Secure Your Hay Load Before You Hit the Road

RESOURCES - PUBLICATIONS

Secure Your Hay Load Before You Hit the Road

Authors

Fred Whitford, Director, Purdue Pesticide Programs

Elysia Rodgers, DeKalb County Extension Educator, Purdue University

Keith Johnson, Forage Specialist and Professor Emeritus, Purdue University

C. K. Wilkins, Indiana Farmer

Mike Templeton, President, Surface Transportation Consultant

Brad Kohlhagen, Adams County Extension Educator, Purdue University

David Osborne, Ripley County Extension Educator, Purdue University

Kevin Leigh Smith, Senior Lecturer and Communication Specialist,

Purdue Agricultural Sciences Education and Communication

Contents

- The Concept of Loose and Soft Loads

- Shapes and Weights of Hay and Straw Bales

- Minimize Movement During Transportation

- Put Load Securement Regulations to Work

- Display the Slow-Moving Vehicle Emblem

- Allow Traffic to Flow

- Prevent ‘Leaky’ Loads of Loose Chaff

- Pull No More Than Two Wagons

- Conduct a Stop and Check Road Inspection

- Remember the Hitch Pin and Safety Chain

- Tires are the Underbelly of Trailers

- Don’t Gamble with the Law: Secure Your Hay and Straw

- Acknowledgements

- Disclaimer

Introduction

Hay and straw bales scattered across a field in front of a large red barn with horses grazing in a nearby pasture are iconic photographs that capture the essence of rural living — a way of life. However, those same hay and straw bales are no different than a field of corn, soybeans, or tomatoes — they are products used on the farm and sold to produce income for the farm. Hay becomes highly valuable when drought, floods, and other environmental emergencies require producers to transport forage to keep livestock in good health. Producers will feed each cutting of hay directly to livestock during times of limited growing conditions.

One important market for forage products is selling hay to those who raise beef and dairy cattle, horses, goats, and sheep but lack sufficient land to produce their own hay. Producers may grow hay close to the barn on land they own or lease or many miles away from a farm. Not only does work get done more efficiently when the hay is grown closer to the barn, it also creates an ideal situation in which hay can be moved from the field to the barn via farm lanes. This leaves no chance for interaction with public traffic. Transporting hay on public roads changes the whole dynamic of forage production.

Hay protected from rain maintains its quality for an extended period, making it a valuable commodity. Whether used for a dairy, feed lot, or single horse, hay provides the nourishment to keep animals healthy and productive.

When grazing is not an easy option, quality hay that meets nutritional needs is important for feeding livestock through the winter

For many, using slow-moving farm wagons on roads is inefficient if they have to move hay more than a few miles. Farmers with significant hay acreage who use public roads often invest in semi-tractor-trailers equipped with lights, brakes, heavy duty suspensions, larger tires, and turn signals. To cut down on the backand-forth travel from field to barn or customer, the trailers are designed to haul 350 to 500 (or more) small square bales. While it is more efficient, these semi tractor-trailers increase the costs of operation beyond just equipment cost. Additional costs include fuel, insurance, labor, repairs, and special equipment to load and unload.

Regardless of what producers use, one important consideration of moving equipment on county and state roads is to reduce the potential for traffic accidents. Most farmers agree that many drivers on the roads are less accustomed to operating around slow-moving equipment such as farm wagons. Drivers traveling at high speeds may suddenly find themselves behind slowmoving hay wagons. When left with few options, drivers may take last-second evasive maneuvers, such as weaving around equipment, or into oncoming traffic, ditches, mailboxes, trees, driveways, and utility poles. Defensive driving is no longer an option.

Consider all the highway advertising signs where lawyers say, “Call us if you are involved in a truck accident.” There are enough truck accidents to keep injury lawyers fully employed. You could be the most conscientious driver in the world, but any time you spend on the road means more opportunities for accidents to occur regardless of who is at fault.

Think about all the near misses and potential liability you would be exposed to if the hay you are hauling falls onto the public road. It’s serious. That’s why this publication will focus on transporting and securing loads of hay when you haul them on public roads. We will explore how to calculate the number of straps and the strap strengths you will need to safely secure each load based on current state and federal regulations. Our goal is to reinforce the idea that loads of hay transported on highways, when properly secured, can avoid civil fines, prevent accidents, and provide a better defense against lawsuits — not to mention the lost income from damaged loads of hay.

The Concept of Loose and Soft Loads

Hay is considered a “loose” and “soft” load. What we mean by that is that a load of hay is made up of individual bales pushed against each other from side-to-side and front-to-back. Securing these loads can be further complicated when hay bales are stacked on top of one another in layers. Taking evasive action, such as slamming on the brakes when someone cuts in front of you, can force the load to shift forward and backward. On the other hand, turning too quickly can force a load of round bales to roll backward and shift side-to-side.

SOMETHING TO PONDER

“When I am hauling hay and I lose part of a load, it’s a liability I would rather not assume. I don’t want a bale coming off and hitting someone’s windshield or making them swerve. I want the hay to stay on the truck. We must make the effort and never assume that we can make it safely without strapping down a load.” — Comments from a farmer

Transporting hay and straw on public roads raises issues of personal and business liabilities. You can reduce liability by properly securing loose loads to the decks of trailers and off highways. Hay bales on highways can lead to serious injuries and significant property damage when improperly secured. While there are legitimate load securement questions raised when law enforcement personnel stop a vehicle, the tickets and fines they might issue are minor compared to being brought into a courtroom for an accident caused from hay bales falling off your truck or trailer.

Unfortunately, when hay or straw falls on a highway, it may contribute to traffic accidents as drivers try to avoid the bale by swerving to the side only to collide with others passing them in either direction. In other cases, the first vehicle might miss the bale at the last second, but the vehicle immediately behind it may not have time to respond before striking the bale and losing control.

Shapes and Weights of Hay and Straw Bales

Bale sizes include small, medium, and large square bales; round bales; and large round and square bales wrapped in plastic as baleage. Small square bales can weigh between 45 to 70 pounds, while large square bales can be 800 to 1,500 pounds. With these heavier weights, producers use farm machinery like telehandlers, skid loaders, and tractors to pick up the bales and place them on trailers. One advantage of transporting larger bales is that they do not tip over as easily as smaller bales.

Round bales are cheaper to produce for many farmers because their farm machinery can create hay of different sizes depending on need and what they are feeding the livestock. Producers can also produce bales with soft or hard cores. Round bales are the most common type of hay produced in the eastern half of the country.

In the last 25 years, wrapped bales (in long tubes or individually), better known as baleage, have become more common. Producers cut the hay, bale it when moisture levels are between 45 and 55 percent, and then wrap the bales with several layers of plastic. The hay ferments inside the plastic for several weeks and becomes silage that is then fed to livestock.

Weights of Bales

To better understand how to safely secure hay and straw to trailers, you need to know the specific weight of what you are hauling. Knowing the size of each bale and the differences in weight between hay and straw are key.

|

Approximate Weights of Common Hay and Straw Bales

|

||

|

Type

|

Size (L x W x H)

|

Weight (Pounds)

|

| HAY | ||

| Small square | 14 x 18 x 35 inches | 45-70 |

| Medium square | 16 x 22 x 44 inches | 100-140 |

| Large square | 8 x 3 x 3 feet | 800-1,000 |

| 8 x 4 x 8 feet | up to 1,500 | |

| Round | 4 x 4 or 4 x 5 feet | 750-1,500 |

| 5 x 5, 5 x 6 feet | 1,000-1,500 | |

| Baleage | 4 x 5 feet | 1,000-1,400 |

| STRAW | ||

| Small square | 14 x 18 x 35 inches | 40-50 |

| Large square | 3 x 4 x 8 feet | 600-750 |

| 4 x 4 x 8 feet | 750-1,000 | |

| Round | 4 x 4, 4 x 5, 5 x 5, or 5 x 6 feet | 800-1,200 |

Minimize Movement During Transportation

Can you imagine following a truck when a bale falls off a trailer? Your split-second decision is to immediately swerve if you have time. If you do not have time, the bale can damage your vehicle. These unwanted interactions can damage vehicles and injure people, leading to serious legal consequences that may take years to resolve through the courts.

