6.Calibrating Spray Drones for Liquid Applications

RESOURCES - PUBLICATIONS

The Evolution of Spray Drones, Their Capabilities and Challenges for Pesticide Applications

6.Calibrating Spray Drones for Liquid Applications

DRONE FACT

A drone can only be effective, efficient, and safe if operators properly check and calibrate them for each type of application (corn, pastures, aquatic, and so on). Maintaining accuracy depends on periodically checking and calibrating drones during spraying season.

You might assume that manufacturers would perform a standardized calibration test on their spray drones before shipping them out of the factory. It appears to be a pretty straightforward process: open the box, assemble the drone, enter the flight parameters into the controller, and mix and pour the product into the tank. You are now up and running, ready to start spraying…. right? If only it was this easy!

This “ready-to-spray out of the box” assumption can lead to some major application problems because every spray drone must be calibrated properly to ensure it applies products at the correct rates and across the desired swaths. This should not come as any great surprise because the same holds true for new ground sprayers or any application equipment.

Regardless of the type of sprayer used, sprayers can only be effective, efficient, and safe if they are properly checked and calibrated before they are taken to the field. Accurate applications also depend on periodically checking and calibrating drones during the spraying season. This is especially important when operators significantly change any of the components in the setup (such as new nozzles, nozzle spacings, and so on).

The primary goal of calibrating spray drones is to determine the actual application rate over a given area for a given time. Operators should adjust their equipment if there is more than a 5 percent difference between the actual application rate and the intended application rate.

Selecting Nozzle Type and Size

Although nozzles are some of the least expensive components of spray drones, they significantly influence sprayer performance. Nozzles meter the amount of liquid sprayed per unit area, control the application rate, and affect the uniformity of spray within the swath. Nozzles also influence droplet sizes, which affects both target coverage and spray drift risk.

Purdue Pesticide Programs offers a detailed publication about spray nozzles:

Agricultural Spray Nozzles: A Comprehensive Review (Purdue Extension publication PPP-153).

It is available from Purdue Pesticide Programs (ppp.purdue.edu)

or the Purdue Extension Education Store (edustore.purdue.edu).

Drones are often equipped with flat-fan nozzles, but the spacing and orientation can be very different from traditional application equipment.

Nozzles come in a wide variety of types and sizes. Generally, nozzles with a flat fan spray pattern are preferred for spray drones using nozzles, but spacing and orientation can be very different from traditional application equipment.

We don’t have as many nozzle options for drones as we do for ground equipment because spray drones have smaller pumps and limited output. The electric pumps on spray drones may be limited to less than 5 gallons per minute (GPM) depending on the drone’s size (these pump systems are similar to ATV spot sprayers). This is why most drones use nozzles with low flow rates (0.1 or 0.15 GPM) instead of the higher flow volumes fitted on ground sprayer booms.

Using nozzles with higher flow rate capacities will likely create problems because drone pumps will not be able to generate enough flow to operate the larger nozzles effectively. It should be noted that our nozzle selection and calibration discussion here does not include rotary atomizer nozzle types that are used in newer spray drones. For a more thorough review of these spray drones and nozzles, see page 45.

To determine the size (flow rate in gallons per minute) of a hydraulic nozzle that will adequately satisfy your intended application rate in gallons per acre, follow these steps:

Step 1. Select the desired application rate in gallons per acre (GPA).

Step 2. Select a practical and safe flying speed in miles per hour.

Step 3. Determine the effective spray swath for the drone in inches. Do not use the maximum swath manufacturers' list in drone manuals. See page 39 for differences in maximum and effective spray widths. This step differs from traditional spray calibrations that use the width of the nozzle spacing for the calculations.

Step 4. Determine the flow rate (GPM) the drone requires for the application:

Gallons per Minute (GPM) = ( GPA x MPH x W ) / 5,940

(By the way, the 5,940 number used in this equation is a constant to convert GPA, MPH, and inches to GPM.)

Let’s use an example that shows the calculations using a T30 that has 16 nozzles, but only turns on 12 when spraying. You want to spray a fungicide at 2 GPA, at a speed of 15 mph. There are 12 nozzles on the drone, and you would like to maintain a swath width of 25 feet (300 inches).

Based on the inputs, what flow rate per minute must the nozzle need?

