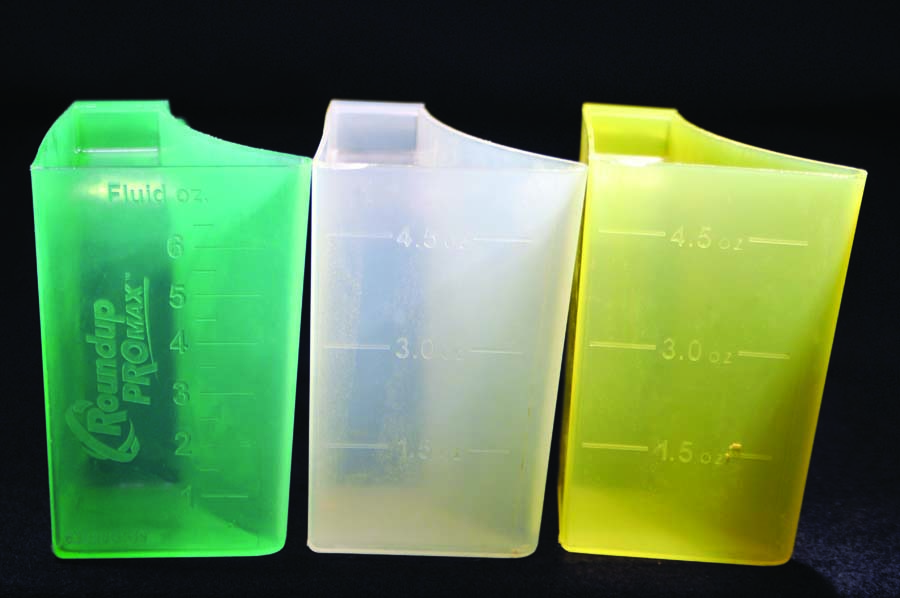

(Above) A container that measures fluid ounces. (Right) One tube measures fluid ounces, the other dry weight. (Left) Make sure the container measures dry ounces if it is not labeled as fluid ounces.

- Be cautious of measuring devices for closely related products that are formulated differently.Only use a fluid-ounce device for measuring liquid products and a dry measuring device for dry products.

Quick Pro® is a soluble granule. The yellow and white measuring cups attached to these containers measures the same exact amount of dry ounces. A similar liquid formulation of this product requires the green measuring cup. Throw in other cups with similar sounding names, and it is no wonder that measuring errors are made. Always keep measuring cups with the container to avoid inaccurate application rates.

