7.Operational Setup in the Field

RESOURCES - PUBLICATIONS

The Evolution of Spray Drones, Their Capabilities and Challenges for Pesticide Applications

7.Operational Setup in the Field

Arguably, spraying with a drone takes more effort to prepare and complete than a ground rig in the same field. While drones appear simple, setup and operation can be quite involved.

Grass lanes within fields provide excellent places to set up drone operations.

Before entering a field, you must consider the following:

- What equipment, materials, and supplies you must bring to each site

- Where to park a trailer or truck

- Where to take-off and land to protect the pilot and equipment from spray drift, dust, and debris

- Where to position the pilot and visual observer so they can always have a visual line of sight during flight while avoiding pesticide exposure

- Where to place the generator and batteries so they do not overheat, but are easily accessible for frequent charging — charging efficiency is better in the shade

- Where chemicals will be mixed

- Where to place a nurse tank and/or where the nearest fill station is located

- Where the drone should be rinsed and cleaned

- Field size, which will help determine whether a single flight or multiple flights will be conducted

- Topography of the field and flight direction

- Locations of infield irrigation equipment

- Locations of sensitive crops, sensitive areas, water bodies, highways, residential areas, and nearby commercial properties

- Local wind speeds and the potential for temperature inversions

- Locations of potential overhead hazards, such as power lines and tree limbs, that can hinder safe take-offs and landings

Field terrain can vary by location. This is why it is always important to be aware of the surroundings of the drone application.

Field terrain can vary by location. This is why it is always important to be aware of the surroundings of the drone application.  Irrigation pivots can be obstacles for drones to work around. A common practice is to split the application into two separate fields to avoid collisions.

Irrigation pivots can be obstacles for drones to work around. A common practice is to split the application into two separate fields to avoid collisions.  A drone, with its relatively small tank size and limited battery life, requires all of the items it needs to continue operating strategically positioned at the application site to improve the efficiency of the operation.

A drone, with its relatively small tank size and limited battery life, requires all of the items it needs to continue operating strategically positioned at the application site to improve the efficiency of the operation. Scan the Application Area for Flight Obstacles

Investigating the lay of the land remains a top priority when using drones to apply pesticides. Take a few minutes to scope out the property to save hours or days dealing with a problem that should have been spotted before the start of the mission. A collision with an obstacle due to hasty flight planning can shut down operations for the day, or even longer, depending on the severity of the drone damage and part availability.

Identifying obstacles in the field before flight is critical. Recognize obstacles pre-flight to avoid collisions, such as a drone becoming entangled in wires. Even obstacles around field perimeters are important if they may intersect the drone’s return path to your loading site.

Identifying obstacles in the field before flight is critical. Recognize obstacles pre-flight to avoid collisions, such as a drone becoming entangled in wires. Even obstacles around field perimeters are important if they may intersect the drone’s return path to your loading site.  While many drones have obstacle-avoidance sensors, it is best to leave a large buffer around obstacles to avoid accidents.

While many drones have obstacle-avoidance sensors, it is best to leave a large buffer around obstacles to avoid accidents. A crashed drone might mean it has flown its last mission. That means an outlay of cash for a new drone, a significant amount of time to receive it, and time to file the proper paperwork to legally operate it. The good news is that if you have the parts, most repairs are rather straightforward. What we see as obstacles can change how we fly the field to work around them. Scout the property for powerlines, irrigation pivots, radio towers, high tension lines, guy wires, fence lines, trees, and over-extending branches in and around a field.

In larger row crop fields, operators can use smaller, less costly mapping or recreational drones to keep the hours off the spray drone. Operators can also use binoculars to help look for nearby obstacles. However, the quickest first step in reconnaissance could simply be viewing the area on various platforms that provide free satellite imagery, such as Google Earth.

Notes from the Field

A drone operator indicated:

“We mitigate obstacle hazards with a scouting flight before we start each field. This allows us to observe the field for any unexpected hazards that would not show up on satellite imagery. It also allows us to verify that our boundaries are far enough away from hazards, by observing the relationship between the boundary on our screen, the drone icon on our screen, and the drone’s location relative to the hazard in the real world.

“For example, if we fly the drone to the minimum safe distance away from the power lines in the field before application, and then observe the relationship between the drone’s position on our screen to the boundary of our application area, we can determine if our boundary needs to be moved closer or farther away from the power lines to optimize our application.”

DRONE FACT

Taking a few minutes to scope out an application site can save you hours or days by preventing your drone from crashing into obstacles.

Exercise caution when using satellite imagery because it may not be up to date — new infrastructure could have been added or certain obstacles could have been removed. Satellite image resolution is also low, which prevents you from seeing obstacles well.