Option 1. Enter the values given above into the equation:

Gallons per Minute (GPM) for entire drone ={GPA x MPH x W (in inches)}/ 5,940

GPM = {2 x 15 x 300}/ 5,940 = 1.515 GPM for entire drone

Step 5. Divide the output for the entire spray drone by the number of nozzles activated during a spray pass.

{GPM for entire drone/ Number of working nozzles} = GPM per nozzle

1.515/12 = 0.126 GPM per nozzle

Please note that most drones come equipped with nozzles from the factory or have rotary atomizers. We are verifying if the nozzle that is on the drone meets our application requirements.

DRONE FACT

The conventional hydraulic nozzles on spray drones have small orifices (01 and 02), which tend to clog. Spray drones with rotary atomizers are relatively less prone to clogging.

Select a nozzle size from the manufacturer’s catalog (or from their website) that will provide the flow rate (GPM) that you determined in Step 5 when the nozzle is operated within the recommended pressure range. For drones with nozzles, you are basically limited to using only two sizes — 0.1 and 0.15 — because drones cannot generate enough flow and pressure to operate larger orifice nozzles properly. So, you should select a nozzle that will deliver 0.126 gallons per minute of spray output.

Take care when using spray width (W) in the equation above to determine the nozzle flow rate (GPM). Several things will affect the actual effective swath width that you should use in the equation, including the flight altitude. This is explained in the section that follows.

These nozzle has a 110° spray width. The nozzle with green tip is a 0.15-gallon per minute nozzle (at 40 psi). The green nozzle would more closely align with what we expect to get out of the drone.

These nozzle has a 110° spray width. The nozzle with green tip is a 0.15-gallon per minute nozzle (at 40 psi). The green nozzle would more closely align with what we expect to get out of the drone.  These nozzle has a 110° spray width. The nozzle with orange tip has a flow rate of 0.1 GPM (at 40 psi).

These nozzle has a 110° spray width. The nozzle with orange tip has a flow rate of 0.1 GPM (at 40 psi). Determining Effective Spray Swath Width

One of the variables in the equation used to determine the gallons per minute flow rate is the spray swath. It is extremely important when determining a value for W in the equation, you should use the effective swath width, not the maximum swath width the drone user manual may provide. The effective swath width considers the need for some spray overlap between passes to achieve a uniform application across the field. Thus, the effective swath width is what you should use for the distance between each sprayer pass.

Spray drone manufacturers often advertise their maximum swath widths. The values they provide represent how far away from the drone some droplets may deposit on the spray target. However, the deposition pattern of droplets across the spray swath will not be uniform. A relatively small number of droplets reach the outer edges of the spray pattern while there are greater deposition levels toward the center of the drone.

A general rule of thumb from the authors’ experiences, the scientific literature, and practitioners is that the effective spray width is between 65 and 75 percent of the advertised spray swath width. For example, if a drone has a maximum spray width of 30 feet, it would have an effective spray width between 20 and 22 feet. This can vary, so you should verify the effective spray width by performing a swath test. Researchers should come up with methods to find effective spray widths easily to better refine effective spray widths in the near future as new findings are reported.

A fungicide application to corn failed to control the pathogen because of incomplete overlap and ineffective spray coverage.

A fungicide application to corn failed to control the pathogen because of incomplete overlap and ineffective spray coverage.  Always conduct pattern testing on your drones to determine effective spray swath width and ensure pattern uniformity no matter the body of research or database of aircraft setups for make and model.

Always conduct pattern testing on your drones to determine effective spray swath width and ensure pattern uniformity no matter the body of research or database of aircraft setups for make and model.  Very small differences in drone setup can change both pattern quality and swath width.

Very small differences in drone setup can change both pattern quality and swath width. For that reason, the drone operator using the controller screen shown below has entered 25 feet for Route Spacing instead of the 30 feet maximum swath width suggested by the drone manufacturer.

One other factor that will play a key role in determining the actual spray swath is flight altitude. The lower the flight altitude (height from the ground or the crop canopy), the narrower the spray swath will get. You also should consider altitude when you select nozzle sizes.

This drone is using 25 feet for an effective spray width instead of the maximum spray width. Using a reduced spray swath allows the drone to overlap between passes to achieve a more uniform application. Sprayers101.com provides an excellent explanation of the difference between maximum and effective swath widths when using spray drones.