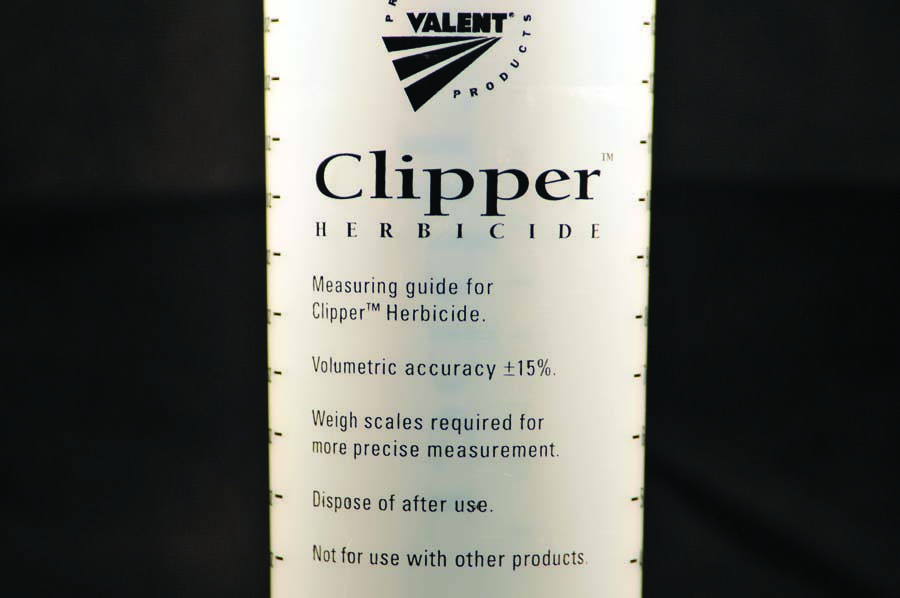

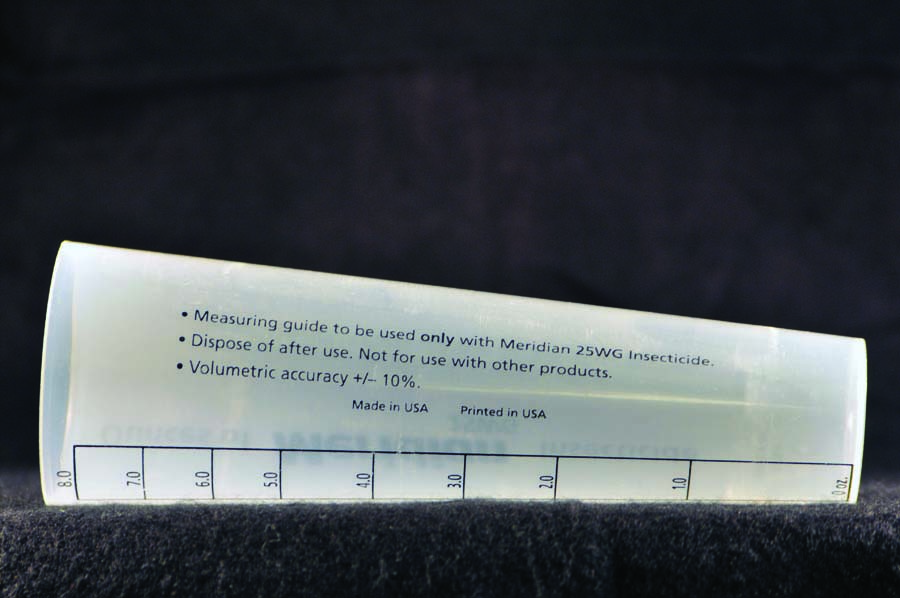

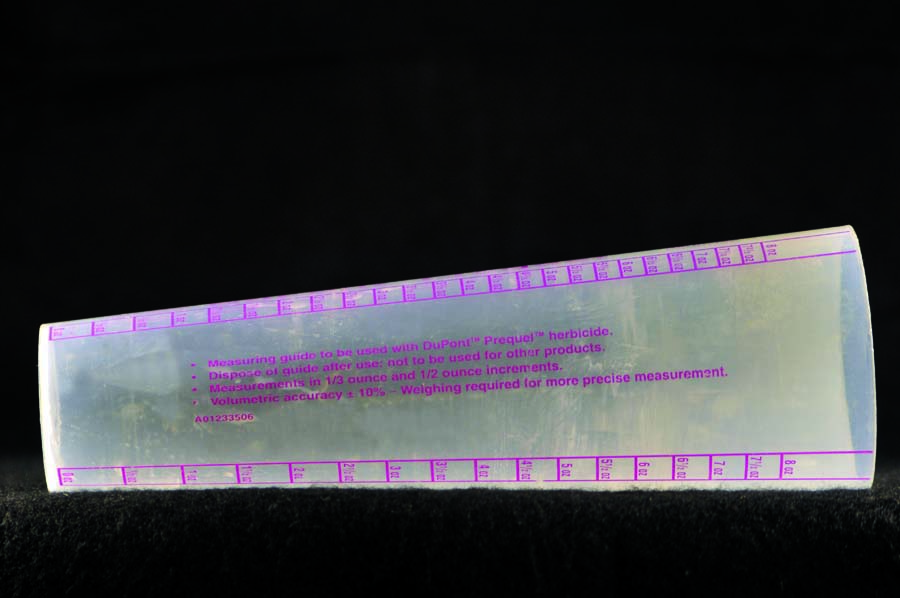

- Read and follow the measuring device instructions.Many clearly state that theymust be used for the products they came with, and discarded after the containers they came with are empty.

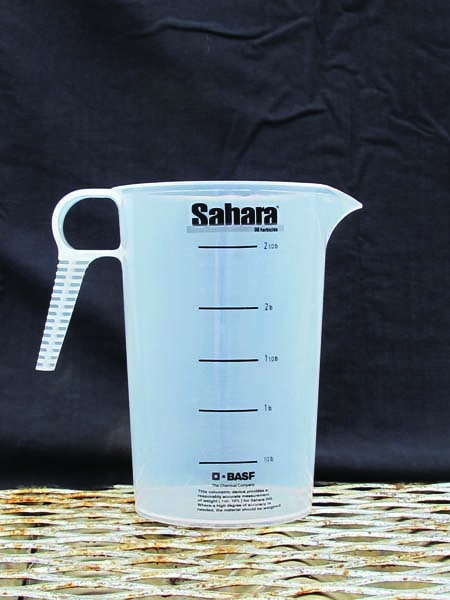

- Be cautious of containers that have different sets of graduation marks indicating both liquid and dry ounces.When hurried or interrupted, the person measuring the product might use the wrong set of measurement lines.

This Sahara® pitcher displays fluid ounces on one side, and displays dry ounces and instructions to use only for Sahara® on the other.

Factors That Affect the Accuracy of Measuring Dry Formulations

WG products (WG, WDG, DF) that are meant to be diluted in water generally include the term “dispersible” to acknowledge that the product is intended for spray applications. Be aware that there are other dry granular products that are designed to be applied dry. Such products generally are designated as granulars (GR or G), and are not intended for spray applications. Wettable powders include the “wettable” descriptor to denote the products are intended for dilution in water (unlike dusts). Consult the product labels or consider diluting a small sample of the product in water to observe its dispersion (or lack of dispersion) if you are uncertain.

Because many WG products are mixed in water and applied using ounces per acre, being off by an ounce or less will affect the results. Consider the following factors when measuring dry pesticide formulations:

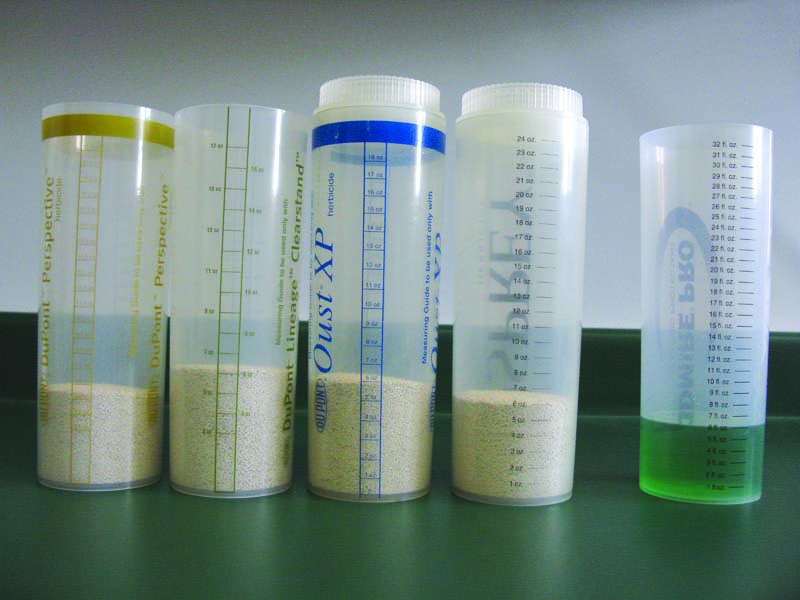

- Remember that measuring devices are product-specific.Be sure to get the rightdevice at the point of sale, and only use the one that matches the product and batch.

Manufacturers design their tubes to reflect label rates, taking into account the volumetric weight of the product. If you substitute a measuring tube meant for another product that will almost certainly guarantee that you will incorrectly mix the pesticide.

