Tires For the Road and Field A Guide to Getting the Best Value and Performance

RESOURCES - PUBLICATIONS

Tires For the Road and Field

A Guide to Getting the Best Value and Performance

Authors

Fred Whitford, Coordinator, Purdue Pesticide Programs

Dennis Nowaskie, Superintendent, Southwestern Purdue Agricultural Center

Dennis Buckmaster, Associate Professor, Purdue Agricultural and Biological Engineering

Steven Turner, Territory Customer Support Manager, John Deere

Steve Hawkins, Assistant Director, Purdue Agricultural Centers

Keith Schaefer, Manager, Best-One Tire and Service of Vincennes, Inc.

Mike Hayden, Liquid Propane Manager, Co-Alliance, LLC

Jerry Boger, Safety and Risk Coordinator, Jackson Jennings Co-op

Pete Illingworth, Farm Technician and Mechanic, Throckmorton-Purdue Agricultural Center

Kevin Leigh Smith, Editor, Purdue Agricultural Communication

Introduction

Business and farm owners spend countless hours comparing vehicles and equipment before any purchase. They can spend weeks comparing brands and models for the best value, durability, warranty, and so on. That decisionmaking process takes time. While you might spend weeks researching the right truck or sprayer to buy, you might only give a minute’s thought to buying replacement tires for a vehicle, trailer, or implement. Too often, the only thought we have about tires is cost. If we give tires any more thought, it is that we expect them to hold air so we don’t have to change a flat. Tires are not glamorous (they’re black, round, and hold air), but consider this: tires support your payload and allow your vehicle or implement to move across terrain or down the road. Imagine the potential damage a blown tire could cause.

Each tire is a complex product that has been manufactured to industry specifications and standards. Those specifications are provided on each tire.

Each tire is a complex product that has been manufactured to industry specifications and standards. Those specifications are provided on each tire.  Imagine the consequences of a blown tire if you’re carrying pesticides and fertilizers.

The environmental damage, insurance claims, and possible legal costs can be extensive.

Imagine the consequences of a blown tire if you’re carrying pesticides and fertilizers.

The environmental damage, insurance claims, and possible legal costs can be extensive.

While we take tires for granted, we should never forget how important they really are. Just remember the last time you had a flat tire and how important the tire was at the moment.

While we take tires for granted, we should never forget how important they really are. Just remember the last time you had a flat tire and how important the tire was at the moment.

A farm or business may have more than a hundred tires for transport cars, pickup trucks, grain trucks, and other equipment. But without properly functioning tires, a vehicle or implement is motionless and unproductive.

A farm or business may have more than a hundred tires for transport cars, pickup trucks, grain trucks, and other equipment. But without properly functioning tires, a vehicle or implement is motionless and unproductive.

Engineering Marvels

It’s amazing what we demand from our tires each day. We expect tires to:

• Move all types of vehicles and equipment

• Control steering

• Maintain traction when it’s wet

• Support heavy loads

• Maneuver around road hazards

• Help stop the vehicle

• Provide a comfortable ride

• Maximize traction in mud and snow

• Hold up under off-road uses

• Improve gas mileage

That’s quite a lot to ask a tire — or any other engineered product — to do day after day. If that weren’t enough, consider that the size and weight of modern agricultural and business equipment demands a lot from tires. Tractors today pull large implements and loads in the field and on the road. Tires need to function efficiently on soil as well as asphalt and concrete. As farms have expanded, tires have had to become more rugged to deal with the wear that accompanies increased highway and transport use.

Businesses also increasingly rely on tires to improve personnel efficiency. Pickup trucks are not only more popular, but more powerful and versatile. We expect them to haul larger payloads and pull heavier trailers during the day. At the same time, we expect the work truck to ride like a touring sedan when we drive prospective clients to dinner. Today’s tires can achieve these expectations.

Specific Applications

The tires that commercial pesticide and fertilizer applicators and farmers use vary in construction and design according to how they’ll be used. Here are six common tire types.

Solid Rubber or Foam-filled Tires

Solid rubber or foam-filled tires are used on slow-moving equipment such as some lawn mowers and forklifts. Since solid tires will not go flat, they are useful for equipment that will be driven over metal, nails, screws, and glass (as is common around construction and demolition sites). Still, these same sharp objects can chew up the rubber, causing the need for more frequent tire replacements. Their lack of air means these tires have a rougher ride.

Passenger Tires

As the name suggests, passenger tires are used on passenger cars and trucks that carry lighter payloads (for example, half-ton trucks or lighter). These all-purpose tires provide excellent road traction in inclement weather, a smooth and comfortable ride, good fuel economy, and a long tread life. However, they are not designed to carry heavy loads or to perform off-road work.

Temporary Spare Tires

Temporary spare tires allow a vehicle to get from the site of a flat or blown tire to the nearest garage. They are designed to be driven only for short distances at low speeds.

Unlike passenger cars, most trucks come with a full-size spare

tire instead of a smaller temporary replacement tire.

Load-carrying Truck Tires

Load-carrying tires are reinforced with several layers under the tread and sidewalls that allow for heavier loads - each layer is called a ply. More aggressive treads give these tires better traction under rugged off-road conditions. Load-carrying tires have three possible disadvantages:

1. Their higher air pressures produce a rougher ride

2. Aggressive treads don’t wear as well as passenger tires

3. They may be noisier

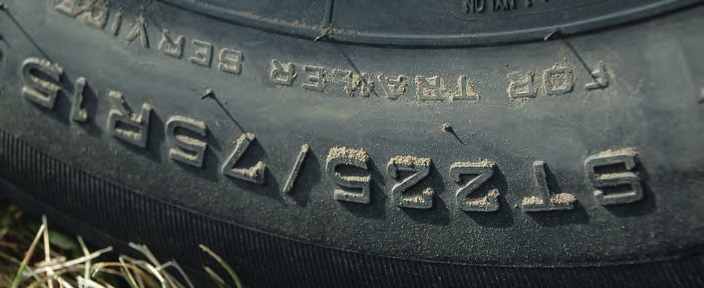

Trailer Tires

A trailer tire has multiple layers of rubber and steel under its tread, and it has reinforced sidewalls that allow it to carry a heavier load with higher air pressure. These tires are designed for lateral twisting, not controlled maneuverability, so do not use them on trucks (just trailers). In general, tires designed for trailers have less aggressive treads than tires designed for trucks — that’s because tires that are pulled do not need to generate traction.

Trailer tires are designed to carry heavy loads.

Trailer tires are designed to carry heavy loads.

Agricultural Drive and Implement Tires

Agricultural drive and implement tires are a diverse group. Depending on the equipment, these tires may have rubber cleats for traction in loose soil, a wider width to help spread the tire’s footprint for flotation and less compaction, or a smooth but stout construction to carry an implement pulled behind a truck or tractor. Flotation is the capability of a tire to stay on top of a soft surface. High-flotation tires provide better traction on soft surfaces. Implement tires are designed to travel slower on highways. Keep in mind that a tire’s longevity depends on actual use. For example, a cleated tire will not last as long if it is frequently driven on concrete or asphalt.

Tractors and self-propelled equipment have drive wheels that have heavy-duty treads (called cleats or lugs). Cleats grab the ground and help move the equipment forward through loose substrate.

Many implement tires have unaggressive treads like trailer tires. That’s because implements will be pulled, so their tires are constructed to carry weight at slow speeds without compacting soil. They are not designed for maneuverability or comfort.

Many implement tires have unaggressive treads like trailer tires. That’s because implements will be pulled, so their tires are constructed to carry weight at slow speeds without compacting soil. They are not designed for maneuverability or comfort.

A One-size-fits-all Tire Doesn’t Exist

If the only things we needed from a tire were that it be round and made of rubber, there would be no need for such a variety of tire designs. Tires are engineered, lab- and field-tested, and sold for specific applications with different specifications for speed, traction, weight, comfort, maneuverability, mileage, costs, and appearance. For some consumers, buying the cheapest tire they can find is their Number One priority. For others, buying the proper tire for the job is most important.