It is important to understand and appreciate weak links in hay and straw transportation. Sometimes, you can see that the hay is not loaded, stacked, or secured as it should be. Some loads simply do not pass the eye test. Before we discuss specific tiedown recommendations, it is important to note how bales can move when transported on trucks and trailers.

WHAT COULD HAVE HAPPENED WITH A DIFFERENT BOUNCE?

“I saw a large round bale roll off a trailer that was heading toward me about a month ago. “It was two hundred yards or so away and heading toward me. I saw the truck shimmy a little. That hint caused me to slow down. That saved me.

“The bale rolled off the top of the load and narrowly missed the front left side of my van. The bale rolled into the ditch and crashed through a fence. I was lucky to have seen the truck bounce just a little. “I was pretty shaken up and had to pull over to settle down. The sad part is the truck driver continued on.” — Comments from a farmer

BALES BAREY HANGING ON

What are people thinking when they load hay in this manner? Round bales want to roll backward. One quick turn around a corner, and these bales can easily slide off onto the roadway.

ALMOST IS NOT GOOD ENOUGH

A single back strap should be at a 45-degree angle to pull it toward the truck. The back bale on the left could easily roll off because these two straps are placed too high to manage the two bales. Dropping the lower strap just a little on the back would make a big difference in securing the back bales from rolling backward. Running two straps fully from front to back could also help better secure the load to the trailer

First Objective: Minimize Forward and Backward Movement

Whether you are transporting round or square bales, load shifting is always a possibility. Of special concern are trailers that lack headboards or rear ramps that provide physical structures that keep loads from moving in either direction.

Keeping round bales on the second level from rolling off the truck when moving can also be a challenge, especially when a driver suddenly stops, turns abruptly, or accelerates quickly. Unsecured loads can potentially roll forward into the truck or backward off the trailer.

Straps are really the only way to tie down loads when trailers do not have physical barriers in the front or back. The operator of this vehicle secured the bottom row of round bales from moving forward or backward by using straps. Placing the back strap down a few more degrees to have it fully secured would slightly improve matters. The strap in this photo appears to be a little too far toward the top of the bale to be well secured. However, the top row is unsecured. The weight of each of the top bales that fit in between the bottom bales is not considered secure according to current regulations.

This gooseneck trailer is transporting a load of large square bales that has been strapped to keep the load from moving forward.

This gooseneck trailer is transporting a load of large square bales that has been strapped to keep the load from moving forward.  Operators often stack hay bales centered on top between two bales on the bottom. It is true that the weight of the top layers will help secure the bottom layer to the trailer bed. However, that placement does not secure the top layers. The top layer will tend to tip on an uneven road. The operator tied off the front and back bales on the bottom layer but also placed a strap over the top of the three bales riding on top to ensure it stays on. This setup should only be used when hauling hay from the field to the barn on the roadway.

Operators often stack hay bales centered on top between two bales on the bottom. It is true that the weight of the top layers will help secure the bottom layer to the trailer bed. However, that placement does not secure the top layers. The top layer will tend to tip on an uneven road. The operator tied off the front and back bales on the bottom layer but also placed a strap over the top of the three bales riding on top to ensure it stays on. This setup should only be used when hauling hay from the field to the barn on the roadway. Second Objective: Prevent Bales from Moving Side-to-Side

You should also consider side-to-side movement when securing a load. Straps along the length of the trailer will help keep hay from falling off the sides. We will cover how many straps you will need and the strength of those securement straps later in this publication.

Third Objective: Center and Tighten Bales on the Trailer

Always center round and square bales on the trailer and pack them tightly. This is crucial to ensure the hay is firmly packed together during transport. Bales that are centered and closely packed provide better support for the straps that secure the load.

Fourth Objective: Stack Pattern Square Bales to Lock Them Together

Depending on the type of bale, there might be as many as six layers stacked one on top of the other. It is a common practice to cross the layers with the long layer followed by a short layer. Crisscrossing in this manner helps to square up the pattern and create a tighter and more stable load.

You can see the difference in the tightness of these loads between. Image A shows bales that have been manually stacked on the wagon in an alternating pattern that helps tie the bales together better to reduce the chance of shifting and tipping. Image B shows an accumulator that makes moving small square bales easier on farmers, but we can see that the bales are not packed as tightly and could easily shift on the wagon when stacked in the same direction.

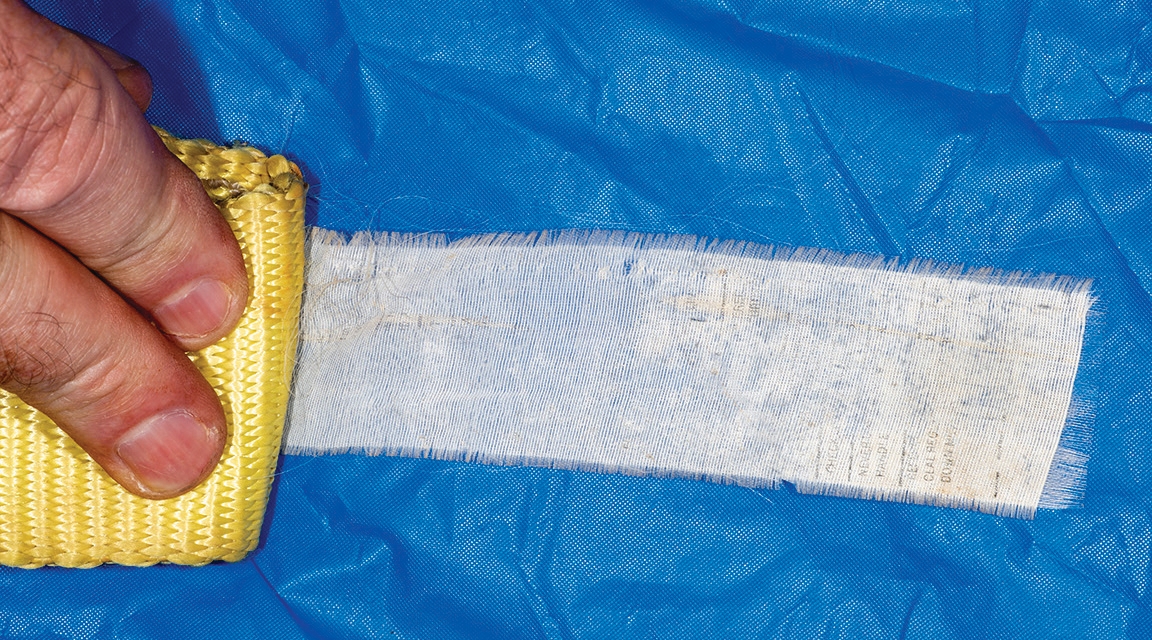

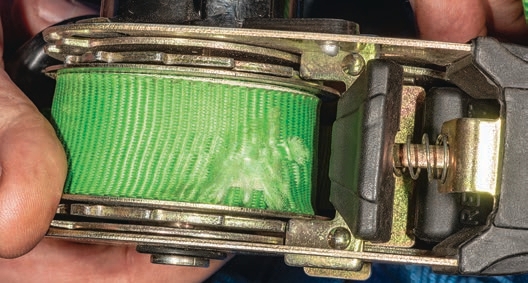

Fifth Objective: Use Quality Straps to Secure Bales

Using cut and damaged straps defeats all the work you took to create a tight load on the trailer. The straps you see in the following two photos are close to failing. If an accident occurred while using defective straps like these, the operator would be cited for clear evidence of negligence. Straps are a cheap investment compared to the potential expenses of a court case or product loss.

Sixth Objective: Pass the Eye Test

The last consideration is to look at your load and see if it passes the eye test. If it does not, the only option you have is to add more straps to better secure the bales. This leads us into the next section about state and federal load securement regulations.

NO STRAPS ON HAY COULD RUIN YOUR DAY

There are differing opinions on whether round bale hauling trailers require straps.