Drones have onboard sensors that are programmed to sense and avoid obstacles. The sensors can stop the drone in mid-air several feet from the object, but some

drones can begin to detect obstacles up to 30 feet or more away. Unfortunately, avoidance systems can fail to detect powerlines, guy wires, and smaller branches along tree lines (especially when the branches have lost their leaves or when you’re operating drones at maximum speeds).

It's also important to map obstacles beforehand and mark them in the mission, because most drones are operated at full speeds for application. While obstacle avoidance systems still work at top speed, drones require longer distances to slow down. Some applicators operate their drones at top speeds by disabling the obstacle avoidance. So, when radar detects the obstacle, it might be too late. Experienced drone operators concede after the fact that it doesn’t take much of a limb sticking into a field or a misjudged power line to bring a drone down.

Obstacle avoidance systems give you room to manually maneuver around or above detected obstacles. Stopping in mid-flight to avoid a detected obstacle is an important safety measure, but realize that hovering can quickly drain batteries, which could lead to forced landings. Fortunately, once drones detect an obstacle, they will shut down pumps, thus stopping product application until the obstacle can safely be avoided. Afterward, safe application can resume.

DRONE FACT

At top speeds, obstacle avoidance systems on some drones may still work; however, drones flying at high speeds need greater distances to slow down compared to lower speeds.

Can You Believe What That Tree Branch Did to My Drone?

We recommend setting up a no-spray buffer that is one-half of the spray width or 10 feet around fence lines with trees and brush. Red waypoints mark an area the drone will recognize as a “no-spray” zone.

More than 90 percent of spray drone crashes were caused by operators flying drones with obstacle avoidance radar turned off or by operators who failed to map obstacles and wires before flight. We strongly recommend you map obstacles before flight to avoid the drone continuously sensing and avoiding them in flight.

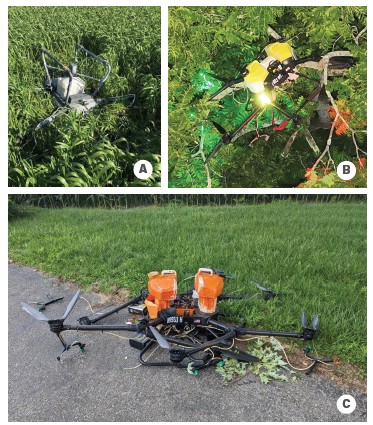

Photos A, B, and C. Unexpected landings can place drones into unwanted and unsafe landing zones, which may substantially damage drones.

Photos A, B, and C. Unexpected landings can place drones into unwanted and unsafe landing zones, which may substantially damage drones.  This drone encountered an obstacle while returning to home base with no remote-control signal and paused. The drone hovered until its battery reached a critically low level, and then attempted to land through the canopy of a mature deciduous forest.

This drone encountered an obstacle while returning to home base with no remote-control signal and paused. The drone hovered until its battery reached a critically low level, and then attempted to land through the canopy of a mature deciduous forest. Crossing waterways can cause obstacle avoidance sensors to stall a drone after it lowers into the depression of the waterway. The drone may identify the abrupt change back to the tall corn on the other side of the waterway as an obstacle. A related problem is flying too low. A tall pigweed or random plant can stall a drone. Make sure that powerlines, trees, and guy wires are not part of the flight pattern as it takes off and lands and are not a concern in the return to home route.

DRONE FACT

More than 90 percent of spray drone crashes occur when operators turn off obstacle avoidance systems while flying or when operators fail to map obstacles and pay attention to wires before flying.

Setting the Field Boundaries and Inputting Variables into the Controller

There are many ways to map the boundaries of a field to help keep your drone on a set spray pattern. One method is to drive around a field using an ATV. For every 30 to 50 feet, enter a waypoint (boundary point) into the controller or tablet.

If there are obstacles the drone needs to fly around, then operators need to manually add more waypoints. Most modern spray drones allow users to mark around the obstacles with different waypoints. Certain brands also allow users to map no-spray waypoints so drones will fly over these areas without spraying any product.

Several programs are available for marking field boundaries.

A second option is to set the boundary by using the spray drone software and background imagery to mark waypoints when the field has too many obstacles or is inaccessible to ATVs for mapping boundaries. Some models and brands do not have these capabilities.

In many cases, field edges run alongside roads and steep ditches, making it impossible to drive ATVs in those areas. A field might be adjacent to a tree line or marsh, which also limits ATV access. Of course, one of the benefits of using spray drones for pesticide applications is their ability to spray fields with irregular shapes. Thus, mapping a field’s boundaries that tracks the entire perimeter may be necessary instead of a simple four-corner field.

A third option to mark field boundaries is to use mapping programs from Google Earth, Google Maps, DroneDeploy, ArcGIS, and other precision ag software. You can export the boundaries as shapefiles and upload them to the drone remote controller. These mapping applications provide acceptable resolution at the time the images were made. If the field remains unchanged, then these satellite images work well for drawing the boundaries. However, make sure to do a site verification before actual flight.