DRONE FACT It is extremely important that you use the e‑ective swath width, not the maximum swath width the drone user manual may provide. Effective swath widths may change according to carrier volumes, adjuvants, spray heights, and vegetation.

Notes from the Field

Crosswinds can cause swath displacement, which drone operators should account for when establishing spray passes. When flying in-wind, spray speeds and pressures will likely change whether flying against a headwind or with a tailwind. This can also affect how the spray swath lays down. This reemphasizes the need to swath test in multiple different environmental scenarios.

Considering the variations in nozzle sizes, spray pattern angles, wind direction, wind speed, and flight altitudes, there is no theoretical mathematical solution to determine the effective swath width. Ideally, operators can check the spray swaths of their drones using methods and instruments that can quantify the spray solution volume or the amount of spray droplets being deposited across the swath. However, this may be limited to university researchers and spray application consultants who commonly use these methods.

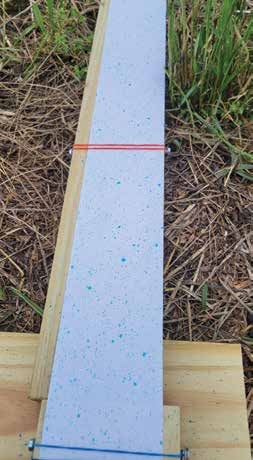

The best way to determine the spray deposition from multiple passes is to visually observe the variations in the spray deposits across the sprayed area. For visual observation, the most effective approach is to lay a strip of white paper tape or water sensitive paper (WSP) under the drone’s flight path. Add some food-grade coloring or foam marker dye in the spray tank, and then fly the drone over the tape or WSP and observe the spray pattern and droplet size spectrum as shown in the photographs below.

Depending on what you observe, you may have to change the flight altitude and/or the overlapped distance between each flight pass. You will need to replicate several adjacent spray passes until you are satisfied with the uniformity and deposition of the spray across the test area.

The most practical way to find out if a spray deposition is uniform is to add a very small amount of dye to the sprayer tank, and then make several passes over a tape laid on the ground just like you would be spraying the area. The dye used for sprayer foam marker systems is commonly used to visualize spray deposits. It also is safe and inexpensive for calibration runs.

The most practical way to find out if a spray deposition is uniform is to add a very small amount of dye to the sprayer tank, and then make several passes over a tape laid on the ground just like you would be spraying the area. The dye used for sprayer foam marker systems is commonly used to visualize spray deposits. It also is safe and inexpensive for calibration runs.  Next, observe the deposition of spray droplets on the tape. Heavy dye concentration on parts of the tape is a good indication of too much overlapping of adjacent passes. No dye on some sections of the tape indicates not enough overlap. This may require you to change flight altitude and/or distance between each pass. Individual applicators can use several pattern evaluation systems, including Swath Gobbler, DropFlight, and AccuPath.

Next, observe the deposition of spray droplets on the tape. Heavy dye concentration on parts of the tape is a good indication of too much overlapping of adjacent passes. No dye on some sections of the tape indicates not enough overlap. This may require you to change flight altitude and/or distance between each pass. Individual applicators can use several pattern evaluation systems, including Swath Gobbler, DropFlight, and AccuPath.  An inexpensive and practical way to determine effective spray width, spray uniformity, and spray drift is to use water sensitive paper (WSP). Here, the applicator fastened WSP to boards laying on the ground perpendicular to the drone flight path. Operators can use the information from the WSP to adjust the settings (height, speed, etc.) that determine effective spray swath.

An inexpensive and practical way to determine effective spray width, spray uniformity, and spray drift is to use water sensitive paper (WSP). Here, the applicator fastened WSP to boards laying on the ground perpendicular to the drone flight path. Operators can use the information from the WSP to adjust the settings (height, speed, etc.) that determine effective spray swath. Height Influences Spray Pattern

A drone sprays two feet above pavement.

A drone sprays two feet above pavement.  Spraying 5 feet above the pavement is not high enough to deliver an acceptable and uniform pattern.

Spraying 5 feet above the pavement is not high enough to deliver an acceptable and uniform pattern.

Spraying 5 feet above the pavement is not high enough to deliver an acceptable and uniform pattern.

