Keep The Spray Rig On The Road And Out Of Trouble

Fred Whitford, Director, Purdue Pesticide Programs

Dennis Nowaskie, Farm Superintendent, Southwest Purdue Agricultural Center

Jamie Southard, Environmental Health and Safety Director, Effingham Equity

Peter Illingworth, Farm Mechanic Technician, Purdue University

John Obermeyer, IPM Specialist, Purdue University

Mike Titus, Risk and Safety Coordinator, Co-Alliance

What this publication will cover:

The Challenges of Modern Equipment

The Road Hazards Operators Face

More Time on the Road

Less Visibility

Lack of Experience

Narrow Roads

Impatient and Distracted Driving

Drivers in a Trance

Loaded Sprayers Stop Slowly

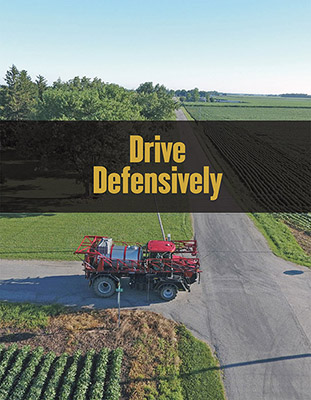

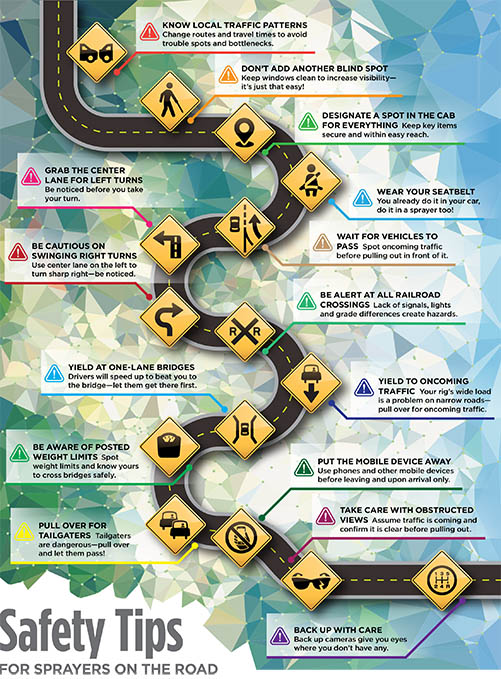

Drive Defensively

Know Local Traffic Patterns

Don’t Add Another Blind Spot

Designate a Spot in the Cab for Everything

Wear Your Seatbelt

Wait for Vehicles to Pass

Grab the Center Lane for Left Turns

Be Cautious on Swinging Right Turns

Be Alert at All Railroad Crossings

Yield to Oncoming Traffic

Yield at One-lane Bridges

Be Aware of Posted Weight Limits

Pull Over for Tailgaters

Put the Mobile Device Away

Take Extra Care When You Have Obstructed Views

Back Up with Care

Think About Your Trailing Vehicle

The Challenges of Modern Equipment

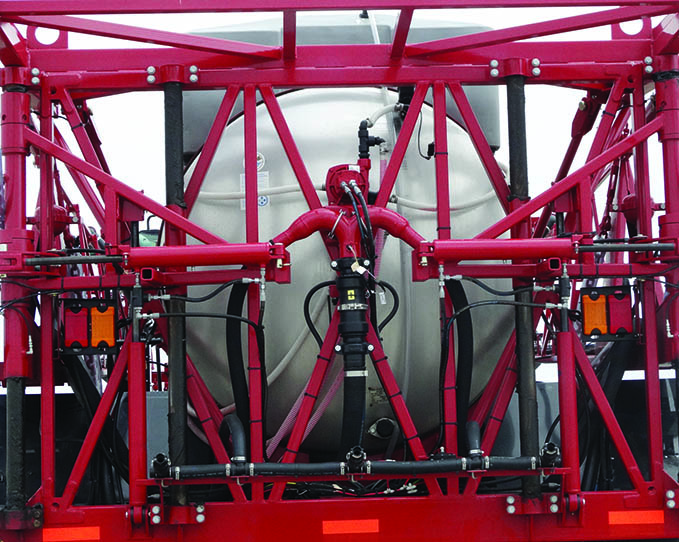

Comparing today’s self-propelled sprayers with any of their counterparts from the past is like comparing cell phones to rotary phones. Earlier sprayer models were built on modified truck chassis, rode rough, were difficult to maneuver, and most functions had to be manually operated. Today’s agricultural sprayers are built on custom frames designed to carry heavier loads (including larger spray tanks), travel at faster speeds, provide a more comfortable ride, filter outside air, and allow many adjustments to be made from a touchscreen console. And today’s sprayer often has a wider wheel base that improves stability and meets row spacing requirements.

On board, the sprayers often have computerized systems that include global positioning, auto steering, auto shutoff on sections of the booms, automatic boom height levelers, and hundreds of other technological adaptions that are now mostly standard options on many field sprayers. With each passing year, equipment engineers continue to improve technologyand design equipment with increased precision, speed, efficiency, safety, and comfort.