You may purchase a tire with the intent of using it on a trailer that will be loaded down with tanks filled with pesticides, fertilizers, and water. You may want the tire to perform well in snow, ice, or rain. Farmers may purchase tires for implements that carry heavy loads across fields, or wide tires that reduce soil compaction.

Consider the difference between the tires on a sod farmer’s tractor and those on a row crop farmer’s tractor. Generally, sod growers use tractor tires that do not have aggressive treads. Instead, sod growers use smoother tires that won’t lift up or cut into the sod. That’s because a sod producer would rather pull forward and back up several times than use aggressive treads that could damage the sod. Row crop farmers, of course, want just the opposite. They will outfit their tractors with more aggressive treads that allow the tires to turn and get traction in loose or wet substrates.

Even trucks use different tires. A lightweight pickup for a residential pest control company needs a much different tire than a truck working off-road to clear brush under utility lines. And those tires will be designed differently than tires intended for a truck and trailer that will carry a backhoe, bulldozer, or skid steer. Trailer tires face the largest range of weight challenges. For instance, a trailer might be used to transport something as small as a riding lawnmower to and from family members’ houses once a week. That same trailer also might carry a large herbicide tank off-road to treat brush. In this second application, the trailer’s tires will obviously have to carry and deal with a much heavier load and traverse much rougher terrain compared to a tire used exclusively on roads. Load and terrain influence tire design and selection. The bottom line is that no single tire fits all applications. Tires are scientifically designed and constructed to meet specific performance goals. It is important to purchase the right tires that suit your intended application.

Construction Technology

Manufacturers incorporate numerous engineering designs and construction methods into tires. Most are invisible to the untrained eye. For instance, a single tire has several different rubber compounds — there is a different compound in the tire’s interior, tread, and sidewall components. Construction Technology Manufacturers reinforce the rubber by embedding fabric and steel into it. This improves the tire’s load-bearing strength and sidewall stability. The reinforcements in tires are similar to rebar placed in concrete: they add strength. Tread patterns are uniquely designed to work in mud, drive on snow, or channel water on rain-soaked roads.

Tires are composed of multiple layers that have been melded together under high heat and pressure. The layers of each tire include:

• Internal (inner) liner

• Steel and fabric reinforcements

• Tread

• Sidewalls

• Bead

Each component is described in more detail on the following pages.

different chemicals, rubber, steel, and fabric.

Internal (Inner) Liner

The inside of a tire is called the inner liner. It is composed of very thin and flexible butyl rubber or halogenated rubber compound. Its main function is to hold air inside the tire. In a tubeless tire, air loss will be minimal if the tire is properly seated against the rim and the inner liner is not compromised.

Steel and Fabric Reinforcements

The inner liner is surrounded and protected by layers of rayon, polyester fabric, and steel cords - these reinforcements protect against punctures from foreign objects on the road or ground. The type and amount of reinforced materials in the rubber largely depend on the weight the tire is designed to carry.

Tread

Manufacturers invest significantly in research to discover how tread depth and channel patterns influence how tires respond to several factors, including:

• Changing environments such as snow, water, and mud

• Handling characteristics such as sudden stops and quick turns

• Running across highway debris or into hazards such as potholes

The tread is a sophisticated and highly engineered layer. Getting the right tire footprint is critical. While there are hundreds of tread designs, layouts, and patterns, any tread ultimately must be able to quickly move air, water, snow, and mud in and out of the channels for satisfactory traction.

The tread on this tire is designed for mud and snow.

The tread on this tire is designed for mud and snow.  As this tire moves over the surface, you can see water being thrown out of the treads.

As this tire moves over the surface, you can see water being thrown out of the treads.  In addition to wide grooves, notice that this tire has small channels on its edges that help water flow out of the tire.

In addition to wide grooves, notice that this tire has small channels on its edges that help water flow out of the tire.  Tires with deep channels push water out.

Tires with deep channels push water out.  Tires with deep channels push water out.

Tires with deep channels push water out.  These treads have been reduced, which slows the rate water can move away from the tire.

These treads have been reduced, which slows the rate water can move away from the tire.  These treads have been reduced, which slows the rate water can move away from the tire.

These treads have been reduced, which slows the rate water can move away from the tire.  The loss of the tread means less contact with the road surface.

The loss of the tread means less contact with the road surface.

Sidewalls

Sidewalls contain fabric and steel that provide strength and that help the tire keep its shape under a load. In addition to supporting a predetermined weight, sidewalls have to be somewhat flexible - the stiffer the sidewall, the less comfortable the ride. For example, when a tire falls into a pothole, drives across a rutted railroad crossing, or runs over debris, it must be flexible enough to absorb the impact without puncturing. In the past, sidewalls were designed to hold higher air pressures and bear more weight.

Today, the tire industry is researching methods to strengthen sidewalls that will allow them to resist to cuts and abrasions, particularly in off-road applications. In the field, radial tires often operate at lower pressures to provide better traction and reduce soil compaction. These new technology tires have very flexible sidewalls, but must still carry weight and provide reasonable handling.

Bead

The bead is around the inside diameter of the tire. When you fill a tire with air, the rigid, internally reinforced bead locks the tire against the rim to form an airtight fit. If the bead weren’t reinforced, it would not hold firmly along the rim’s edge, and air pressure would force the rubber over and off the rim as the tire was inflated.

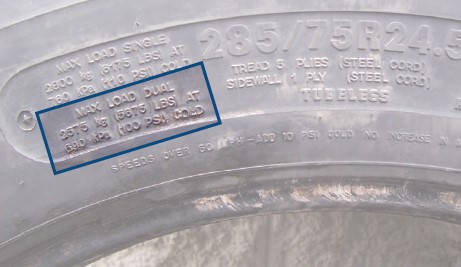

Ratings Stamped on Sidewalls

While they may share common design features, any two tires can be as different as night and day. Separating tire brands based on advertisements can be challenging, daunting, and frustrating. While most of us would rather spend $140 than $200 for a tire, more expensive tires might (in some cases) provide the best value in the long run. Always consider what and how you will use tires before you buy. You can dispel much of the mystery about buying tires by understanding the information tire manufacturers stamp on the sidewall of every tire. Have you ever seen a string of letters and numbers stamped on a tire before? Those

letters aren’t just gibberish: they provide valuable information about the tire. There is a simple formula to the string:

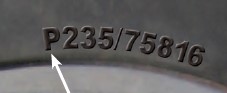

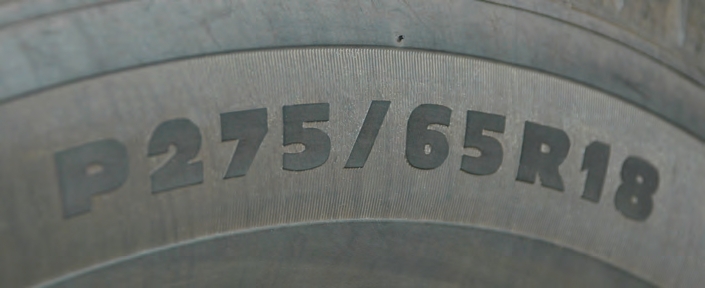

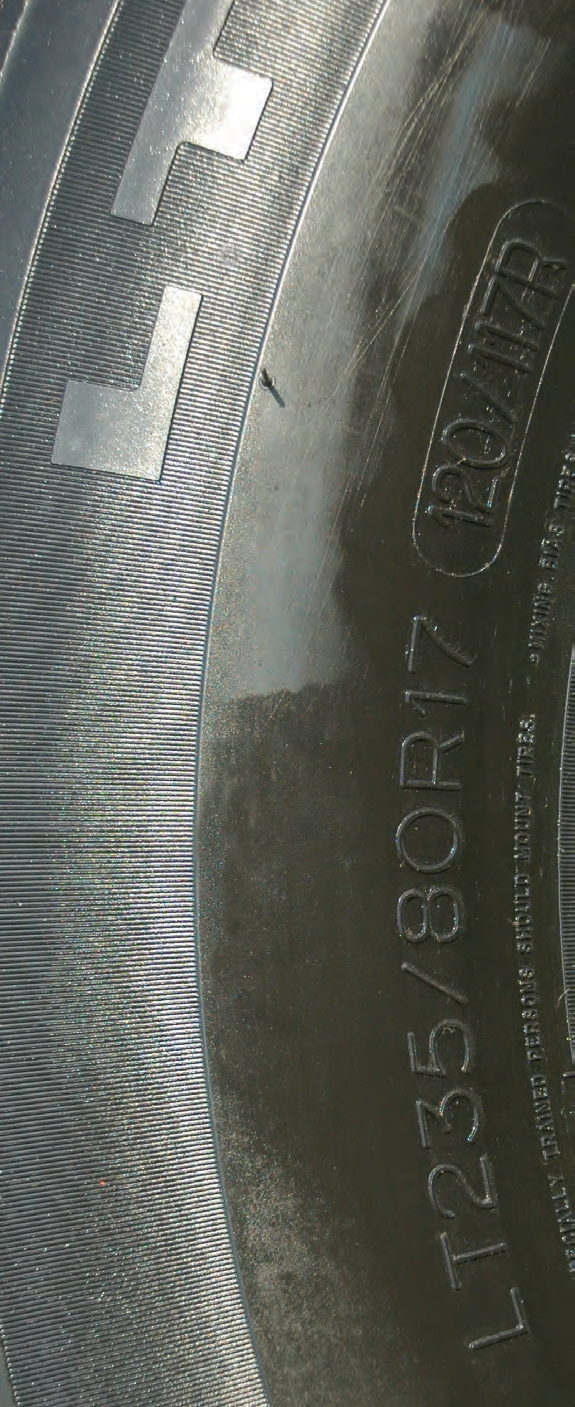

1. Intended vehicle type (optional). The first letter in the string tells you what kind of vehicle the tire is intended for.

2. Width. Next comes the tire’s width. It’s followed by a slash (/).

3. Profile. This two-digit number provides the ratio of the tire’s width to its sidewall height.

4. Construction. This letter describes how the tire is built.

5. Diameter. This last number in the string provides the tire’s diameter.

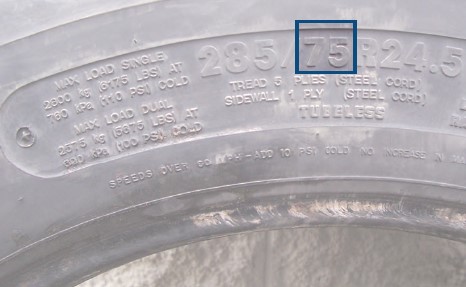

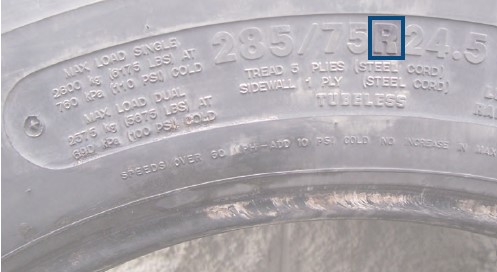

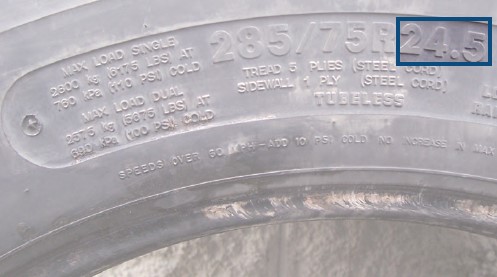

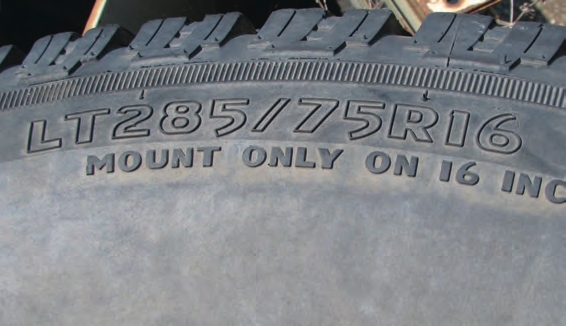

The markings on this sidewall are 285/75R24.5. Can you figure out what the markings mean?

Intended Vehicle Type

The intended vehicle use can come first and last in the string of letters and numbers on a tire. However, intended vehicle type information is optional. If the string of letters and numbers begins with letters, they mean:

The P at the beginning of this string means this tire is meant for a passenger car or lightweight truck. Using a passenger tire on a trailer (as shown here) is a bad idea: chances are that the passenger tire sidewalls may not be strong enough to carry the load.

The P at the beginning of this string means this tire is meant for a passenger car or lightweight truck. Using a passenger tire on a trailer (as shown here) is a bad idea: chances are that the passenger tire sidewalls may not be strong enough to carry the load

P = passenger: cars, minivans, sport utility and light-duty pickup trucks

T = temporary spare

LT = light truck for heavy cargo, or for large towing trailers

ST = special trailer service

If the string ends with letters, they mean:

• LT = wide base or flotation tires

• SL = surface- or speed-limited tire

Width

In the string of letters and numbers, the three digit number that follows the tire type is the tire’s width in millimeters. After the width, there will be a slash (/). Multiply this number by 0.039370 to convert millimeters into inches. For example, a tire that is 285 millimeters wide is 11.22 inches wide.

Measure the width of a rim from the inside of one bead straight across to the other.

Profile

After the slash (/), the two-digit number in the string provides the ratio of the tire’s width to its sidewall height. For example, if you have a 285/75R24.5 tire, the tire’s height is 75 percent of its width. The smaller a tire’s aspect ratio, the wider the tire and the lower the profile it will have.

Low-profile tires react quicker - with less sidewall they offer better handling - however, they often have a stiffer ride. Use the aspect ratio to select a tire so that its height does not interfere with the vehicle’s This axle has two different tires: an 8.00 x 16.5LT and an 8.75 x 16.5LT. The wider tire is about 1 inch taller and 3 inches larger in circumference. That leads to unbalanced loading on the larger tire, which can lead to overheating or unnecessary wear. See Tractor and Implement Specialty Tires, page 40. suspension when it’s fully compressed (as when fully loaded). When a truck hits a pothole or a trailer runs off the shoulder of the road, there has to be space for the suspension to work. If there is not enough clearance between the tire and chassis, the frame will drive into the tire when it is fully compressed and damage or destroy the tire. That is not just expensive, it’s potentially dangerous.

The red truck has enough space to take a larger tire

The red truck has enough space to take a larger tire  The tire on the white truck is probably the tallest it can use without mechanically altering the truck.

The tire on the white truck is probably the tallest it can use without mechanically altering the truck.  This axle has two different tires, that leads to unbalanced loading on the larger tire, which can lead to overheating or unnecessary wear. See Tractor and Implement Specialty Tires, page 40.

This axle has two different tires, that leads to unbalanced loading on the larger tire, which can lead to overheating or unnecessary wear. See Tractor and Implement Specialty Tires, page 40.  This axle has two different tires: an 8.00 x 16.5LT and an 8.75 x 16.5LT. The wider tire is about 1 inch taller and 3 inches larger in circumference.

This axle has two different tires: an 8.00 x 16.5LT and an 8.75 x 16.5LT. The wider tire is about 1 inch taller and 3 inches larger in circumference. Different Sizes, Big Problems

Vehicles or trailers that have different sizes of tires affect performance (top left). Let’s take a closer look at a problem pairing (middle left, below left, below right). What’s wrong with pairing a 205 trailer tire (ST) with a 225 trailer tire? First, the 205 probably can’t carry the same weight as the 225. Second, since both tires are a 75 series, the 225 will be taller than the 205, which could rub when the trailer is loaded or the tire needs to flex. The height difference also means the taller tire would carry more load than the shorter one.

Construction

After the profile is a letter that describes the tire’s construction. The letters mean:

• R = radial

• B = bias or belted

• D = diagonal bias

Diameter

The last number in the string is the diameter of the rim. For example, a tire marked 285/75R24.5 has a diameter of 24.5 inches. Measure the wheel diameter from the bead on one side down vertically to the opposite side of the rim.

Measure the diameter of a wheel rim from the bead on one side down vertically to the opposite side of the rim.