Many salespeople (and others) assume bales on round bale hauling trailers do not need straps because of the trailer’s cradle design. While the hay or straw sits well in the cradle, there is nothing to keep it from rolling off the sides during a sharp turn. Some argue that if they are transporting less than a mile, then strapping the load is a waste of time.

That is, unless you are the one the bale hits when it rolls off. You are liable whether you are going a short or long distance. Federal and state regulations require operators to secure these loads like any other load of bales.

Put Load Securement Regulations to Work

Those hauling hay on public roads are held to a higher standard of care. Routine roadside inspections by law enforcement are random spot-checks to ensure loads are properly secured based on transportation regulations. Those regulations cover working load limits, the number of straps, and the condition of those straps.

Investigations at accident scenes begin when falling hay leads to severe injuries that require hospitalization or result in the death of drivers or passengers. Law enforcement can move the vehicle and hay load to a limited access facility where they can closely examine the operator’s securement techniques.

In some cases, lawyers hire private investigators to recreate accidents or hire expert witnesses to testify on what they believe caused an accident. Expert witnesses provide a second opinion to the findings in law enforcement reports.

SOMETHING TO PONDER

“You are responsible for securing your load anytime you use a road.

“I responded to a car accident because a farmer neglected to secure his large square bales on his trailer, and one of them fell off the trailer and onto the hood of a pickup truck going in the opposite direction.

“The pickup truck proceeded to veer off the road into a field and up a ditch of a road that intersected the one he was originally on. He was going so fast through the field that when he went up the ditch, the truck went airborne and flew over the road and smashed the truck like a soda can when it landed on the other side of the road.

“He was airlifted to the hospital where he later passed away. No matter what, you are always responsible for securing your load. If you work for someone and they tell you to not worry about it, it's only just down the street, they aren't liable if anything happens, you are.”

— Source: Reddit post by user KemikalBond (www.reddit.com/r/farming/comments/ 183huom/i_have_a_question_to_all_ farmers_do_you_secure/)

Hay falling onto the roadway focuses everyone’s attention on whether the load was properly secured. What does “properly secured” mean? The answer is found in the Federal Department of Transportation (DOT) load securement regulations in 49 CFR Part 393.100-114. Our discussion of these load securement regulations will focus on straps because they are the most common tie-down used for securing hay on trailers.

Load securement regulations basically cover four distinct steps:

- Determining the number of straps required to be spread across the load

- Calculating the strength needed across the straps

- Providing a protective device or substitute strap to prevent the cargo from moving forward

- Verifying the integrity of the straps used for securing hay to a trailer

4 QUESTIONS FOR SECURING LOADS FOR THE ROAD

Answering these questions are essential for understanding Indiana regulations regarding straps and securements

1 QUANTITY: What is the minimum number of straps required to secure the hay to a trailer?

2 LOAD: What should be the straps' working load limit (WLL)?

3 PROTECTION: Is there a protective device that prevents forward movement of cargo?

4 CONDITION: Are securement devices in good operating condition?

Question 1: What Is the Minimum Number of Straps Required to Secure Hay to a Trailer?

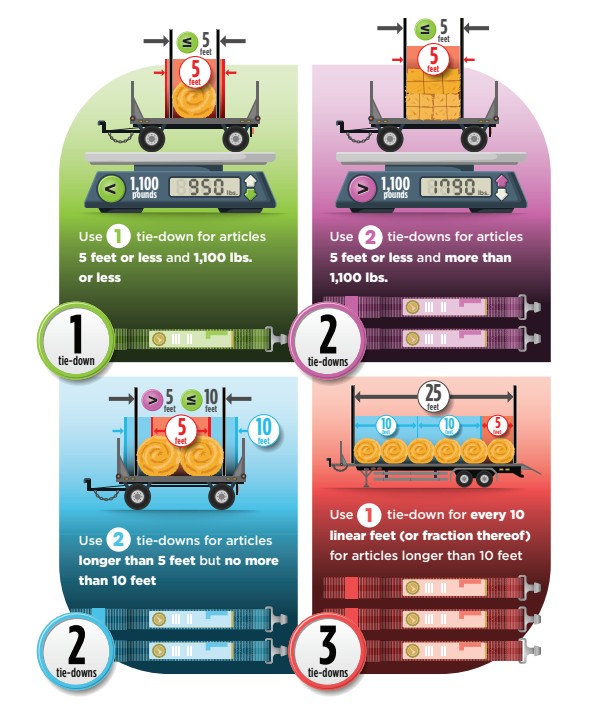

The number of straps required to secure hay to a trailer is based on the weight of the cargo and the length of the cargo on the trailer. This list explains the minimum number of tie downs required to properly secure hay.

• Use 1 tie-down for articles (such as hay) that are 5 feet or less and 1,100 pounds or less

• Use 2 tie-downs for articles that are 5 feet or less and more than 1,100 pounds

• Use 2 tie-downs for articles that are longer than 5 feet but no more than 10 feet

• Use 1 tie-down for every 10 linear feet (or fraction thereof) for articles longer than 10 feet. Assume that a trailer full of stacked hay is 25 feet long. This would require 3 straps — 1 for every 10 feet and 1 for the leftover 5 feet.

MINIMUM NUMBER OF TIE-DOWNS

Know these rules to determine the numbers of tiedowns you need based on the length and weight of the load.

Question 2: What Should Be the Straps’ Working Load Limit?

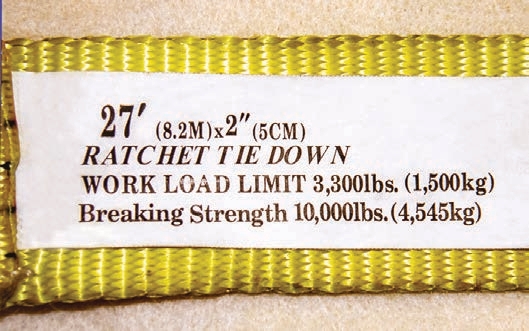

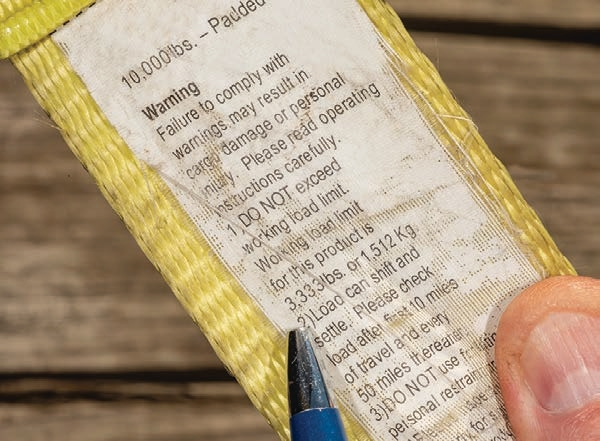

Each strap has multiple parts (including the hook, ratchet, binder, and webbing) all working together as a single unit. Straps for securing hay are commonly in widths of either 2, 3, or 4 inches. Strap manufacturers place an entire strap unit in a “stretcher” to test its strength to the point where the strap and/or its components begin to fail. The breaking point of the strap assembly varies according to the components used in its manufacture.

Every strap has a number — called the working load limit (WLL) — which is a mathematically derived value certified by the manufacturer. The WLL is one-third of the assembly break strength (ABS). This provides a safety margin to account for unexpected load stresses (such as shifting loads) and to account for normal wear and tear on the strap. Manufacturers often sew tags with the ABS and WLL to one end of their straps. A manufacturer can also stencil the WLL onto a strap at various points along its length. If such a tag is illegible or missing on a strap, the DOT sets the maximum WLL for an unmarked strap at 1,000 pounds per inch of width.

You also need to know the weight of your load. Securement regulations require that the collective WLL for all straps must be equal to half or more of the weight of the hay. The reason the WLL is half of the hay weight is that the straps are used to hold the load onto the deck and they are not required to lift objects — those come with a different set of federal regulations.