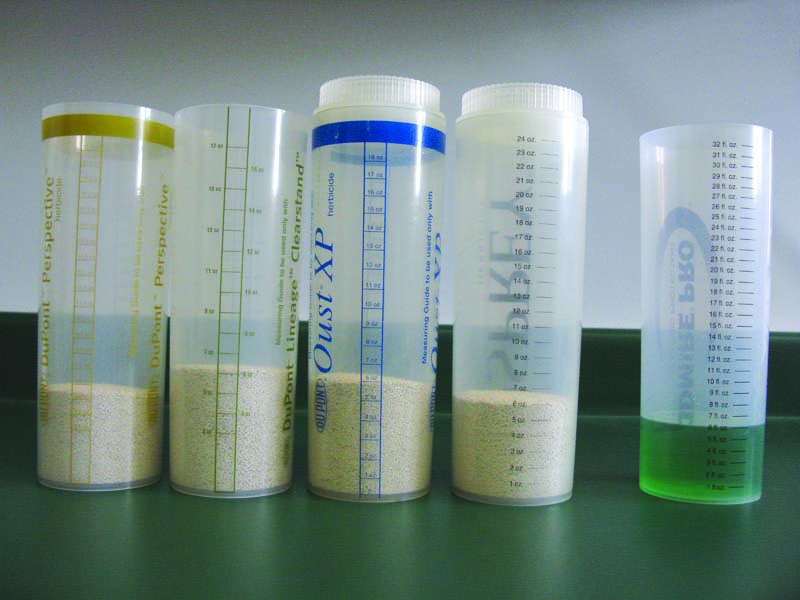

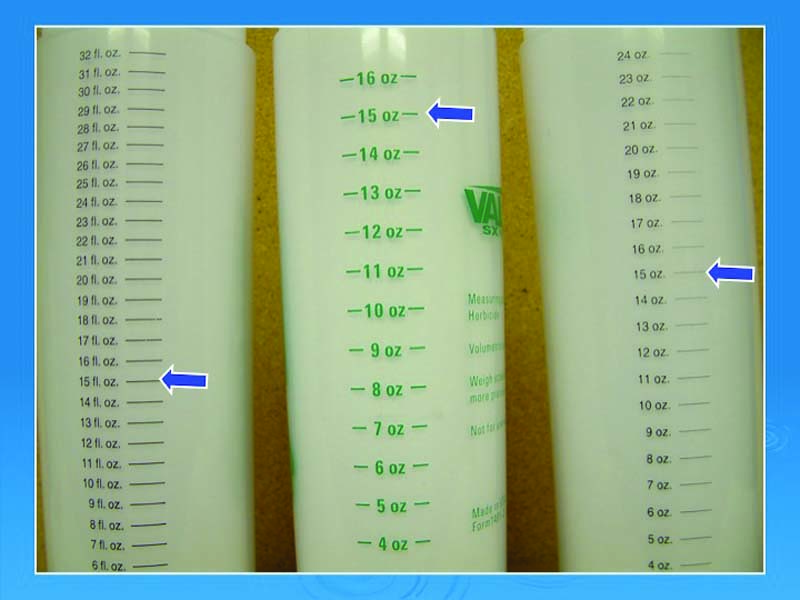

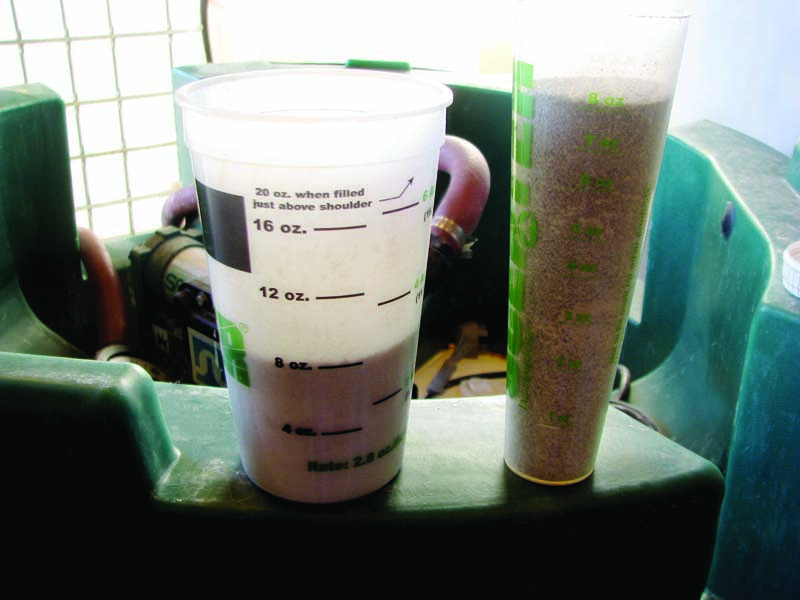

These WG tubes clearly show how the graduations for measuring the weight of dry materials are product-specific. Each tube contains 6 dry ounces of product. For comparison, see 6 fluid ounces of the green liquid in the tube on the right.

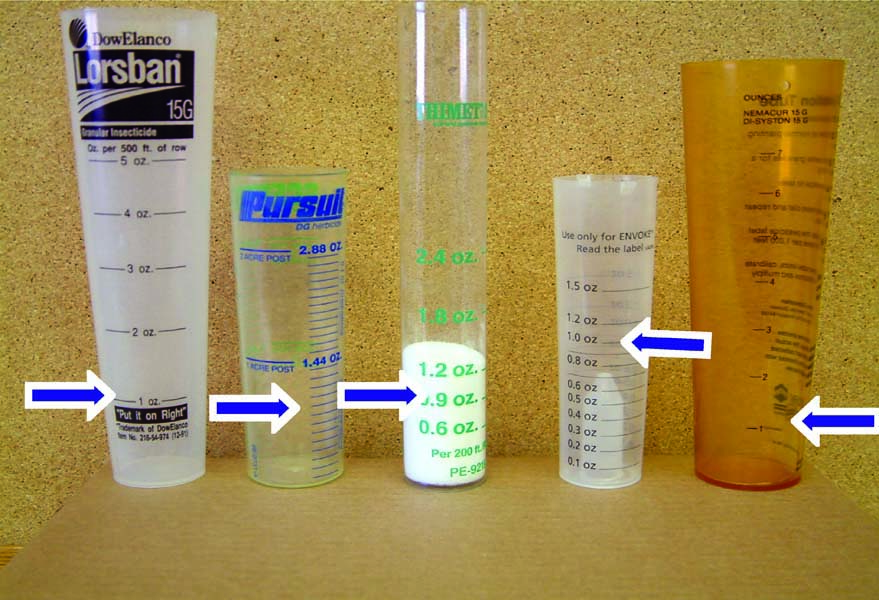

These WG tubes clearly show how the graduations for measuring the weight of dry materials are product-specific. Each tube contains 6 dry ounces of product. For comparison, see 6 fluid ounces of the green liquid in the tube on the right.  These three measuring tubes look similar. The tube on the left measures liquids. If you used that tube to measure 15 dry ounces of either of the dry materials at right, then your dose would be significantly too low. And if you used the dry measuring tubes for the wrong product, you could have similar dosing problems