However, these innovations and changes have brought their own challenges. Today’s drivers and mechanics need to possess technical computer skills to operate or repair this modern equipment. Wider wheel bases mean sprayers are wider, heavier, and faster. This means that collisions have become more than minor fender benders.

In addition, sprayers with larger booms and new tank placements have more blind spots. While sprayers today have increased top-end speeds and can travel in excess of 40 miles per hour, they still travel much slower than typical traffic on public roads and highways. It doesn’t take long on a two-lane road for a line of vehicles to form behind the slower moving sprayers. When drivers are forced to slow down, many become impatient, annoyed, and even angry. If they have to stay in line behind you for an extended period, it doesn’t take long for cars and trucks to begin weaving in and out of line like the drivers at the start of the Indianapolis 500.

You quickly realize that what is considered safe to pass is a judgement made strictly in the eyes of the beholder. Most operators can recall at least one instance when they looked in the rearview mirror and a driver, tired of waiting, decided it was time to pass the long line of cars that accumulated behind the sprayer. Instinctively,the sprayer operator looked ahead and saw an oncoming semi. He began to slow down and drift toward the shoulder of the road, because he knew it was going to be a close call.

At the last possible second, the passing vehicle quickly cuts in front of the sprayer narrowly missing the rig and barely averting a head-on collision with the oncoming semi. As if the near miss was sprayer’s fault, the driver of the car gave you the sprayer driver a one-finger salute! If the sprayer operator had not taken evasive action, the outcome could have ended much worse.

Of course, operating large and expensive sprayers, tractors, planters, and other equipment on narrow roadways or even crowded highways is no joking matter. Drivers must constantly anticipate what other drivers will or will not do. This publication provides suggestions and guidance that will allow operators of larger agricultural equipment to safely navigate the congested roads that we share with the distracted and impatient public.

There are a number of reasons why it is more difficult to navigate today’s larger sprayers, on county and state highways. Let’s take a closer look at eight of them.

MORE TIME ON THE ROAD

Historically, farmers worked fields close to their homesteads. But over the years, many farmers have expanded their operations, which means that they and the agricultural retailers they work with must travel longer distances to get to and from their acres. Retailers have also consolidated and cover larger areas.

LESS VISIBILITY

A sprayer cab is often surrounded with obstructions that reduce visibility. Bigger equipment requires more metal in its construction, and more metal means more blind spots. When 90- and 120-foot booms are folded in their transport positions, they are literally right outside the cab windows, which makes a clear view out the window all but impossible.