Let’s use an example to explain how to calculate WLL. In this example, we will use a 30,000-pound load of hay on a 48-foot trailer. Cumulatively, the straps you use must have a WLL of 15,000 pounds or more You must use five straps for this load (one for every 10 feet plus one for the leftover 8 feet) Assume the straps are two inches wide and the tags indicate the WLL of each is 3,300 pounds. Five straps with a WLL of 3,300 pounds each, when combined, would equal a WLL of 16,500 pounds (3,300 x 5 straps). This would adequately cover the 15,000 WLL required to meet the one-half of the load threshold set by the DOT.

| Working Load Limits for Unmarked Straps | |

| Unmarked Web Width (inches) | WLL (pounds) |

| 1 | 1000 |

| 2 | 2000 |

| 3 | 3000 |

| 4 | 4000 |

This photo shows a manufacturer’s tag attached to a strap. The tag clearly shows the relationship of the Working Load Limit (WLL) and assembly break strength. It also shows within a manufacturer’s product line, the wider the strap, the more force it can withstand before failing. Wider straps also mean higher WLL’s. These values vary among manufacturers depending on the materials that make up the strap.

This photo shows a manufacturer’s tag attached to a strap. The tag clearly shows the relationship of the Working Load Limit (WLL) and assembly break strength. It also shows within a manufacturer’s product line, the wider the strap, the more force it can withstand before failing. Wider straps also mean higher WLL’s. These values vary among manufacturers depending on the materials that make up the strap. Question 3: Is There a Protective Device that Prevents Forward Movement of Cargo?

One concern of transport is that a load can shift forward, smash the cab, and severely injure the driver. Some trucks and trailers have protective structures at the heads of the trailers that are strong enough to prevent the forward movement of hay into the cab in case of an accident or drastic deceleration. If your equipment does not have a protective device (such as a headboard), federal regulations require an additional strap be placed on the front end of the load.

This extra strap is often referred to as the penalty strap. The issue with hay is that many gooseneck trailers and wagons come equipped with a front railing, but operators load hay higher than that protective device. A sudden stop can mean the top unsecured layers can move forward and crash into the back or top of the cab. This is why an extra strap is required to prevent the load from shifting forward.

(A, B, and C) These photos show protective structures at the front ends of trailers. (D) While this trailer has a protective device, stacking hay above it will not prevent the top layer from moving forward.

Unfortunately, hay can fall off the backs of trailers just as easily as the fronts. The main difference is that a vehicle’s acceleration (backward movement of the load) is much less than the vehicle’s deceleration (forward movement of the load). Regulations only address the forward movement of a load; however, we recommend placing an additional strap around the rear bales when a trailer does not have a gate or ramp. No matter what the regulations say, operators are still responsible for securing their loads.

A HEADACHE RACK EXTENSION CAN STOP LARGER LOADS FROM MOVING

A headache rack extension is a front-end barrier that is adapted to move up or down depending on how high the hay is stacked.

Question 4: Are Securement Devices in Good Operating Condition?

Straps can abrade and tear during normal use, which means you will need to replace them at some point. It goes without saying that a strap’s assigned WLL only applies when the strap is in good working condition. A strap with worn or damaged webbing or attachments means the WLL is no longer valid. The question then becomes: How much damage is too much? This table explains DOT regulations for taking a strap out of service.

Straps are not expected to be perfect when they are repeatedly used. However, once a strap has exceeded the damage criteria, then the strap is considered defective and no longer counted as a legitimate strap.

In terms of regulatory enforcement, when a strap is defective, that means two things:

- The defective strap no longer counts toward the total number of straps a load requires

- The defective strap no longer counts toward the cumulative WLL a load requires

If an operator uses a defective strap, it means the load may not have enough WLL or number of straps. If pulled over by law enforcement, the truck could be put out of service. It is considered a good practice to carry extra straps in case you must replace a defective strap at a roadside inspection, or you notice a defective strap as it falls apart on your trip. By having an extra strap to replace a defective one, you can add its WLL back and continue without having the load placed in an out-of-service category. You may still get a ticket for not complying with the load securement regulations, but you can continue to get the hay delivered to its destination.

| Damage Criteria* | |

| Original Width of Strap (inches) |

Take Out of Service When Torn or Worn Areas Are (inches) |

| 1 3/4 | > 3/8 |

| 2 | > 3/8 |

| 3 | > 5/8 |

| 4 | > 3/4 |

DAMAGE IS CUMULATIVE ACROSS THE SURFACE OF THE WEBBING THROUGHOUT THE TENSIONED AREA

* The amount of tear and worn areas

DOES THIS LOAD COMPLY WITH LOAD SECUREMENT REGULATIONS?

Enforcement Question 1: Do you have the required number of straps?

Enforcement Question 2: Do you have one-half of the load being carried in the WLL?

Enforcement Question 3: Do you need an extra strap to prevent the cargo from moving forward or backward?

Enforcement Question 4: Are straps within the legal limits of wear and tear?

Treating Bales as a Single Load

What Would Be Required for This Load of Hay?

Single Load or Individual Load: Single load based on the hay being pushed tightly together.

Length of Trailer: 48 feet

Number of Straps Required: 5 Weight of Hay: 30,000 pounds

Minimum WLL Required: 15,000 pounds

WLL For Strap: 3-inch straps rated at a WLL of 5,000 pounds

Cumulative Working Load Limit: 5,000 x 5 = 25,000 pounds

Protective Device to Prevent Forward Movement: This trailer has a headache rack in the front to hold the lower tier of round bales. The operator will need one additional strap to hold the front bale from moving forward. The operator could run a strap from front to back over the top layer to keep them from moving forward. Another option is to place one strap on the front bale and one on the rear one and three in the middle between the front and the rear.

What Would Be Required for This Load of Hay?

Length of Trailer: 25 feet, plus an 8-foot upper deck equals 33 linear feet

Number of Straps Required: 4

Weight of Hay: 9,750 pounds

Minimum WLL Required: 4,875 pounds

WLL For Straps: 2-inch straps rated at a WLL of 3,300 pounds

Cumulative WLL: 3,300 x 4 =13,200 pounds

Protective Device to Prevent Forward Movement: The deck has a rail that keeps the lower tiers of rectangular bales in place, but the top two levels are not contained by that railing. Along with the four straps, the operator must use an additional strap up front to tie down the leading edge of the hay on the extended deck.

What Would Be Required for This Load of Hay?

Length of Trailer: 25 feet

Number of Straps Required: 3

Weight of Hay: 7,700 pounds

Minimum WLL Required: 3,850 pounds

WLL For Straps: 2-inch straps rated at a WLL of 3,300 pounds

Cumulative WLL: 3,300 x 3 = 9,900 pounds

Protective Device to Prevent Forward Movement: The top layer is not secured from moving forward. The operator must add an additional strap — not for securement, but to keep it from rolling forward. Another option would be to place a strap over each of the three top bales. These three straps would hold the load on the trailer as well as keep the top layer from moving forward.

What Would Be Required for This Load of Hay?

Length of Trailer: 11-foot truck bed with a headache rack

Number of Straps Required: 2

Weight of Hay: 5,040 pounds

Minimum WLL Required: 2,520 pounds

WLL For Straps: 2-inch straps rated at a WLL of 3,300 pounds

Cumulative WLL: 3,300 x 2 = 6,600 pounds

Protective Device to Prevent Forward Movement: The headache rack (as seen on page 24) provides this protection, so no additional strap is required. In this case, the operator has built an extended headache rack that can be adjusted to meet the height of the hay load.

What Would Be Required for This Load of Hay?

Length of Trailer: 18 feet

Number of Straps Required: 2

Weight of Hay: 3,300 pounds

Minimum WLL: 1,650

WLL For Straps: 4-inch straps rated at a WLL of 5,000 pounds

Cumulative WLL: 5,000 x 2 = 10,000 pounds

Protective Device to Prevent Forward Movement: None present, so an additional strap is needed. This is a very complicated situation given that the operator is moving less than 50 small square bales on a short trailer. The strap over the top is secured to the front of trailer that protects against forward movement. The strap encircling the sides of the hay provides no benefit of holding the bales onto the deck. This load would require two straps to hold the hay to the deck.

What Would Be Required for This Load of Hay?

