Extracting Stuck Equipment Safely

Fred Whitford, Coordinator, Purdue Pesticide Programs

Dennis Nowaskie, Superintendent, Southwest Purdue Agricultural Center

Steve Hawkins, Assistant Director, Purdue Agricultural Centers

Doug Busdeker, Area General Manager Farm Centers, The Andersons

Mike Depoister, Owner, TriPower Towing and Recovery

Steve Queen, Safety and Risk Coordinator, Trupointe Cooperative

Jamie Southard, Safety and Regulatory Director, Effingham Equity

There’s More to Equipment Extraction than Hooking and Pulling 4

When an Unstoppable Force Meets an Immovable Object 10

A Lucky Pull 12

Just Because You Can Doesn’t Mean You Should 14

Know What You’re Dealing With 18

Communicate With the Recovery Team 22

Understand the Zones of Extraction and Forces of Resistance 24

Choose the Right Connecting Equipment 36

Check Attachment Device Ratings 52

Tips for Recovering Vehicles or Equipment 60

Remain Calm 72

What to Do if Bad Things Happen 74

Properly Inspect, Clean, and Store Recovery Devices 76

Inspect Equipment Post-Recovery 82

Take Action Today 86

Conclusion 90

Acknowledgments 94

Disclaimer 95

There’s More to Equipment Extraction than Hooking and Pulling

How many times has someone asked you, “Hey ol’ buddy, my truck is stuck in the mud. It’s not stuck bad. Can you pull me out?”?

If you’re like most people you don’t hesitate to at least try to help. You want to help your friend, and you expect that your friend would help you if the situation were reversed. Although you may be full of good intentions, it could be very costly and deadly if you don’t know what you’re doing.

The truth is that for every story of a successful vehicle extraction, there is usually a story about something that has gone wrong — sometimes very wrong.

Every vehicle extraction brings its own unique set of challenges and concerns. This publication examines the ratings of towing devices, factors to consider before you pull out stuck equipment or vehicles, and when calling a professional wrecker service is warranted. Our goal is that equipment operators will be better equipped with the knowledge to safely and effectively extract stuck vehicles without injuring the drivers, bystanders, equipment, or the environment.

If you’ve never personally experienced an extraction gone wrong, consider the following true story from one producer.

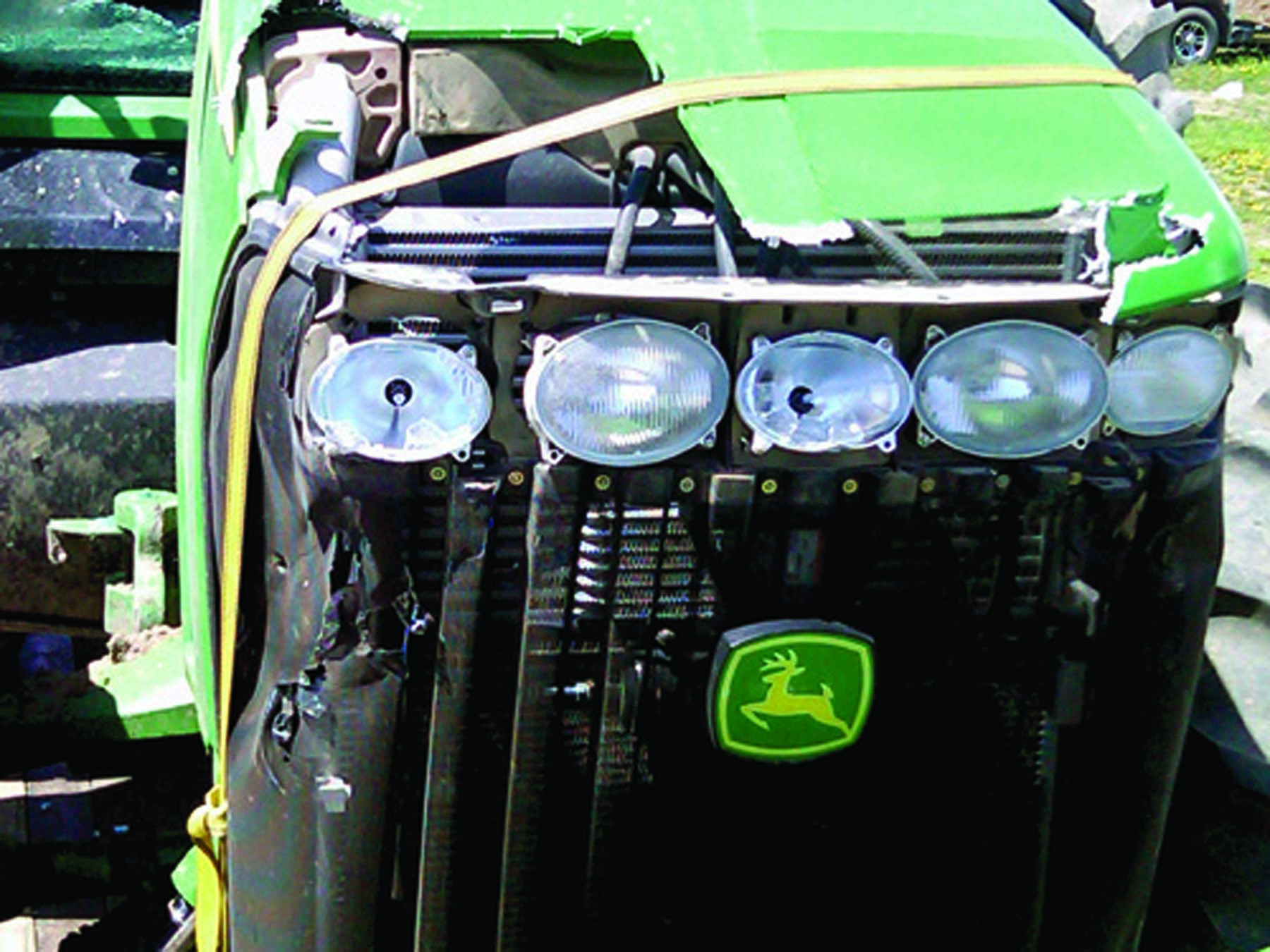

“We have three John Deere tractors on the farm: two 8295s and one 8345. We were using an 8295 to pull the planter when it got stuck in a wet spot. The initial plan was to use the other 8295 to pull it out, but the first attempt failed due to a lack of power.

We brought out the 8345 tractor and attached it to the chain, but this also failed to even move the stuck tractor and planter.

“We then attached the 8345 to the stuck 8295 with the planter, and then attached the 8295 to the front of the 8345. That’s when

everything went wrong.

“A cotter pin snapped, and the clevis shot through the back windshield of the 8345. It struck the driver in the arm and bounced off the two most expensive computer parts in the cab before it shot through the front windshield. It went about another 80 feet past the other tractor.

“The driver had to be taken to the hospital. He has had one surgery to date, and there are plans for a second surgery and a skin graft. The damage was extensive and his doctors are still determining whether he will permanently lose any range of motion in his arm.

“After the driver was hit, he could not move his arm, so there was nothing holding the tractor back. The 8345 shot into the back of the 8295, and now we have an 8345 in the shop with a lot of damage.

“In the end, it took two, four-wheel-drive tractors with duals to pull the stuck 8295 and planter out. The driver’s injury and equipment damage was all caused by the tremendous tension placed on a single cotter pin pulled by equipment with lots of power.

“It is also just one example of how things can go wrong when people get in a hurry and don’t realize what can go wrong. Think about what could happen before you try to pull out any equipment. The safety of the drivers should have been the most important thing here.”

What started out with good intentions turned into an expensive and painful experience for everyone. A broken piece of metal can easily become a missile — and a split second or a few inches determine whether that missile results in a near miss or serious injury.

Whether a farmer or a company owns the stuck equipment, operators tend to share a common goal: get it free and running as quickly as possible. Growers have a short window of time to do everything they need to, while retailers are under pressure from customers to complete work in a timely manner. It never fails; just when you are busiest and feeling the pressure, someone gets a piece of equipment stuck in the mud.

All too often, that sense of urgency keeps us from thinking about the consequences of what can happen if we don’t take the proper precautions before we try to pull someone’s equipment out of a ditch or mud hole.

We never plan to get equipment stuck — it just happens. When it does, we react, often with a single-minded “We have to get it out as quickly as possible and get back to work” attitude. For some of us, our first thought may even be, “What do I have to do to get this out of here quickly so the boss doesn’t find out?”

It’s this mindset that motivates people to grab the first thing they find without really thinking about what they are about to do or prepared for what may soon follow. The fact is: well-intentioned people can still make poor decisions and take the wrong actions.

‘I’ve Done This Before; I Know What I’m Doing’

When equipment gets stuck, a lot of people probably think, “I’ve done this before; I know what I’m doing.” But after a problem occurs, it’s too late to undo what was done. If someone gets hurt or equipment is damaged, we have to live with that forever. Before you extract any stuck tractor, truck, or implement, step back and think about what you are about to do.

It is essential that equipment operators recognize the real dangers associated with pulling application equipment, tractors, or trucks out of mud, sand, or snow. Extracting equipment is anything but routine, and owners and operators need to understand the potential repercussions of unsafe practices (such as of using a cut towing strap, undersized clevis or chain, or a weak attachment point). Such shortcuts can lead to expensive repairs, injuries that last a lifetime, or worse, a person’s death.

Practice Conscious Awareness

Operating safely is all about being consciously aware of what’s happening and anticipating the unexpected. Extracting stuck equipment is never routine because every situation is different. It only takes a split second to turn the most benign activity into one that causes serious injury or even death.

Be aware of all the equipment you are using and all the conditions around you. If the extraction breaks equipment, the flying debris can be just as lethal as a bullet from a gun.

When an Unstoppable Force Meets an Immovable Object

It takes more pulling strength to move something mired in the ground than it takes to pull the same object over the road. When you tow something on the road all you have to do is get the weight of the towed vehicle moving forward.

When equipment is stuck, you’re moving “dead weight,” which requires you to overcome additional forces. A dead weight pull places incredible stress on the straps, cables, chains, and other devices from the time we start pulling until the time the stuck vehicle is dragged forward — that stress can be up to many times the weight of the stuck object.

The stress on the connections is so great because there are two opposite forces that are, essentially, trying to rip the connections apart. It’s the force created when one vehicle pulling in one direction is increased against the force of the stuck equipment that doesn’t want to move. As the towing unit exerts more pulling force, the strength and integrity of the connecting devices and attachment points are put to the ultimate test. If the pulling force is greater than the force holding the stuck vehicle in place, then the stuck vehicle will be pulled toward the towing truck or tractor.

However, if the force exerted on the chains, straps, and clevises exceeds the rated capacities of those connectors, the connections can snap, break, or tear, before the stuck equipment comes free. When the connectors fail under such pressure, it sends debris flying through the air with tremendous speed and force.

Practice “conscious awareness” and anticipate the unexpected. Extracting stuck equipment is never routine because every situation is different.

It only takes a split second to turn the most benign activity into one that causes serious injury.

A Lucky Pull

When we pull trapped equipment out of mud and snow, we tend to rely on past experiences. If the way we pulled it out worked before, we’ll often do the same thing again. But those are often faulty assumptions — there’s no guarantee that what we used before will stay intact this time.

Unfortunately, simply “hooking and pulling” can push your luck to the extreme and you may end up with results you would never want to contemplate. While it’s tempting to simply hook, jerk, and pull with whatever is handy, you unknowingly rely on past luck that the chain links, knotted strap, or clevis with a replacement bolt didn’t snap, tear, or pull apart the last time.

Relying on luck in such a potentially dangerous situation is never wise. Familiarize yourself with the do’s and don’t’s of extracting stuck equipment. Not only will that help you remove the equipment, you’ll do it without injuring people, property, or the environment. You should be aware of the factors involved and not rely on luck.