Measure the diameter of a wheel rim from the bead on one side down vertically to the opposite side of the rim. If you replace a rim with one that has a different diameter, it can affect vehicle handling. For example, if you replace a 16-inch diameter rim with a 20-inch diameter rim, the rim height increases by 2 inches. Without making mechanical modifications, the tire placed on a 20-inch rim will need to be 2 inches lower. Reducing the height of the tire by 2 inches compensates for the larger rim, and this allows enough space for the suspension to fully engage. Changing the overall diameter also affects the gear ratio and transmission operation, especially on vehicles equipped with automatic overdrive. Altering the rim size can also influence when antilock braking systems engage and air bags deploy. These devices are calibrated in the factory to operate based on the circumference of the original tire. If you change the rim and do not compensate for the size of the tire, that alters when the air bag and braking system will deploy. An oversized rim might respond faster, an undersized one might be slower.

Test 1:

Understand the Basics

Look at the string of letters and numbers on these tires. See if you can describe important information about them.

• Type: P = passenger car

• Width: 225 millimeters

• Profile: 60 percent height to width

• Construction: radial

• Diameter: 16 inches

• Type: ST = trailer

• Width: 235 millimeters

• Profile: 80 percent height to width

• Construction: radial

• Diameter: 16 inches

Test 2:

Spot the Differences

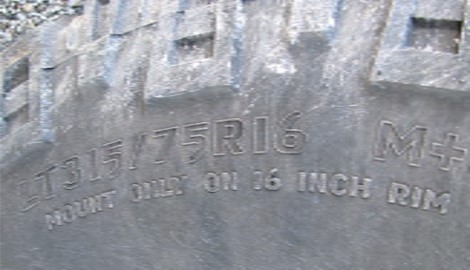

Examine the four tires in these photos and describe the differences between them.

• Type: all tires have an LT, which means they are all suitable for light-trucks or trailers

• Width: 225, 235, 285, 315 millimeters

• Profile: 75, 85, 75, and 75 percent height to width

• Construction: all are radials

• Diameter: all are 16 inches

The tire you should select depends on the gross vehicle weight rating, fender well clearance, and the load rating of each tire. In other words: match the tire to the application.

Additional Information on Sidewalls

Tires also have additional details stamped o n them, including their:

• Weight-carrying capacity (load index)

• Speed rating

• Maximum pressure

• Sidewall construction

• Uniform tire quality grade (which provides ratings for tread wear, traction, and temperature) Where and how this information appears will vary from one manufacturer to the next.

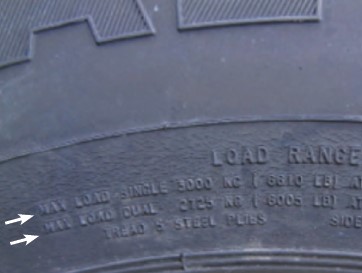

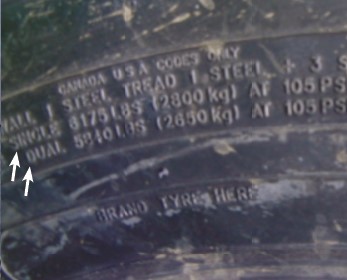

Weight-carrying Capacity

Manufacturers express how much weight a tire can support in four different ways. They can include the:

1. Load index

2. Load range (expressed by a letter)

3. Ply construction

4. Actual maximum load

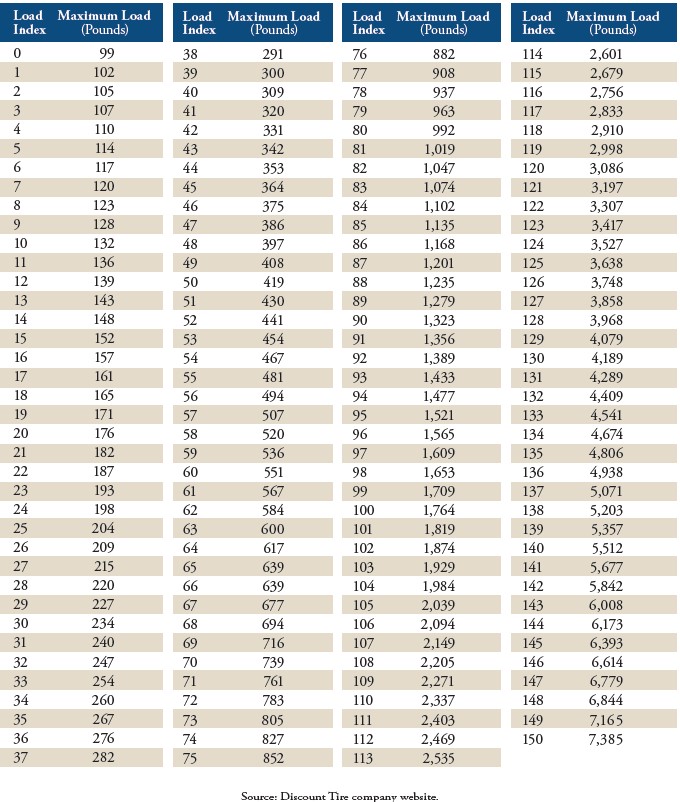

Load Index. The weight a passenger car and light truck tire can support is linked to its load index - the higher the tire’s load index, the greater its load-carrying capacity.

For example, a tire with a load index of 144 can bear up to 6,173 pounds. To understand a load index, you should consult a chart, like the one on the next page.

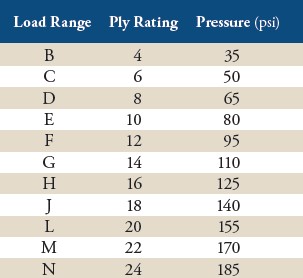

Load Range and Ply Rating. For truck, trailer, and implement tires, the maximum load can be expressed as a single letter. For LT tires, the letters are A through N, but skip I and K. The letters correspond to the old ply system (see below). For these ratings, the higher the letter, the more weight the tire is designed to carry. The more weight it can carry also translates to a higher ply rating. Load range letters replaced ply ratings, because today’s materials can provide higher load ratings with fewer actual plies. For load range ratings A-F, you can calculate a tire’s ply rating by multiplying the letter’s position in the alphabet by 2 (the load range values from J to N don’t exactly match their position in the alphabet because there are no ratings for I and K). For example, E is the fifth letter in the alphabet. That means an E-rated tire is equivalent to an older 10-ply tire. If you have a tire’s ply rating, divide it by two and determine its position in the alphabet. A 14-ply rating would be the seventh letter in the alphabet: G.

Tires with a load range of A (equivalent to 2-ply rating) are for wheelbarrows, lawnmowers, and some ATV tires, not for highway service. Other equivalencies are provided in this table.

A tire with a 16-ply rating is equal to a tire with an H load rating.

The load range lettering system provides important practical information. Tires with the same size and load range letter will carry the same load. If a truck or trailer is “under tired,” then selecting a tire with a larger letter means it could carry more weight.

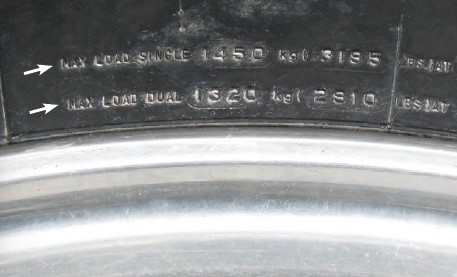

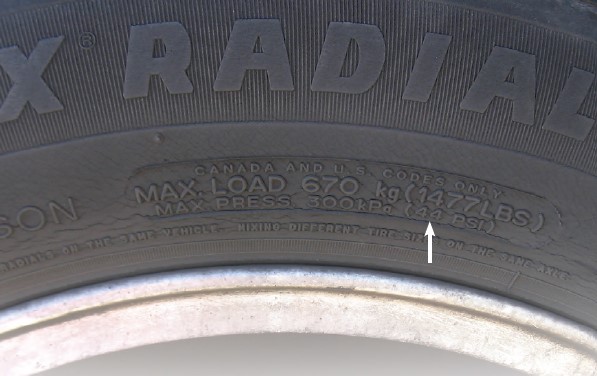

Actual Maximum Load.