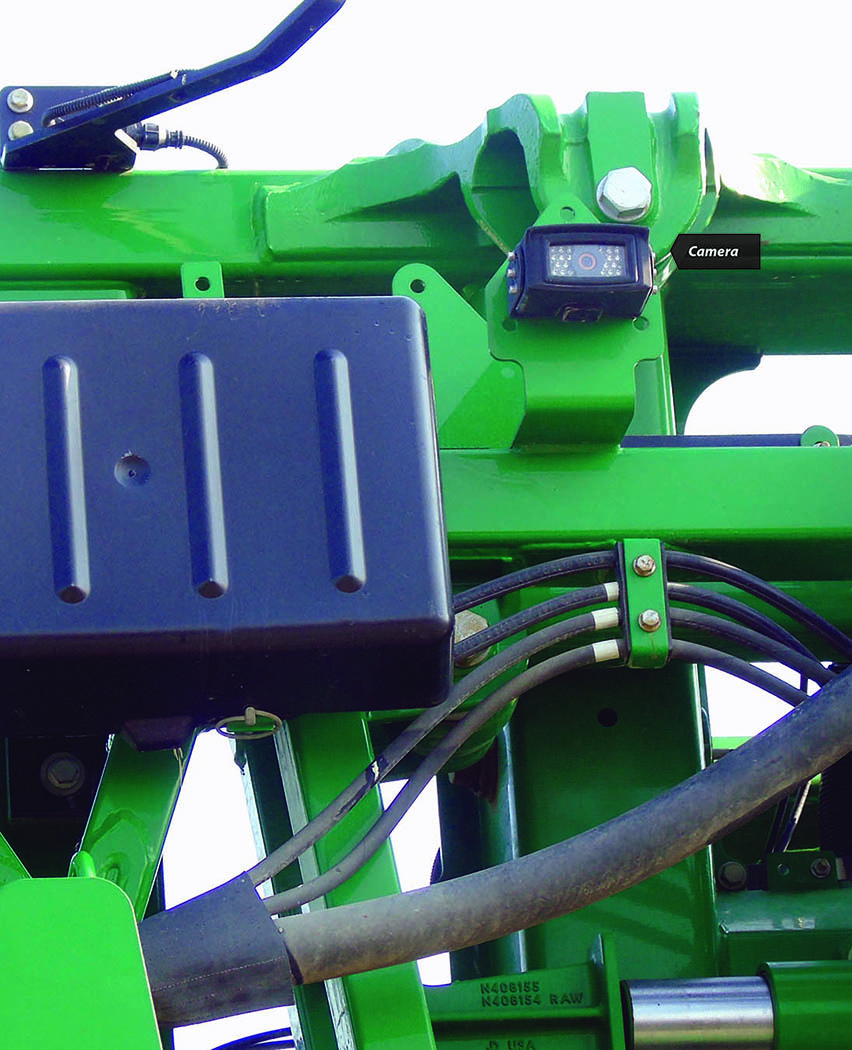

When spray booms are folded, it makes it difficult to see if anything is approaching your rig. Adding monitors, screens, and computers in the cab to improve sprayer control further obstructs the driver’s view (right).

And the larger tanks that are mounted directly behind cabs make it impossible to see what is directly behind sprayers without digital cameras. Rearview cameras have become standard options on newer pieces of equipment, and they can easily be retrofitted to older machines. If you install cameras, try to have them connected to existing cab monitors.

LACK OF EXPERIENCE

Fewer people grow up on farms today. This makes it difficult to find employees with the skills and experience required tooperate large agricultural equipment. That’s not to say that inexperienced people can’t learn how to operate these complex sprayers, but it requires new operators to undergo intensive training earlier. It can easily take a year of field application experience before operators become proficient at and confident about operating spray rigs in the field and safely on roads and highways.

NARROW ROADS

It seems rural roads are more congested with farm equipment, commercial trucks, large trailers, and vehicles of every size and description. Rural roads were not designed to handle the volume of traffic, the weight of today’s agricultural implements (such as bridge postings), or the size (width) of modern farm equipment.

One of the problems with narrow roads is that they often don’t have shoulders that allow sprayers or wide equipment to pull over. Mile after mile of narrow shoulders with steep embankments, ditches, mailboxes, utility poles, and culverts line each side of the road, which makes it nearly impossible to pull over safely. This can lead to impatient drivers passing at the most inopportune or unsafe times.

IMPATIENT AND DISTRACTED DRIVING

These days, it seems there are plenty of people who are running late for work, school, or some other appointment. The last thing many motorists want to see in front of them is a slow-moving piece of agricultural equipment. It only takes a minute or so for some to lose their temper. At such times, a frustrated or agitated driver can make a bad decision and try passing at the worst possible time.

In other situations, drivers may be distracted. Instead of focusing on what is happening in front of them, these drivers might be talking or texting on their mobile devices, dealing with children in the back seat, eating, doing paperwork, or listening to music. Inexperienced drivers are also a big problem. Locals know the rigs and realize they can turn at any time. Inexperienced motorists never realize they could turn into a field, not a road, and whamo!

DRIVERS IN A TRANCE

In some instances, drivers you share the road with may not know what to do when they approach a sprayer. Many sprayers do not have brakes like other vehicles. Drivers can become confused, because there is no difference in the color of the lights between the hazard orange flashers and turn signals. In addition, warning lights and turn signals on agricultural equipment are mounted much higher than on most vehicles.

It may not take long to put some drivers in a “trance.” After a few minutes of following a sprayer with blinking hazard lights, drivers subconsciously adjust to the constantly blinking lights by ignoring them. So, when the sprayer operator slows down to make a left turn, the vehicle following the sprayer may attempt to pass even though the left turn signal is flashing.

LOADED SPRAYERS STOP SLOWLY

Sprayers stop more like a train than a car or truck. Often, other vehicles want to turn onto a road you are traveling on. They see your slow-moving rig and long trail of vehicles behind you, and many will attempt to pull out in a hurry to get in front of you. This gives you little time to react and slow down or stop a loaded sprayer. This can also mean big trouble for the line of vehicles following too closely behind the sprayer.