A windshield or side of a truck is no match for flying metal slamming into it at high speeds.

Just Because You Can Doesn’t Mean You Should

Consider the following story from a retailer.

“I had one location break every chain in their shop before they called our shop manager to have a wrecker pull out a piece of stuck equipment. After they broke the third, fourth, or even fifth chain, a light bulb should have lit up in someone’s head that they were not using the right equipment to do the job. They only stopped when they ran out of chains.”

Those people were probably lucky — those broken chains could have injured someone. If you need to extract stuck equipment, one of the more important decisions you need to make is to determine whether you have the right equipment. Do you have the right truck or tractor, the proper attachment equipment, or the knowledge to pull the vehicle out of its mess?

After assessing the situation, you might say, “There’s no way I can get you out safely, we might as well call a wrecker.” If you know you don’t have the right equipment for the job, don’t let someone try to cajole or coax you into changing your mind. In these situations, common sense should always trump valor.

Everyone is in a hurry, under pressure, and eager to return to the day’s operations. But that should not make you lose the conscious awareness that brings good judgment.

Every situation is different and you need to assess each one differently. Survey each situation and really analyze the problem before you try to remove a stuck vehicle. And be aware that you may have to change your mind in the middle of an extraction. If you realize you didn’t assess the entire situation or that circumstances changed, stop what you’re doing and keep your people and equipment safe.

Before you decide whether to extract a stuck vehicle, understand that there are circumstances when you should always call a professional wrecker service. Always call a professional when:

• The towing vehicle’s engine stalls out in the lowest gear while trying to pull.

• The towing vehicle’s tires do nothing but spin and smoke.

• Your attachments, chains, straps, etc., break.

• You need to attach multiple chains ropes, or straps to reach the stuck vehicle.

• The only apparent option is to hook multiple trucks or tractors together to attempt to pull.

• You don’t know or understand what you are doing.

• You will cause more damage if you do it yourself.

• You will do more damage to the stuck unit by jerking on it.

• You don’t know the rated capacities for the towing equipment — straps, clevises, chains, and so on.

• The towing equipment has not been inspected.

• Extracting the vehicle will require a running start from the towing vehicle.

• Tempers are flaring — when that happens, poor judgment frequently prevails.

It’s difficult to admit when a situation has beaten you, but carefully reassessing the situation will determine the proper course of action. Listen to what your “gut” instinct tells you. If you don’t feel comfortable doing it, then don’t!

Know What You’re Dealing With

Before you attempt to extract any stuck equipment, you need to know what the equipment is carrying. It’s one thing to extract a truck loaded with grain or a planter, but equipment loaded with potentially hazardous materials (such as a pesticide sprayer, liquid fertilizer applicator, liquid manure spreader, or fuel truck) can pose additional risks. Human safety is still a factor, but you also need to consider how a spill could affect the surrounding environment if something goes wrong. You need to be aware of where the spill could go and what could go wrong.

At first glance, this stuck sprayer poses nothing unusual. However, with the unit mired over running water, it becomes important to really study the situation before taking action. A mistake here could lead to a pesticide spill and contaminate this creek.

Being bogged down in a marsh is serious. If product is spilled it could contaminate not only surface water but groundwater, too.

If the stuck equipment is carrying potentially hazardous materials:

• Make certain the tank holding the material is secured.

• Account for any materials on the equipment.

• Inspect the tie-downs to see if they are still intact.

• Consider unloading materials from the stuck equipment before attempting to extract it. Removing the product could be safer and make the load lighter.

• Inspect the hoses and fittings to ensure they are intact and have not been damaged.

• Make sure hoses will not be ripped off if you pull the equipment forward or backward.

• Take precautions to prevent the product from getting into water.

• Have personal protective equipment on-hand in case of a spill.

And you should always do the following (whether the equipment is carrying hazardous materials or not):

• Assess how badly the equipment is stuck.

• Figure out what further damage may be caused if you continue.

• Determine whether the axles are dragging.

• Determine if the vehicle bellied out or is resting on the frame or rear-end housing.

• Figure out if the extraction will require a general pull or more effort.

• Know if the equipment is loaded or empty.

• Know where the equipment is located.

• Determine if the equipment is in sand, clay, or snow.

• Make sure you can reach the stuck vehicle without getting any other equipment stuck.

• Assess the condition of the ground under the pulling vehicle.

• Make sure you have the right equipment — straps, clevises, and so on.

• Have the equipment that is rated to do the job.

• Make certain all the extraction equipment is in good condition and has been inspected to ensure its integrity.

• Take precautions to protect all drivers and bystanders from injury and flying debris.

• Determine whether the load will shift if the equipment is pulled forward or backward.

• Determine whether the equipment is leaning to one side.

• Determine whether unhitching a trailer from a truck will cause either of them roll over.

• Know where power lines are located to avoid contact with them.

Be aware of power lines when extracting equipment to avoid the risks of serious damage or injury.

Communicate With the Recovery Team

Whether you extract the equipment yourself or hire a wrecker service, always communicate your assessment to the recovery team. You and the team should account for all the equipment and materials before attempting any extraction.

And before extracting any stuck equipment that is carrying potentially hazardous materials, make sure the recovery team has the following on hand:

• Product labels

• Material safety data sheets

• Personal protective equipment

• A backup plan

• Spill recovery materials

• Emergency phone numbers

Understand the Zones of Extraction and Forces of Resistance

What makes many removals challenging is that each extraction is specific to the site. There are four distinct zones for any extraction:

1. Stuck zone

2. Tow zone

3. Danger zone

4. Clear zone

When you evaluate any extraction site, you must individually consider the factors in each of the zones. For example, you need to consider the mechanical considerations (such as weight relationships, pulling positions, and connection types) in each zone. Blend the information from each zone to develop a plan and course of action.

The following sections describe the four zones of extraction and the special considerations for each one.

The Stuck Zone

As the name suggests, the stuck zone is the area immediately surrounding the stuck equipment. When assessing this zone, your first goal is to determine how much weight you need to move. If you don’t have a good estimate of the weight that is bogged down in the mud, snow, or sand, you are trusting your efforts to luck, which is never advisable.

When you calculate weights, consider more than just the weight of the truck or equipment. You need to calculate the total gross weight of what is stuck, including the vehicle, possible trailer, and the payload that you will need to pull.

You can get the empty weights from owner’s manuals or data plates attached to the equipment. Another way to determine the weight of the buried truck or trailer is to use the gross vehicle weight rating (GVWR). Using the GVWR will overestimate the actual weight, and if the truck is empty, it will build in a 10-20 percent safety factor

If the vehicle is only marginally stuck and has some traction to help the towing unit, then the empty weight of the pulling equipment has to be at least equal to the loaded weight of what’s being pulled. The deeper the vehicle or equipment is stuck, the heavier the truck or tractor you’ll need to pull out the stuck equipment.

However, total weight is just one force that the towing vehicle will have to deal with. When a farm tractor or sprayer is mired in mud, there is a gripping or suction force that holds it in place — think of the extra force you need to lift a stuck boot out of the mud. A piece of equipment mired in mud will require extra force to break the suction that is “locking” the tires in place. One technique is to attach a tow rope to the stuck vehicle, put force or tension on the rope, and let it sit for a while. The strain from the tension will slowly break the stuck vehicle lose.

You will also need to account for the resistance the stuck vehicle or equipment confronts when it is pulled forward against the soil pushed in front of the tires. This resistance remains in place until the wheels can be lifted up and over the ridge of soil — think of rolling a cart over the threshold between two rooms. In the stuck zone, remove or dig out dirt around the sidewalls and in front of the tires. Removing some material will help the tires climb up as they move forward instead of running into a wall of mud.

These three forces of resistance — the total weight of stuck equipment, the suction factor of the medium the equipment is stuck in, and the resistance against the ridge of that medium — are the forces that will work against the pulling force of both the towing vehicle and whatever attachments link the towing vehicle to the stuck one.

While you can calculate the weight of the stuck equipment, it’s impossible to precisely calculate the other forces that are pulling against your towing

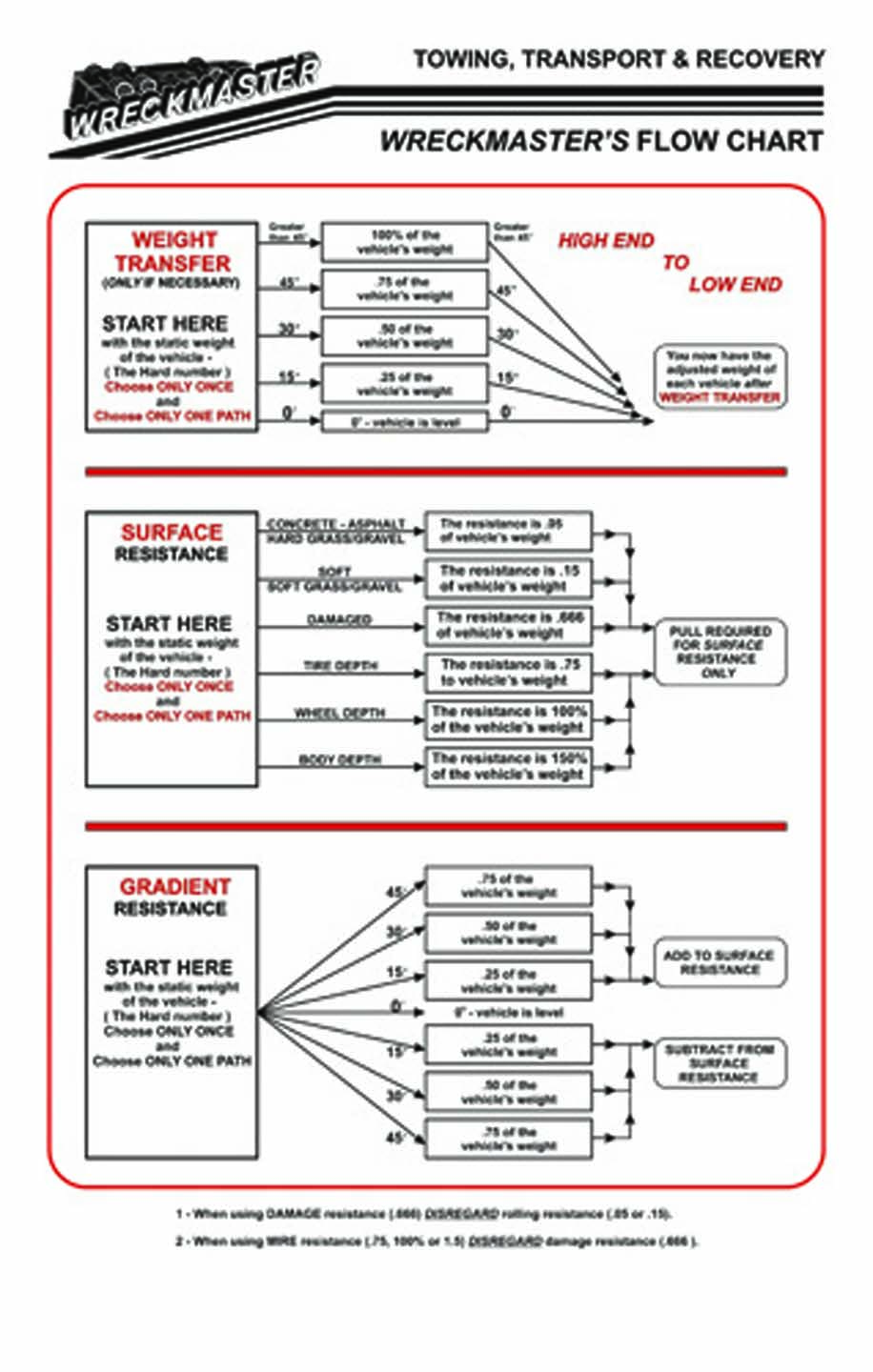

vehicle. WreckMaster, a company that trains and certifies towing industry professionals, developed a set of important guidelines that the industry uses to estimate the resistant forces that must be accounted for when attempting to extract stuck equipment or vehicles (see page 29).