Spraying 5 feet above the pavement is not high enough to deliver an acceptable and uniform pattern.  A drone spraying 10 feet above pavement.

A drone spraying 10 feet above pavement.

This photo shows a spray width testing card showing deposition after being sprayed by a drone.

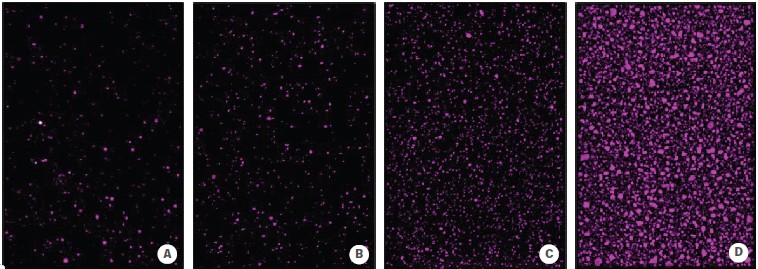

This photo shows a spray width testing card showing deposition after being sprayed by a drone. Another approach researchers have used for decades to determine spray deposition uniformity with ground equipment is to use water-sensitive spray cards (page 43). Users place spray cards perpendicular to the sprayer’s travel route. The cards turn blue anywhere water drops hit them. In general, the more water that hits the cards, the more blue droplet stains appear on the cards, and the better the spray deposition or coverage.

As you would expect, water-sensitive cards placed toward the end of the swath show less coverage compared to the center. Researchers will study the distribution of spray droplets and use analytical methods to better quantify the intensity of those spray droplets. There are some phone applications (like DropLeaf) that can quantify the differences in the spray cards. Just take a photo of the card and the app will generate spray droplet data.

Using a fluorescent dye along with Kromekote cards show spray distribution when applicators use (A) 1 GPA; (B) 2 GPA; (C) 3 GPA; and (D) 15 GPA.

We will need new research as new technologies appear in the marketplace.

We will need new research as new technologies appear in the marketplace. Calibrating the Spray Drone

Regardless of the type of sprayer you use, you can only achieve your goal of protecting crops against pests if you properly check and calibrate the sprayer before you take it to the field (and recalibrate and recheck periodically during the spraying season). Like ground applications, the various combinations of pesticides, adjuvants, and other chemicals can alter the physical properties of the spray solution. In turn, those properties influence sprayer calibration, swath width, and spray deposition.

Arguably, the chemical inputs in spray solutions from drone applications may have an even greater impact because the concentrations are 5 to 10 times more concentrated than the more diluted ground applications. The primary goal of calibrating a spray drone is to determine the actual rate of application in gallons per acre, and then to make the necessary adjustments if there is a difference greater than 5 percent between the actual application rate and the intended application rate. As is true for all sprayers, travel speed, nozzle type, flow rate, and spray pressure (which influences both the flow rate and the droplet size) all affect application accuracy. The three rules of application accuracy apply to all spraying equipment, including spray drones:

- Maintain a uniform flight speed. This is essential to keeping the application rate relatively uniform throughout the operation. Faster flying speeds will result in lower application rates, while slower flying speeds will do the opposite — higher application rates. Most spray drones are equipped with rate control capabilities that provide consistency in application when speeds change; however, application speed should remain the same throughout the field.

- Maintain an optimum spraying distance between the nozzle and the target. Drones have radar altimeters to take care of height. Operators cannot control height during autonomous flights with most drones. This often requires operators to make hard choices about productivity and coverage.

- Maintain a uniform spraying pressure. This is essential for keeping both the application rate and droplet size consistent during the application. Lower spray pressure leads to lower application rates and larger droplets. Conversely, high spray pressure leads to higher application rates and a greater number of smaller, drift-prone droplets. Both extremes waste pesticides and provide poor pest control.

Speed Versus Performance

Operators will always be tempted to push the limits by maximizing speed and width to allow their drones to cover more ground quicker. In such situations, you are pushing the pumps and spray widths to their limit.

While getting a job done as quickly as possible is important, making sure the application is done properly the first time should be your primary goal. Having to respray a field not only costs you money, but also time you could have used to generate new revenue.

DRONE FACT

As with ground applications, various combinations of pesticides, adjuvants, and other chemicals can alter the physical properties of spray solutions in drone tanks. The results can influence sprayer calibrations, swath widths, and spray deposition.