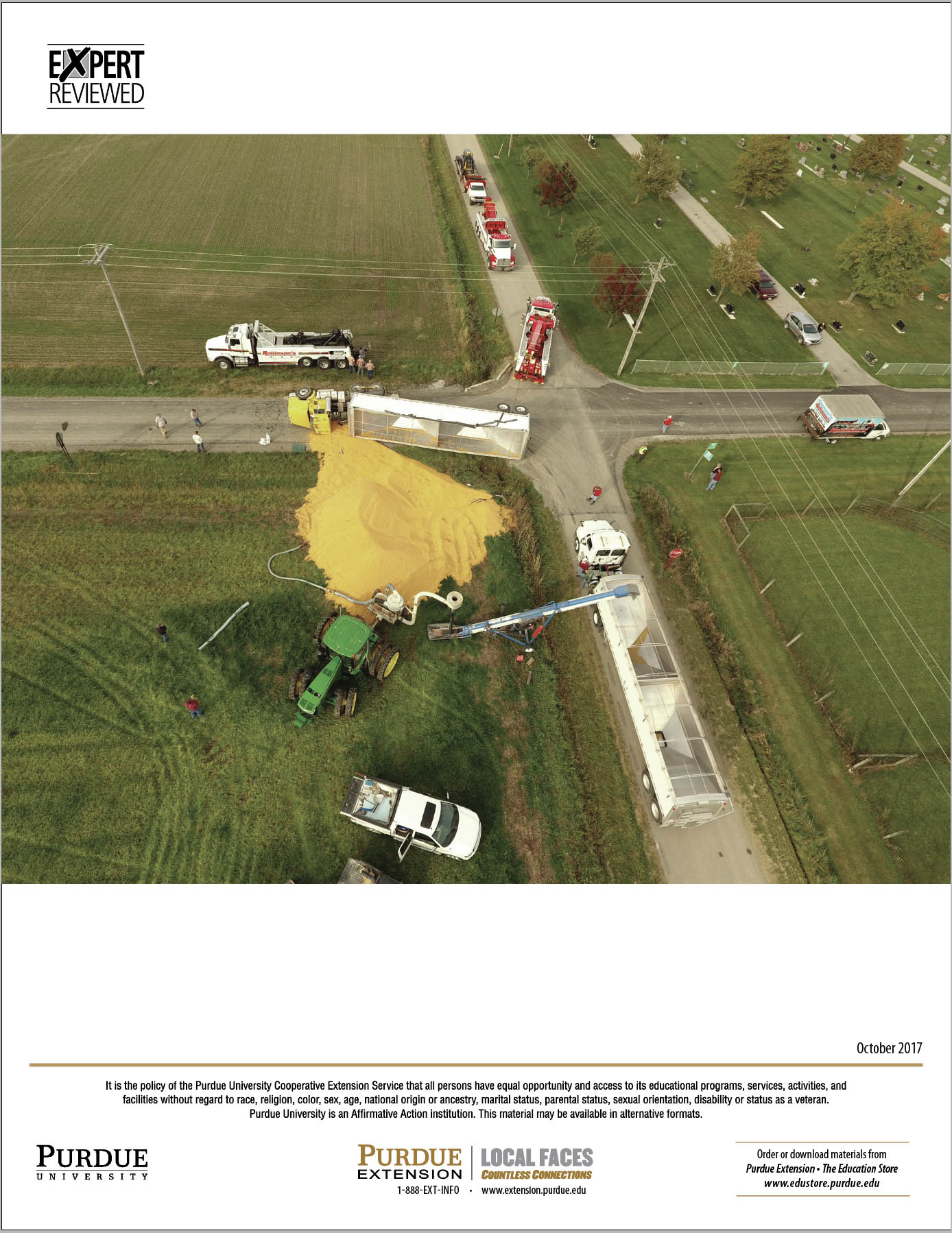

These photos show the aftermath of a car-sprayer collision. The driver of the car came to the end of the driveway and looked both ways. The sprayer driver pulled over to the side, but the car didn’t appear to move, so the sprayer operator assumed the car was going to let him pass. At the last moment, the car pulled out and the sprayer ran over the car. The car driver walked away without injuries, but the operator was injured by not being belted in the sprayer.

Workdays can get long and tiring when the weather is favorable, and you must apply fertilizer and lime, spray weeds, or plant or harvest crops. You try to get as much accomplished as you can, as fast as you can. However, you’re not doing anyone any favors if your fatigue results in a crash. Getting to and from the field safely is really more important than getting the field work done in the first place.

We’d all do well to remember the great advice we probably heard from our driving instructors: Keep your eyes open, keep your eyes on the road, and always be aware of the other driver. Practicing good defensive driving techniques is still good advice even for those experienced at operating agricultural equipment on roads and highways.

People do some pretty thoughtless things. There are YouTube videos that show motorcycles and other vehicles driving under moving sprayers. You can’t control how others drive and “you can’t fix stupid,” so you need to try to anticipate what others might do while they are in front of the sprayer or behind it.

On the following pages, we offer 15 suggestions to try to keep you safe and productive.

KNOW LOCAL TRAFFIC PATTERNS

With just a little planning, you can choose better routes to take to and from jobs. A little planning before you leave can actually save time throughout the day. Rather than distributing work orders and maps as employees head to their sprayers, give them time to review the day’s scheduled jobs before heading out to the field.

A safe journey begins before you even put the sprayer on the road. It’s important that drivers know where they are going before they ever leave the plant or farm. Provide them with a map of where they are going, especially if they are spraying a field they have never been to before. Managers should highlight the route, explain where to turn into the field, and what operators should watch for when they get back on the road (such as small culverts, narrow bridges, power lines, railroad tracks, or other obstructions). Relaying that knowledge and experience is a crucial to make the job safer for all drivers, but especially new operators.

After assigning the day’s work, allow time for operators to make mental maps of what roads they will be traveling that day. If possible, avoid any roads that have heavy traffic during the morning or evening commutes. Avoid roads that may have weight limits on bridges. Try not to schedule fields that are along bus routes when you know school buses are picking up or dropping off children. It goes without saying that you should avoid school zones and road construction zones at all costs whenever possible.