They have identified three resistance factors to consider:

1. Rolling resistance

2. Mire resistance

3. Gradient resistance

ROLLING RESISTANCE

Rolling resistance is the force it takes to put a vehicle in motion. On a hard, flat surface (such as concrete or asphalt), the towing vehicle must add 5 percent of the vehicle’s weight to the weight of the vehicle. On grass or gravel, the rolling resistance is 15 percent of the towed vehicle’s weight.

MIRE RESISTANCE

Mire resistance accounts for how deeply the tires are buried. When equipment is mired in mud to a depth that covers the lower part of the wheel, you should add an additional amount of force that is 75 percent of the vehicle’s weight. When the wheels are mired in mud up to the bottom of the wheel rims, the amount of force that needs to be added is 100 percent the vehicle’s weight.

The deeper a vehicle is buried, the more force you need to extract it. The force involved is called mire resistance.

GRADIENT RESISTANCE

Gradient resistance accounts for the force of gravity pulling against the stuck equipment. The steeper the slope, the greater the stress exerted on the towing vehicle. Use the Gradient Resistance Flow Chart (above) to estimate gradient resistance and add that to the surface resistance.

The Tow Zone

In the tow zone, you need to account for the factors surrounding the towing vehicle. It’s easy to say that the towing vehicle needs to be large enough to overcome the forces of resistance that were described in the stuck zone. How big the towing truck or tractor needs to be depends on the weight of what’s stuck and how deep it is buried in the ground.

A good rule of thumb is that the towing vehicle needs to be of equal weight to the stuck vehicle. If the stuck truck can assist, a towing vehicle that weighs as much as the stuck one is usually sufficient to get the job done.

But stuck vehicles are often buried deeper, because the drivers believe they can get them out. When drivers spin their wheels or rock back and forth, they often bury the equipment deeper in the mire. When that happens, the stuck vehicle can’t help, which puts the entire burden of extraction on the towing vehicle.

Being grounded means you will need more powerful equipment to extract the truck.

Ideally, you want to position the towing vehicle on higher ground. This will give you a mechanical advantage to overcome and negate the forces that hold the stuck equipment in the mud. It is easier on the towing vehicle if it can pull the stuck vehicle’s wheels up and out of the hole and onto solid ground. If the towing vehicle is pulling forward or downward, it is forcing the stuck equipment into the immovable ground.

Anything you can do to reduce the total weight that the towing vehicle must pull and to overcome the forces of resistance will help reduce how much the towing equipment will need to work and will help reduce the stress on all the devices connecting the two vehicles.

Here are some things you can do in the tow zone to reduce the forces of resistance:

• Place the towing vehicle on solid ground. This will improve traction, which will help the towing vehicle pull more weight.

• Do not connect more than one vehicle to the stuck vehicle. Doing so only doubles the odds of something going wrong. Chances are, you alreadyused your best tractor, truck, and equipment to hook the first towing unit to the stuck vehicle. If you were to select another tow vehicle, it’s more than likely not ratedheavy enough or in the best condition.

The Danger Zone

It’s safe to say that there is great potential for danger anywhere around an extraction site, so it makes sense to always take precautions within the danger zone.

You can have a towing vehicle of sufficient size and properly positioned to free a vehicle trapped in mud, loose sand, wet grass, or slippery ice. But you also need to pay attention to the connectors that link the two together. Make certain any connectors can withstand the pressures exerted on them when they are being pulled in opposite directions.

The devices used to pull out stuck equipment take the full brunt of the forces of resistance exerted on them. If the forces of resistance surpass the ratings of any of the attachment points (clevises, hooks, straps, cables, chains) something will inevitably fail.

When connections fail, bad things happen: broken windshields, damaged vehicles, injured bystanders, and even casualties. Throughout this publication, there are plenty of examples of broken windshields, dented tailgates, bloodied seats, and bent steering wheels. All of these show what can happen when the full force of flying metal hits something — or worse — someone, when things go wrong.

An ‘Angel from Heaven’ Was Listening

Consider the following story about an extraction gone wrong.

An agricultural retailer was top dressing wheat with a sprayer when he hit a wet spot in the field and got stuck. He called the shop and was told it was no big deal (that section of the field had a history of being wet). The person at the shop promised to send a Rogator (which was spreading fertilizer less than two miles away) to pull him out.

Within half an hour the Rogator arrived, backed up to the stuck sprayer, attached a tow strap, and attempted to pull out the sprayer. But the Rogator had no luck — it was just spinning its wheels. So, they tied a second strap to the sprayer using a shackle. This allowed the towing vehicle to get on more stable ground. When the Rogator pulled forward, it had better traction. But the strap had been looped over the Rogator’s axle. An alignment pin on the axle and bolt on the airbrake canister were rubbing on the strap.

The strap broke, and the Rogator shot forward. When it did, the strap and shackle flew back toward the stuck sprayer and through the windshield. The shackle hit the operator, and the impact shattered his shoulder blade and cut an artery.

The Rogator operator jumped out and ran back to the stuck sprayer. When he climbed in the cab, the Rogator driver saw blood all over the seat and noticed the severity of the injury. He took off his shirt and told the injured driver to hold it on the wound and to put as much pressure on it as he could.

The Rogator driver tried call for help with his cell phone, but he couldn’t get a signal in that part of the field. He told the injured operator that he was going out by the road to see if he could get a phone signal and call for help. He called the shop, and then both he and the shop called 911.

Luckily, an off-duty EMT paramedic lived just down the road and heard the 911 call on her scanner. When she heard the address, she thought that it was right out her back door. She called the 911 center to verify the address, then jumped in her car and drove to the scene. She got within 400 feet of the stuck vehicle before her own car got stuck in the muck, so she ran the rest of the way to the injured driver. The injured driver, who was only 22, had severe trauma. To save his life, the EMT pinched the artery with her fingers to stop the bleeding.

At the time of the incident, the company’s safety coordinator was working at another branch. Medical helicopters had already arrived by the time he got to the scene, and emergency personnel were getting the injured operator out of the cab. The helicopter flew the injured driver to a trauma center and he was given 13 units of blood.

The injured driver knows he was lucky, and credits his survival to “an angel from heaven” down the road who happened to be listening.

Never side-load a shackle. They lose much of their strength this way.

The Clear Zone

The clear zone is the only area around the extraction that is safe. There’s nothing like a stuck vehicle to attract an audience. Some come to offer advice or assistance, others come just to watch the action and have something to talk about in the coffee shop.

But, only two people — the operator of the towing vehicle and the driver of the stuck equipment — should be in the vicinity of either vehicle as it begins to tighten the strap, cable, or chain.

Everyone else is nonessential to the extraction process, which means they need to clear the area. Nobody should be in the area under any circumstances when work is in progress — that includes keeping people out of the passenger seats of both vehicles.

There should never be another person in the danger zone when you are extracting a stuck vehicle. The person on the four-wheeler is in great danger because a piece of metal or strap could come lose during the pulling process.

You should always establish a circular clear zone around the entire area of at least 100 feet to avoid flying debris. Don’t allow any bystanders within 100 feet of the work area. And if you are using an extra long chain, cable, strap, or rope, keep spectators even farther away.

As a rule of thumb, ask that all nonessential personnel watch the extraction from either side of the working area (not the front or back). If something goes wrong, it’s more likely that flying debris will go forward (toward the towing vehicle) or backward (toward the towing stuck vehicle) than to the side. You could also place another vehicle between the spectators and the clear zone, and ask the bystanders to stand behind the vehicle in case any debris starts flying.