However, directly setting and adjusting spray pressure may not be possible because spray drones do not have pressure gauges or pressure controls. Alternatively, operators could adjust travel speeds to reach desired GPA outputs. Similarly, keeping spray height uniform could be difficult if a drone is not equipped with a terrain sensor. Luckily most, if not all, spray drones come with terrain sensors.

All spray drones come with controllers that allow drone operators to set their spray parameters such as height, swath width, gallons per acre, and travel speed. Controllers also allow users to plan autonomous routes for applications. These are good starting points for accurate spraying. However, operators can only attain proper application rates if sprayers are in proper working order and correctly calibrated. Sprayers that are not accurately calibrated may apply too much or too little chemical, resulting in unsatisfactory efficacy and wasted pesticides. Poor calibration can also increase the risk of injuring the crop, fail to control the pest, or increase drift risk.

In several ways, calibrating drone sprayers is somewhat similar to calibrating ground sprayers. Drone remote flight controllers are really acting like in-cab display controllers on ground sprayers. Both systems require initial calibration checks before hitting the field for the first time after purchase or at the beginning of each spray season.

For ground sprayers, you enter calibration mode and run water through the sprayer for a known amount of time, and then measure the volume you catch from the nozzles during that period. You record the volume you caught and enter that into the in-cab spray controller, so the computer can correct the built-in calibration settings. This essentially improves the accuracy of the flow meter to the new calibration amount or flow rate.

When 1 Gallon Is Not Equal to 1 Gallon

Several drones may use imperial gallons instead of U.S. gallons.

An imperial gallon equals 1.20 U.S. gallons. In the calibration section, two gallons per acre using imperial gallons would require 2.4 U.S. gallons. Review the owner’s manual or contact the sales representative to see which gallon unit your drone uses.

Spray drone remote-control modules do not have ways for users to enter any calibration data. Drone control modules will use internal application formulas to control the output through the pump and flow meter. You cannot directly influence the flow rate of a nozzle by turning a knob or entering a value in a pop-up window that alters the pump and flow meter. We are also at a disadvantage of not knowing the spray pressure, because this is not displayed on the controller. There are several lesser-known brands that have this type of control.

There are several ways to calibrate spray drones to work around this problem. Use the calibration method that you are accustomed to if it happens to be different than the procedure outlined in this publication. Regardless of the method you use to calibrate sprayers, you will have to take certain measurements. You should follow the important operational principles mentioned in this publication to achieve maximum efficacy from the chemical applied.

There are a few things you must do before starting the calibration process. Needless to say, you will always wear gloves and goggles for safety reasons when mixing, spraying, and calibrating sprayers. After you have your proper PPE, clean spray systems to remove any pesticide residues to allow for safe calibration.

Next, run the sprayer on the ground, inspect it for leaks, make sure all vital parts function properly, and that the sprayer has a good set of nozzles. Check the flow rate of each nozzle for a set period (minimum 30 seconds) to identify the nozzles that may be clogged or worn out. If it is difficult to run the spray process with the drone on the ground, you could remove the nozzles from the drone and put them on a standard sprayer to check the flow rate.

Spray drone nozzles are more prone to clogging because the nozzles designed for drones have smaller orifices to accommodate the lower carrier volumes drones apply. Compounding the problem is that most drone nozzles do not have screens in the nozzle body assembly. Furthermore, drone sprayers apply more concentrated spray solutions, which have a greater risk for chemical incompatibility and for particulates to build-up in the tank. For these reasons, you must frequently check the flow rates of spray drone nozzles. Even partially clogged nozzles will cause underapplication and non-uniform spray deposit on the ground.

Be sure to clean all clogged nozzles before you calibrate sprayers and clean nozzles daily (especially after spraying mixtures that contains dry products). Never use sharp objects (such as wires or knives) to unclog nozzles. They will damage nozzle orifices, which will affect the spray pattern. You should also not hold any nozzle close to your mouth and blow air into it — you don’t want any chemical or debris in the nozzle splashing on your face or eyes. Always use a soft brush to unclog nozzles.

Chemical incompatibility and not wearing gloves — a bad combination.

Chemical incompatibility and not wearing gloves — a bad combination. If the flow rate of an existing nozzle on a drone exceeds 10 percent of the flow rate of a new nozzle of the same type and size (at the same pressure setting), then consider the nozzle on the drone worn-out, and replace it with the new one of the same type and size.