Length of Trailer: 25 feet

Number of Straps Required: 3

Weight of Hay: 16,170 pounds (14 bundles of 21 bales at 55 pounds per bale)

Minimum WLL: 8,085

WLL For Straps: 4-inch straps rated at a WLL of 5,000 pounds

Cumulative WLL: 5,000 x 3 = 15,000 pounds

Protective Device to Prevent Forward Movement: None is present, so an additional strap is needed. While there are plenty of straps on this load to keep it secured to the deck of the trailer, another strap around the back of the load to keep bundles from falling off the back of the trailer is recommended. An excellent job of securing each level of the large 21-bale bundles.

Treating Each Bale Separately

What Would Be Required for This Load of Hay?

Approximate Weight of Each Bale: 750 pounds

Number of Straps Required: 1 strap (each bale is less than 5 feet and weighs less than 1,100 pounds)

Minimum WLL: 750 pounds

WLL For Strap: 2-inch strap rated at a WLL of 3,300 pounds

Cumulative WLL: 3,300 x 1 = 3,300 pounds

Protective Device to Prevent Forward Movement: Yes, no additional 2-inch strap required. There is nothing really holding each row of two round bales together so treat each bale across the deck as a separate load. If each bale weighs 750 pounds, then two bales would weigh 1,500 pounds. Each row would require two straps (length between 5 and 10 feet) with a combined WLL of 750 pounds (half of total). These large straps have enough working load limit, but the violation would be that the load was short of straps.

This operator is treating each stack as a separate load. He appears to be using 4-inch straps on each row running the width of the trailer. This load would pass a DOT inspection with ease.

Alternative Load Securement Method for Hay

The Federal Motor Carrier Administration has granted an exemption from the securement regulations we have outlined so far. This exemption allows those who haul hay an alternative method of securing their loads (Federal Register 2024-13324 (89 FR 51586). The exemption covers the strap placement on hay, but the WLL requirements do not change.

The basic regulation exemption to the one strap every 10 feet along the length of the trailer is that the hay can be secured by two parallel longitudinal straps over the top of the load along with a minimum of four straps running from side to side when loaded more than one tier high.

This multi-layer stack of hay will have enough straps running from side-to-side, but it is short one strap on top running from front to back. The alternative load securement method requires two straps running parallel to the trailer (see blue arrow).

This multi-layer stack of hay will have enough straps running from side-to-side, but it is short one strap on top running from front to back. The alternative load securement method requires two straps running parallel to the trailer (see blue arrow).  This photo shows an example of an alternative method of securing hay. Two straps run down the length of the trailer and six straps running from side-to-side. This hay is about as secure as a load can be.

This photo shows an example of an alternative method of securing hay. Two straps run down the length of the trailer and six straps running from side-to-side. This hay is about as secure as a load can be.  These hay trailers are popular with growers. They allow each bale to fit into a cradle. While they look secure, there is nothing holding the hay down except gravity. A sharp turn could cause the bales to roll onto the roadway. While law enforcement might allow these to move on the roadway like this, experts testifying in an accident case would argue that they are not secured as required by federal and state transportation regulations.

These hay trailers are popular with growers. They allow each bale to fit into a cradle. While they look secure, there is nothing holding the hay down except gravity. A sharp turn could cause the bales to roll onto the roadway. While law enforcement might allow these to move on the roadway like this, experts testifying in an accident case would argue that they are not secured as required by federal and state transportation regulations. HAULING HAY IN AN ENCLOSED TRAILER

While hauling hay in an enclosed trailer does not have as many regulations, it does not mean there are none. Obviously, the sides and roof will keep the hay inside the trailer. However, operators using enclosed trailers still need to keep the loads from moving forward and backward. (A) The trailer in this example is fine because the trailer is filled with hay. (B) The load in this example needs a way to prevent the load from shifting backward. One option is to place straps from side-to-side hooking into the railing on the side of this trailer.

Display the Slow-Moving Vehicle Emblem

Ever hear about tragic accidents. Some of these accidents could have been prevented if a driver had not been talking or texting or driving while intoxicated or tired.

Although you may not have caused the accident, you must deal with your insurance company, repair or replace your damaged vehicle or equipment, and cover the medical expenses of an injured driver or passenger. To your surprise and dismay, your insurance provider informs you that the attorney representing the individual responsible for the crash is claiming you should pay part of their damages because of alleged negligence on your end.

You may be thinking, “How could I be negligent when the other driver rear-ended my hay wagon while they were speeding distracted with their phone?” A driver who causes an accident is responsible for covering their part of the collision. To which you might reply, “Cover their part! They caused the accident in the first place by running into me.” However, it is the opposing attorney’s responsibility to see if any of your actions or inactions contributed to the accident. This is where slow-moving vehicle signs are important.

Consider a scenario in which an accident occurs on a rural road at dusk while you are pulling a wagonload of hay. Did your vehicle have a slow-moving sign or visible flashers to warn the driver barreling toward you? The other driver’s attorney may argue that your slow speed contributed to the accident, because you failed to notify their client that you were operating at speeds much slower than the posted limit.

The lawyer will push the narrative that if their client had known you were going at a slow speed they could have prevented the accident by slowing down. Both sides began discussions on what it would take to settle the claims without going to court.

Displaying a slow-moving vehicle sign is a legal requirement that protects drivers and the public. It is intended to advise drivers approaching from the rear that they are encountering equipment that is moving at a slower than posted speed. Hopefully, approaching drivers are paying attention to the bright orange and red sign in front of them. Even if they ignore the sign, you have done your part in warning them of your slower travel speed as long as the sign is visible.

Before harvesting season and transporting hay begin in earnest, make sure all wagons and implements have slow-moving vehicle signs that are clearly visible from the rear. One serious mistake we see is when a wagon has a slow-moving vehicle sign, but it is hidden by following wagons without visible signs. The best approach is to attach slow-moving vehicle signs to every wagon to ensure you properly notify approaching drivers. This is an important part of covering your legal liabilities.

A serious accident like this caused by another driver’s negligence may still have you paying part of the damages when you have not done your due diligence. An actual bill for a 50-mile trip via Lifeline helicopter was $70,000.

A serious accident like this caused by another driver’s negligence may still have you paying part of the damages when you have not done your due diligence. An actual bill for a 50-mile trip via Lifeline helicopter was $70,000.  This photo shows a good example of what not to do when transporting a round bale on a 3-point hitch. Issues we see include: no slow-moving vehicle sign; the load is ready to fall off; and the hay conceals the flashers. The lack of visible mirrors also means the operator cannot see any trailing vehicles when they pass or when making a left turn. It is a tragedy in the making. If an accident occurred, this operator might be partially responsible for claims. Remember to keep round bales on a 3-point hitch below the center of gravity to keep the tractor from getting out of balance going down a road.

This photo shows a good example of what not to do when transporting a round bale on a 3-point hitch. Issues we see include: no slow-moving vehicle sign; the load is ready to fall off; and the hay conceals the flashers. The lack of visible mirrors also means the operator cannot see any trailing vehicles when they pass or when making a left turn. It is a tragedy in the making. If an accident occurred, this operator might be partially responsible for claims. Remember to keep round bales on a 3-point hitch below the center of gravity to keep the tractor from getting out of balance going down a road. CODE ORANGE 25

If you are traveling less than 25 miles per hour on a highway in Indiana, you must display a slow-moving vehicle sign. “When any vehicle, whether pulled, towed, self-propelled, or animal drawn, which is not under ordinary circumstances moved, operated, or driven at a speed in excess of twenty-five miles per hour, is moved, operated or driven on any public highway which is open for vehicular travel, it shall display a triangular slow moving vehicle emblem” (Indiana Code 9-21-9-1).

According to Indiana law, would examples A, B, and C require slow-moving vehicle signs? The answer for A is “no” because the truck and gooseneck trailer will travel faster than 25 mph. The answer for B is “yes” if it is on a public road and travels less than 25 mph. The answer is “no” if it only moves on private property. The answer for C is “no,” assuming it will travel faster than 25 mph.