Choose the Right Connecting Equipment

Chains

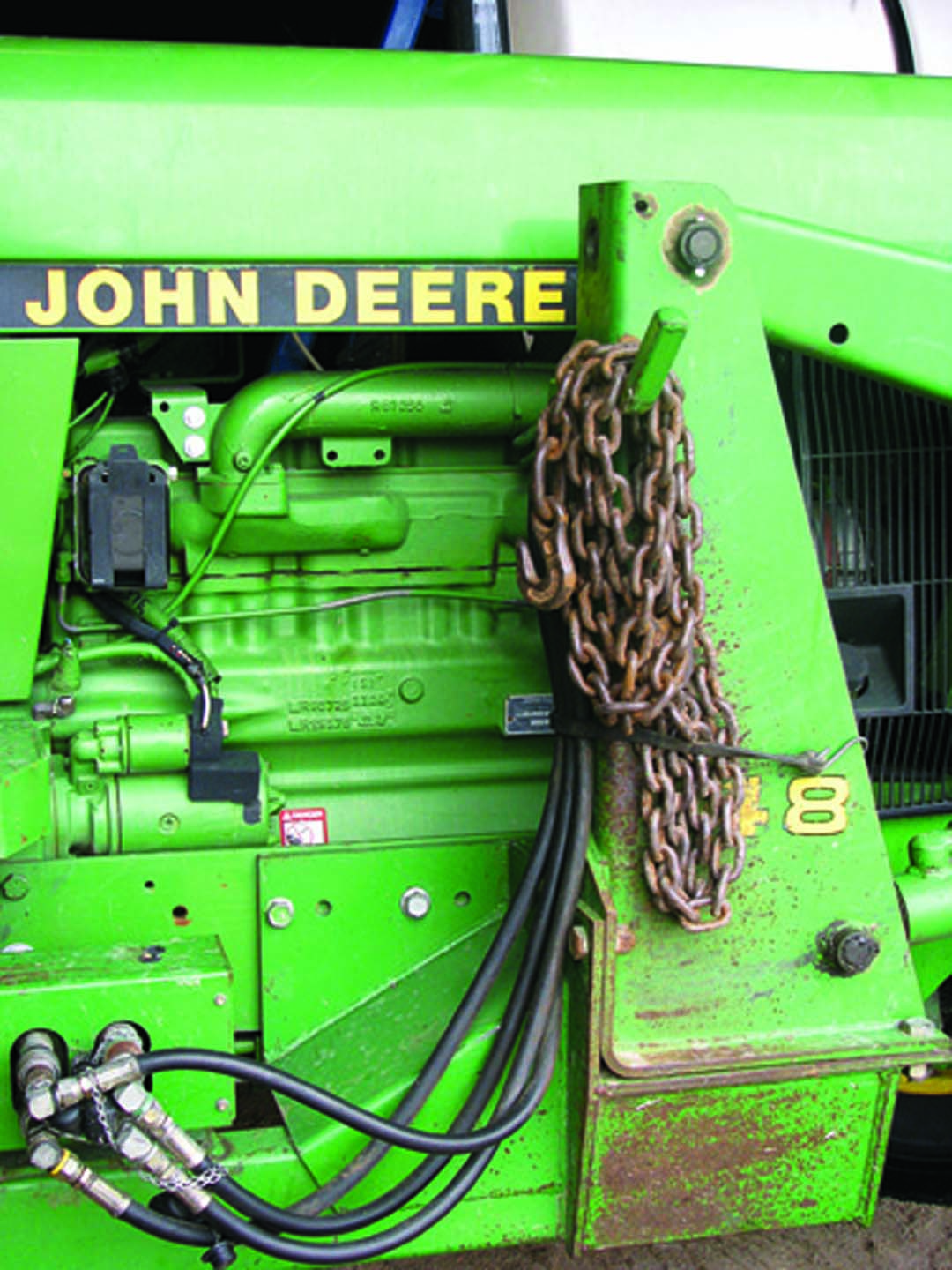

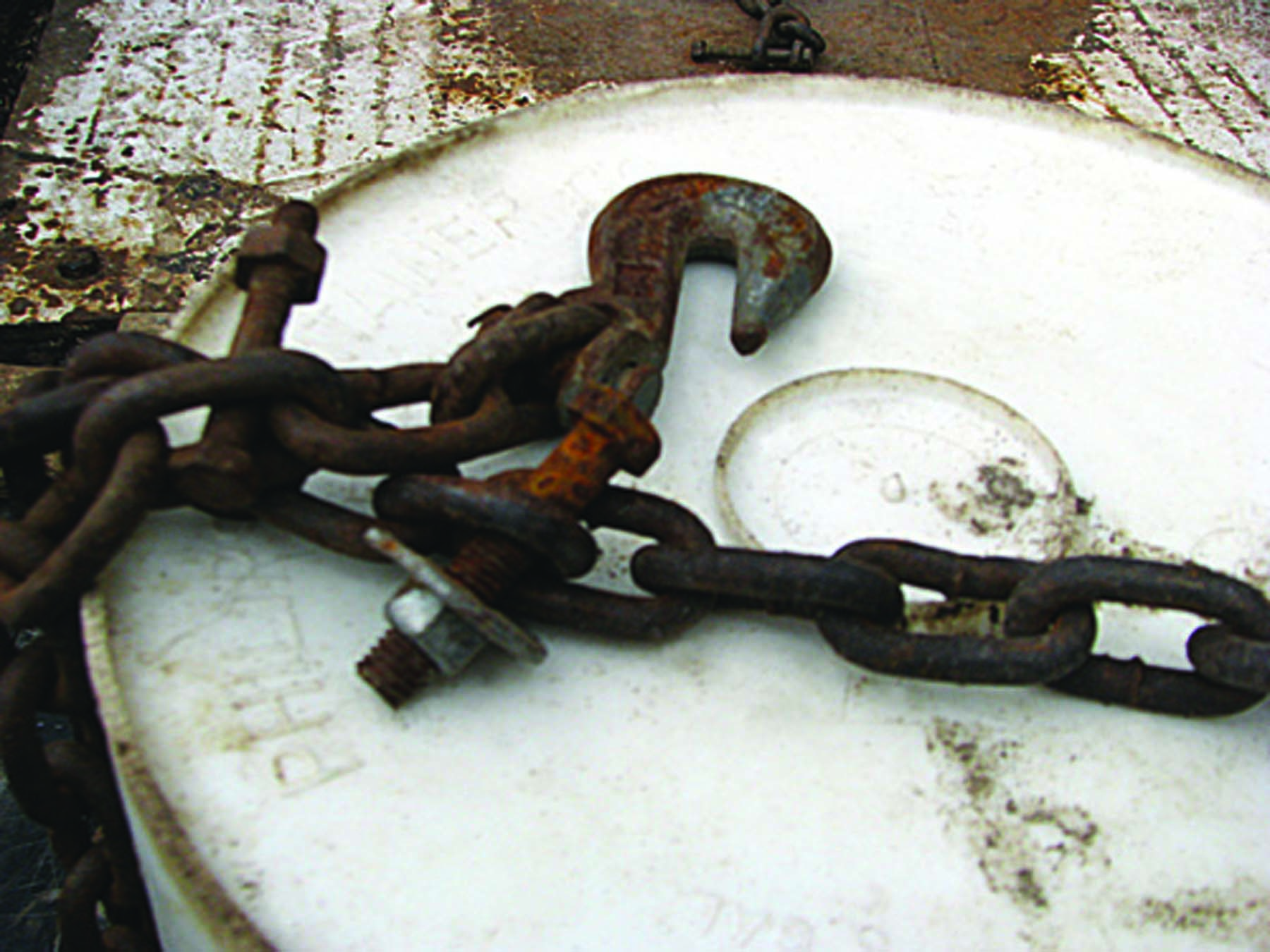

We all grew up pulling out equipment with chains. An important weakness of chains is that they are not always the best choice for recovery. To make matters worse, many old chains have been improperly repaired by welding two links together when one broke, or by using mismatched hooks with a lower grade than the original chain. Chains also rust when you leave them out in the rain, and they can stretch when you use it to pull a load that was too heavy — which leaves the chain weaker the next time you use it.

You might hear somebody argue, “But this old log chain belonged to my grandpa and it’s always worked. It’s pulled out dozens of vehicles and it’s never failed.” Although the chain worked a thousand times before, it only takes one time for one link or a hook to fail and send someone to the hospital, or worse, to the cemetery.

All towing and pulling equipment is rated for pulling capacity. Always match the rating to your task. Whether you prefer using chains, cables, tow ropes, or recovery straps, every one of these devices can fail if you push them beyond their limits.

It is critical to better understand the materials that are commonly used for towing or pulling:

• Chains

• Wire ropes (cables)

• Lift straps

• Tow ropes and tow straps

• Recovery straps and ropes

Knowing the strengths and limitations of these materials forms the foundation for safe practices in and around the four zones of extraction.

It isn’t just the condition or size of the chain you need to pay attention to. Be careful how you use chains, too. At one time or another, we’ve all backed up to the stuck equipment, got a good running start, and attempted to jerk the vehicle out. It may have worked once, but chances are that the chain will snap from absorbing the initial shock. If any one of the links are stretched, cracked, or weakened in any way, the chain can snap from the extreme pressure exerted on it. That’s why it’s best to not to jerk on a chain when trying to pull a vehicle out.

This is an impressive looking chain, but the hook and chain are only grade 30. Low-grade chains and hooks like these will meet their match and break.

All this is not to say that chains will not work. For example, using chains from the shop might be good for pulling out light vehicles that are not deeply stuck in mud or those vehicles that can’t get enough traction on ice or snow to move forward. And as long as you don’t jerk them, you can use chains to extract heavier equipment as long as the chains are designed and rated for towing the weights they will encounter.

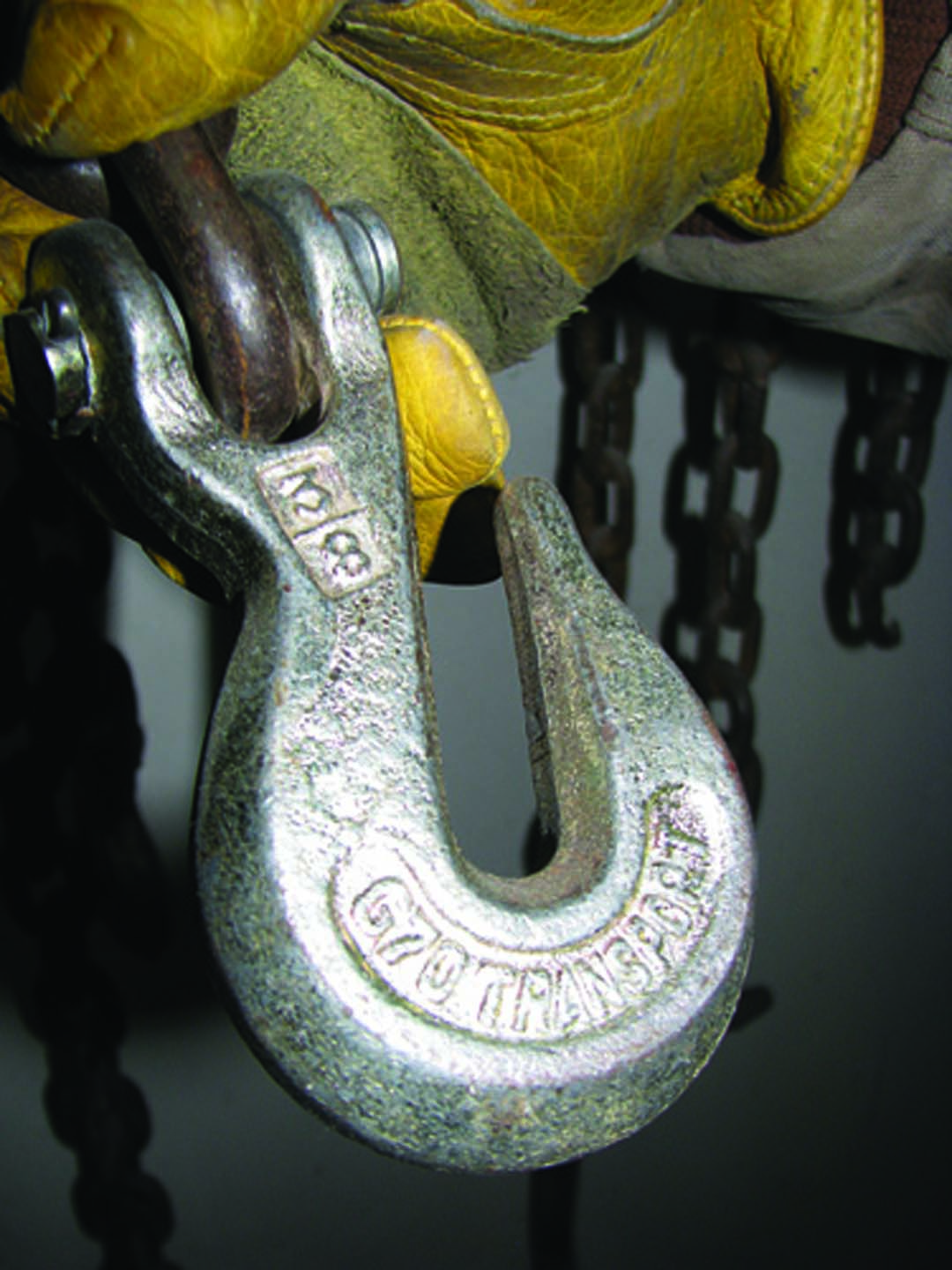

If you are going to use a chain to pull, it must be a chain designed for recovery and must be strong enough to do the job without snapping — that means a grade 80 for most vehicles and a grade 100 or greater for larger farm equipment. Always equip chains with the proper hooks.

It’s also important to inspect all chains and hooks after each use. Operators tend abuse chains and other tow equipment during the extraction process. But after the extraction is over, operators toss them back into storage and forget about them until the next emergency. After every tow, thoroughly inspect all equipment and discard anything that’s damaged. This critical step can save lives and prevent costly vehicle damage.

You need chains that are strong enough to hold the equivalent of steel coils on trailers. With chains, it’s best to purchase them from a company that assembles them so that the chain and hooks are matched and rated for your specific purpose. It will also enable you to purchase with some confidence. A properly rated chain works well as long as you don’t jerk on it when you are pulling.

It is worth repeating: chains work fine as long as you don’t jerk on them.

What are the odds that this truck can be pulled out of the mud without jerking on the chain? Probably slim to none. But jerking on the chain increases the probability that something will give way, especially when the chain is undersized or in poor condition.

The right way to use a chain is to slowly tighten the chain until you pull the slack tight, and then pull forward with the towing vehicle. If the towing vehicle starts spinning and doesn’t move the

object, either get a larger towing vehicle, or call a wrecker. Don’t jerk the chain!

It is a natural instinct to back up the towing vehicle, get a running start, and yank the stuck equipment out. But that is the worst mistake you can make with a chain, because chains snap when they are jerked, which can send potentially deadly missiles through the air. Because jerking is so common, we don’t recommend using chains as the attachment device when extracting equipment.

Hooks and Links Are Critical Parts

Any hooks you use with a chain should, at a minimum, have a rating capacity equal to the chain. While two hooks may be 3/8 inch, one can have a relatively low grade 43, while another can have a grade 70.

Never use a chain if its hooks have been altered in any way or if the hooks’ ratings are not equal to or greater than the chain’s rating. Certain hooks have wings or ears on them to keep the chain from pinching too tight around the hook. It allows the force to be distributed on all links instead of just one.