A word of caution: Larger spray drones usually have two sets of pumps and flow meters. Each set controls one set of nozzles. So, when you check flow rates on such spray drones, pay attention to which pump and flow meter the nozzle is connected to. If there is a noticeable difference between the flow rates between the pumps, it is likely that the discrepancy may be caused by a malfunctioning pump or flow meter.

Once you complete these pre-calibration checks and you have a good set of nozzles on the drone, you are ready to fine tune your spray operation by going through a set of steps we describe as calibration. Although the concepts presented here for calibrating drone sprayers apply to most drones makes and models, we encourage you to check if your drone’s manufacturer provides specific procedures because drones may come with different nozzle configurations.

There are eight steps to calibrate a spray drone, which applies to most drone types.

Step 1. Measure and mark off an area equal to at least 1 acre (make it larger for more accuracy).

Step 2. On level ground, completely fill the sprayer tank with water, or fill it up at least more than half the tank volume, and mark the water level on the tank. Prime the sprayer and note the volume remaining in the tank.

Step 3. Spray the marked area from Step 1.

Step 4. Return and land the drone to its launch point.

Step 5a. Fill the tank to the same level you marked before spraying the marked test area. Record the volume of water you added to refill the tank to the marked level. (Note: Weighing the drone before and after application can be an alternative if you have a reliable scale available where you calibrate).

Step 5b. Subtract the volume of water you added to refill the tank from the volume of water you originally put in the tank. This will determine how much liquid the drone used. This can work if the tank has site markings on it and they are accurate enough to make a reasonable estimate.

Step 6. The refill volume is equal to the application rate per marked test area.

Step 7. Convert the number of gallons used to treat the test area in step 6 to gallons per acre.

Step 8. Compare the measured (actual) application rate with the recommendation on the pesticide label (the intended rate). If the difference between the recommended rate and the measured rate is greater than 5 percent of the recommended rate, adjust the drone sprayer to reduce the application error so that it deviates less than 5 percent of the intended rate.

An Alternative Approach

An alternative method for calibrating drone sprayers is to record the time it takes to spray the marked area, and then collect and measure the spray from each nozzle for the same time period. The total spray you collect is the number of gallons applied in your test area (as in Step 6). Then, follow Step 7 above to convert this to gallons per acre.

How to Reduce Application Error

Currently, there is no way for drone operators to adjust the flow rate except by entering a slightly lower or higher value in the controller. With ground sprayers, when applicators need to adjust the application rate, they usually do one of three things:

- Change the travel speed

- Change the spray pressure

- Change the nozzle (if the first two methods are impractical) Unfortunately, there is no ability to adjust the flow rate in drones by changing spray pressure because only the internal control system adjusts the pressure.

Working Through a Calibration Example

Let’s say you want to spray a product using a drone that has 10 nozzles at a rate of 2 gallons per acre (based on label recommendations) while flying at a speed of 10 mph.

To determine the actual application rate, you marked off an area equal to 1.5 acres. From start to stop, it took 4 minutes to spray this area. Then you landed the drone and ran the pump in the same way as the calculation, but with each nozzle directed into a bucket for 4 minutes (see photos on page 49). You measured the amount of liquid in each bucket: 315 ounces. This would be the total for all nozzles in the sprayer, not from an individual nozzle.

As with traditional sprayer calibration methods, operators can use a calibration catch to determine the accuracy of the spray drone’s output. Although the sprayer was cleaned, it is always a good idea to wear protective chemical gloves.

What Is the Application Rate in Gallons Per Acre?

First, convert 315 ounces to gallons — a gallon is 128 ounces.

(315/128) = 2.46 gallons

Next, determine the application rate per acre. You applied 2.46 gallons to a test plot of 1.5 acres.

2.46 gallons ÷ 1.5 acres = 1.64 gallons per acre

What Is the Percent Application Error?

Your intended rate is 2 gallons per acre, but the actual rate was 1.64 gallons per acre. Subtract the actual rate from the intended rate and divide that by 2 gallons, then multiply by 100 to get your application rate as a percentage.