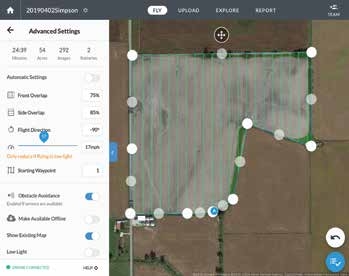

This is an example of the software available with many drones. This image shows an application in progress after the operator developed a detailed flight plan. Yellow lines indicate the drone’s flight paths. Each purple dot is a waypoint that indicates a change in the application boundary, which signal the drone to change direction.

Remember satellite images cannot spot small obstacles and telephone line poles are hard to see. If you use a precision ag software platform, you can make accurate field boundaries from planting, application, or harvest maps that most farmers currently use.

Don’t forget that with satellite imagery the data displayed might be a few years old. This is only a problem if, for example, the field has added or removed a building, parts of the property were sold for homes, powerlines or cell towers were added, or trees were removed to make larger fields. Sometimes, the satellite data will document the image dates; however, in-person scouting is always required to confirm that the satellite imagery is correct, and the operation can be safely completed. When using these images, it is best to scout the field to verify the boundaries and any obstacles the imagery could have missed.

A fourth option is to map the field with an RGB drone, download the images from the drone to a computer, and then stitch images into a precision map (technically called orthomosaic map). This option can easily mark obstacles and field boundaries on the orthomosaic map, and then export those to the spray drone as shapefiles. This is also the most time-consuming method, but precision level is the highest among all other planning options mentioned above.

Operators may input certain application variables in the planning phase or at the edges of fields. Operators enter spray variables, such as height above canopy, drone flying speed, spray volume (gallons per acre), and application swath width. On newer drones with rotary atomizers, there is also an option for selecting desired droplet size. Operators can enter other parameters (such as distance offset from the boundary) in the field. Operators also need to determine flight directions that result in more efficient operations with the fewest turns. These input variables can change from field to field depending on the crop being treated, product being used, and field conditions.

The Pilot’s Eyes Focused on Drone

Under federal law, the pilot and visual observer are required to have a visual line of sight with the drone, so the operator can maintain full control of the unit and safely ground the aircraft if unforeseen circumstances occur. It is important to find an area where you have a continuous and clear line of sight to watch the drone as it makes its application across the field, pond, or county right-of-way. That position is no longer limited to the entrance of the application site like ground equipment, because now you can select a location that gives you a clear view of the area being treated.

A useful tactic to maintain the line of sight is to find the highest elevation where you can watch the drone make the application across the field. This spot becomes the staging area where you will land and take-off. For fields with low canopy crops, you can also walk along field boundaries to have a line of sight. In some cases, you may need to relocate the staging area to have a better line of sight. This is not always a fixed spot but can change as needed to maintain line of sight and to attain greater efficiency with drone applications.

Can You See the Drone?

There are several horticultural crops like orchards, vineyards, and fruit and bush crops that may make it very difficult to maintain a visual line of sight. It is not easy and will require a lot of thought and changes in practice to accomplish the legal requirement for visual line of sight.

Another advantage of using an optimal field observation site has to do with keeping the drone and controller in constant communication. The antenna on the remote controller uses a radio signal to remain connected to the drone. Drone and controller communicate best when there are no major obstacles interrupting the signal. If communication is lost, the drone may initiate the return-to-home function. Furthermore, finding a central staging location can help make efficient use of the batteries to limit empty payload flight time return to refill.

When standing on the edge of a tall crop (like tasseling corn) or rolling hills the controller and the drone can drop the signal with one another. This can result in the pilot losing the ability to direct the drone in flight. Flying from higher ground to lower ground helps maintain a strong signal and provides the pilot full operational control.

A flight can be autonomous (preprogrammed flight) when the drone is programmed to fly only over a certain area. Autonomous flights are typical of most applications because it can be difficult to achieve optimal and constant speed, height, and field coverage during manual flight.

Always pick the highest point possible for a staging area, which will give you a clear view of the field and obstacles.

Always pick the highest point possible for a staging area, which will give you a clear view of the field and obstacles.  This is an example of a difficult field to fly because of the rolling hills and potential to lose contact and visual line of sight with the drone. The operator may have to fly half of the field from this end of the field and find another vantage point to cover the rest of the field.

This is an example of a difficult field to fly because of the rolling hills and potential to lose contact and visual line of sight with the drone. The operator may have to fly half of the field from this end of the field and find another vantage point to cover the rest of the field. With an autonomous flight, the operator creates the flight by uploading data from the controller to the drone. If the drone and controller lose connection during an autonomous flight, the drone can continue its programmed mission until the radio signal is reestablished with the controller. However, you will not be able to control the drone until the signal between drone and controller is reestablished. Be aware that current rules require that if the drone loses communication with the remote controller for a longer period, then it must initiate its return-to-home function so that the drone will return to the take-off location and communication can be regained.