These three measuring tubes look similar. The tube on the left measures liquids. If you used that tube to measure 15 dry ounces of either of the dry materials at right, then your dose would be significantly too low. And if you used the dry measuring tubes for the wrong product, you could have similar dosing problems

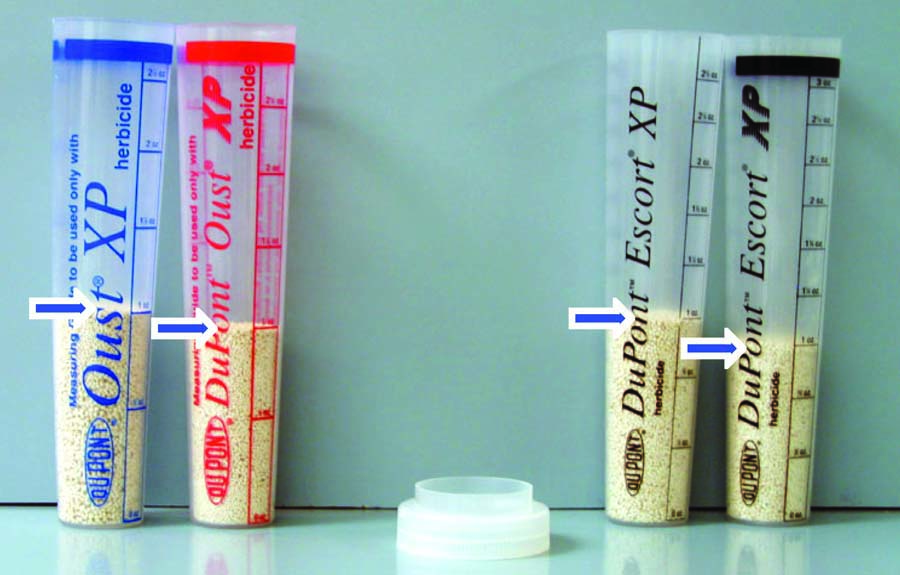

Many WG products come with their own measuring devices. All measuring devices provide similar warnings: the dry ounce measurements on each device are only for a specific product and are not meant to be used with other products.

- Do not tap down the material in the measuring container.Package engineers calibrate product measuring devices based on the practices expected from typical customers. These calibrations most closely match the loose bulk density of a product than its higher tapped bulk density. If you tap the volumetric measuring device to minimize a product’s volume, that may result in exceeding your desired application rate.

- Turn the container over several times before pouring the material in the measuring tube.This will ensure a more uniform mixture of the product.

- Gently invert the measuring device, after sealing the top, and then return the sample to the upright position with minimal disruption.If you do this and assess the resulting WG product volume, you can improve the consistency of your volume measurements.

- Do not accept tubes other than those that are shipped with the product at the time of purchase.It’s common for manufacturers to ship fewer measuring tubes than the number of pesticide containers in a package. When you purchase individual packages from a case at the retailer, make sure to ask for the tube that came out of the box in which the product was shipped.

You should have a measuring tube for each lot of material you purchase.

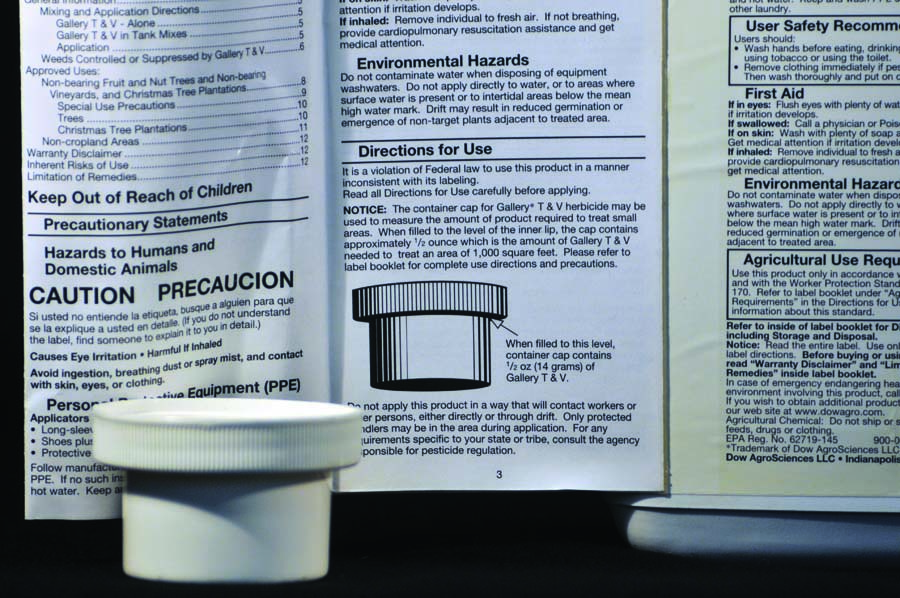

- Use the measuring scoop that comes with dry materials. The scoops, like the tubes, are product specific. Sometimes they are built as part of the cap or they are provided separately.

It is important to use the measuring device that comes with a specific product.

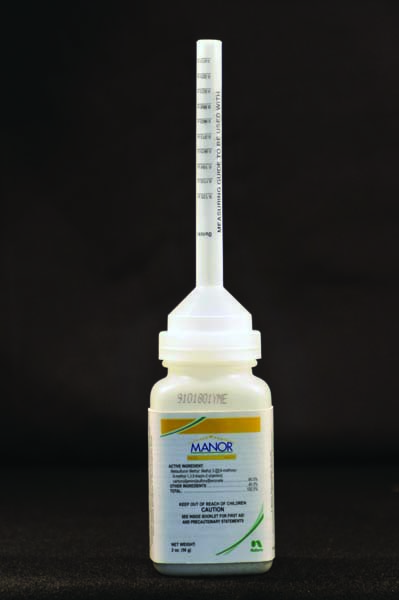

Some product caps serve as the measuring device. In such cases, product labels provide specific instructions for how to use the markings on the cap.