A

A  B

B  C

C A WORD OF CAUTION: Wagons often lack stability (roadworthiness) when they are towed by a motor vehicle at highway speeds. The ideal speed is 25 mph.

SLOW - MOVING VEHICLE SIGN BACK AND CENTER: Indiana law is clear on how slow-moving vehicle signs should be displayed. “Whenever a vehicle is moved, operated, or driven on a highway that is open for vehicular travel, the vehicle shall display a triangular slow moving vehicle emblem mounted as near as is practicable to the center of mass and at an approximate height of not less than three (3) and not more than five (5) feet from level ground or pavement surface. The emblem shall be mounted so as to be entirely visible from the rear, day or night” (Indiana Code 9-21-9-2).

Operators often ask where to position slowmoving vehicle signs. According to Indiana code, a slow-moving vehicle sign should be displayed in the center of the wagon and between 3 and 5 feet off the pavement.

How important is the slow-moving vehicle sign when transporting hay in the winter? Under dangerous driving conditions, it is difficult enough to see regular traffic in front of you when blowing snow obscures and distorts your vision. Factor in icy roads and slowing down quickly at the last minute will not be an option. Although this truck has its flashers on, the hay blocks them from view. The slow-moving vehicle sign is the only thing that drivers approaching this trailer will see at a distance.

(A) This slow-moving vehicle sign is perfectly placed on the wagon. It is centered both top to bottom and side to side. (B and C) This operator made a good start by placing signs on the back of each wagon. However, the sign on the lead wagon is too high (B) and the sign on the trailing wagon is too far to the right (C).

This wagon has rear warning lights as well as two slow-moving vehicle signs. The two tail-lights attach with magnets and work with wire plugs in rear of the truck or tractor. These mounted lights give you tail, turn, brake, and four-way flashers. While agriculture implements do not require lights and flashers, using them is an additional layer of protection for the operator. Notice that the slow-moving vehicle signs are not in the middle.

This wagon has rear warning lights as well as two slow-moving vehicle signs. The two tail-lights attach with magnets and work with wire plugs in rear of the truck or tractor. These mounted lights give you tail, turn, brake, and four-way flashers. While agriculture implements do not require lights and flashers, using them is an additional layer of protection for the operator. Notice that the slow-moving vehicle signs are not in the middle. FIND OUT MORE

All publications are available from the Purdue Extension Education Store (edustore.purdue.edu) and Purdue Pesticide Programs (ppp.purdue.edu).

Purdue Pesticide Programs offers several publications related to transportation safety (click on the image to read the publication):

Allow Traffic to Flow

Imagine you are pulling a trailer loaded with hay when someone behind you starts honking their horn and gesturing with their hands and fingers. As you look in your side mirrors, you notice a long line of vehicles trailing behind you. You ask yourself why that person is continually honking their horn when you have every right to be on the road just like them?

The drivers you share the road with do not always take kindly to equipment that slows them down and makes them late. As drivers line up behind your equipment, you probably notice cars weaving in and out as if they were on a racetrack looking for a chance to pass. The driver near the back of the line puts the pedal to the metal, starting to pass even though there is a double line on the highway that says not to, and the hill in front screams, “Beware.”

That impatient driver can create an unwanted chain of events - it doesn’t matter who is right or wrong. Perhaps, as the car passes you, it sees an oncoming truck coming over the hill. The driver swerves and hits a telephone pole.

After the dust settles, lawyers for the driver who chose to recklessly pass and became severely injured as a result, alleges you were negligent by not pulling over as required by Indiana law. Their attorney wants you to pay for his client’s medical care and rehabilitation treatments.

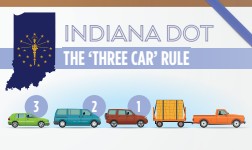

By law, slow-moving farm equipment must pull over to allow faster traveling vehicles an opportunity to pass. The criterion for when to pull to the shoulder is when three or more vehicles line up behind farm equipment - we call this the Three Car Rule.

The vehicle right behind you often will not pass you even with plenty of opportunities. It is usually a vehicle back in the line that attempts the long run around all the other vehicles and you. In this photo, you can see a truck pulling a trailer passing a slow-moving vehicle while a hill looms in front of them. Who knows what is coming over the hill in the opposite direction. Is this a lucky day for the passer and you? Maybe not!

THE ‘THREE CAR’ RULE

A person may not drive a motor vehicle…at a slow speed so that three or more other vehicles are blocked and cannot pass on the left around the vehicle; shall give right-of-way to the other vehicles by pulling off to the right of the right lane at the earliest reasonable opportunity and allowing the blocked vehicles to pass.

CODE: 9-21-5-7

Farm vehicle drivers are required to move to the right if and only if it is safe to do so. Obviously, pulling over is not prudent or safe if the right shoulder has a ditch or steep embankment or if it is lined with power poles, mailboxes, and driveways. Leaving part of your equipment in the road as you pull over can also create problems because a passing driver could clip your equipment. Be cautious if you choose to pull over on someone’s driveway. The weight of your equipment could potentially damage it.

It cannot be overstated how important it is to have clear views of what is on your right and left sides and behind you while transporting hay. Without clear views, you are driving blind.

It cannot be overstated how important it is to have clear views of what is on your right and left sides and behind you while transporting hay. Without clear views, you are driving blind. Prevent ‘Leaky’ Loads of Loose Chaf

Now consider this scenario. An individual called the sheriff to complain about chaff falling from your trailer. It might seem odd to you that someone living alongside a road would get so upset about that, but it does happen occasionally. The sheriff ’s deputy tells you (whether they want to or not) to keep the material from blowing off your trailer or they will have to “Write you up."

Indiana law, as written, is clearly on the complainant’s side. It is unwise to haul hay on a road where a person has complained about small amounts of chaff blowing off. While it might be inconvenient, altering your route might go a long way toward solving the problem. Some operators tarp their loads of hay or straw when they travel longer distances. Tarping your load also would help prevent most complaints from neighbors along your travel route. A tarp also can keep hay from getting wet from rain or snow. A sound practice is to tightly wrap the bales you make with plastic netting or baler twine. Hay bales that are more compressed and compact are less likely to lose vegetative material.

THE LEAKY LOAD PROVISION

A vehicle may not be driven or moved on a highway if the vehicles contents are dripping, sifting, leaking, or otherwise escaping from the vehicle.

CODE: 9-21-8-48

Pull No More Than Two Hay Wagons

Often, you may see an operator pulling multiple wagons on farm lanes from the barn to the field, within the field, and back to the barn; it’s a way of saving several trips a day. Moving several wagons might also be necessary when hay needs to be covered quickly, such as when rain is looming. Hauling a long line of wagons on a farm is obviously much different than pulling them on a public road. Indiana law states that operators cannot pull more than two wagons on local, county, or state roads. Slow-moving implements of agriculture (like wagons) are not allowed on any interstate.

Beyond state law mandates, a “train” of more than two wagons makes it more difficult for other vehicles to safely pass you, particularly when you consider how narrow some county roads are. Also, it might be difficult to maintain control of the wagons even at 20 mph. Some wagons do not trail as safely because of loose linkages. This creates a side-to-side swaying effect, which can be difficult to control. A wagon swaying over a shoulder might tip the wagon and the load. It is also possible that if you brake an undersized tractor or truck pulling multiple wagons downhill, you could find it to be challenging because of the weight pushing on the vehicle.

Although there are valid reasons for doing so, there is too much liability to pulling more than two wagons on public roads.

PULLING A ‘TRAIN’ OF WAGONS

A farm tractor may draw no more than two wagons or farm implements upon a highway.

CODE: 9-21-10-1

Conduct a Stop and Check Road Inspection

There are several reasons why drivers should conduct roadside inspections after their hay trailers have been on the road for a few miles. The most important reason is that loads of hay will shift and settle, which causes straps to loosen, especially at the beginning of a trip. Before entering a heavily traveled road, stop to check that the straps are still tight over bales and correctly positioned.