An important consideration with autonomous flights is battery life. If the return-to-home function is set to initiate when battery life is lower than what is required to return to the home base, the aircraft will be forced to land. This can damage the drone if the landing area is not ideal for the drone, such as in the middle of a corn field.

The return-to-home function also poses a risk when the signal connection is lost. When a drone is on the returnto-home by itself and you cannot control it, it will fly a straight line back to home. This means the drone can run into obstacles. In such cases, it will either crash into or stall in front of the obstacle. If it stalls in front of the obstacle and connection cannot be reestablished before the battery runs out, the drone will do a forced landing and crash into the crop or whatever is on the ground, which could be an irrigation pond.

Those operating drones are developing innovative solutions to seeing over tall crops and other obstacles.

For instance, spraying fungicides on tall corn presents unique challenges to keeping lines of sight on drones. One recommendation is for the pilots to stand on double deck trailers to see above the top of corn. Operators should also use signal enhancing devices to extend signal range. (A) This photo shows the antennae on the controller. (B) This photo shows antennae on top of the drone that receives the signal from the controller.

(A) This photo shows the antennae on the controller. (B) This photo shows antennae on top of the drone that receives the signal from the controller.  This pilot placed a ladder on a flatbed trailer to improve line of sight. Safe ladder use now becomes an issue that must be addressed.

This pilot placed a ladder on a flatbed trailer to improve line of sight. Safe ladder use now becomes an issue that must be addressed.  Drone operators have found many ways to equip vehicles to operate drones in the field.

Drone operators have found many ways to equip vehicles to operate drones in the field.  Highly specialized trailers can support spray mixing, loading, battery charging, and elevated observing. In addition, they can provide adequate room for safely landing and walking around drones for inspections and repairs between flight missions.

Highly specialized trailers can support spray mixing, loading, battery charging, and elevated observing. In addition, they can provide adequate room for safely landing and walking around drones for inspections and repairs between flight missions.

A grass strip, if one is available, makes for a perfect launching and landing site.

A grass strip, if one is available, makes for a perfect launching and landing site. Taking Off and Landing From ‘Hard’ Surfaces

Spray drones produce strong downdrafts when taking off and landing. The downdrafts throw dirt, dust, and small pebbles into the air. In dusty areas, operators may need to clean drone motors, connectors, and electronics more often due to debris finding its way to the inside the drones. Dust storms during take-offs and landings frequently clog flat fan nozzles, which is yet another concern.

This makes it important that drones take off and land on grassy sites or landing areas that do not have much debris to reduce the amount of dirt and dust around the drones. Many commercial operators purchase or build trailers customized for drones where they can store the supplies, aircraft, and essentials. These trailers can also have higher decks where drones can land and allow pilots and observers to have good vantage points of the operations. Custom trailers can add significant expense to an operation, but may be necessary for efficient, legal, and safe operations.

A landing platform, such as the one shown here, can provide a solid base from which to operate a small drone.

A landing platform, such as the one shown here, can provide a solid base from which to operate a small drone.  However, application drones are much larger and require larger landing pads.

However, application drones are much larger and require larger landing pads. DRONE FACT

When drones take off and land, their downward drafts can kick up dust and other debris that may clog flat-fan nozzles and disrupt the drones’ motors and electronics.

Equipping a Trailer for Your Spray Drone

Tanks and product mixing typically will be like larger ground rig operations except on a smaller scale, since drones apply a lower volume of water in a given area. However, drone operators will need to add power generators and charging stations that ground sprayer operators do not normally need.

A Clean Water Supply

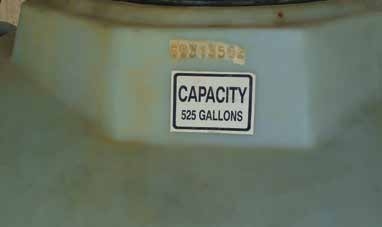

Under most circumstances, application sites do not have accessible clean water for mixing pesticides, rinsing or flushing tanks, washing off residue from drone surfaces, or cleaning hands. The amount of clean water operators bring to application sites varies by the size of the operations. Consider the number of acres you plan to apply in a day and at what volume you plan to apply to estimate the amount of water you will need.

For example, if a drone pilot plans to fly 200 acres at 2 gallons per acre, the operator will need at least 400 gallons of water, plus additional water for rinsing, cleaning, and hand washing. If the application site is near a farm, the operator can refill smaller tanks. But areas may be far away from a water source, so it is always best to bring all the water you need for that day.