Application Error = {(2 - 1.64)/2} x 100 = 18%

This 18 percent application error (under application in this case) is more than the 5 percent acceptable margin of error. Therefore, you must make some changes to bring the application error as close to 0 percent as possible — but at least less than 5 percent.

One way to do that is to enter a higher value in the controller (2.5 GPA), and then catch it and see how close we are to the target rate of 2 GPA. Another approach is to tell the drone to spray 2.36 GPA if it is underapplying by 18% (2 gallons x 0.18 = 0.36 gallons; 2 gallons + 0.36 gallons = 2.36 gallons).

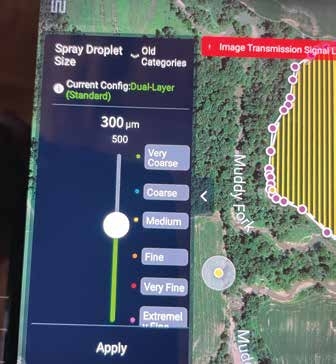

Care and Calibration of Rotary Disc Atomizers

Some new spray drone models come with a set of rotary disc atomizers instead of hydraulic flat-fan nozzles to atomize the spray solution. An advantage of rotary atomizers is that operators can use their tablet/controller to select from a range of droplet sizes — very fine to very coarse — without having to change nozzles. However, there is limited research to verify whether the rotary atomizers actually achieve those classifications as designated through ASABE S572.

Rotary atomizers, as seen on many new drones, allow operators to easily change droplet size by selecting the desired size in the remote controller. More research is needed to verify how accurate these droplet sizes are and if they meet label requirements for droplet size specification.

The calibration process for drones with rotary discs is generally the same as that for drones equipped with hydraulic nozzles. You start with a set of rotary discs that come with the drone when you purchase it. You do not need to worry about the type or size of nozzle you should have on the drone, as you would if you had hydraulic nozzles.

To determine if you are getting the intended gallons per acre application rate from drones with rotary discs, use the same procedure explained earlier for spray drones with hydraulic nozzles. With a rotary atomizer, you cannot use a single-catch container under each nozzle, because the rotary atomizer sprays liquid in all directions. Instead, use a bag that can guide all the spray into it. Although it is a bit more difficult to do, you will still need to check the flow rate of the disc atomizer and calibrate the drone as described earlier.

Examples of rotary atomizers equipped on several new drone models.

Examples of rotary atomizers equipped on several new drone models.

Clogging is not a major issue with these atomizers. However, other issues may surface after extended use of the rotating disc assembly. Some have suggested that the increased pump sizes on newer drones have resulted in rotary atomizers being “flooded.” This has led to improper droplet formation and a “drooling” type effect. In such cases, the drones produce larger droplets and deposit a high concentration directly beneath the nozzles, leading to streaking in fields. Another potential issue is the change in rotation speed of the discs. The rotation speed of the discs influences spray droplet size. Higher rotation speeds tend to produce smaller droplets, while lower rotation speeds tend to produce larger droplets.

Unfortunately, it is not easy to determine the rotation speed of these discs. It requires having a digital tachometer, which many newer models now have. If you have one, stick a tape on the side of the disc and while the disc is rotating, aim the digital tachometer on the tape. This will tell you the speed of the rotating disc in revolutions per minute (RPM).

You need to compare your measurement with the motor’s top RPM. Some manufacturers recommend when operators should replace these discs. Droplet formation will also be affected, to a smaller degree, by cleanliness of the serrations (groves) on the disc. So, cleaning the discs (and other parts of the drone) becomes even more important if spray mixtures contain solid particles.

The rotary atomizer (spinning disc) nozzles (like the ones shown here) can create a very uniform droplet size distribution, but more research is needed to fully validate their capabilities on spray drones.

The rotary atomizer (spinning disc) nozzles (like the ones shown here) can create a very uniform droplet size distribution, but more research is needed to fully validate their capabilities on spray drones.  The small grooves in the spinning discs act as tiny channels that distribute liquid while it is dispersed. The liquid eventually forms droplets as it leaves the spinning disc. The grooves wear with more abrasive materials. Always carry spare discs to quickly replace them in the field.

The small grooves in the spinning discs act as tiny channels that distribute liquid while it is dispersed. The liquid eventually forms droplets as it leaves the spinning disc. The grooves wear with more abrasive materials. Always carry spare discs to quickly replace them in the field.