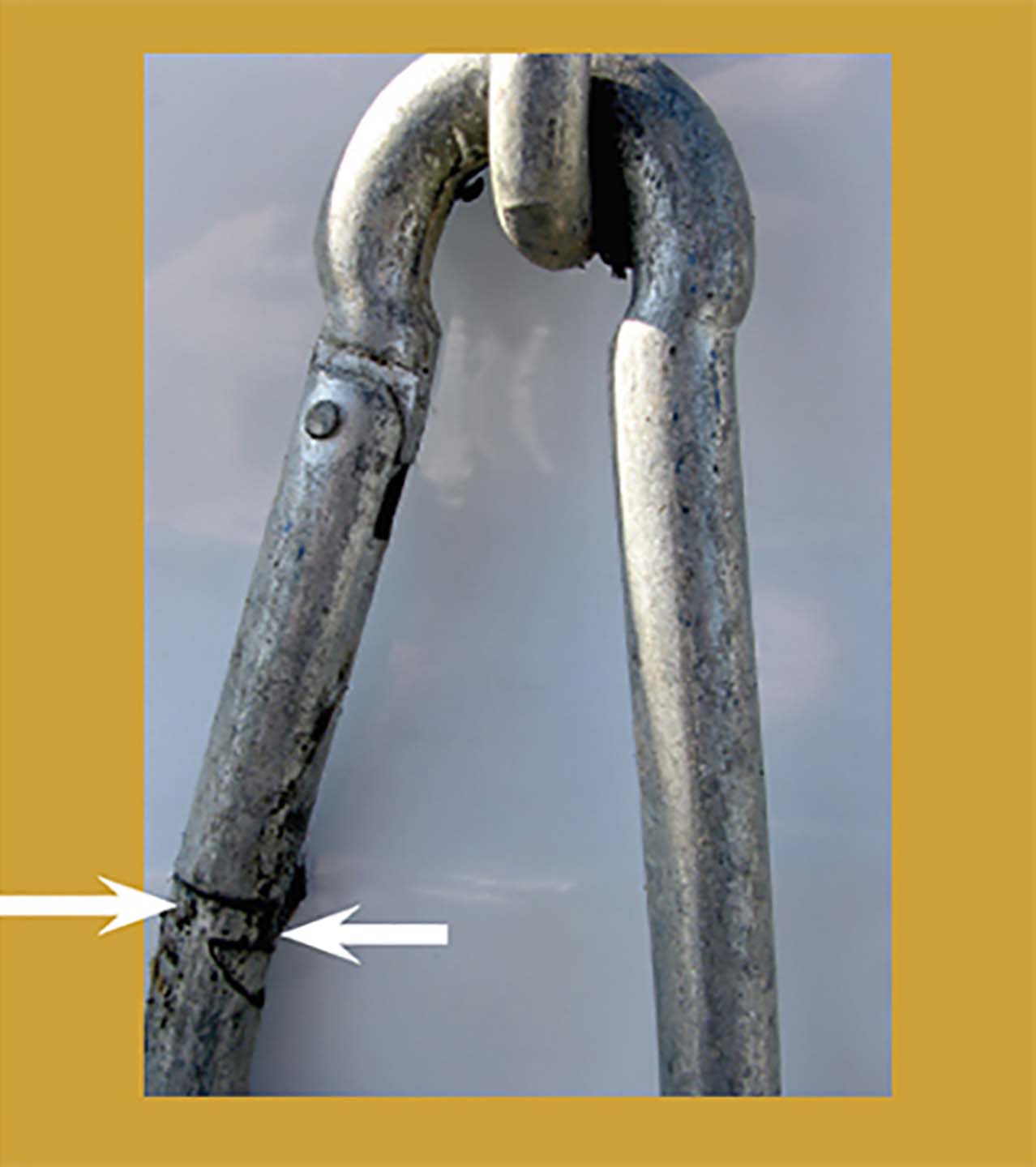

Never make a loop at the end of a chain and attach it with a bolt. This compromises the strength of the chain. The chain’s strength is no longer the weakest point or limiting factor. Now, all of the force will be placed on a loosely tightened nut. Bolts are made to work when they are tightened down for whatever they are holding. Use the chain and the hooks as they are intended to be used.

It is extremely dangerous to connect two separate chains with just a bolt.

While commonly used on chains, these connectors cannot stand the stress they will encounter during vehicle or equipment extraction. Notice how little metal there is on the post. This greatly weakens the connector.

Wire Ropes (Cables)

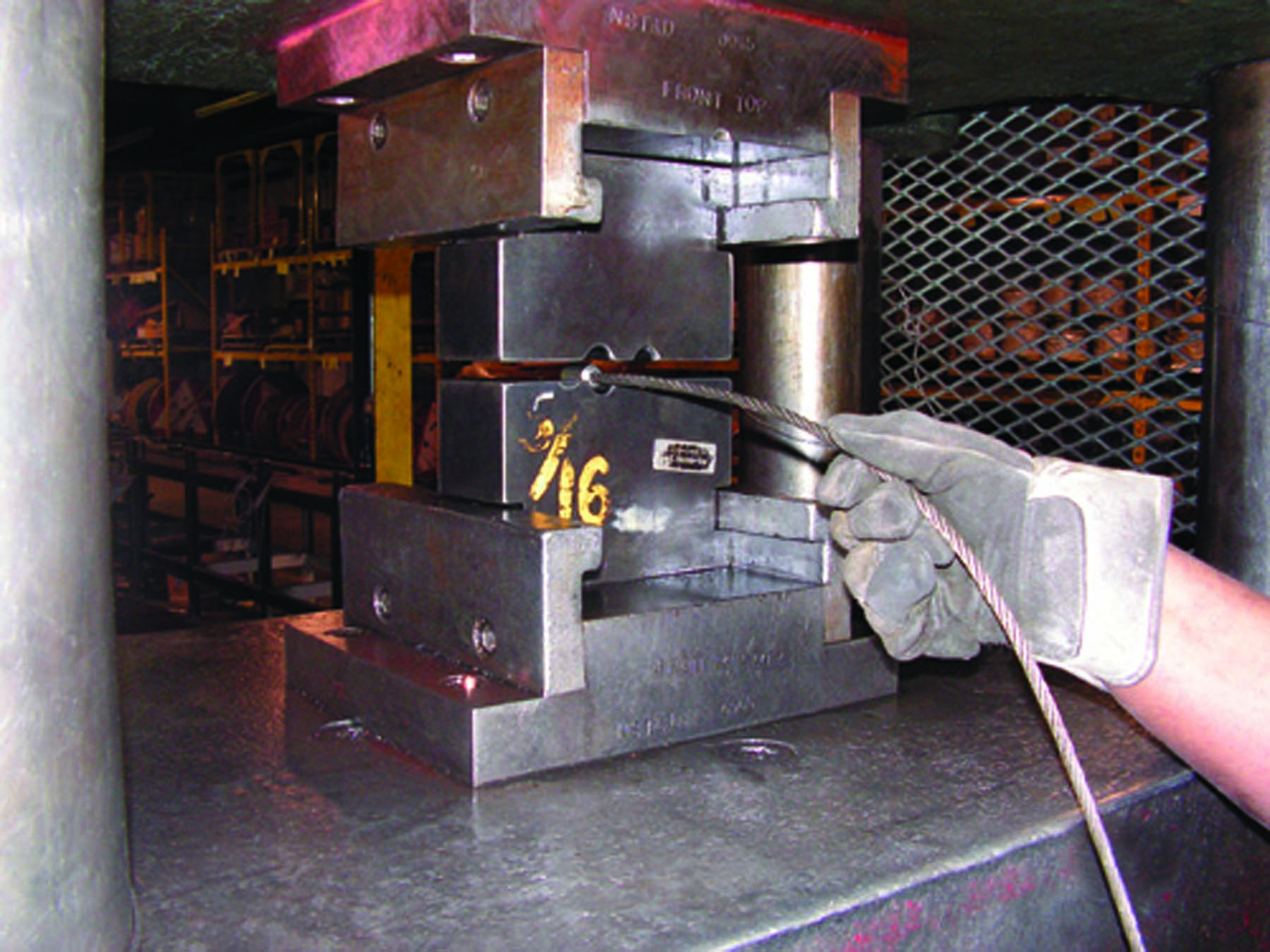

Wire ropes (commonly called cables) work well for pulling out lodged vehicles, which is why most (if not all) people who make their livings by extracting struck equipment depend on them.

That doesn’t mean you can jerk cables. They are not designed for impact and should never be jerked on. If you’ve ever watched a wrecker service pull someone or something, the towing vehicle is usually parked and has stabilizer legs in place as the operator applies a steady and constant pull with the cable or the wench. The wire rope is slowly reeled onto a spool, pulling the stuck equipment toward the towing vehicle.

The operators are using two cables to pull this vehicle out of a quagmire.

It will require a heavy-duty cable to pull this piece of equipment out of the mud.

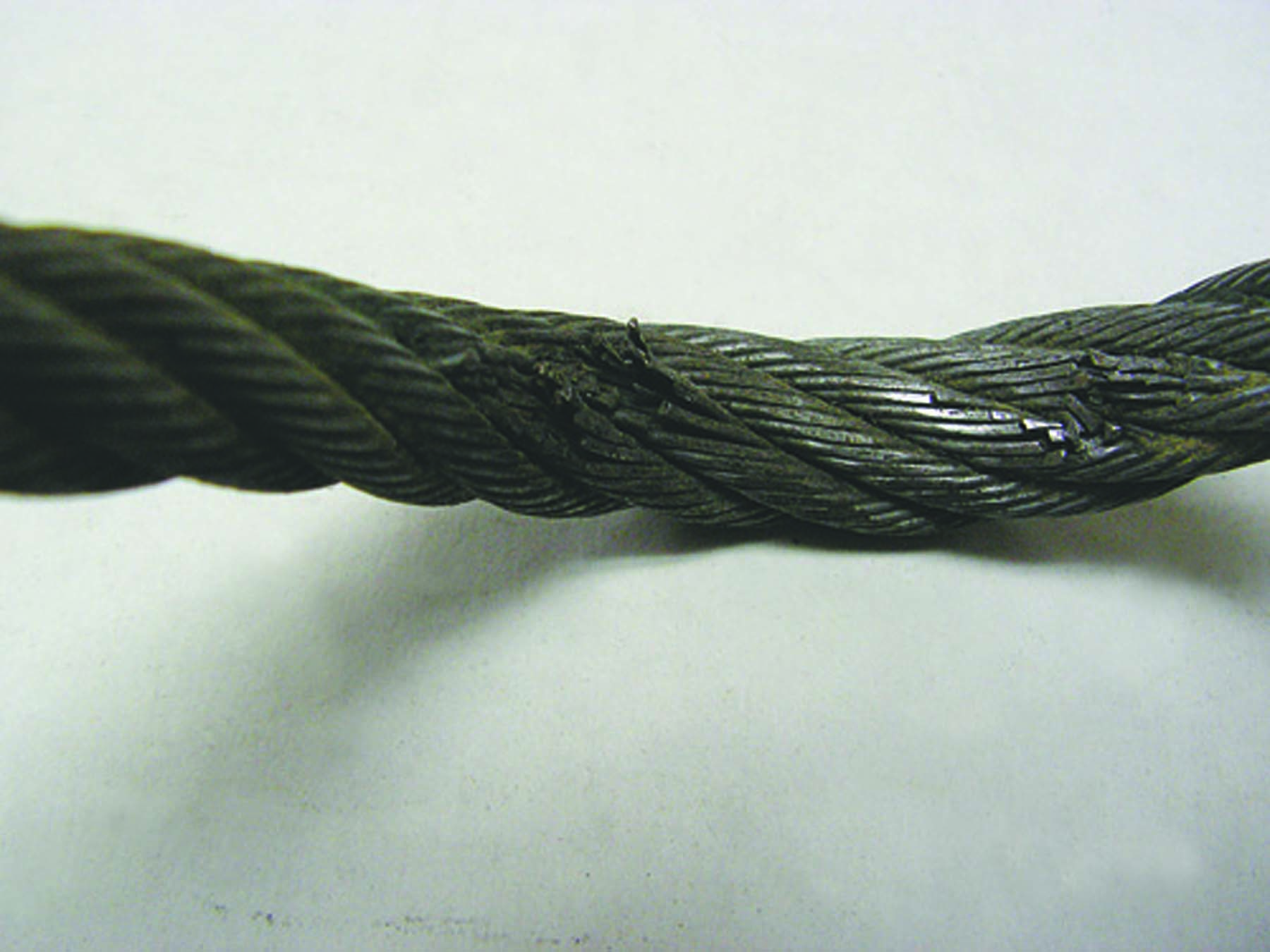

Although wire rope (cable) is the choice of most professional towers, it does have a few drawbacks. If you’ve ever worked with cable, you quickly learn that you should only handle it while wearing heavy gloves. The individual strands of wire that make up the cable may be cut or broken, which can cut up your hands.