It is vital that drone operators carry separate fresh water supplies with them. Not only is this for operator safety, but operators need fresh water to rinse out drones and clean equipment. Use pressure regulated pumps and garden hoses to ensure plenty of fresh water.

Think Personal Safety First

Not all spray drone operators have applied pesticides with ground equipment or even worked around pesticides. Regardless of the mixing method, make sure operators follow all safety precautions for handling and mixing pesticides. At a minimum, all operators should wear gloves, which are fundamental to personal safety. We also suggest operators wear at least one layer of clothing (long sleeves and pants). After a day’s application, be sure to wash these clothes separately from household laundry.

Mixing Operations

There are two options for mixing pesticides at the job site:

- Add the pesticide product(s) directly to the drone solution tank for mixing

- Fill the drone from a premixed solution of the pesticide product

You should avoid the first option as much as possible for several reasons. Products may be incompatible, there may be a lack of agitation during mixing, it could compromise worker safety, and increase the risk of spills. Filling drone tanks by hand also can be very inefficient.

We recommend using pre-mixed pesticide solutions in large mixing tanks. Newer mixing trailers/trucks even have enclosed mixing systems that can directly draw chemicals from original containers into mixing tanks, then pump premix from mixing tanks to drone tanks without exposing chemical handlers. Still, you should wear gloves and any other necessary personal protective equipment pesticide labels require when mixing and loading spray mixes.

This photo shows an operator filling a drone solution tank.

This photo shows an operator filling a drone solution tank.  Mixing tanks offer enclosed systems to directly transfer mixed pesticide solutions to drone tanks.

Mixing tanks offer enclosed systems to directly transfer mixed pesticide solutions to drone tanks. Incompatibility Issues

Since drone applications use carrier volumes of 2 to 3 gallons per acre, which are dramatically lower than ground applications, the pesticides mixed for drones are in highly concentrated forms. With so little water and no agitation in the spray tank, some products that work well in more dilute concentrations using 10 to 20 gallons per acre may be incompatible at the higher concentrations in drone tanks. Such mixtures can clog nozzles, spray lines, flow meters, and pumps. Mitigating clogged nozzles requires operators extra time to clean and flush the spray system.

Preventing Liquids from Gelling

To optimize tank mixes, first add 1/2 to 2/3 of the required water to the tank, then add the pesticide, and finally top the remainder of the tank with the rest of the required water.

Never mix concentrated pesticides together first. You should always add each pesticide individually to the tank with water to reduce incompatibility.

We highly recommend you conduct a jar test if you are mixing more than one pesticide into a drone. A detailed explanation of how to conduct a jar test is in Avoid Tank Mixing Errors (Purdue Extension publication PPP-122), available from Purdue Pesticide Programs (ppp.purdue.edu) or the Purdue Extension Education Store (edustore.purdue.edu).

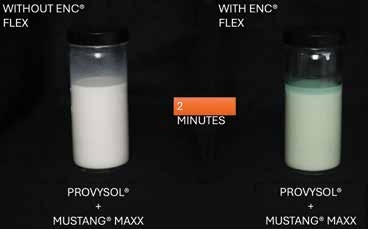

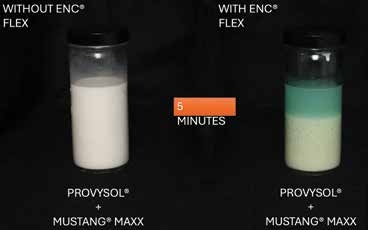

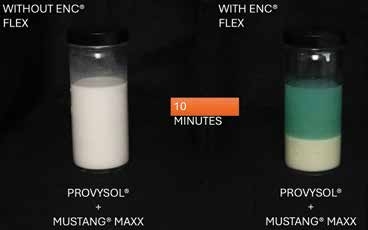

Examples showing how products can negatively interact with each other. Adding one product within a few minutes can cause the products to separate (right side).

Reaction after 2 minutes.

Reaction after 2 minutes.  Reaction after 5 minutes.

Reaction after 5 minutes.  Reaction after 10 minutes.

Reaction after 10 minutes. DRONE FACT

Because spray drone applications use dramatically lower carrier volumes than those used ground applications, pesticides on drones are highly concentrated.

Poor Mixing Due to Lack of Agitation

Most drones lack agitation systems that are common in ground application equipment. We should keep in mind that the pumps and spray configurations on drones are more similar to ATV spot-spray systems than they are to sophisticated commercial ground application systems. Agitating the spray tank on a drone requires two people on both sides of the drone to pick it up and shake the tank to mix the product.

Anything other than pesticides that easily dissolve in water will have difficulty becoming suspended due to the lack of agitation. It is important to start spraying as soon as possible to avoid chemicals settling to the bottom of the tank and clogging the flow meter, pumps, nozzles, and filters. Also, at the end of the day do not let leftover spray solution sit in the tank after the drone gets back. The best option is always to spray any remaining solution out in the field and come back empty.