Manufacturers often provide the actual maximum load on the sidewall. Sometimes, that information is presented in addition to the load range letter or ply rating. In such cases, it may say something like “Max. Load 990 pounds.” A tire’s maximum load is set at a specific air pressure. If you use a tire at a lower than recommended pressure, you reduce its maximum load limit.

On single-axle trailers, each tire can handle 100 percent of the maximum load weight. For paired tires, the tire’s carrying capacity is reduced due to unequal load sharing. In addition, paired tires cannot dissipate heat as quickly as a single tire because only one side of the tire is exposed to outside air. Heat is (by far) the greatest enemy of any tire.

Another way manufacturers indicate the weight single or dual tires can carry is to provide two load index values. The first value is for single tires and the second number is for dual tires. For example, a tire may have a 120 load index as a single tire and 116 as a dual tire. In such cases, its maximum weights would be 3,100 as a single tire or 2,800 as a dual tire.

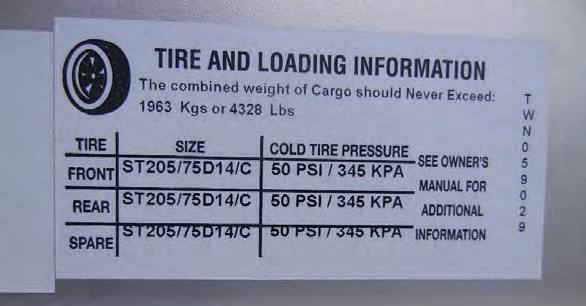

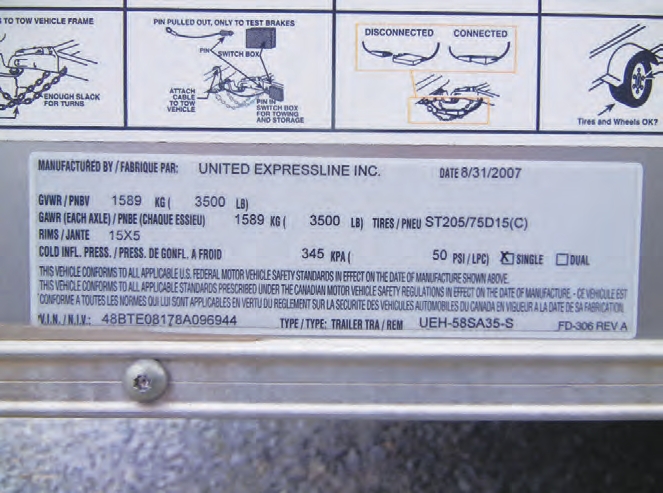

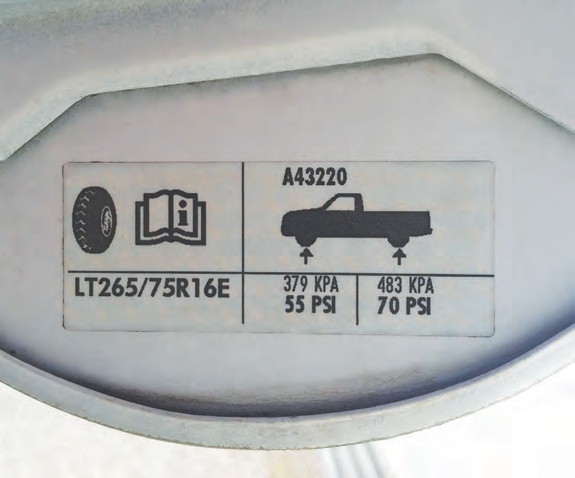

What is the correct inflation pressure? Do not inflate a tire to the maximum pressure

that’s stamped on its sidewall - that’s the maximum inflation for carrying heavy loads. Instead, follow the vehicle manufacturer’s recommendations, commonly found inside the vehicle’s door jam or in the owner’s manual.

What is the correct inflation pressure? Do not inflate a tire to the maximum pressure

that’s stamped on its sidewall - that’s the maximum inflation for carrying heavy loads. Instead, follow the vehicle manufacturer’s recommendations, commonly found inside the vehicle’s door jam or in the owner’s manual.

Speed Rating

While heat is required to construct a tire, heat can also contribute to its structural breakdown. The faster a tire goes, the higher the internal temperatures it must withstand. Tires used on police vehicles or racecars are made with a softer rubber that dissipates heat. The downside is that these soft-rubber tires do not last as long as conventional tires. But when any tire is driven beyond its speed rating, the extra heat can cause major problems, including tire separation. That’s why many tire manufacturers include information about maximum speeds on their tires.

Tires are designed for the anticipated heat they produce. Racecar tires must withstand extreme heat but still need to be changed many times over the course of a long race.

Speed ratings can be indicated with a letter (from A to Y). For example, a tire with an S speed rating has a maximum speed limit of 112 miles per hour. The table to the left provides the maximum speeds for each rating. The 106 before the S is the load index

When you replace tires on vehicles that travel at highway speeds, always buy tires that have equivalent or higher speed ratings, never lower. Going to a lower speed rating will change the vehicle’s handling characteristics. Also, remember that after you repair a speed-rated tire, it will no longer perform at its rated speed.

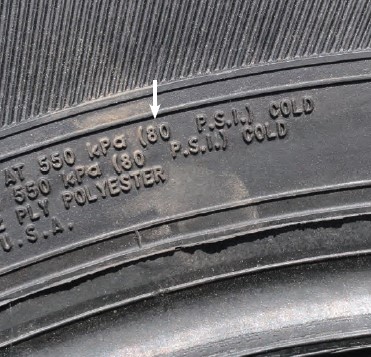

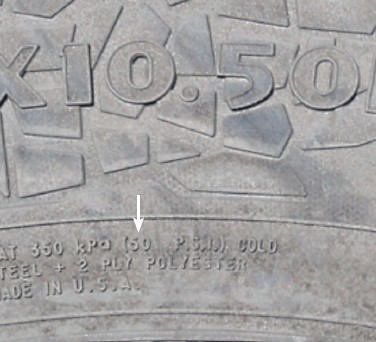

Maximum Pressure

When a tire provides a maximum pressure, that value represents the maximum cold inflation pressure of the tire that corresponds to maximum weights. For more information about tire pressures, see It’s All About Pressure.

Sidewall Construction

A sidewall may offer a general description of the amount and type of materials used to construct that tire. Tires that need to carry more weight and be inflated to higher pressures are reinforced with stronger materials that add to the tire’s overall strength. A stouter tire has more plies.

Uniform Tire Quality Grade

The uniform tire quality grade is a set of three codes that provide limited information about tread wear, tire traction, and temperature limits.

Tread Wear Rating. The tread wear rating is often misunderstood, because the literal interpretation of tread wear is how long a tread will last. However, there are many factors that influence tread wear, so it is important to realize that the tread wear rating does not directly indicate the tread’s lifespan. The types of roads it drives on, individual driving habits, maintenance practices, and loads all influence tread life. No one can tell you for certain how many miles the tread on a particular tire will last.

There are too many variables associated with wear and tear to make any realistic predictions. Unlike the other information on a tire, the tread wear rating is not a regulated standard. The value on the tire is left to the tire manufacturer’s discretion. In other words, comparing tread wear values among different tire manufacturers is not helpful or practical. When a manufacturer assigns tread wear ratings, they are based only on comparisons of their other tires. A manufacturer makes one of its tires a baseline comparison tire, which is given an arbitrary tread wear value of 100. The manufacturer will then compare each of its tires to

this baseline comparison tire.

So if a tire is given a tread wear rating Describe the Tires of 150, that indicates the tread would last 1.5 times longer than the tread on the manufacturer’s baseline comparison tire. If the baseline 100 tire is expected to get 30,000 miles, then the 150 tire is expected to get 45,000 miles. Don’t forget: these ratings are only estimates and that the comparisons are only good for the tires produced by that manufacturer. The number of miles you get out of a set of tires will depend on your driving habits and how well you maintain the tires.

Traction Rating. The traction rating describes how well a tire stops the vehicle when the brakes are quickly applied on wet pavement. The traction rating does not indicate how well a tire corners on a wet surface, ice, snow, or mud. Traction ratings are one of four letter codes: AA, A, B, and C. AA represents the best, straight-ahead stopping potential on wet pavement.