Putting any large piece of farm equipment on a major highway or through towns and cities during peak traffic hours could cause mishaps or collisions when the trailing traffic grows impatient.

DON’T ADD ANOTHER BLIND SPOT

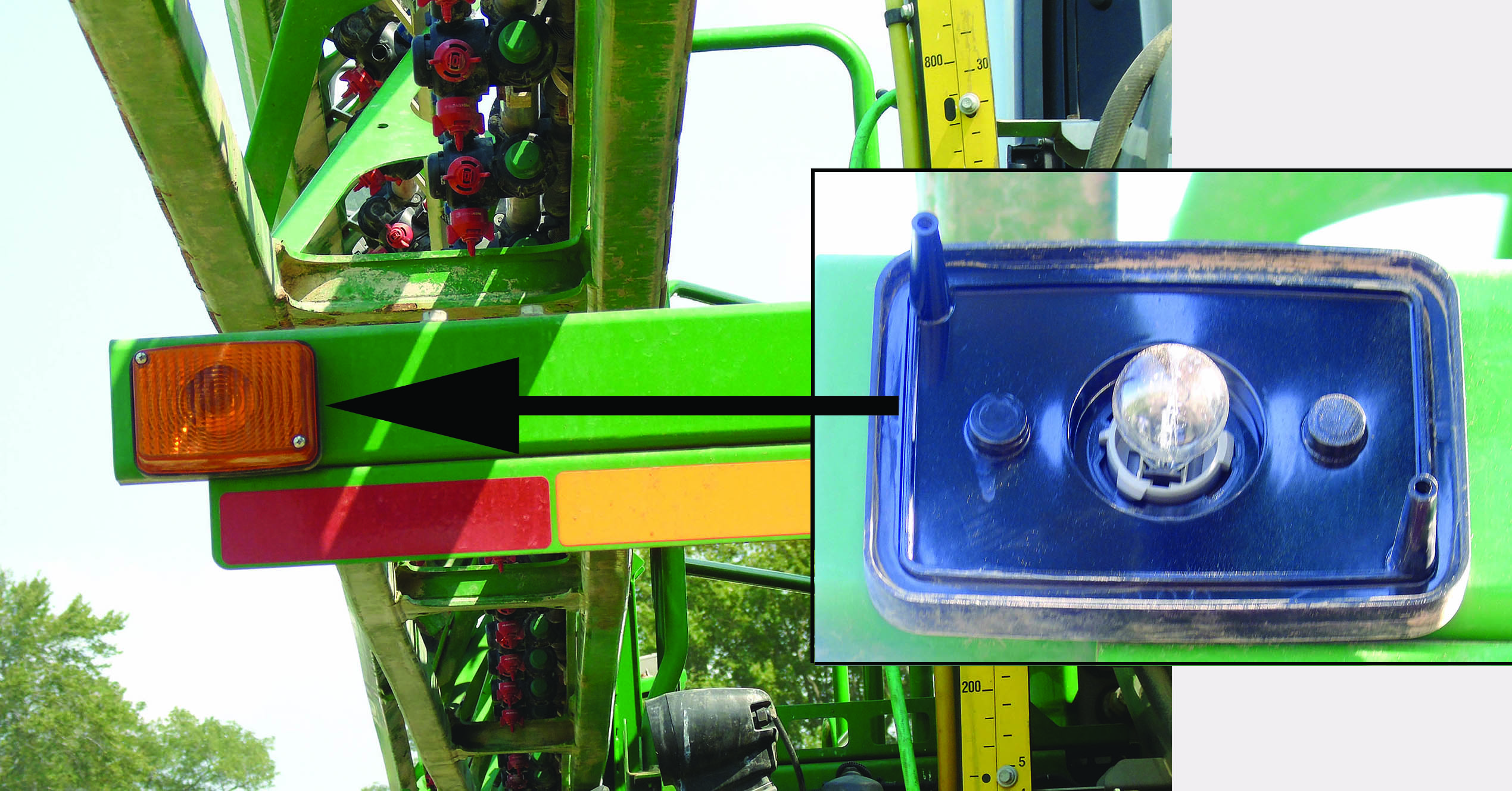

Today’s sprayers have many blind spots. If you don’t have a clean windshield, you may take away the only unobstructed view you have from within the cab. Before leaving in the morning, clean windows, mirrors, lights, and flashers of dirt, dew, frost, ice, grease, insect and bird splatters, and chemicals.

Mud-crusted lights (top) are ineffective at warning other drivers. Driving into the sun with a dirty windshield will make seeing obstacles from the cab difficult.

The difference between a dirty windshield and a clean one is the difference between night and day. Take a few minutes in the morning to clean windshields and mirrors to make your daily trips on the road as safe as possible. Drivers can also clean windshields and lights while they wait for tender trucks to bring their next load.