You also have to pay attention to how many of the wires are cut — if enough get cut, the integrity of the cable will be compromised. Each cut or broken strand reduces the cable’s overall strength.

Make sure to use the proper cables for the job. A major safety concern is that people can pick up a cable that has just been lying around, rig it with attachments, and place it into service as a recovery cable. While the cable may look fine, you can’t look at a cable and determine its strength.

If you grab a piece of cable and think, “This is heavy, so it’s going to work,” that could be a deadly decision. Like any equipment always know the ratings of the cables you’re using. And before you store them, always label cables so you can identify their ratings next time.

It’s relatively common for people to fabricate their own cables by running through a big slip hook, doubling back and attaching a cable clamp (wire rope clip) on it. But attaching a hook on the end of the loop places tremendous pressure on the wire strands. As force is applied to the loop, the wires on the clipped end will bend toward the towing truck, placing the stress on those bent strands.

This equipment has no thimble, a wrong repair link, stretched links, and a rope knotted to a chain. It’s a collection of bad ideas just waiting for an opportunity to break. Use the proper equipment rated for the job.

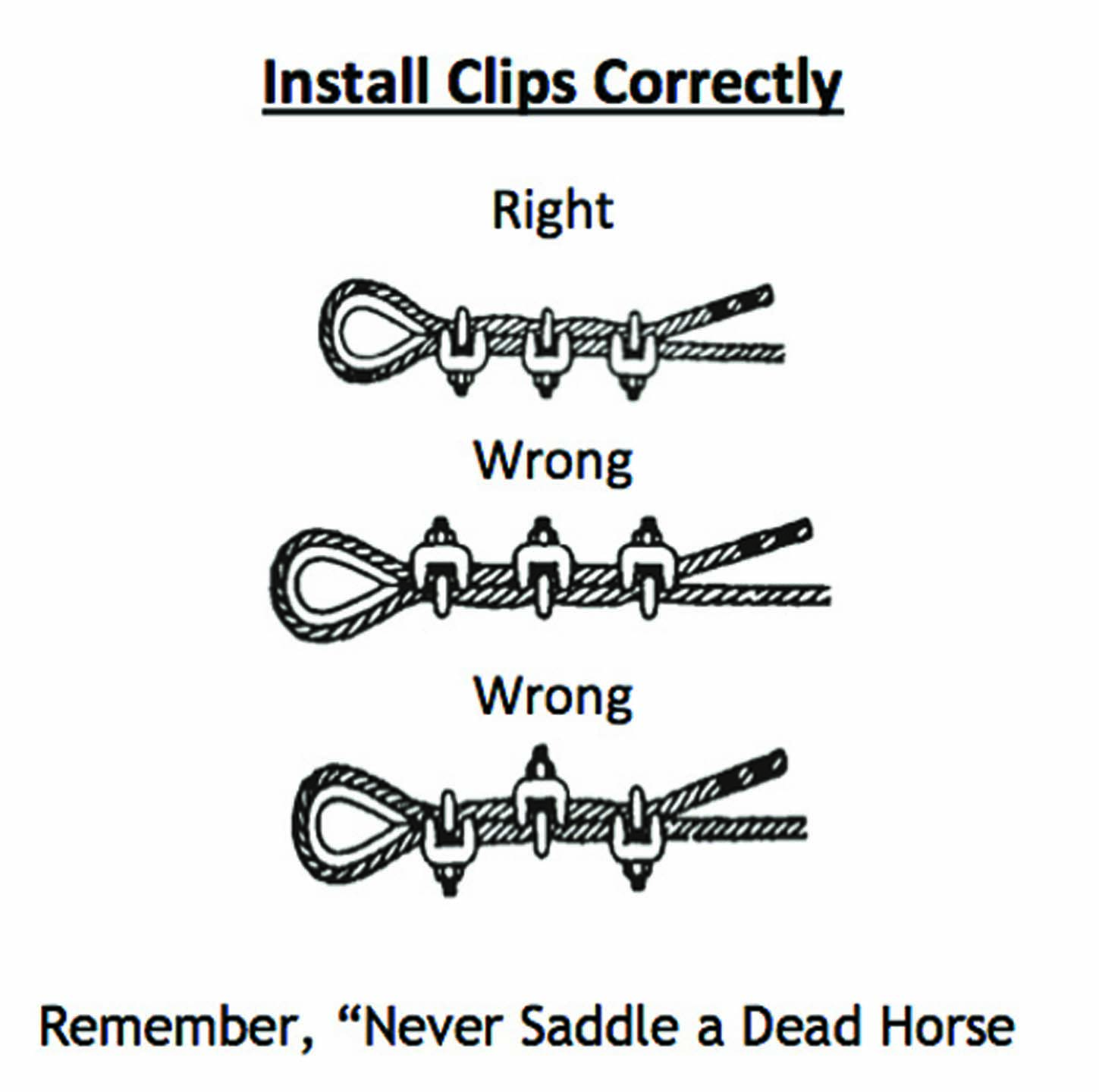

If you want to prevent the wires from crimping or pinching, the wire rope must go around a thimble. The cable sits within the groove of the thimble, much like a fiber rope rides on a pulley. When you pull the cable, the thimble evenly distributes the pressure across the end of the cable. The hook is placed in the loop for attachment, thus putting pressure on the thimble, which helps prevent the cable from bending, pinching, crimping, and breaking. It is very important that the thimble match the cable in size or it will damage the cable.

When you use cables, remember the phrase “Never saddle a dead horse.” This refers to the clips that hold the loop together. Generally, you want to have a shorter piece of the wire rope extending beyond the loop (about 12 to 18 inches). This short piece is called the “dead” part of the cable because it is not part of the cable that will be used during the pulling. The longer piece that attaches back to the towing vehicle is called the “live” cable.

If you use saddle clips, position the first saddle clip near the dead end of the cable and leave a few inches beyond the last clip. Attach the U-bolt into the saddle clip with the round part of the U-bolt going over the dead wire of the cable. Tighten the bolts down toward the live cable. The reason the U-bolt needs to squeeze down on the dead wires is because when the wires are squeezed against each other they sometimes are crushed. Crushing the wires in the dead section is better than damaging the strands on the live section.

The next step is to place the thimble into the loop. Apply the next saddle clip near the end of the thimble and hand-tighten. Add a third clip in the middle of the other two clips. Again, make sure the U-bolt is going across the dead end and the saddle is sitting on the live end of the cable. Additional clips for larger diameter cables (such as 3/4 inch) may be a good idea. If you can see light between the cables you need to tighten up the dead end or not all of your clamps are holding. You may need to retighten the clip bolts because the cable may stretch and become slightly smaller after the first use.

Just like steel chains, you can order cables to meet your specifications. If you want to use a wire rope for recovery, spend the money to have a professional make one with the proper strength outfitted with the proper connectors and length. And remember: never jerk on a cable.

Lift Straps

When lifting objects into the air, you don’t want the lifting rope, chain, or cable to stretch or have any give. Like chains and wire ropes, lifting cables and other specialized equipment for lifting heavy objects are not intended to be jerked on. This can limit their use in recovering stuck vehicles. For overhead lifting, a chain has to be grade 80 or higher; any other lifting slings have to be tagged and rated for lifting.

Some situations require more than just a hook and pull. Any time you can pull stuck equipment up and out will make the extraction easier.

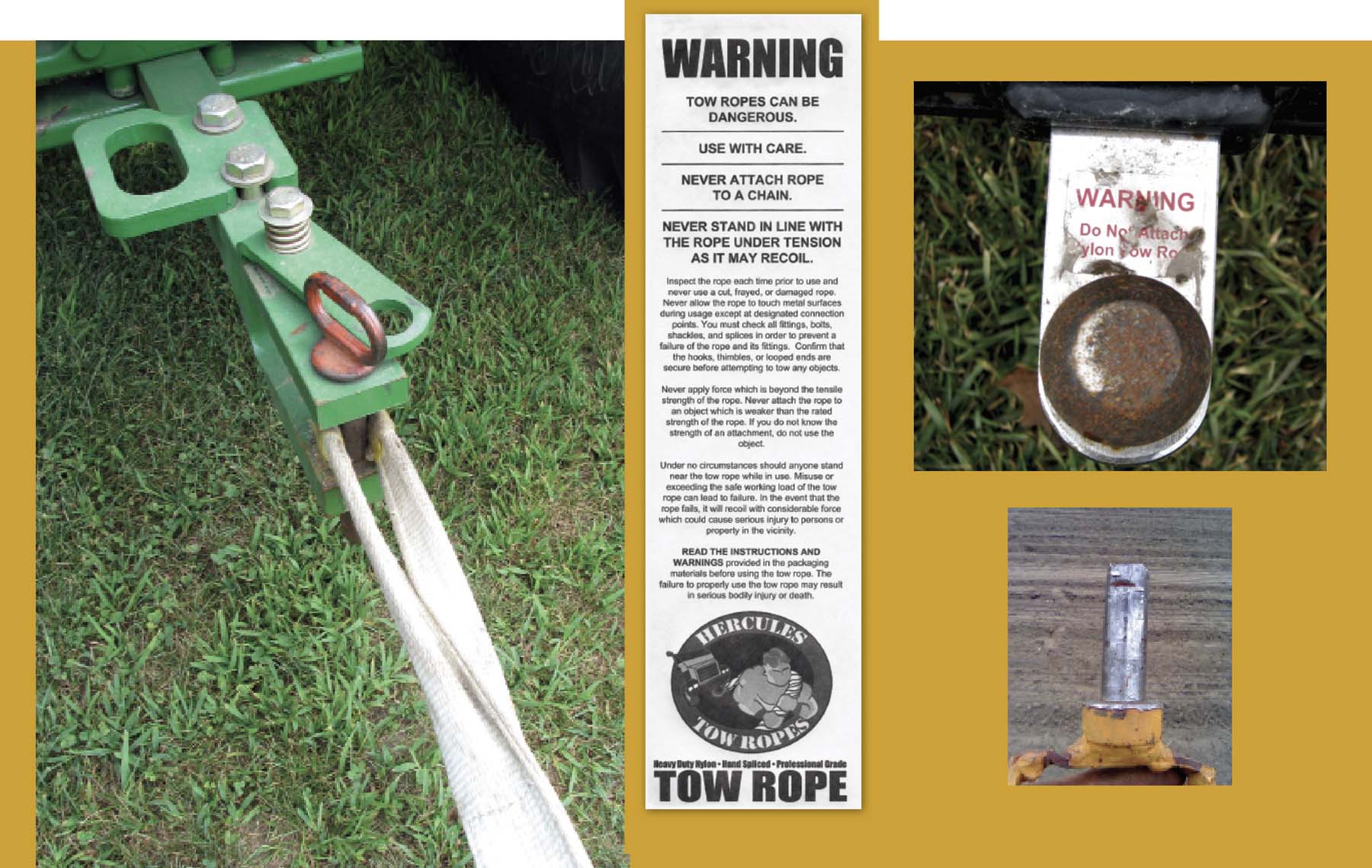

Tow Ropes and Tow Straps

Tow ropes and straps are designed not to stretch or have any give. These are qualities you want when you are towing another vehicle down the road. When it gets tight, it doesn’t stretch, which is why it’s called a tow strap or tow rope.