Temperature Rating. The temperature rating measures how well a tire dissipates internal heat while in motion. These letter ratings are based on government regulated standards. The temperature grades are:

| Temperature rating | Maximum Rating Speed (mph) |

| A | more than 115 |

| B | 100-115 |

| C | 85-100 |

The federal government requires that all tires have at least a C rating.

Test 3:

Describe the Tires

You can make the following conclusions a bout these tires:

• The bottom tire has a higher tread wear rating (500 vs. 440). If the same manufacturer made both tires, then the bottom tire ought to outlast the top one if both are used the same way. However, if different manufacturers made these tires, then there is no way to adequately compare tread wear ratings.

• The tires have the same traction rating (A), so their wet, straight-line breaking would be the same.

• The bottom tire has a higher temperature rating (A vs. B), so it will dissipate heat better than the top tire.

Tractor and Implement Specialty Tires

Tractors and self-propelled equipment must have tires that generate traction in soil. Such tires have elevated rubber assemblies (lugs) that help the tire “grab” loose substrate. There are many designs, including some made specifically for forward or reverse applications. However, tractor and implement tires must have the ability to “clean out” for the best performance.

Tractor tires must support the vehicle’s weight and generate traction. Implement tires just need to carry weight.

Tractor tires must support the vehicle’s weight and generate traction. Implement tires just need to carry weight.  A bias tire that is 16.5 inches wide and 16.1 inches in diameter.

A bias tire that is 16.5 inches wide and 16.1 inches in diameter.  Can you figure out what the markings mean?

Can you figure out what the markings mean?  Can you figure out what the markings mean?

Can you figure out what the markings mean?  A high-flotation agricultural field tire that is 73 inches high, 44 inches wide, and fits on a 32-inch rim.

A high-flotation agricultural field tire that is 73 inches high, 44 inches wide, and fits on a 32-inch rim.

A radial agricultural tractor tire that is 800 millimeters wide, has an aspect ratio of 70, and fits on a 38-inch rim.

A radial agricultural tractor tire that is 800 millimeters wide, has an aspect ratio of 70, and fits on a 38-inch rim.  The load determines a tractor tire’s minimum tire pressure. Farmers often want to operate at the lowest pressure possible for maximum flotation and traction, but they often forget to adjust the pressure after they change the load.

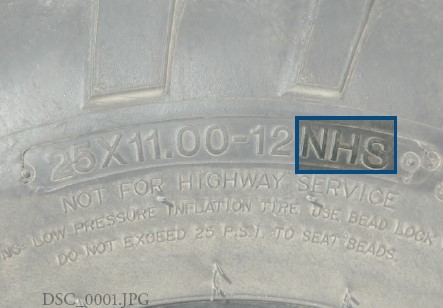

The load determines a tractor tire’s minimum tire pressure. Farmers often want to operate at the lowest pressure possible for maximum flotation and traction, but they often forget to adjust the pressure after they change the load. The markings on tractor and implement tires are different than most other tires. The coding format for implement and tractor tires depends on whether they are bias or radial tires. Other tires have a metric designation, which are a different format.

Bias tire markings provide the width (W - in inches), diameter (D - in inches), and sometimes the height (H - as percentage of the tire). The coding is presented in one of two ways:

1. W-D

2. H x W-D

Metric-marked radial tire markings provide the width (in millimeters), height (in inches), radial, and rim size (in inches). If there is an SL at the end of the stamped number, it means the tire is service limited (that is, speed limited). This would be common on wagon tires, for example.

Some tires have an NHS (non-highway service) designation, meaning they are not to be used on highways. This would be common on skid steer loader tires or tractor tires. Other tires may be marked very clearly that they are not to be used on highways.

A tire might also have a VF (very flexible) designation. These tires can run at lower tire pressures, which allows the tire to put more tread on the ground. More tread helps spread the weight over a larger surface area, which reduces soil compaction. Self-propelled sprayers often use VF tires.

This tractor tire can carry heavier loads at field-working speeds.

This tire indicates the maximum weight it can carry at highway speeds. As speeds increase, the maximum load is reduced.

Maximum highway speeds are listed directly on slow-moving and implement tires. These tires can support heavier weights than other tire types, but their speeds are significantly restricted. Some growers think they can overcome the speed limitations of implement tires by replacing them with tires that have a greater speed rating. While plausible, this is usually a bad idea.

The tire with the greater speed rating can carry the load at faster speeds, but the wagon’s steering components, tongue, and running gear may not be built to operate at increased speeds. Towing a wagon loaded with cargo at high speed may lead to equipment failures and highway crashes. Furthermore, trying to stop this equipment by driving at higher speeds may overheat the brakes on the towing vehicle, which can impair the ability to stop properly. Braking force and power change as the square of speed. Doubling speed requires 4 times the breaking force.

Choosing Replacements

Before choosing replacement tires, see what your vehicle or implement manufacturer recommends. If you expect to purchase the right tire for your equipment, you can’t just say, “I have a farm truck” and hope to get it right. That simply doesn’t provide enough information to properly assess your needs.

Do you use your truck only on a small farm to carry small loads? Or do you use it on a 2,000-acre farm to carry much heavier loads such as 500-gallon poly tanks? This is why you need to have some estimate of the maximum load is before you order replacement tires.

You are the only one who knows for certain how you will use the tires. The more information you can provide, the better. You can end up with the wrong tire if all you tell your tire dealer is, “I want a tire for my truck.” So how do you talk to your tire dealer about replacement tires? Let’s start with selecting passenger car tires, because it’s a simpler process. When selecting a replacement, tell your dealer how you will drive your car, how many people it will carry, and how much weight you’ll put in the cargo space.

For trailers, the most critical question to ask before replacing a tire is: how much weight will the tires carry? Tire dealers want to sell replacement tires that have load ratings that meet or exceed the heaviest loads or the trailers’ gross vehicle weight ratings. Getting the right tire for a trailer starts with knowing the heaviest possible payload the trailer will carry.

Tires for a pickup are another story. For starters, no two people drive a pickup the same way. For that matter, no two people load or pull a trailer with the pickup the same way. Some people use pickups like cars - they never haul or tow anything. Others use pickups as work trucks - they transport supplies and haul equipment in the bed every day. A working truck must have tires that can support the weight of the cargo in the bed, and the weight that is transferred from the trailer to the truck.

Before buying any replacement tires for a trailer or other equipment, know how much weight they will carry.

Before buying any replacement tires for a trailer or other equipment, know how much weight they will carry. Let’s say you use a 3/4-ton truck to pull a horse trailer to county shows over the course of five weekends throughout the year. That pickup will require different tires than a pickup that will haul a 200-gallon diesel fuel tank in the bed and pull a trailer with a 1,000-gallon poly tank of fertilizer. You want the sales representative to ask questions about how you use your vehicle rather than just match the tires you already have. There are significant differences in how people use their trucks and load their trailers. You never want a salesperson to provide you with a tire and price without asking you questions first. You may drive away with new tires, but will those tires last and perform for your needs?

Anybody can sell tires, but a professional salesperson should match tires to the application. Work with a knowledgeable sales representative who is interested in your needs. A salesperson who is too busy or isn’t interested in your needs may not ask the right questions or know the right ones to ask. When a tire sales representative does ask you questions, be prepared to answer the nine questions that follow. Your answers to these questions - along with prices, brand preferences, recommendations from friends, past experiences, trade magazines, media reports, and consumer advocacy ratings - should be used to select the tires that best fit your operation. By doing a little homework, you can save hundreds (if not thousands) of dollars in the long run and can save you trouble by buying the right tire the first time. Before buying any replacement tires for a trailer or other equipment, know how much weight they will carry.

1.What Kind of Vehicle Do You Have?

Make sure the tire representative looks at your vehicle’s tires and wheels. If you are not the original owner, the previous owner may have changed them. Make sure the tire representative looks at all the tires to ensure they are appropriately matched and rated.