DESIGNATE A SPOT IN THE CAB FOR EVERYTHING

Designate certain areas in the cab where you can organize and easily reach paperwork and field maps. Make sure you place lunchboxes and tools in areas where they won’t slide around in the cab and distract you. This is especially true for water and pop bottles — they can easily roll under foot controls, rendering the controls useless. And never reach for a dropped object while driving.

WEAR YOUR SEATBELT

You need to wear a seatbelt at all times — even in the field. If it’s mandatory to wear a seatbelt in a truck or car, then why should it be optional in the cab of a sprayer? The last thing you need is to be thrown out of the seat onto the floor or even out of the cab during a collision in a field or on the road. Every year, applicators injure their necks and backs from hitting holes, ruts, and washes during in-field applications. Seatbelts reduce injuries and save lives.

WAIT FOR VEHICLES TO PASS

You can avoid a lot of stress by simply looking at approaching traffic in the lane you will be traveling. If you hastily pull a sprayer or other piece of equipment in front of faster moving vehicles, you increase the chances a long line will form behind you in a matter of minutes.

GRAB THE CENTER LANE FOR LEFT TURNS

If you have ever followed slow-moving equipment on the highway, you know how a person can be mesmerized watching the hazard lights flash off and on. Once that happens, the lights lose their purpose and meaning. This is why it is important to “wake up” drivers who have been following for a period of time, especially when making a left turn.

Mounting strobes on the back of a machine is an excellent way to increase your visibility to the vehicles behind you. Butyou have to be careful with where you mount the strobe lights. Some lights strobe in a full circle. If the light is placed too high, the lights can distract or blind the driver. Be sure to mount the strobe light (or mount a directional strobe light) so that it isn’t in the driver’s line of sight.

Another way to “wake up” a trailing driver is to briefly turn off the flashing lights before you make your left turn. As you approach your exit, turn off the flashers for a few seconds, then turn on the left turn signal alone before you turn all the flashers back on. Some suggest to only turn on the left turn signal, not any of the flashers. Once you have all the lights back on, slowly move the sprayer to and over the center line as long as there is no oncoming traffic.

Don’t be surprised if some drivers still try to pass as you start to make the left turn. Once again, you can’t control other drivers. When you start to make a left turn, you should expect that a motorist will attempt to pass on you — on the left or right. Hopefully, this gesture of turning the lights off and then back on and placing the vehicle near the center line will signify to whomever is following that you are slowing down to make a left turn.

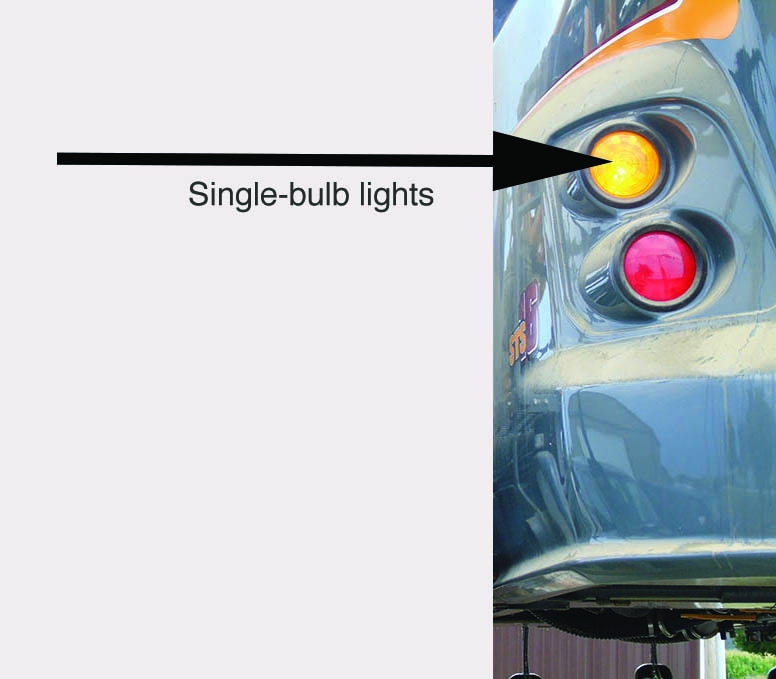

Whether you turn off your lights like this or not, think about the actual turn signal light the drivers behind you will see. To those behind you, a turn signals may just look like blinking rectangle or circle. There are turn signal lights that are have an arrow shape. It’s a small thing, but that arrow can tell those behind you that this blinking light indicates you intend to turn. Consider asking dealers for such signals on new equipment, and think about retrofitting your existing equipment.

When an equipment operator grabs the center lane before a left turn, it is pretty clear to trailing vehicles that they should not pass.

LED lights are a newer technology that have become increasingly popular and can help other vehicles see you. Notice how much brighter the LED lights are (below) compared with traditional, single-bulb lights (above). When purchasing new equipment, ask dealers for LED lights, and consider retrofitting existing equipment with LED technology.