Stopping to inspect loads is a wise move because hay will routinely shift and settle, causing straps to loosen. However, we strongly discourage you from stopping on the highway to check load straps. Check straps on a side road not the highway. You only need to travel a half-mile for the load to settle. It is our experience that you should only stop on the side of a highway, especially an interstate highway, when there is an emergency like a flat tire. It is just too dangerous.

THE 1-MILE CHECK: “I store hay about a mile away in a barn. When I get an order, I load the hay and tighten the ratchet straps. I drive 1 mile to where my scales are located. I have had to retighten 100 percent of every load when I check them at the scales. It is hard to believe that hay settles and straps loosen all within 1 mile.” — Comments from a Farmer

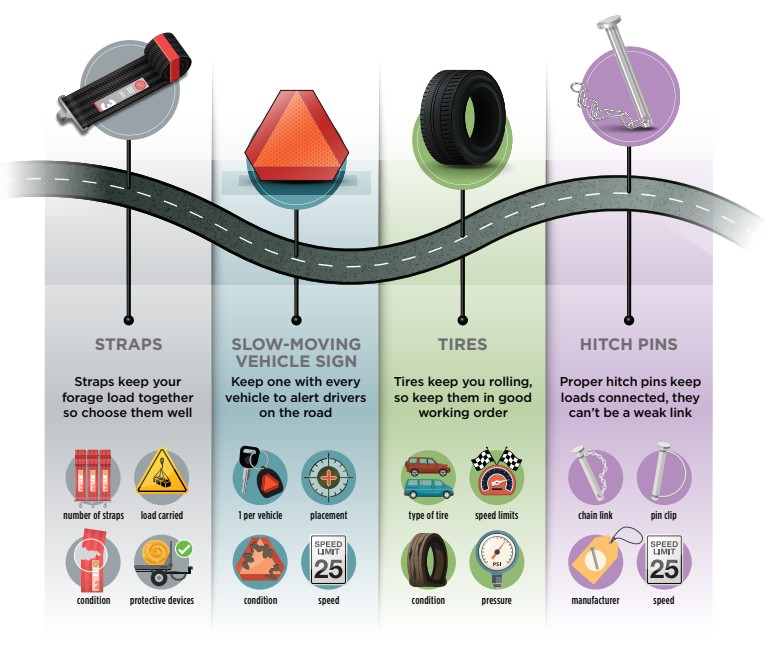

Remember the Hitch Pin and Safety Chain

While we are often concerned about fastening down hay on a trailer or wagon, another important safety consideration is whether that trailer or wagon is securely attached to the truck or tractor. It is important to place the appropriate hitch pin that connects the trailer or wagon to the towing unit to keep them together when traveling on the road.

It is common to reach in a toolbox or in the back of a truck for any old hitch pin that will fit into the receiver. You may think it is good-to-go when it fits. What you might not realize is that hitch pins are graded like all other bolts — Grade 2 (soft), 5 (medium), and 8 (hard). If you put a Grade 2 bolt between a wagon loaded with hay and a truck or tractor, there is a good chance the hitch pin will bend or shear under pressure.

Here are a couple of tips when considering hitch pins:

• Attach hitch pins to wagons or trailers with chains to keep them from getting lost and to ensure they will always be available.

• Make sure hitch pin clips are present and used before you enter roadways. Crops or field debris can push out clips, leaving pins unsecured in their receivers. Potholes or railroad tracks can also pitch hitch pins, leaving wagons or trailers unsecured.

• Always purchase manufactured hitch pins for pulling hay wagons and trailers on the road. Homemade pins might work well around the farm, but using them on the road is a huge liability when they fail.

• Take the time to hook your wagon or trailer chains to the truck or tractor in case a hitch pin shears. Safety chains are designed to keep loads behind you and not let them go freewheeling into oncoming traffic.

CALCULATING HITCH PIN LOADS

If we load a wagon with 90 straw bales averaging 38.6 pounds each, then the loaded wagon would carry 3,474 pounds. The front wagon has a gross empty weight of 1,890 pounds and the rear wagon has a gross empty weight of 1,820 pounds. Thus, the front wagon has total weight of 5,364 pounds and the rear wagon weighs 5,295 pounds.

Would a pin rated for 5,300 pounds work for either wagon?

No. The rear pin is barely strong enough to hold close to 5,300 pounds. The front pin connecting the tractor to the first wagon is not strong enough. That front pin needs to hold more than 10,659 pounds because it secures the weight of the two combined wagons, not just the first one. This is why the grade of the pin is so critical.

FIND OUT MORE

Both publications are available from the Purdue Extension Education Store (edustore.purdue.edu) and Purdue Pesticide Programs (ppp.purdue.edu).

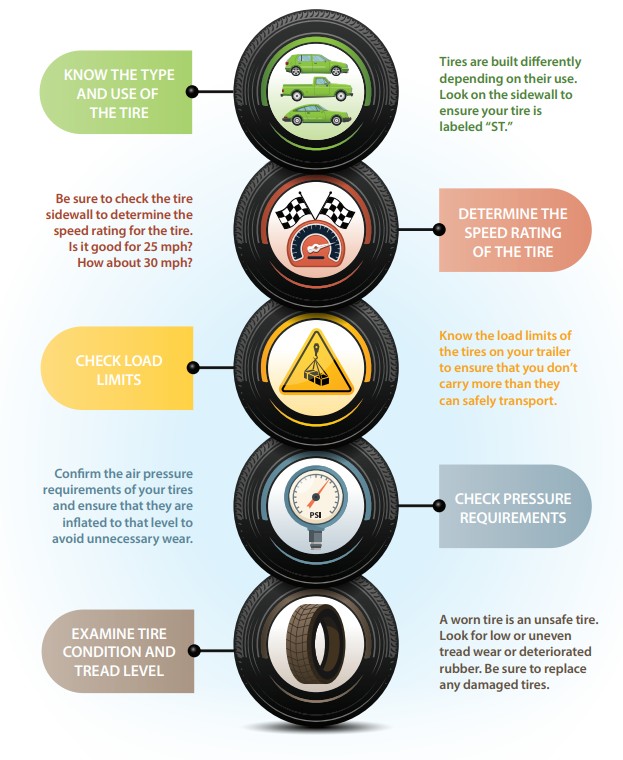

Tires are the Underbelly of Trailers

All the work of putting a safe and legally compliant wagon or trailer on the road can be quickly undone if a worn tire explodes under the weight of a load of hay. Look along the side of any road and you’re bound to spot the remnants of blown tires along the shoulder.

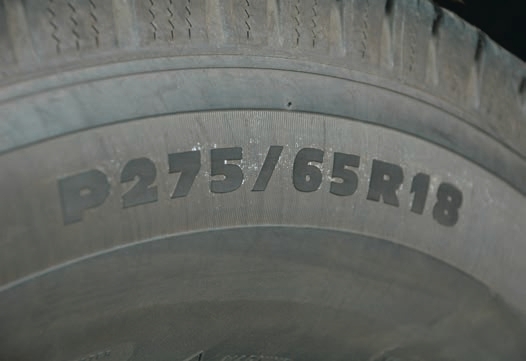

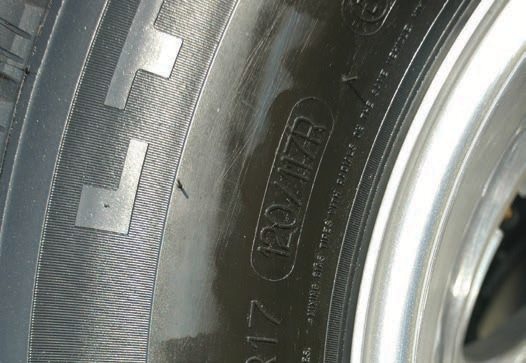

Tires for trucks, cars, trailers, and wagons are built differently based on to the job they do. A trailer tire is not designed to steer — instead, it follows the lead of the truck. Trailer tires have reinforced sidewalls meant to carry heavier weights. Passenger vehicle tires are built for comfort, handling, and turning. Passenger vehicle tires are not built to hold heavy loads and should never be used on trailers. Tires have valuable information right on them — maximum air pressures, load weights, and speed rated. One of the more important pieces of information is the type of vehicle or implement for which the tire is manufactured. Tires with a P are passenger vehicle tires, with an LT are for trucks, and with an ST for trailers.