Mixing Pesticides in Drone Tanks Is Inefficient

Given the relatively small solution tanks on drones, operators may need to load and mix a fresh spray solution every two to five acres. If you decide to mix pesticides in the drone tank, you will be devoting considerable time to both mixing the product and agitating the product once it is in the tank. This method also introduces more opportunities for mixing errors, which can reduce pest control or severely injure crops.

Premixing Pesticide Solutions in Large Supply Tanks

The general consensus of experienced drone operators is that operations are more efficient when they premix pesticides in larger tanks such as shuttles or minibulks. Make sure to mix only what you need. This process would be like many commercial applicators that mix “hot loads” in larger supply tanks at mixing facilities, and then transfer them to sprayers in the field.

DRONE FACT

Remember, the pump and spray configurations on drones resemble ATV spot-spray systems more than sophisticated commercial ground systems. However, most new drones are equipped with rate and droplet size control capabilities that are comparable to those found on ground rigs.

Race Car Pit Stop Mentality

Watch a pit stop when a race car driver enters for fuel and tires. In a matter of seconds, the driver is back out on the racetrack. Some drone operators have a similar philosophy: one minute on the ground and the drone needs to be back in the air.

When this drone returns to base, the operator swaps the battery, quickly fills the tank from the larger one (sitting in a utility vehicle), and sends the drone back out to spray with minimal loss of time. Many commercial operations are set up with larger-volume tanks to be more efficient when filling up drone sprayers. But the extra weight might mean operators need to upgrade trailers and trucks.

These larger tanks should be equipped with the ability to agitate mixtures and to pump chemicals directly into a drone’s spray tank. Remember, since these mixtures are highly concentrated, some form of agitation in the shuttle or minibulk may be required to ensure that operators achieve the correct dosage and compatibility from their first fill to the last.

Tip From the Field

One operator offers this tip.

“We commonly use IBC totes because they are readily available and often free. They are a challenge to properly agitate and clean out because of the flat bottom. We highly recommend using agitation and some kind of round tank with a sump for complete, thorough cleanout.”

Battery Management at the Job Site

Batteries are generally the heaviest components on empty spray drones. Battery capacity is important because it determines flight time and the effective payload. However, there is not a firm answer to the question, “How long will a battery last?”

The answer is that it all depends on the drone’s load, battery size, battery age, drone weight, field layout, route design, and local weather conditions. An empty drone may be able to fly for 15 minutes, while the same drone fully loaded may only fly six to eight minutes. This is why it is important to plan your operation strategically. For example, you do not want a fully loaded drone to fly to the other end of the field (and use up half of its battery life) before it begins dispensing product.

It is true that larger payloads allow drones to treat more acres per tank, but the extra weight from the larger spray tanks also reduces battery life. Heavier drones (such as those with larger payloads) will discharge their batteries quicker to keep them aloft and spraying. Operators must replace batteries on spray drones more often than on drones used solely for imaging and surveillance.

How fast a battery discharges can also depend on the effects the ambient air has on a drone — wind speed and direction, air density, humidity, and temperature can all affect battery life. Battery life can also be linked to the mission itself. Manual flying requires more battery power as the pilot adjusts the drone’s course, speed, and altitude. Autonomous flying can help conserve battery life and improve efficiency.

Keep Batteries Charged

It may be a good idea to replace your spray drone’s battery each time you refill the tank — even if the battery is partially charged.

You don’t want to run out of battery life before you need to refill the tank. When its battery gets low, a drone is programmed to stop the mission and go back to the staging area even if it has material in the tank.

All drone spray operations will vary by site. Missions that have many turns or short rows will use more battery power. Turning also makes the operation less efficient because the drone must slow down as it approaches the end row, then speed back up once it begins its next swath. When planning a mission, minimize turns as much as possible because they slow down the drone. Flight plans with longer rows will get longer battery life than flight plans that contain many turns.

Battery life is also significantly reduced when the drone spends time hovering and operating at slower speeds. If possible, fly in long rows without losing the signal, and then fly at higher speeds with moderate swaths. This increases the drone’s efficiency when it comes to maximizing battery life. Be careful when flying on very sunny summer days with temperatures greater than 95°F. Batteries can overheat and cause the drone to make a forced landing.

Always arrive at a job site with your full complement of charged batteries. The number of batteries you need will vary depending on the drone, battery charger, and the generator you use to power the charger. Some chargers charge batteries as quickly as drones can discharge them, while other chargers are much slower. If you have slower chargers, you will need many batteries to support continuous flight.