Some product caps serve as the measuring device. In such cases, product labels provide specific instructions for how to use the markings on the cap. - Keep WG measuring devices with the product. Always keep these measuring tubes with the corresponding pesticide container.

- Do not reuse leftover measuring tubes. Product formulations can and do change. If the manufacturer changes the formulation, the formulation’s product density may also change. In such cases, the manufacturer will calibrate new measuring devices to most accurately dispense the product. Also, if a new batch of product has a different particle size, the way the WG particles settle into a tube will change, and the manufacturer will change the position of the lines on the tube accordingly. For this reason, it is a best practice to discard all measuring tubes and devices after you use all of the product.

For example, notice the slight variations in the 1-ounce markings between different batches of Oust XP® and Escort XP® (see photo below). The tubes’ designs and colors differ, indicating a change in the formulated product. These examples show why it’s important to follow the manufacturer’s instructions to “dispose of after use.” In many applications, these slight differences can make a significant difference in product performance.

Sometimes, manufacturers change measuring devices, but not product formulations. In this photo, you can see the measuring devices still measures 8 dry ounces. But unless you weigh the products, you have no way of knowing whether one container is different from the other. You should always discard a measuring tube after you use the product.

Sometimes, manufacturers change measuring devices, but not product formulations. In this photo, you can see the measuring devices still measures 8 dry ounces. But unless you weigh the products, you have no way of knowing whether one container is different from the other. You should always discard a measuring tube after you use the product.

Never use an old measuring tube for dry materials. Instead, properly dispose of or recycle all tubes after use. Saving them for reuse may lead to inaccurate measurements on future applications.

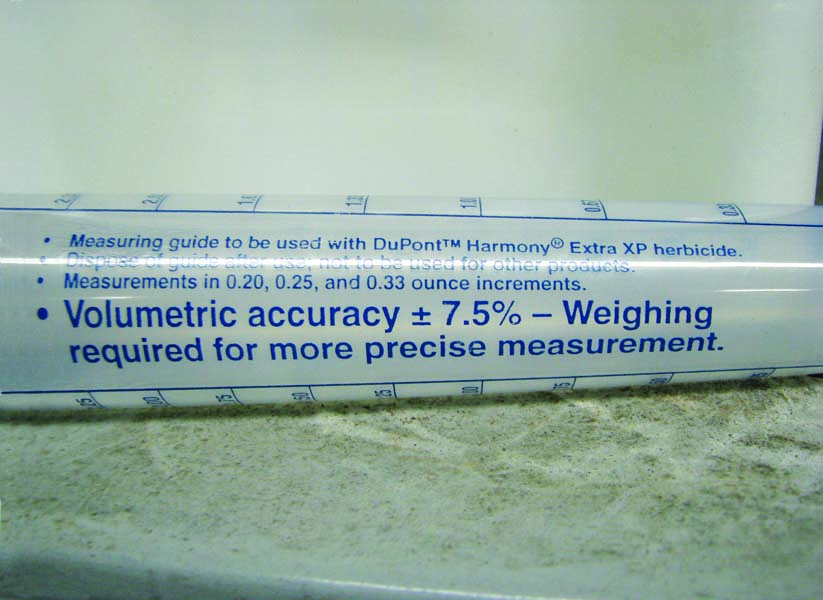

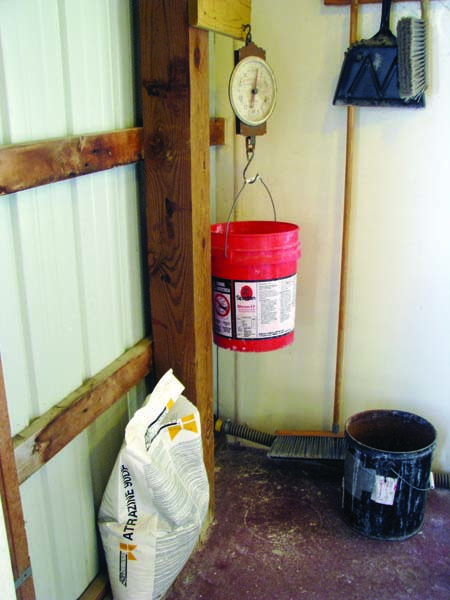

- The most accurate and consistent way to measure dry flowables is to weigh them on a scale.The combinations of normalproduct density variance, user technique variance, and general measurement accuracy, could, in worst cases approach 15 to 20 percent. Manufacturers often suggest weighing out products when more precise measurements are required.

Select a scale that allows you to tare (zero) out the weight of the container (a plastic cup in the photo abelow left) in which the dry materials are placed. In this example, the plastic container was weighed. With the push of the “tare” or zero button, the weight reads zero. By adding the material after you tare the device, you will get a reading that does not include the weight of the container.

Follow the scale manufacturer’s instructions to check and adjust the balance calibrations, as needed. It is also a good practice to check the scale’s accuracy using a known weight standard.

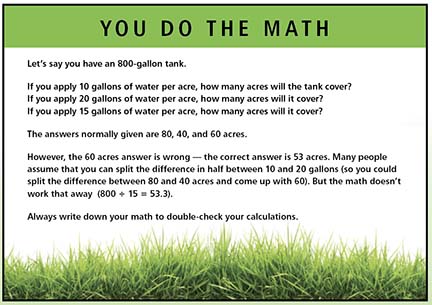

- Reduce the amount of measuring.There are two different approaches you can take to reduce measuring error. The first is to consume the whole container of product, since manufacturers fill their containers by weight, not volume. By minimizing the use of volumetric measuring tubes, you can save time and achieve the best measuring accuracy.

For instance, one herbicide is packaged in 6-pound lots. Six pounds is equal to 96 ounces. At a rate of 3 dry ounces per acre, the container will treat about 32 acres. A 1,000-gallon tank calibrated to apply 10 gallons of finished spray per acre would cover 100 acres. Thus, adding three of the 6-pound units to 960 gallons of water would require no measurement of product.