BE CAUTIOUS ON SWINGING RIGHT TURNS

While a sprayer may have a small turning radius, there are still plenty of situations that require you to swing out wider into the left lane in order to make a sharp turn onto narrow culverts and lanes on the right side of the road. Once again, you should briefly shut off the flashers, then turn on the right turn signal. Check all mirrors and slowly move the sprayer toward the center line before making the swinging turn.

BE ALERT AT ALL RAILROAD CROSSINGS

Many rural railroad crossings do not have signals, lights, or crossing arms. The grade and unevenness of the tracks at many crossings may be in such a state that you will need extra time to maneuver the intersection, especially with a full load.

It becomes “cross at your own risk.” But remember, if school busses and trucks have to stop at railroad crossings, why not sprayers? As the operator of a large piece of equipment, can you legitimately argue that you don’t need to stop unless the railroad crossing arms are down and the lights are activated?

We’ve all read about (and seen photographs of) a driver of a tractor, sprayer, or other piece of farm equipment who misjudged the distance and speed of an oncoming locomotive as they tried to beat the train to the crossing. If unsuccessful, what’s left of the equipment is often unrecognizable. Operators who take chances like these are often killed.

Collisions with trains occur far too often. Ask the sprayer operators who were trying to beat the train to the crossing, if it was worth the few minutes they tried to save.

To avoid train collisions, you should make a habit of stopping at all railroad crossings even if it means others will pass you to try to beat the train. For safety, it is imperative that the sprayer yield at all railroad crossings.

Shut off the radio, look both ways, and listen. In a few cases, you might even have to open the door of the cab to look down the track and listen for any sounds of an oncoming locomotive when tracks are partially obstructed. Treat all crossings with the respect they deserve. Don’t take chances. It’s better to be five minutes late than to not arrive at all. Remember: You can stop. Trains can’t!

YIELD TO ONCOMING TRAFFIC

Many highways and rural roads are too narrow for today’s wider sprayers. It’s not unusual for such equipment to take up more than their lane. Drivers who are familiar with meeting sprayers on narrow roads may even pull over to let the wider equipment pass. Whether this is out of courtesy or fear, remember that drivers are not legally obliged to pull over. Thank them as you pass.

There are also drivers who believe that they own their side of the road and that it is your responsibility to pull over. They do not understand that there may be no shoulder for you to pull over or that mailboxes or power lines prevent you from any such maneuver. In these situations, pulling over slightly and stopping may be the only option you have.

You need to decide whether you should proceed or stop long before the sprayer and vehicle are side-by-side. If an approaching vehicle is not slowing down or pulling over, then it’s your obligation to start scanning ahead and searching for a place on the shoulder between the light poles, culverts, and mailboxes with enough space to pull the rig over.

If you can’t spot such a place due to obstructions or unsafe shoulders, immediately start slowing down.

There may be times when you have to come to a complete stop on the road to let an oncoming vehicle pass. This action can be risky, since drivers following you may think you are slowing down to let them pass. You don’t want a driver behind you to pass the sprayer when an oncoming car is approaching. If you stop, pull on the shoulder of the road as far over as possible so any vehicles behind you can see the vehicle approaching.

YIELD AT ONE-LANE BRIDGES

Yield to all oncoming traffic as you approach narrow and one-lane bridges if the sprayer will take more than a lane. Many drivers will speed up just to beat you to the bridge, so you might as well play it safe and yield to them.

BE AWARE OF POSTED WEIGHT LIMITS

You are responsible for observing posted weight limits over bridges. A bridge posted at 12 tons means the bridge can safely support that weight. Most rural bridges can be shorter than the length of the sprayer, which means the full weight of the load will never be on the bridge at any one time. Know your weights when fully loaded and be aware of the length of your sprayer.

While we seem to focus on highway bridges, more accidents probably occur on farm bridges that allow access on fields that border creeks. Here’s a warning from an agricultural retailer’s risk manager:

“Yesterday’s bridges do not work well with today’s equipment. Share these photos and advise your readers they should not be crossing any on-farm bridges with application equipment, tender trucks, or fuel trucks. If you need to cross bridges like these, discuss the situation with the grower. Other means of crossing the ditch safely need to be made available. The loss of equipment, environmental impact, and injuries to an employee are definitely not worth it.”

PULL OVER FOR TAILGATERS

Tailgaters! You hate them! There are drivers who will not pass even if it’s a five-mile stretch of open road. Such a driver is as dangerous as one who passes recklessly. When you have a tailgater, other drivers will become frustrated and agitated that they can’t get around the vehicle that won’t pass you.

It never fails that after a while, another car in line will try to pass both the driver who won’t pass you and your sprayer. Once the first one makes a move to pass, then others will follow. If this situation occurs, find a place to safely pull over in order to force the driver who won’t pass to get in front of you.

PUT THE MOBILE DEVICE AWAY

At some point, you have probably seen a vehicle swerving back and forth on the road. Often, the vehicle is moving erratically because the driver is talking or texting on their phone.