The air pressure in tires is also critical. Most tire remnants along the road were underinflated or used beyond the point of no return. Tires blow when they can no longer support the weight placed over them.

Checking tire pressure is simple enough, but it is one of the most neglected tasks and it costs drivers a significant amount of money each year. A tire underinflated by 6 pounds can reduce tread life by 25 percent. This means you have to purchase tires more often.

Unless the tire pressure is extremely low (that is, almost flat), you cannot visibly tell how much a tire is underinflated. Putting a load of hay on an underinflated tire increases the odds of the tire blowing on the road and losing control of the vehicle or trailer. We recommend that if you increase the weight of the load, make sure to increase the tire pressure to the maximum air pressure the tire is designed to hold.

A WORD OF CAUTION

A grower had to slide under the wagon to air up a flat implement tire. With his face close to the gravel and dirt floor and next to the tire, he began to fill the tire with air. Within moments, the tire exploded, pushing dirt and gravel into the grower’s eyes. Blinded at the time, he was lucky a friend made an unannounced visit. The friend took the farmer to an optometrist who was able to save the farmer’s eyes. Jacking up and rotating the tire, you can see where the tire had sat for such a long time that it rotted. Closely inspect any tire that has been on the ground for an extended period. If you must get close to a tire like this farmer had to, wear safety glasses.

TIRES GET YOU THERE

Don’t overlook your tires when loading up your transports because if they fail you, all other safety measures are undone

GOING FROM BAD TO WORSE IN A FEW MINUTES FIND OUT MORE

Tires For the Road and Field (Purdue Extension publication PPP-99) provides an in-depth review of tires — how to read the information on sidewalls, maintenance to perform, and replacement schedules. Available from the Purdue Extension Education Store (edustore.purdue.edu) and Purdue Pesticide Programs (ppp.purdue.edu). “I was in a half-ton truck pulling an old John Deere planter trailer with two small trailer tires on each side. As usual, it was overloaded — round bales stacked two high and two wide with no straps, and I only had to go a few miles to the home farm. It didn’t take me long that hot day to learn that being overweight with bad tires was a problem waiting to happen. I was almost home when a trailer tire blew but kept going on the other three tires. Seconds later, I saw flames in my passenger-side mirror coming from the load over the blown tire. After assessing the situation quickly, if I drove faster, I could get to the farm for water to save the load. It didn’t dawn on me that the faster I went, the more the fire would spread.

“The fire quickly engulfed the entire load. I didn’t make it much further when the heat and increased wheel burden blew two more tires. I could barely move with one tire to even get it off the road. I then decided I had to save the truck. Flames were almost melting the back of the truck. Of course, the hitch pin was bent, nearly impossible to unhook with it loaded down. I had to crawl under the truck to escape the flames to beat the pin out. I saved the truck but then had a field fire. Someone passing by earlier must have called the fire department.

“To this day, I always reflect on that situation. Could having quality tires and the right weight over those tires prevented the fire? Of course. Having exposed tires in contact with bales is also a mistake. I used this trailer for the wrong purpose. I realize it is human nature to think, ‘It worked the last few loads that day, so why not make one more!’

“No one realizes how fast fire can spread through hay and straw — and even faster if it is windy and you decide to travel faster! After the fact, I realized I should have just stopped when the first tire blew. Trying to outrun a forage fire doesn’t work. I should have pulled into a place where it could burn and take the loss.”

— Comments from a farmer

FIND OUT MORE

Tires For the Road and Field (Purdue Extension publication PPP-99) provides an in-depth review of tires — how to read the information on sidewalls, maintenance to perform, and replacement schedules.

Available from the Purdue Extension Education Store (edustore.purdue.edu) and Purdue Pesticide Programs (ppp.purdue.edu).

Don’t Gamble with the Law: Secure Your Hay and Straw

At first glance, transporting hay and straw should be an easy task — bale it, stack it on a trailer, and move it from one point to another. However, pulling hay on the road (even for just a few miles) is anything but easy. We discussed many topics in this publication — straps, slow-moving vehicle signs, hitch pins, and tires. All are part of what it takes to safely transport hay from the field or barn to its destination.

It is worth your time and effort to safely secure and transport your loads to mitigate the liabilities you face when transporting hay. A quick internet search shows headlines that describe hay falling off trailers and wagons resulting in tragic accidents. These headlines emphasize the importance of reviewing your operation to ensure the safe transport of hay.

Falling hay bales from passing truck kills driver

Two juveniles and one female injured after hay bale falls on top of their car from passing trailer

Woman killed by hay bale in tragic semi-truck accident

Minnesota couple dies after hay bale falls on their vehicle

Hay bales hit minivan on Colorado highway, leaving it undrivable

Cyclist left with brain damage after hay bale falls from trailer and hits him

Minor injuries after hay bales fall from trailer, hit SUV, forces other vehicles off road

Man dies after being crushed by falling bales of hay

THE HARD REALITY OF MOVING SOFT LOADS

Four areas you must understand to transport forage loads safely - for you and for others on the road

A FEW MINUTES WOULD HAVE PREVENTED A TOTAL LOSS

“Dad was transporting 39 big square bales to the dairy. He pulled into dairy too fast, and they fell against his cab. He decided to keep driving to get weighed at the dairy.

“The lady at the scale office told him his hay was smoldering. He then saw flames and ran to the truck and thought if he quickly drove around in a circle that the burning bale against the exhaust pipe would fall off the trailer. As he turned into the wind, it ignited the whole load of hay.

“We lost everything — hay, truck, trailer, and almost, my dad. I did not know it at the time that the black smoke I was seeing from the farm was our truck on fire. The cause of the problem was that we didn’t strap the bales down allowing the bales to contact the hot exhaust.”

— Comments from a farmer

In the event of an accident, not only can you be responsible for another person’s injuries or potential death, but you could also be faced with dealing with injury attorneys, insurance companies, settlements, and lawsuits. Everyone would agree they would rather secure the load and prevent problems before they happen than deal with the aftermath of an accident. It is a whole lot easier to take a few minutes before you leave the farm to check your load than to spend six years defending yourself and your actions in court.

ONE THOUGHT TO REMEMBER

You will never be penalized for providing more securement than the law requires. You will most certainly be penalized for not providing enough as shown in this photo.

Acknowledgements

Thanks to Dawn Minns for graphic design and Adduci Studios for illustrations. Thanks to the following individuals who provided valuable comments and suggestions that improved this publication:

Kelly Heckaman, Purdue University

Kelly Leyse, High School Teacher

Gene Matzat, Indiana Farmer

Tom Orwig, Indiana Farmer

Todd Richey, Indiana Farmer

Jason Tower, Purdue University

Disclaimer

This publication is intended for educational purposes only. The authors’ views have not been approved by any government agency, business, or individual and cannot be construed as representing a perspective other than that of the authors. The publication is distributed with the understanding that the authors are not rendering legal or other professional advice to the reader, and that the information contained herein should not be regarded or relied upon as a substitute for professional consultation. The use of the information contained herein constitutes an agreement to hold the authors, companies, or reviewers harmless for liability, damage, or expense incurred as a result of reference to or reliance upon the information provided. Mention of a proprietary product or service does not constitute an endorsement by the authors or their employers. Descriptions of specific situations are included only as hypothetical case studies to assist readers of this publication and are not intended to represent any actual person, business entity, or situation. Reference in this publication to any specific commercial product, process, or service, or the use of any trade, firm, or corporation name is for general informational purposes only and does not constitute an endorsement, recommendation, or certification of any kind by Purdue University. Individuals using such products assume responsibility that the product is used in a way intended by the manufacturer and misuse is neither endorsed nor condoned by the authors nor the manufacturer.

Reference in this publication to any specific commercial product, process, or service, or the use of any trade, firm, or corporation name is for general informational purposes only and does not constitute an endorsement, recommendation, or certification of any kind by Purdue Extension. Individuals using such products assume responsibility for their use in accordance with current directions of the manufacturer.

August 2025