2. How Do You Use the Vehicle?

You must be able to explain how you use the vehicle in your operation. Do you use it only to commute to work? Is it a full-time work truck? Does it stay on the highway, or do you take it off-road from time-to-time?

3. What Will You Haul in the Bed and How Much Will it Weigh?

How much weight a tire will carry is one of the most critical (but overlooked) considerations when purchasing tires. Many people never take the time to pull their heaviest loads across the scales to weigh them. In most cases, users significantly underestimate their load weights.

4. What Will the Truck Tow?

Will you use the truck to pull a trailer or implement? If so, then you must account for the tongue weight on the back tires when you consider tire ratings.

5. What Kind of Drive System Do You Have?

Does the vehicle have a 2-wheel drive, 4-wheel drive, single or dual axle? All

factors are important when selecting tires.

6. How Much Weight Will Be Over the Tires?

If the tire will be used on farm equipment, how much weight will the tractor or implement have to support over the tires?

7. Has Residue Damaged Your Tractor Tires?

Field residue can damage or wear tires. One tire manufacturer indicates that corn, bean, and cotton stalks have a hardness of 80 to 95 as measured on a hardness scale (or durometer). If the tread hardness is rated lower (say at 65 to 70) tread damage from stubble may be an issue. Make sure to read whether your tire warranty covers stubble damage. Many tire manufacturers are investigating other ways to prevent stubble damage.

These photos show how soybean and corn stubble can pit the rubber of farm tractor tires.

8. Is Soil Compaction Important?

If you need to avoid compacting soil, consider VF/IF (increased flexion) tires. These tires allow sidewalls to bend more, which allows lower inflation pressures and creates less compaction. It has been suggested that VF/IF tires can create a footprint that is 22 percent larger than standard radials. Spending a little more money up front for the right tires can pay for itself in as few as one or two seasons because of increased yields resulting from less compaction.

9. How Fast Will You Travel on the Highway?

While there are not many choices, some tires may allow you to go a little faster on the highway. Make sure your tires accommodate your speeds.

Something to Think About

Many farm tractor and application equipment tires are in short supply. Consequently, manufacturers are telling us that some tires have not had the proper time to cure and harden that they used to have in times past.

One retailer started a program to keep most of his tires in a “tire bank” for at least year before mounting them on equipment. He’s established a tire bank to draw from. The retailer believes this practice gives tires the time they need to cure properly.

Tires on New Equipment

Just because a tire is mounted on new equipment, that doesn’t mean the tire is right for your operation. When you purchase new equipment, always evaluate the tires before you drive them off the lot. Look closely at the tire ratings and determine if they will perform the job you need them to.

For the most part, manufacturers do a good job of matching tires to their equipment. When you purchase tires, consider how you will use it. For example, let’s say you are purchasing a trailer that will haul any of these:

• A riding lawnmower

• A 2,000-gallon liquid fertilizer tank

• A 4,000-pound pesticide minibulk container

• An 8,000-pound skid steer

The main question with any new truck, trailer, or implement is how will your driving, towing, and hauling differ from the average person buying the same piece of equipment? The answer to this question will determine whether the truck or trailer has the right tires to get the job done. In some cases, the standard tires that come with the new equipment may not be strong enough to do the job you expect them to do.

Breaking In a New Tire

Tire manufacturers provide specific instructions about how to break-in new tires. Always follow their instructions. In general, tires require special treatment during the first 500 miles of highway use. During the break-in period, drivers should accelerate slower, take corners wider, and brake more gradually. It’s also important for drivers to remember that new tires may also have different reaction times and handling characteristics than the tires they replaced.

Warranties and Registrations

Each time you buy a tire, you will be asked to send in a registration card. Often, tire dealers send the registration information to the manufacturers on your behalf.

Registering your tires is important. The manufacturer adds your name and the specific purchase to their database. In the event there is a recall, the manufacturer can inform you directly about the recall or help you resolve issues while on the road away from home.

Every tire manufacturer has a warranty to cover its tires. A warranty typically states that if a tire malfunctions due to a defect, the tire may be replaced at no cost or at a pro-rated cost. Warranties are based on a number of years and mileage. For example, a tire might have a 5-year/40,000 mile tread life/mileage warranty.

Let’s assume you purchase a 60,000-mile tire, and only get 40,000 miles on it before it wears out. Manufacturers typically pro-rate their tires in these situations. Provided you have properly maintained the tire as the manufacturer specified (by maintaining proper air pressure, rotation, etc.), then the manufacturer would issue a credit for 20,000 miles, which would be one-third of the cost of a new tire.

A warranty is usually only valid for the original purchaser of the tire, and for the vehicle that the tires were mounted on. When you file a warranty claim, you will need the original bill of sale, the date the tires were installed, and the number of miles on the vehicle — so keep receipts and records! The number of miles a warranty covers is important. A tire with a 60,000- mile warranty might cost 20 percent more than one with 40,000-mile warranty, but it would increase the number of miles by 33 percent. The additional 20 percent purchase cost can be justified based on the extra miles the warranty covers.

Tire dealers commonly offer extended warranties and “full” coverage for tires they sell. Some guarantee that the tire will be fixed or replaced regardless of the reason. These extended warranties are basically insurance

policies — you pay an additional premium for the extended coverage. Before you buy any extended warranty, analyze the use and driving habits of all who drive the vehicle. A truck that is driven to construction sites every day would be a better fit for a road hazard warranty than a city commuter. Having two or three flat tires repaired would definitely make it worth the money.

It’s All About Pressure

Maintaining proper tire pressure is one of the least appreciated factors in tire performance and longevity. TireRack.com and other industry websites suggest that a tire underinflated by 6 psi could lose as much as 25 percent of its tread life and could increase fuel consumption by as much as 5 percent.

National Traffic Highway Safety Administration studies indicate that underinflated tires are the leading cause of tire-related crashes in this country. Unfortunately, it is impossible to look at a tire and tell if it’s underinflated by 6 psi. Fortunately, it only requires a little time and an inexpensive pressure gauge to assure the pressure is correct.

With any equipment you own, you want the tires to operate as they were designed.

Pressure affects the tire’s cornering, stability, braking, traction, comfort, fuel economy, and durability. Having too much or too little air in a tire is like throwing money out the window while you drive down the highway. A properly inflated tire ensures that the contact with the road and sidewall flexing are within engineering specifications. With too little pressure, a tire will flatten out; with too much pressure, there is not enough rubber on the road.

Underinflating a tire lowers its profile, meaning more rubber is placed on the road. From a handling perspective, underinflated tires “squirm” and feel loose. A symptom of running underinflated tires is that the outer edges of the tread become worn. Less air in the tire allows the tread on the outside edges to push down, which forces the center of the tread to cup inward. This places more weight on the tire’s

outer edges relative to the tread in the middle.

Not only do underinflated tires wear unevenly and handle poorly, they conduct more heat because more rubber is put on the highway. That generates more friction, which means rising internal temperatures that can lead to tread separation.

While underinflated tires are the more common concern, overinflated tires can lead to tire handling and wear problems, too. Overinflation reduces a tire’s grip on the road. Also, they can create safety concerns.

Overinflated tires can cause a trailer to wander or “fish tail.” A tire that is overinflated by 6 psi can become a danger when encountering potholes and highway debris. Too much air pressure makes the sidewall stiffer,

which allows less deflection when running into or over objects. When an overinflated tire hits a pothole, railroad track, or other object, it won’t require as much force to knock the bead off the rim or blow out the sidewall.

Overinflation affects tire wear in two ways. First, an overinflated tire tends to bounce more. Every time a tire bounces off the pavement and then reconnects with the road, the tread loses a small amount of rubber at the contact point. This causes uneven wear on the tire. Second, an overinflated tire will show more wear on the center of the tread - the opposite of what you see on an underinflated tire. A tire with too much air pressure forces more tread from the tire’s center to make contact with the road (instead of distributing the weight across the whole surface of the tread).

An overinflated tire wears more in the center of the tread.

Checking Air Pressures

Rubber is porous. While manufacturers alter the physical and chemical properties of rubber to be less porous, tires can lose 1 or 2 psi per month under normal operating conditions. A tire can also lose air if it has an improperly seated bead that doesn’t fit tightly against the rim. Valve stems can also slowly leak as the rubber ages or through the valve’s internal screw if it loosens slightly.

