3.Interest in Spray Drones for Pesticide Applications

RESOURCES - PUBLICATIONS

The Evolution of Spray Drones, Their Capabilities and Challenges for Pesticide Applications

3. Interest in Spray Drones for Pesticide Applications

The acceptance of spray drones in agriculture indicates a greater interest among growers in using and benefiting from them on their farms. We examine several documented benefits that spray drones bring to agriculture and industry on the following pages.

Spray Drones Finding Wide Utility

One thing is for sure: agriculture, industry, and government have quickly adapted to employing spray drones in ways no one could have imagined five years ago.

Each year, spray drones continue to expand into new markets. Emerging uses for spray drone technology include managing issues in several settings, including:

- Mosquito control

- Ponds and lakes

- Utility rights-of-way

- Fruit trees

- Blueberries

- Grapes

- Agronomic crops

- Pastures and rangeland

- Turf

- Forests

- Pastures and hayfields

- Vegetables

- Greenhouse roof painting

- Cover crop seeding

- Fertilizer applications

- Spot spraying invasive weeds

Drones will continually evolve to meet the ever-changing needs for each specific industry and agricultural sector.

DRONE BENEFIT: Relatively Low Cost

Drones can be a lower cost, more suitable piece of equipment for small- and medium-sized farms. A modern self-propelled sprayer can easily cost 15 times more than a current, well-equipped spray drone. However, the cost of an enclosed trailer, mixing tanks and equipment, generators to charge batteries, and possibly a new truck can run the cost to more than $100,000.

DRONE BENEFIT: Challenging Fields and Difficult to Access Terrains

Many areas within fields or on farms may have limited access by ATV, boats, wheeled sprayers, and trucks. This is especially true for applicators trying to control mosquitos in the interior of remote areas or right-of-way companies treating brush around pipelines that run through marshes or treating under mountaintop powerlines. Aerial and ground rig operators turn this type of work down because it is not profitable based on the low number of acres and the high costs of operating the equipment.

There are situations where drones can spray fields when soil conditions are too wet for ground access. Wheel track compaction can be an issue that using drones can avoid. Furthermore, some manned aircraft or larger ground rig custom applicators require a minimum number of acres to be applied.

Drones may offer farmers with smaller operations an opportunity to hire custom spray drone services that require fewer acres. Drones can make applications to small fields much easier than some equipment; however, like other equipment, efficiency and operator satisfaction increases for drones in big square fields similar to conventional application equipment.

In many cases, steep hills can make pesticide applications with ground sprayers difficult and dangerous (think of equipment rollovers). A drone operator can fly hilly areas, which helps prevent fatigue and potential injury from people carrying backpacks up and down steep terrain and uneven ground.

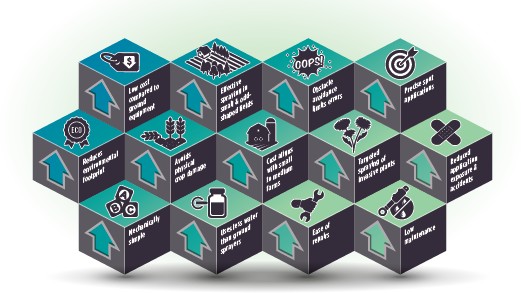

THE UPSIDES OF SPRAY DRONES

Agriculture and businesses can benefit from spray drones. Drones have particular qualities that make them worth your time and money

DRONE BENEFIT: Autonomous Presets and Obstacle Avoidance

Spray drones flying closer to the ground (10 to 15 feet) are typically equipped with supplementary radar sensors that detect obstacles in all directions — above, below, left, and right. These sensors allow for drones to automatically follow terrain, so they can maintain altitude for proper application and avoid obstacles.

The 360-degree radar can essentially scan surroundings continuously. The drones involved with applications require cameras that show front images (that is, field views of what are you about to encounter) to create an applicator log that can track where the drone has been.

Cameras on spray drones provide real-time visuals of the approaching terrain, crop, and other obstacles during applications.

Autonomous take-off and landing flight options help overcome operator errors. These safety features are analogous to the parking sensors and back up cameras on modern passenger vehicles. The intent is to make piloting drones safer and less stressful for operators and to help avoid accidental crashes and mid-air collisions.

DRONE BENEFIT: Applications Made Within Line of Sight

Drone operators know where they are applying, because they can view the flight paths and areas they are treating with onboard, real-time cameras during applications. In addition, pilots must maintain line-of-sight with their drones throughout their flights to monitor any performance or safety issues.

Spray drone controllers provide operators real-time information about application rates, speed, flight height, and droplet sizes in most newer drones. All of these parameters are necessary to track applications. Although line-of-sight is a current FAA regulation, at the time of this publication there are petitions to remove these requirements for pesticide applications awaiting FAA decisions.

DRONE BENEFIT: Farmers Control Spray Timing

By owning their own drone sprayers, farmers can more easily control application timings than they

can if they must rely on airplane services that have long lists of work to be done. This is more than just convenience — farmer-owned drones can enhance crop protection efforts with more timely pesticide applications.

Some fields (like this one) are easier for operators to maintain a line of sight than they could with rolling or uneven fields, especially when spray drones move farther away.

DRONE BENEFIT: Large Pool of Potential Pilots

Drone sprayers are easy to operate and almost anyone can be trained to safely and effectively operate them in a relatively short time.

DRONE BENEFIT: Reduced Environmental Footprint

Spray drones can reduce site disturbance, soil erosion, and site compaction compared to ground equipment.

DRONE BENEFIT: Avoids Physical Crop Damage

Drones are also an effective and safer option for taller or thicker canopy crops where ground equipment can damage the crops, especially in the tire or tracks or in the presence of viny weeds like burcucumber and morningglory. Fungicide applications after corn tasseling have been one of the most common uses of spray drones in agronomic crops.Crop damage can also be reduced in smaller, irregular shaped fields.

DRONE BENEFIT: Combats the Spread of Invasive Weeds

Operators can map weeds that may be growing in certain parts of fields, pastures, rangeland, or wetlands, and then use drones to spot-spray these areas at a much lower cost than broadcast applications. Because they are airborne, drones will not pick up invasive weeds, which helps to prevent their spread from field to field.

DRONE BENEFIT: Reduced Applicator Exposure and Accidents

Using drones to spray can significantly reduce applicators’ exposure to pesticides compared to making the same applications with certain types of ground-based equipment — particularly open-cab sprayers, backpacks, and ATVs. With spray drones, applicators are physically distant from the immediate area where the spraying is done. However, filling drone tanks, swapping and charging batteries, handling controllers, and taking sprayers back to trailers or trucks can create important sources of operator exposure. It is important that spray drone operators still follow the PPE guidelines on pesticide labels to minimize this exposure potential.

DRONE BENEFIT: Work Around Obstacles

Drones can spray around obstacles and tree lines much easier than airplanes and larger ground sprayers.

DRONE BENEFIT: Easier Repairs

Repairing spray drones after a forced landing or crash is fairly easy. Operators can fix most of the issues simply by replacing broken or malfunctioning parts. Additionally, if operators are intimidated by the thought of repairing their own drone, there are often trained technicians available to do the repairs.