The second option is to only measure out the product once. Using the same example as above, use the whole container to make each batch of finished spray mix. When partial loads are required, use the tube once to get the amount required.

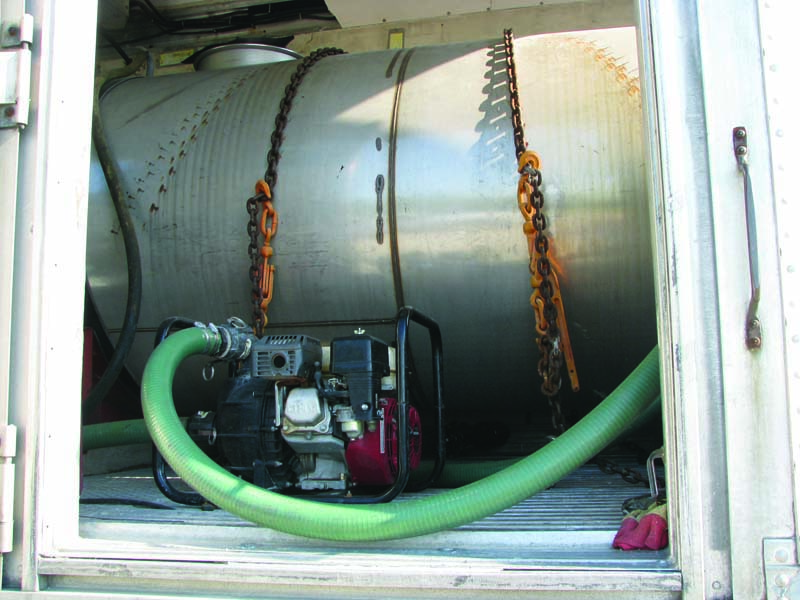

Tank Size and Spray Mix Agitation

There are several other factors to consider if you want to get the correct rate applied to the treatment site. Two of these are tank size and spray mix agitation.

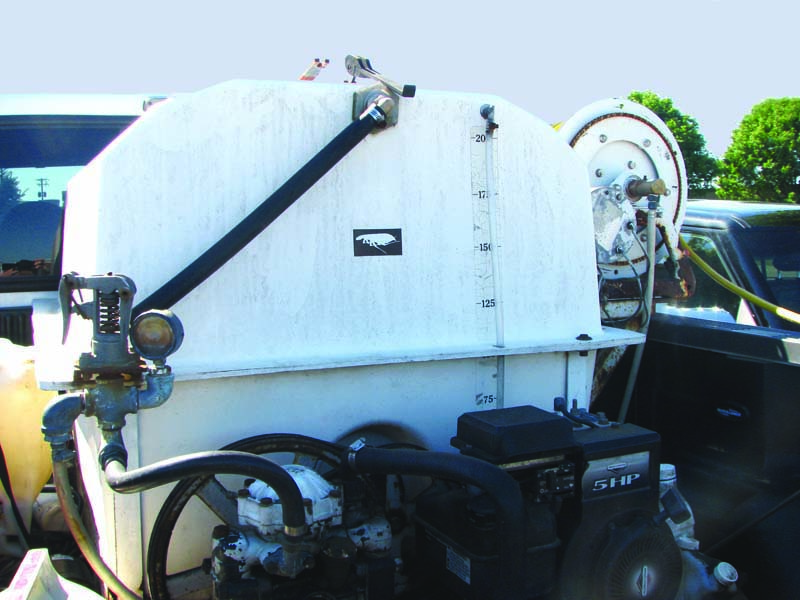

Many applicators ignore the marks on their application tanks and use flow meters to measure water. This practice can be particularly helpful if you are mixing on less than-level ground.

Many applicators ignore the marks on their application tanks and use flow meters to measure water. This practice can be particularly helpful if you are mixing on less than-level ground.  With today’s sophisticated equipment, electronic flow meters can be a great asset when filling sprayers. In this case, the digital readout is mounted in a position that makes it easy to read during the filling process.

With today’s sophisticated equipment, electronic flow meters can be a great asset when filling sprayers. In this case, the digital readout is mounted in a position that makes it easy to read during the filling process.

Tank Size

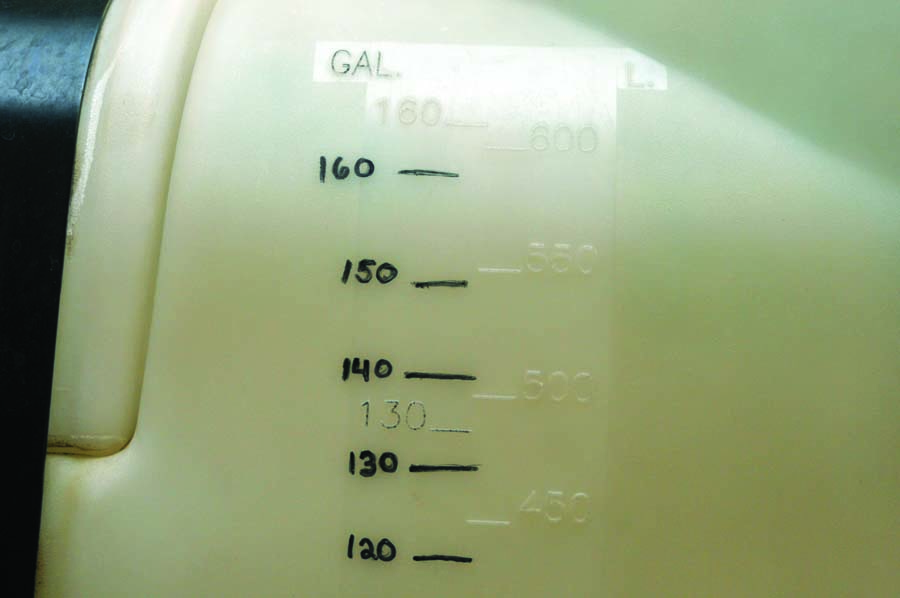

You probably assume that the markings on your 5-, 100-, 250-, 500-, or 1,000-gallon tanks are accurate. Unfortunately, this is not always the case.