Texting or talking on a mobile device while operating a sprayer on the road is a distraction you should avoid at all times — not to mention the fact that it may be illegal in your state while driving. To set a good example, managers should never call their operators while they are on the road. It should be company policy that drivers are never asked to use a cell phone when operating a sprayer. Instruct your drivers to check their phones once they have arrived at their destination, and not while driving.

Even using your phone hands-free is not much safer than using it in-hand, so the best approach is to simply put the phone down. Every driver needs to have 100 percent of his or her attention focused on what is happening on the road, not 80 percent on the road and 20 percent on the phone, or worse, vise-versa.

TAKE EXTRA CARE WHEN YOU HAVE OBSTRUCTED VIEWS

Whether it is a line of trees or a sharp curve that allows you to only see one of the two lanes, exiting a field and getting on the road can be very dangerous if one of the lanes is obscured. Before you pull on the road, make sure there is no traffic in the lane. Then, slowly proceed onto the road as you start to make the turn. If a vehicle unexpectedly comes around the corner, they will be able to avoid the sprayer by passing it in the open lane.

BACK UP WITH CARE

New sprayers often have rearview cameras that you can view by looking at the monitor inside the cab. If your sprayer does not have a rearview camera, consider installing one so that you can see clearly what is directly behind you and below you. As with many rearview mirrors, you cannot see vehicles that are parked close behind the sprayer. The cost of installing a camera is much lower than the costs of replacing a totaled vehicle or of taking down time to repair the sprayer.

THINK ABOUT YOUR TRAILING VEHICLE

For years, equipment operators have been advised to have vehicles with emergency lights follow the equipment. The thinking was that these trailing vehicles offered another level of safety.

However, many equipment operators have expressed reservations about trailing vehicles. Impatient drivers often pass and get into the gap between the equipment and the trailing emergency vehicle. At other times, the “train” — the equipment plus the trailing vehicle — is simply a larger obstacle for the motorist to pass. And many equipment operators say that having a trailing vehicle is simply another distraction they have to be aware of on the road.

If you decide to have a vehicle follow your equipment, always be aware of the gap between them. The gap should not be so large that a car can get in between. And the equipment operator must be aware that there is another vehicle following very close behind.

Operating agricultural equipment on highways can be difficult. Having a clear mind will help you make good decisions when needed. Be patient, even when other drivers are rude, aggressive, and inattentive. Pattern your driving habits to know that if you have to yield, then you will yield. It’s true that it may cost you a little time, but in the grand scheme of things, will saving time really make a huge difference over the course of the day? Definitely not.

Most people who operate vehicles focus their attention to what is going on around them. However, those are not the ones you need to be concerned about. You’re actually more worried about those who are not focused and believe they own the road. In their minds, you and your sprayer have no business slowing them down or, for that matter, even being on the road.

You have to be alert and aware of your surroundings at all times. Keep distractions to a minimum. Even if you lose focus for a split second, bad things can happen the moment you take your eyes off the road. Plan ahead, know your local traffic patterns and roadways, and pay attention, so you can get your work done, earn yourpaycheck, and return safely home to your loved ones.

ACKNOWLEDGEMENTS

Thanks to Dawn Minns for graphic design. Thanks also to those who offered constructive comments during the development of this publication:

Doug Anderson, Anderson’s Fertilizer Service

Kevin Cox, T.S.T Farms

Jason Deveau, Ministry of Agriculture and Food Ministry of Rural Affairs

Dave Jenkins, Crop Production Services

Jonathan Kessler, Crop Production Services

Andrew Landers, Cornell

Kip Landwehr, Winfield Solutions

Jon Leuck, Purdue University

Brian Miller, Miller Risk Management

Bryan Overstreet, Purdue University

Jean Payne, Illinois Fertilizer and Chemical Association

Brian Scheid, White River Cooperative

Jay Shininger, MacAllister

James Sweigart, Risk Management of East Central Indiana

DISCLAIMER

This publication is intended for educational purposes only. The authors’ views have not been approved by any government agency, business, or individual and cannot be construed as representing a perspective other than that of the authors. The publication is distributed with the understanding that the authors are not rendering legal or other professional advice to the reader, and that the information contained herein should not be regarded or relied upon as a substitute for professional consultation. The use of information contained herein constitutes an agreement to hold the authors, companies or reviewers harmless for liability, damage, or expense incurred as a result of reference to or reliance upon the information provided. Mention of a proprietary product or service does not constitute an endorsement by the authors or their employers. Descriptions of specific situations are included only as hypothetical case studies to assist readers of this publication, and are not intended to represent any actual person, business entity or situation. Reference in this publication to any specific commercial product, process, or service, or the use of any trade, firm, or corporation name is for general informational purposes only and does not constitute an endorsement, recommendation, or certification of any kind by Purdue University. Individuals using such products assume responsibility that the product is used in a way intended by the manufacturer and misuse is neither endorsed nor condoned by the authors nor the manufacturer.