Tow ropes and straps are designed only for towing and you should not use them to extract stuck equipment. They are just like cables and chains in that they are not meant to jerk on. More importantly, if you see a rope or strap with a chain or hook on it, then it is meant for towing only.

This tow rope has a hook that is rated at 1 ton. But this equipment is not rated for anything more than towing a lightweight vehicle on the roadway. In addition, the latch cannot take any weight.

Recovery Straps and Ropes

Recovery straps and ropes are commonly called jerk straps, yank ropes, and jerk ropes. They are designed and fabricated much differently than their counterparts used for towing. They are lighter than chains and cables. And unlike tow ropes and straps, recovery straps and ropes don’t have any hardware attached to them and the material allows for stretching under tension.

Recovery straps and ropes are made of nylon, which can be stretched, making them in the same manner as rubber bands or bungee cords. Recovery straps and ropes stretch (up to a point) but return to their original shapes. When a towing vehicle pulls forward, the recovery strap continues to stretch until it builds up enough tension that it actually helps pull out a stuck vehicle.

Unlike cables and chains, you can get a running start and jerk on recovery straps and ropes. The design of the strap absorbs all the jerking motion. If you jerk on a recovery strap, you will actually pull the vehicle out very smoothly, whereas, if you jerked on a chain or cable, you would most likely snap the chain or risk a chance of whiplash from the sudden jolt.

Another advantage to using a recovery strap or rope is that the towing vehicle should never have to spin its wheels. If the towing vehicle is stopped in its tracks after repeated attempts with a tow strap, you know the vehicle you are using to pull with is not large enough to get the job done.

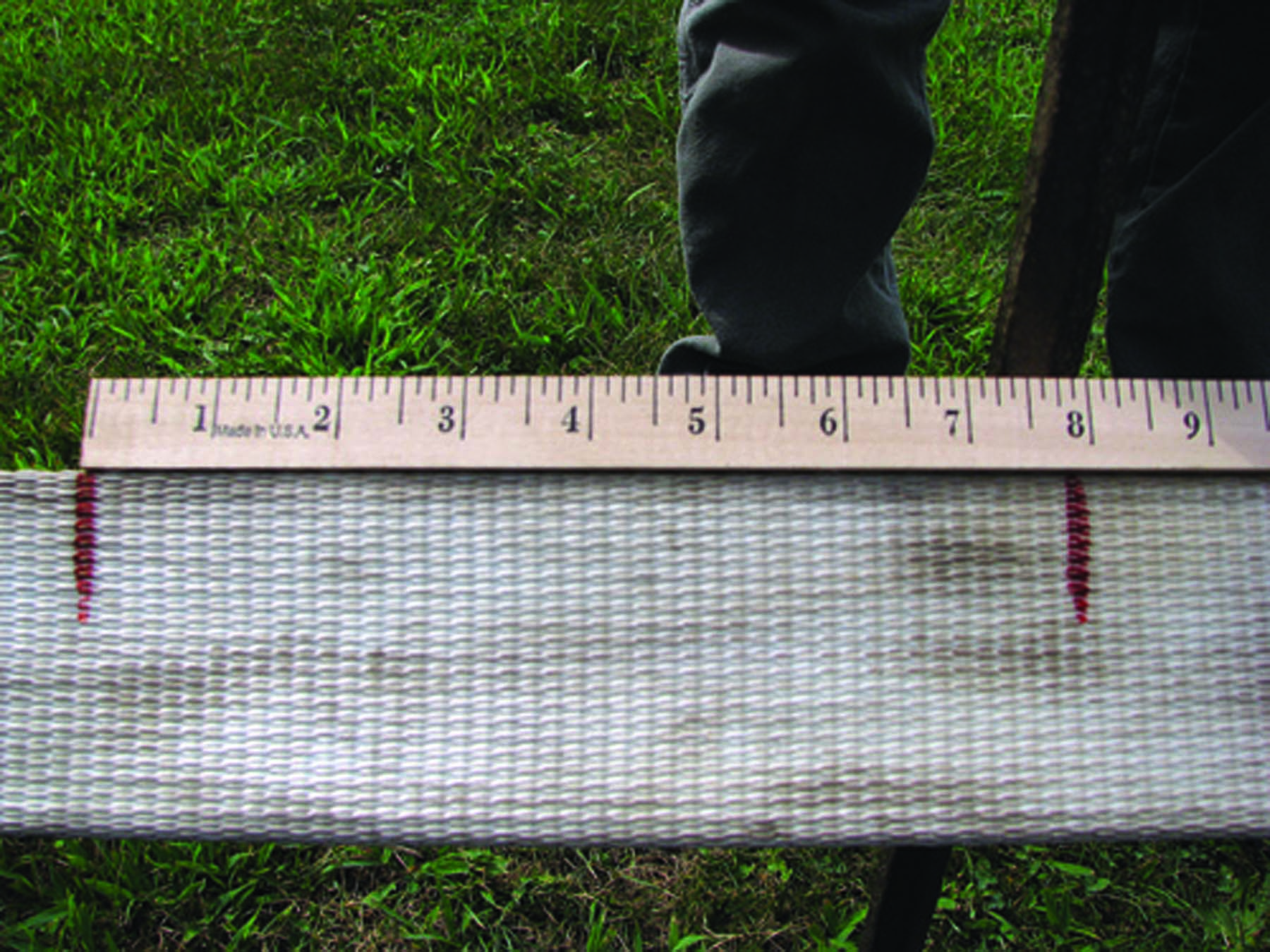

(Left) A red mark was made on the strap before extraction. This recovery strap stretched 8 inches during the extraction (right).

Check Attachment Device Ratings

Straps and ropes used for recovery are made to withstand different stress levels based on how they are manufactured. The manufacturer includes a label on each device that provides users with valuable information and confirms what the manufacturer is willing to guarantee.

The strength of a recovery strap is determined by two factors: its width and the number of plies (or layers) it contains. The wider the strap, the more strength it will have. Manufacturers can achieve comparable strength by reducing the width of the strap and increasing the number of plies (a two-ply strap will be stronger than a one-ply strap of the same width). Before selecting any strap, cable, chain, or rope, be sure it is rated strong enough to extract the stuck equipment.

The recovery strap on the right is for smaller equipment of less than 15,000 pounds. The recovery strap below is rated for 110,000 pounds.

When purchasing a new clevis or hitch pin always ask for the grade and breaking point. Never assume it is strong enough to do every job based on weight and appearance just because it is new.

Clevises, Hooks, and Hitches

While most of the attention is devoted to straps, chains, ropes, and cables, it’s important to realize the other items used to extract stuck vehicles also have ratings that are just as important. Remember that metal, if placed under enough stress, will break. And when it does, it could lead to severe injuries, or worse, death.

Typically, there are two common types of clevises used to link recovery ropes and straps to the towing and stuck equipment. The first type, although it comes in different shapes, uses a hitch pin with a safety clip or hair pin that keeps the hitch pin secure in the clevis. The second type is actually called a shackle (or sometimes a screw clevis) because it has a pin that screws into the clevis.

The shackle design seems to be the product of choice. The screw mechanism with threads is stronger and more reliable than a clevis with a single safety pin holding the device together.

If the safety pin were to come out of the pin, it could allow the hitch pin to come out of the clevis enough for the device to spread and come apart. On the other hand, the entire bolt would have to break for the shackle to come apart.

Using a clevis or shackle allows the eyelet on a recovery rope or strap to remain open across a larger area. This distributes the stress on the web across more of the width of the strap or diameter of the rope.

When possible, attach the strap or rope so that it is on the pin and not on the body of the clevises.

When possible, attach the strap or rope so that it is on the pin and not on the body of the clevises.  This equipment looks impressive, but looks can be deceiving. Always look for the ratings associated with each piece of equipment. In this case, pay particular attention to the receiver hitch platform and make sure it is rated equal to or greater than the pickup.

This equipment looks impressive, but looks can be deceiving. Always look for the ratings associated with each piece of equipment. In this case, pay particular attention to the receiver hitch platform and make sure it is rated equal to or greater than the pickup.  Never replace the original pin that came with your device with bolts from your bins or local hardware stores (left). If you need to replace the pin, replace it with a pin that is comparable to the pin that came with the original equipment at the time of purchase.

Never replace the original pin that came with your device with bolts from your bins or local hardware stores (left). If you need to replace the pin, replace it with a pin that is comparable to the pin that came with the original equipment at the time of purchase. There are many instances where metal at one end or the other can be attached to a tractor or truck through a hitch. When attaching a rope or strap to a tractor, the preferred point of attachment is the drawbar because it is designed to carry heavy loads. Make sure the hitch pin and safety pin are strong enough to prevent the clevis from separating under pressure.

It is usually not a good idea to use a truck hitch to extract stuck equipment. In fact, many manufacturers’ hitch tag instructions caution against using the hitch to pull out equipment.

If you hook something to the hitch to pull it out, make sure you do not exceed your vehicle’s tow ratings. All hitches found on trucks — weight carrying hitches — have ratings. All parts of the hitch mechanism (including the receiver, insert, and ball) each have ratings. If you use the original equipment mounted bumper when pulling a vehicle, remember it doesn’t take too much pulling before you exceed the capacity of the hitch mechanism. A ball hitch is designed to handle a direct pull, but not a jerk, and cushion-mounted hitches are not designed to pull out stuck vehicles.

The insert and ball has been bent downward from the forces being applied on it from pulling out a stuck vehicle. A little more force could have easily broken the ball or insert.

The insert and ball has been bent downward from the forces being applied on it from pulling out a stuck vehicle. A little more force could have easily broken the ball or insert. It is important to know the strength of the hitch pin holding the grain cart to the tractor as well as the strength of the frame of the grain cart and its pin.

Tips for Recovering Vehicles or Equipment

Before you try to extract any stuck vehicle with a cable, rope, or chain, consider the 28 tips described below. Remember, your goal is to have the pulling force exceed the immovable force — only then will the truck or stuck equipment move forward. If there is not enough force pulling forward, then whatever is stuck will not move.

On the other hand, when the force exerted on any towing equipment exceeds its listed ratings, flying debris will be the result. It’s just that simple — and just that dangerous.

1) Know How Deep It’s Buried

There are different degrees to how stuck something may be. The stuck vehicle may require just a little pull if it’s just a slick surface. But if its axles are buried and its frame is dragging on the ground, you know you’ll need more towing power. Use the resistance factors from page 29 to account for the anticipated resistant forces.

2) Know the Size of the Stuck Equipment

It’s always a good idea to know how much weight you are trying to pull. It’s also important to determine whether the stuck vehicle will be “dead weight” (meaning it will not be able to assist with the extraction), or it will be able help with its own extraction.

3) Ensure the Towing Vehicle Is Large Enough

Hooking onto a stuck vehicle that is twice the size of what you are using to pull it out may not be wise. The towing vehicle needs enough weight to get good traction or its wheels will just spin. For best results, consider using a vehicle at least the same size (or larger) as what you’re trying to extract.

Make Certain Your Chains, Cables, Straps, or Ropes Are Properly Rated

Read the tag that comes with the recovery strap. Never use equipment unless you know it can handle the job. Make sure it has a tag or that you know it strength rating. Never use equipment if you can’t determine its rating. The equipment may need to be rated 1 or 1.5 times the weight of the stuck equipment, depending on the resistance factors.

Keep the Tailpipe Uncovered

Always inspect the tailpipe of the stuck vehicle. Make sure the exhaust fumes are vented and not stuck in the mud or obstructed in any way. You don’t want exhaust gases to build up inside the stuck vehicle.