It is important to know how much is actually in your tank, since the amount of the product’s active ingredient that you need depends on the amount of spray you need to deliver to a given area.

You can use a flow meter to check the actual number of gallons marked on a tank. Fill the tank and stop the flow meter at the increments marked on the tank. The flow meter and the tank marking should match up. As was the case with the scale, make sure the flow meter is calibrated according to the manufacturer’s instructions.

Another way to measure tank size is to weigh the truck or trailer carrying an empty tank on truck scales. For example, a 500-gallon tank on a truck or trailer should be weighed with the truck or trailer empty. Assume that the number of gallons indicated on the tank is correct. Then fill the tank with water to the 500-gallon mark.

Reweigh the truck or trailer with the tank filled to 500 gallons. Subtract the original truck weight with the empty tank from the second weight of the truck with the tank filled to 500 gallons. Divide this number by 8.34 pounds (one gallon of water weighs approximately 8.34 pounds) to calculate the number of gallons in the tank. It should be close to 500 gallons. If not, remark the 500-gallon graduation mark on the tank.

Measuring the tank to ensure that its markings are correct is an easy step that can lead to more precise applications. Notice the difference in where the 30-gallon mark is and the actual measurement taken with a flow meter. Make sure the tank is level when remarking.

Measuring the tank to ensure that its markings are correct is an easy step that can lead to more precise applications. Notice the difference in where the 30-gallon mark is and the actual measurement taken with a flow meter. Make sure the tank is level when remarking.  A flow meter check determined that the markings on this tank are all off by 10 gallons. Make sure the flow meter is correct by calibrating it according to the manufacturer’s instructions.

A flow meter check determined that the markings on this tank are all off by 10 gallons. Make sure the flow meter is correct by calibrating it according to the manufacturer’s instructions.

Spray Mix Agitation

It is also important to assure that you apply crop protection products consistently across the entire treated area. WG products are formulated to disperse into very fine particles (about 1-15 microns in diameter) when they are diluted in water. The formulation processing used to prepare these products includes particle size reduction.

The WG products are then granulated (agglomerated) to minimize their dustiness for user safety. The granulation process also significantly increases the product density for easier handling for end-users.

Spray tank agitation is a basic requirement for WG products. Generally, users fill their spray tanks to 1/2 to 2/3 of their full volume, begin spray tank agitation, and then add the WG product to the spray tank. Then, they finish by filling the spray tank to its full volume for spray application. This mixing method allows sufficient time for the WG product to wet and disperse into the water fully.

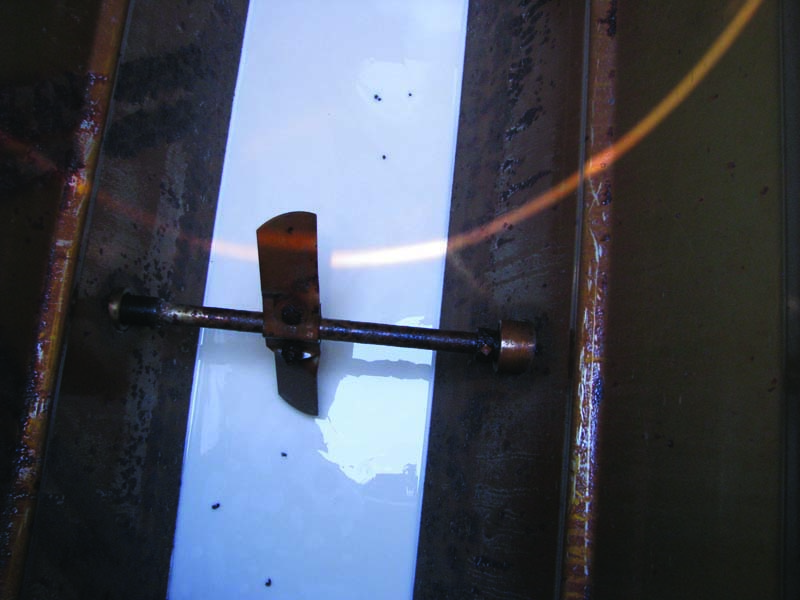

It is important to constantly agitate these spray mixtures to prevent solids from settling out of suspension over time. The agitation maintains a consistent spray mixture. Fiberglass and steel tanks may be equipped with paddle-type mechanical agitators.

Polyethylene (poly) tanks may employ pressurized bypass agitation to maintain a uniform mixture. In some cases, valves can be installed to better direct the incoming water at the bottom of the tank.

Polyethylene (poly) tanks may employ pressurized bypass agitation to maintain a uniform mixture. In some cases, valves can be installed to better direct the incoming water at the bottom of the tank.  Make sure to recirculate the hose reels at the beginning of the day. Materials may have settled in the bottom of the tank overnight.

Make sure to recirculate the hose reels at the beginning of the day. Materials may have settled in the bottom of the tank overnight.

Without agitation, product will settle at the bottom of the tank. As a result, solution taken from the bottom of the tank will have a much higher concentration of the product than solution taken from the top of the tank. This can lead to inconsistent results and unwanted damage.

Without agitation, product will settle at the bottom of the tank. As a result, solution taken from the bottom of the tank will have a much higher concentration of the product than solution taken from the top of the tank. This can lead to inconsistent results and unwanted damage.

There are many ways to agitate tanks and help to keep product suspended in water. A sparge tube is a tube with holes mounted on the sidewall of the tank. It is normally in the lower third of a tank with the spray directed downward, which causes swirling up and over the top of tank solution.

Ideally, agitation will be designed to constantly sweep the tank’s bottom to prevent particle settling, either via use of bypass agitation or sparge bar systems.

If you will apply a WG formulation with a backpack sprayer, be sure you can agitate the spray suspension. Use a backpack with paddles or some other type of agitator in the tank. When using a hand sprayer, simply shaking or inverting the closed applicator intermittently is generally adequate for maintaining a uniform spray mixture. The frequency for agitation may vary by product but is best determined by visually looking for obvious stratification from top to bottom.

A best practice to assess remixing intervals would be to dilute some product in a glass jar (jar test), and monitor how long it takes both for sediment to form on the jar bottom and to observe stratification in the upper liquid.