Most batteries have lights that indicate how much battery life remains. (A) These four lights indicate the battery is fully charged. (B) This battery has used up half of its battery charge

Depending on the type of drone you purchase, you need a minimum of three batteries or as many as 12 for continuous flying. Some batteries have a history of overheating and may require cooling stations to keep them within specified operating temperatures. Overheated batteries can cause aircraft to unexpectedly lose power in midflight, potentially resulting in crashes.

It is always good to speak with people who have experience with the specific drone you are interested in purchasing. They will have insight on how many batteries and chargers you will need to keep your drone in the air.

DRONE FACT

Before you purchase a generator, check your drone’s battery charger requirements and make certain the generator can safely maximize the battery charging process. How quickly a generator can charge batteries is important for spray drone applications.

Generators for Charging Batteries

It is never wise to purchase a generator for your drone without knowing the generator specifications or your battery charger requirements. A generator will be the workhorse behind the scenes while the drone is operating. Generators work constantly to recharge batteries while operators continually swap them in and out during the drone’s operation.

Some charging systems run on 110v supply, but you can achieve a faster charge rate if converted to a 220V and 50A system that may be custom designed. Electronic load management for the generator is always a nice feature. This feature can minimize fuel consumption and noise during periods of reduced generator demand.

Before you purchase a generator, check the requirements for your charger. You want to be sure any generator can maximize the efficiency of your charger. Additionally, you might consider how loud the generator might be — there are low-noise options if the pilot and visual observer will be near the generator all day long.

Generators may differ in the number of outlets they have and in their output ratings for the circuit. Sometimes the generators require special wiring to achieve what you need. To provide faster charging for current spray drone batteries, operators require a 240v 50 AMP plug. This means generator output needs to be greater than 9500v when running. Remember, generators may also be running agitation pumps, cooling fans, or other electronic needs at an application site so make sure your generator is properly sized and has the number of outlets you will need.

Generators are necessary for operations that include multiple batteries that require charging. Do not charge batteries under full sunlight because they can overheat very quickly. In addition, do not place generators inside sealed trailers because the exhaust is a health hazard and oxygen depletion will eventually compromise a generator’s engine combustion. Remember that generators that are too small or that do not have well-regulated voltage output can damage drone battery chargers.

Tip From the Field

Some advice from a drone operator.

“Most air-cooled, gas-powered generators are not designed to operate at maximum capacity 12 hours per day in 80° to 90° heat in July.

“Many operators rely on these small engines and get by in the short term, but in the long term, a better option might be a liquid cooled generator. We utilize commercial grade, liquid-cooled diesel generators that are enclosed in noise deadening housings. These will provide service for years to come, and ensure we deliver proper voltage to our chargers because we are only operating between 50 and 70 percent of generator capacity.

“We do not require our operators to wear hearing protection because of a screaming small engine all day. The drawback of our commercial units are cost, size, and weight; although we feel in the long run that cost will be comparable to constantly replacing consumer-grade generators.”

Cargo-Carrying Trailers Are Popular Additions

As an alternative to trucks, operators often use open and enclosed-type trailers to carry drones and other items they need for spraying, mixing chemicals, and charging batteries. These trailers are comparable to farmers outfitting trailers with minibulks, tanks, water, pesticides, adjuvants, pumps, and metering systems to keep their operations functioning.

Enclosed trailers offer additional advantages. They can protect equipment and supplies against dust and poor weather conditions, and they can deter theft because people cannot see what is inside. For additional information about equipment theft, see Protect Your Trailers and Contents from Theft (Purdue extension publication PPP-134), available from the Education Store (edustore.purdue.edu) or Purdue Pesticide Programs (ppp.purdue.edu).

Operators can place generators in enclosed trailers if the trailers are ventilated to the outside. Be aware that carbon dioxide can build up in trailers and can choke out combustion for the generators. Keeping generators in ventilated trailers can keep operators from having to load and unload some supplies at every job site.

An advantage of enclosed trailers is that operators can park them overnight by simply disconnecting them from their trucks. Getting to the field is as simple as hooking up the trailers and getting to the first job that day, or simply keeping trailers constantly connected during the busiest times of the year.

One major benefit of enclosed trailers is that you can outfit the tops with landing surfaces or observation decks that provide a higher elevation to maintain line-of-sight with the drone during flight.

Other options for transporting necessary equipment to the field for drone applications exist. Light- to mediumduty trucks with flatbeds may already be available and you can convert them to spray service on a seasonal basis. This same style of trucks may have an enclosed bed known as a box truck. Some examples on farms would be “retired” moving trucks, such as U-Haul vehicles or retired food service trucks used to supply commercial passenger aircraft. Box trucks can provide a secure storage area for equipment and supplies, plus allow for a possible landing and observation deck on top of the box.

Tips from the Field

Here is some insight from a drone operator.

“Open versus enclosed trailers come with trade-offs.