Dig Around the Tires if Necessary

In extreme situations, you may need to shovel dirt from the front and sides of wheels that are stuck. When the wheels are free, they may be able to help with the extraction process.

Keep a Fire Extinguisher Handy

Be prepared for a possible fire when stuck equipment bottoms out. Hot engines or transmission housings on dry grass can be an issue. Broken lines when tying at the wrong point can spray hot liquids. Make sure you have the proper equipment on hand in case any of these issues start a fire.

Unload to Reduce Weight When Warranted

In some cases, it may be a good idea to lighten the load of the stuck vehicle. The lighter the vehicle you are pulling, the easier it will move and the less force it will have against your towing vehicle. Unloading stuck vehicles can also help prevent the stuck vehicle from getting top heavy if one side is down.

Consider Disconnecting Trailers or Implements

If it can be done safely, consider separating the load from the stuck vehicle to help with the extraction. Disconnecting trailers should be a last resort because it can lead to other troubles. The trailer usually gets damaged and is much harder to reach because you have to keep the tongue out of the mud.

Get the Towing Vehicle as Close as Possible

The shorter the attachment between the towing and stuck vehicles, the less chance it will cause injury if there is any flying debris. If the connection is short, debris is more likely to hit the tailgate than the windshield.

However, make sure the attachments are long enough so the towing vehicle is out of the mud hole and on solid ground. This is why it is important to have between 25 to 30 feet of cable, rope, strap, or chain on hand to use if needed. It allows some flexibility where to place the towing truck.

Position the Towing Unit on Higher Ground When Possible

One important factor when pulling out of mud is height. If you can pull up (by getting the towing vehicle on higher ground than the stuck one), you will have more success. Instead of pulling straight, you want to pull up and forward. If the vehicles are level, you will encounter more resistance when you pull. If you can lift up even slightly while you pull forward, it will make the extraction process easier.

Make Sure the Towing Vehicle Has Better Traction

If the towing vehicle gets stuck in the mud, too, you have a real problem. Good traction usually means the stuck vehicle will come out.

It will be rather difficult to extract this truck because the towing tractor does not have firm ground to work on. Also, the attachment point being used on the tractor is not the drawbar. A homemade frame may not have the force required to extract the truck.

Pull in a Straight Line When Possible

The best way to pull, if possible, is to pull forward and straight like a train pulling a freight car. Depending on the situation, it may be easier to pull the stuck vehicle backwards. For example, if a vehicle ran off the road and a few feet into a muddy field before it got stuck, it would be much simpler and easier to pull it backwards than to go completely through the field. Also, there may be better locations to hook a rope or chain to the rear of a vehicle. However, recovering a trapped tractor from the back can cause serious damage.

Try to Make Only Two Attachment Points

The two attachments points are to the towing vehicle and the stuck vehicle. It is not a good idea to hook multiple chains, straps, or ropes together. For instance, if you attached two, 30-foot ropes together, the real issue will be the clevis that connects the two ropes in the middle. The amount of force you generate could snap one of the ropes. If you need more length than what you have, call a wrecker service.

Tying two or more recovery straps together with a knot reduces the overall towing power. The rope is at full strength when it is flat and the fiber is not pinched together. The strength of the strap is now based on the strength of the knot.

Make Sure the Attachment Points Will Hold Under Pressure

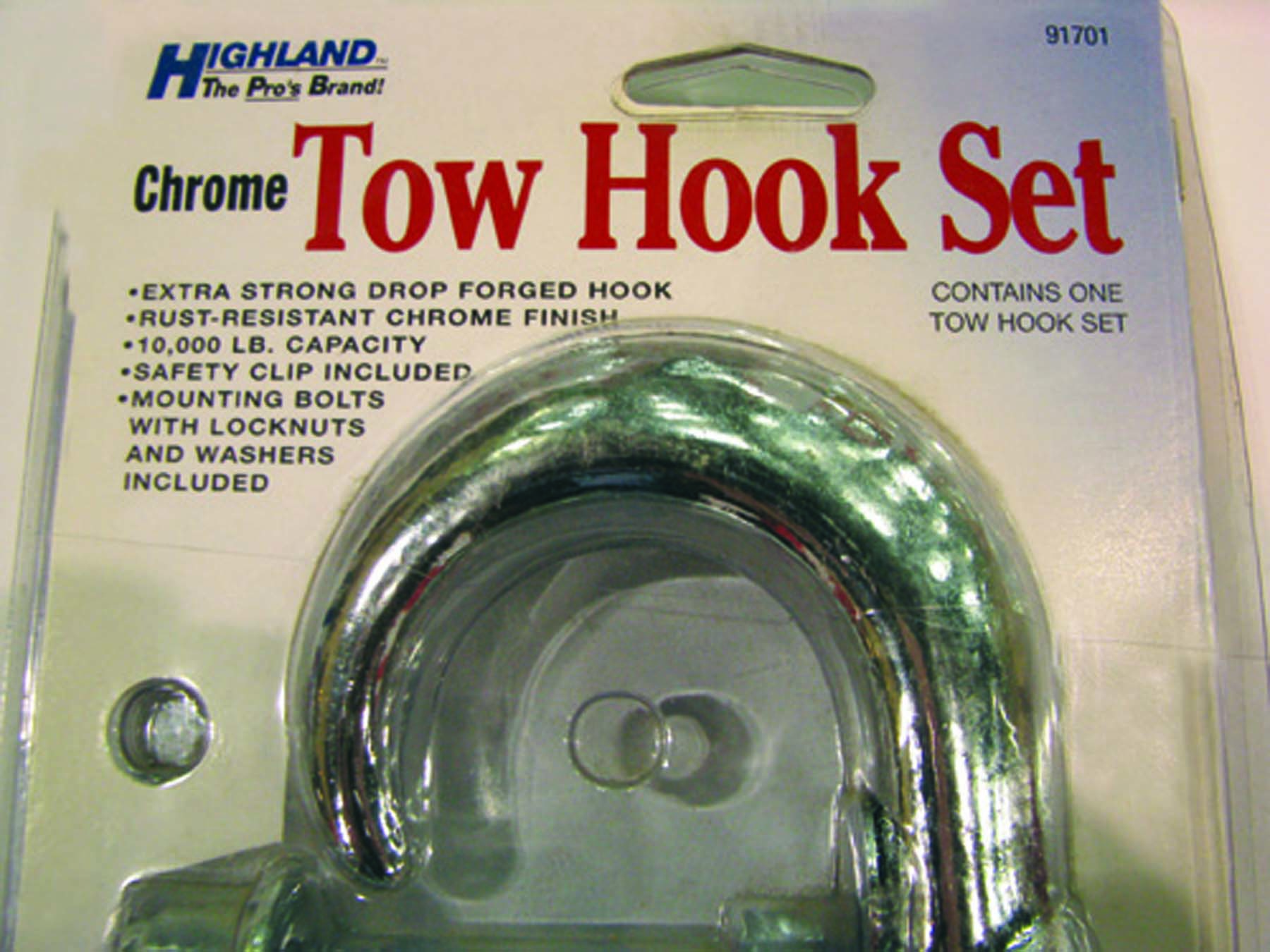

It’s always best to attach a hook to the vehicle’s tow hook or its frame. When hooking underneath a vehicle, make sure that when the rope, chain, or strap tightens it will not destroy the oil pan, steering mechanisms, or any other mechanical items. Many 3/4-ton and heavier trucks come with factory-mounted tow hooks. Manufacturers install these tow hooks for a reason, so take advantage of them when towing or being towed.

How and where you attach connections to equipment will determine how successful and safe you are when extracting it. If you hook to a high center of gravity attachment (such as a three-point hitch), it may cause the towing vehicle to flip over, especially if hooked to a smaller tractor. When you use a tractor to pull, always hook to the lower drawbar because that is where it is designed to have the most leverage and pulling strength.

Don’t pull sideways on tow hooks.

Don’t hook to bumpers, because they can be ripped away from the truck. Sometimes equipment is just slightly stuck and spinning on the surface; other times it is buried to the axle. When a truck is buried to its axle, it’s hard to hook to the frame or tow hook. In such cases, the bumper is the easiest place to hook — but it also is the easiest part to tear off. Take the time to dig out the dirt to reach a better place to hook rather than just hooking to the bumper.

As a last resort, attaching to the truck hitch might be your only option. Understand that in most cases, manufacturers warn against using the hitch and attachment this way. Any damage will likely be the responsibility of the person or company doing the towing.

Ask the Driver of the Stuck Truck to Attach Devices

It’s nice and neighborly to pull someone out, but it can be costly to you and the business if you’re helping someone who doesn’t work for you. Always have the person in the stuck truck or equipment attach the connectors to his or her own vehicle. That puts the liability on the driver of the stuck equipment. And if, by chance, something goes wrong during the recovery, it won’t be your fault because you did not hook it up.

Use Your Own Equipment

Do not use your customers’ extraction devices to pull out your equipment. You have no knowledge of the equipment’s condition, rating, and other characteristics.

Keep Sharp Edges from Touching Towing Devices

Use edge protectors any time ropes or straps touch part of the equipment. This is especially true if the edge is straight and sharp. A piece of canvas can protect a strap, but make sure nothing will interfere with the cable, chain, or web. It is best to have a straight line with no interference of anything touching.

Hook From the Bottom

Make sure the tip of the hook faces up. If it breaks or comes off while pulling, it will fall toward the ground instead up through the air.

Place the Clevis Directly on the Equipment

You can mount a clevis directly to the tractor, truck, or pulling truck. However, the strap or rope needs to be on the pin, not on the side of the clevis or shackle.

Place Something Heavy on the Strap, Chain, Cable, or Rope

You can purchase cable blankets or dampening blankets. Put something on the web, chain, or cable such as a jacket, a 1- to 2-inch section of rope, a truck mat, or another chain over them as dead weight. If the cable or strap breaks, the extra weight hanging on it will force it toward the ground instead of up in the air.

Do What You Can to Protect Windshields

If you have a toolbox in the back of the bed, open the lid to protect the towing vehicle. Lift the hood of the stuck vehicle. Put a piece of plywood over the back window of the towing vehicle. Any of these measures can provide some protection. Even when you feel you have everything calculated right, there is always the possibility that flying debris will strike the driver if something breaks.

Remove Nonessential People From the Danger Zone

You have enough problems as it is; you don’t need to injure an innocent bystander.

Get the Stuck Equipment to Help

If the vehicle you are pulling can help with its own extraction, it will take some of the strain off the towing vehicle. It may help if you turn the tires on the stuck vehicle, which might help break the suction.

Give Instructions to the Driver in the Stuck Equipment

Before attempting any extraction, make sure all members of the extraction team agree on signals (such as “Stop!”) first. Make sure everybody wears seatbelts. Let the driver of the stuck vehicle know that he or she should not move until the towing vehicle is in motion. Make sure to determine whether the towing driver will stop as soon as the stuck vehicle is clear, or will continue to pull the stuck vehicle to complete safety. Be ready to stop so you don’t run into the pulling vehicle.

Use the Lowest Gear Available

If you are using a stick shift to pull, always start in first gear. The same could be said with an automatic transmission.

Pull Straight Ahead to Maximize Towing Power

Towing is always best if the towing vehicle pulls straight ahead. When the towing vehicle is at an angle to the stuck equipment, there is increased stress. If the stuck vehicle is next to the edge of a deep ditch, there may be no way to avoid pulling at an angle without the stuck vehicle slipping into the ditch and overturning. In situations like that, it may be best to call a wrecker.

Apply Power Slowly and Smoothly

When you use a cable or chain, always take the slack out before you push the accelerator slowly and smoothly. Pulling slowly is always better than putting the “pedal to the metal.” If you are using a recovery strap or rope, you can try jerking on them to give a little extra punch to move the vehicle.