Preparing a slurry of WGs before adding it to the tank may be practical in some cases, but is not a generally required practice. One common limitation for WG-type formulations is that they generally are not designed to be added directly to concentrated liquid fertilizer mixtures. The concentrated fertilizers often interfere with the solubility of the binders and surfactants used to formulate and agglomerate the solid particles. The result would be incomplete granule dispersion and poor particle suspension due to insufficient wetting or incomplete disintegration of the WG product.

In such cases, making a slurry of the WG in water before adding it to the concentrated liquid fertilizer or micronutrient spray mixtures would be necessary. This practice assures that the WG will be fully dispersed and suspended before adding it to the spray mixture.

Making a slurry of WGs in water also may be helpful to avoid certain spray mix antagonisms with other product formulations or tank-mixture ingredients. Making a slurry also may be helpful in cases when the water is extremely cold and product dispersion rates are unusually slow.

It is critical to carefully read and follow a WG product label’s use instructions about tank mixtures with other products. It is especially important to make sure to add the products to the tank mixture in the order specified on the label.

And remember, not all dry or granular product formulations are intended or designed to be used in liquid spray systems. Instead, some dry products require granular solid application equipment. These products are not designated as WGs. Often, they are designated as granulars (GR or G). Attempts to add these types of products to liquid spray systems will lead to difficult equipment clean-outs.

For best results, read product use labels carefully. Contact your dealers or manufacturers if you have any questions about a product’s use. Test products before you apply them by using a quart glass jar to assess a particular product or tank-mix prior to preparing mixtures in the application equipment if there are possible concerns or questions.

Conclusions

Applicators used to measure products by the pound and gallon. Today, the trend is to measure by the ounce. This requires a greater level of precision in measurement.

Precision in pesticide application depends on the equipment and applicators working in unison to properly deliver an appropriate dose of a labeled product safely to a given site and pest. Today’s products are generally more pest-specific and use lower amounts of active ingredients per unit of area.

For these reasons, there is less room for error before and during an application. If you over- or under-apply pesticides, it can be expensive to you and your customers. You also could harm the environment. What’s more, over-applying a pesticide is illegal.

The precision instruments available in today’s spray technology are only as good as what you put into them. Seemingly minor errors in measuring pesticides into the spray tank may have a large impact on the end results. If measuring devices or tank marks are inaccurate, that can multiply errors.

Know and understand the differences between liquid and dry ounces, both common units of measuring for pesticide products. If you use measuring devices enclosed with pesticide packaging, use and then discard them when you have used up the product. Keep in mind that manufacturers often change their product formulations with only subtle differences in the label and package.

The common instruction to “Read and follow label instructions” has new meaning. When you look at the big picture in spray technology, realize that the subtleties of measuring the product or carrier

are often neglected and may be the difference between application success and failure. Using an inaccurate measuring container, following the imprecise measurement marks on a spray tank, confusing dry with liquid ounces, or using a WG volumetric measuring device intended for another product will limit application accuracy. These issues show just how important it is to correctly measure pesticides for the best performance.

Investigate, and if necessary, correct measurement errors in the pesticide application process. Don’t let hidden pitfalls derail your pesticide application.

ACKNOWLEDGMENTS

Thanks to Dawn Minns for graphic design. Thanks also to those who offered constructive comments during the development of this publication.

- Bob Avenius, TruGreen

- Gerry Blase, Asplundh

- Larry Bledsoe, Purdue University

- Phil Blevins, Virginia Tech

- Adria Bordas, Virginia Tech

- Ron Calhoun, Residex

- Gurinderbir Chahal, Purdue University

- Jim Colias, Matt’s Lawncare and Landscaping

- Roger Dawner, Ohio State University

- Curt Elsik, Huntsman Corporation

- Harold Enger, Spring-Green

- Rick Foster, Purdue University

- Eric Frazier, Willow Oaks County Club

- Nicola Gallagher, DuPont Professional Products

- David George, Engledow Group

- Bobby Grisso, Virginia Tech

- Kevin Harness, Farmer

- Harvey Holt, Green Systems Analytics, LLC

- Wayne Hug, DeAngelo Brothers

- Bill Johnson, Purdue University

- Matthew Johnson, Aquatic Control

- Matt Kraushar, Purdue University

- Craig Martin, FMC Agriculture Products

- Jason Myers, CWC Chemical

- Jeff Nagel, Ceres Solutions

- Bob Wolf, Wolf Consulting and Research, LLC

- John Wooge, Virginia Tech

Disclaimer

This publication is intended for educational purposes only. The authors’ views have not been approved by any government agency or business. The publication is distributed with the understanding that the authors are not rendering legal or other professional advice to the reader, and that the information contained herein should not be regarded or relied upon as a substitute for professional consultation. The use of information contained herein constitutes an agreement to hold the authors harmless for liability, damage, or expense incurred as a result of reference to or reliance upon the information provided. Reference in this publication to any specific commercial product, process, or service, or the use of any trade, firm, or corporation name is for general informational purposes only and does not constitute an endorsement, recommendation, or certification of any kind by Purdue University. Individuals using such products assume responsibility for their use in accordance with current directions of the manufacturer.

Find Out More

Purdue Pesticide Programs offer a number of publications on related topics to help you manage your operations better. All publications are available from The Purdue Extension Education Store (888) EXT-INFO (496-4636).

The Impact of Water Quality on Pesticide Performance (PPP-86). Understand how your mixing water influences pesticides.

The Impact of Water Quality on Pesticide Performance (PPP-86). Understand how your mixing water influences pesticides.  Pesticides and Formulation Technology (PPP-31). Learn the details of pesticide formulations and how to use them effectively.

Pesticides and Formulation Technology (PPP-31). Learn the details of pesticide formulations and how to use them effectively. It is the policy of the Purdue University Cooperative Extension Service that all persons have equal opportunity and access to its educational programs, services, activities, and facilities without regard to race, religion, color, sex, age, national origin or ancestry, marital status, parental status, sexual orientation, disability or status as a veteran.

Purdue University is an Affirmative Action institution. This material may be available in alternative formats.

Order or download materials from Purdue Extension • The Education Store

July 2012