“We prefer open trailers, because that way, we always have a landing zone on the back of our trailer. When moving from field to field, the drone lands in its transportation spot and we do not have to carry the contaminated drone into our enclosed trailer. Furthermore, by landing on our open trailer we reduce the amount of dust and debris that is kicked up into the air on takeoff and landing. Finally, we land the drone on the same level that our operators stand, so there is no up and down ladder or stairs for our operators to climb to refill the drone and swap batteries.

“We can park inside overnight and thus, theft protection is not a concern for us. Also, many enclosed trailers are not built heavy-duty enough to carry the weight required for all the water and spray solution we need to operate all day.”

Tips from the Field

Here is some insight from a drone operator. “Many times, trailers need some special modifications to securely hold down all this equipment for transport.

“It is important to carefully consider equipment placement and adding the necessary secure points to make sure the equipment stays in working order and does not get jostled. This is especially important when traveling on rough terrain to reach a site/recharge point.”

On-Site Parts and Repairs

Just like other mechanical devices, drone parts break down and need to be replaced. Keeping spare parts on-hand can reduce downtime and get you up and running within a day or sometimes within several hours. The main supporting frames of most drones are constructed of carbon fiber, a material that is light but durable. However, drones are also constructed of plastic materials to reduce their weight, so it is easy to see how external parts can degrade by sunlight.

Common operational factors can also cause wear-andtear on drones. Rotors get chipped and broken when they hit obstacles or make rough landings. Motors can fail if dirt and debris infiltrate the internal parts.

Having spare parts on-hand can save a lot of time, considering it might take days to get your shipment anywhere from within the United States. Your spare parts inventory could include nozzles, inline valves, pumps, flow meters, batteries, electronic speed controllers, motors, and a set of rotor blades.

How many of these parts you carry in your inventory will depend on how quickly you can access parts from dealers or manufacturers. If you have a reliable dealer who can ship parts quickly, you may not have to keep as many items in stock.

Quick access to spare parts could mean a job only comes to a standstill for a few minutes rather than days. Some argue that keeping replacement parts in inventory is a lot of money just sitting there. While that is true, ask the question: “How much money are you losing while the drone is inoperable?” A $10-part can cost you hundreds, if not thousands, of dollars in down time. It can also upset customers while they wait for their fields to be treated.

Down time is money lost for you and potential crop losses for the farmers you serve. Furthermore, replacing drone components can be relatively simple. Circuit boards and motors are often connected with a few screws and a plug that you can switch quickly. While some diagnostics are too difficult for the average person to do, some dealers can help diagnose an issue over the phone or with a simple video call. As drones become more popular, increased customer and technical support will become available, too.

DRONE FACT

Keep basic spray drone parts (such as rotors and nozzles) on-hand to save time and money. It could take days to ship replacement parts.

Personal Safety Like Any Other Application

Apply the best management practices for handling and mixing pesticides with a drone that you normally follow for any other application method. First, operators must wear whatever pesticide product labels list as the minimum personal protective equipment (PPE).

What makes drone applications different is the higher pesticide concentration of the product solution compared with application methods that use higher carrier volumes and more dilute solutions. While both methods apply the same amount of pesticide active ingredient per acre, the pesticide solution in the tank can be more concentrated at the extremely lower carrier volumes that drones use.

A Difference in Concentration

Keep in mind that drone tank mixtures are low-volume applications rather than what you may be accustomed to dealing with in other equipment. With ground rigs, some pesticides are often diluted in 10 to 20 gallons of water per acre.

However, drones may be applying the same pesticide rate per acre in 2 gallons of water. You are mixing, applying, and handling a more concentrated spray solution. That requires you to follow additional safety precautions when spraying with drones. At a minimum, you need to follow all label-recommended PPE.

Make sure that no one is working or playing in application areas. It goes without saying that you should not operate drones when people are fishing on a pond, highway workers are repairing the shoulder of a road, workers are weeding in a tomato field, or students are detasseling corn.

An issue you need to address early is the wind direction relative to the staging area. If you would be uncomfortable spraying with a ground rig because of the potential for spray drift, then there is no reason to apply pesticides with a spray drone. Always follow label directions regarding wind speeds and/or specific state requirements.

While the tops of hills provide good lines of sight as required by the FAA, pilots and visual observers should be aware they could be positioned downwind of applications. Even if they are not positioned downwind of spray passes, droplets may still drift toward staging areas during the first couple passes made. You can always relocate yourself and crew temporarily until you complete those passes to avoid exposure to spray drift.

This photo perspective shows a good example of maintaining a line-of-sight even when spraying over a tall crop like corn.

This photo perspective shows a good example of maintaining a line-of-sight even when spraying over a tall crop like corn.  It is important to wear chemical-resistant gloves when handling spray drones because the aircraft exterior will have pesticide residues.

It is important to wear chemical-resistant gloves when handling spray drones because the aircraft exterior will have pesticide residues.