Investing in a high-quality air gauge provides substantial dividends: tires last longer and handle better.

Unless it’s flat, it’s impossible to determine how much air pressure is in a tire just by looking at it. Most tire dealers suggest checking the air pressure:

• Once a month

• In late fall or early winter when temperatures drop and again in early spring when temperatures rise

• Before an extended trip (don’t forget to check the spare tire)

• When placing a heavy load on a trailer or truck

Air is a gas that compresses when it is cooler and expands when it is warmer. In fact, for every 10-degree (Fahrenheit) change in outside temperature, tire pressures can change 1 psi. As temperatures drop in late fall or early winter, tire pressures drop as the air compresses. If the vehicle has a tire pressure monitoring system, this can trigger a warning light or sensor to indicate that the tires have low air pressure.

The best time to check air pressure is when the vehicle or tire has been sitting overnight. It is also good to check tire pressures when the vehicle has been idle for a few hours or driven for just a few miles.

The user of this wheel marked his lug nuts. If they happen to loosen during normal use, he will notice because the marks won’t line up anymore.

Avoid reducing tire pressure after driving a long time. The air in the tire will have expanded due to heat, which increases the tire pressure. As the tire cools, the pressure will drop. Checking and reducing the pressure in heated tires could result in significantly underinflated tires.

If you must adjust the pressure of a warm tire, inflate it about 4 psi more than the cold inflation pressure, and then check the tire’s air pressure after it has sat overnight. Check the pressure in all tires, including the spare. It won’t do much good if you have to replace a flat tire and the spare you have is low on air - or worse, flat.

These tires have cold pressure ratings of 65 psi

These tires have cold pressure ratings of 65 psi  These tires have cold pressure ratings of 80 psi

These tires have cold pressure ratings of 80 psi  These tires have cold pressure ratings of 100 psi

These tires have cold pressure ratings of 100 psi  These tires have cold pressure ratings of 50 psi

These tires have cold pressure ratings of 50 psi Finding and Using the Correct Pressure

A common mistake is to adjust a tire’s pressure based on the pressure rating listed on the sidewall. The number on the sidewall is actually the maximum air pressure the tire was designed to hold based on the load it can support. Never adjust trailer or truck tire pressures to the maximum rating unless you’re also carrying its maximum load. If you inflate to the maximum pressure, the vehicle will have a rougher ride and the tire will wear more quickly.

Base actual tire pressures on vehicle manufacturer recommendations. These pressure recommendations are found on a sticker placed on the inside of the driver’s door or in the owner’s manual. The vehicle manufacturer’s recommendations account for the vehicle’s weight, number of passengers that can be transported, and typical loads carried in the truck bed or car trunk.

Rear back tires may require more air pressure to accommodate heavier loads.

Always read the vehicle or equipment manufacturer’s tags carefully, because there are cases when the front and rear tires have different pressure settings. For instance, the back tires of a truck, trailer, or implement may require higher pressures than the front to help accommodate the extra weight in the bed or of a trailer.

The Nitrogen Controversy

There’s an ongoing argument about the merits of paying for nitrogen to fill tires. However, both sides in this dispute agree that regularly checking tire pressure is far more important than whether you use air or nitrogen to inflate them.

Never Underestimate the Power of Compressed Air

Putting air in a tire is easy, right? You simply hook the air chuck from the compressor to the valve stem and begin inflating. You’ve done it countless times. It’s no big deal. But it doesn’t always turn out they way you expect, as this example demonstrates. A farmer needed to inflate the front right tire on this wagon before he could move it (arrow, top photo). The only way to get to the tire was to slide himself between the wagon and the stall divider.

This put his face right next to the tire. The last thing he remembered was seeing the pressure gauge register 15 psi. The next thing he heard was a loud boom followed by dirt, dust, and rocks thrown into his face. He had no idea that the tire he was inflating had rotted on the bottom from sitting on the ground. As the tire filled with air, the rubber gave way and all the dirt and rocks on the ground were blown into his eyes. In a matter of minutes he was injured and blinded. He was rushed to the optometrist and given emergency treatment. The farmer was lucky he was wearing his glasses. Without them, he might have lost his eyesight. Wearing safety glasses when airing up old tires is a precaution to consider. It might just save your eyes.

Balancing, Rotating, and Aligning

While tire pressure is important to maintain even tread wear and maximize performance, tire balance, tire rotation, and wheel alignment also influence and extend the useful life of tires.

Tire Rotation

Rotating tires on front-wheel drive vehicles is critical. The steer tires of front-wheel drive vehicles constantly twist and turn. They also have to carry the weight of the engine and transmission, which are usually positioned over the front axle. That

extra weight and motion causes the front tires to wear faster than the rear ones.

With more weight on the front of the vehicle, the rear of the vehicle will obviously be lighter. A lighter back end can cause tires to bounce, creating flat spots in the tread. You may not ever feel the tires constant bouncing because the jolts may be absorbed by the shocks, struts, and suspension systems. The purpose of rotating tires is to have each tire experience wear from both the front and back positions. By rotating tires from one position to another, you will help them wear more uniformly over time. It will also ensure that all the tires on the vehicle will need to be replaced about the same time, instead of having to replace one or two prematurely due to excessive or abnormal wear.

Tire manufacturers recommend rotating tires every 4,000 to 5,000 miles. Constant tire rotation is no different than changing the oil in your car - if you want uniform tire wear and longer life, rotate them on schedule. Many drivers rotate the tires on their vehicles with every oil change since the mileage recommendations are about the same as changing the oil - it just makes sense to do them at the same time. If an uneven wear pattern becomes excessive, it is too late to rotate.

There are several rotation schemes to move tires from one position to another. Consult your vehicle owner’s manual. The Tire and Rim Association suggests these methods:

• On a front-wheel drive vehicle, move the front tires straight back, and then place the back tires in front on the opposite sides of the vehicle.

• On four-wheel and rear-drive vehicles, move the back tires straight to the front, and then place the front tires in back on the opposite sides of the vehicle.

• The X-pattern for rotation takes the front left tire to the right rear, and the right front tire to the left rear.

Another possibility is to employ a five-tire rotation. This is usually done when the spare tire is the same as those on the vehicle. In a five-tire rotation, you start with taking the spare off the rack and placing it on the right rear position each time you rotate the tires, and then follow one of the rotations above. The tire that would be placed in the right rear position becomes the spare.

Dual-wheel vehicles can be challenging and have unique tire rotation recommendations. Some experts suggest moving the inside tire on the rear axle to the front axle position on the same side. What was the

outside tire on the rear will replace the inside tire, and the front tire will take the outside position of the dual. Others suggest swapping the two tires on the front with one another, and doing the same for the back duals.

Wheel Alignment and Measuring Angles

The purpose of keeping the vehicle in alignment is to make sure the tires don’t receive excessive wear from something other than air pressure - for example, from leaning to the right or left. Proper alignment also maintains steering and braking performance. A properly aligned vehicle can drive straight on a level road without pulling to one side or the other. If you have ever experienced a vehicle that constantly pulls to the right or left on a level road, then you probably have experienced a vehicle that is out of alignment. A visual inspection of the tires can show evidence of a vehicle that is out of alignment. When a vehicle is pulling to one side or the other you may notice one edge of the tire has a deeper tread than the other side.

Adjusting the alignment of a vehicle requires special equipment that measures and sets the appropriate angles established by the vehicle manufacturer. Depending on the car or truck model, alignments can consist of three adjustable steps known as:

1. Camber

2. Toe-in

3. Caster

On some vehicles, adjusting the caster and camber are no longer required or even possible.

Setting the Camber. This adjustment is a measure of the tire’s vertical axis to see if the tire is straight up and down. If the tire leans out (positive camber), its outside edge will wear quicker. If the tire leans in (negative camber), its inside edge wears quicker.

Setting the Toe-in. This adjustment makes sure the tire is pointing straight ahead. “Toe-in” means that the front and center of the tire is pointed toward the center of the vehicle. “Toe-out” means the center of the tire is pointed out and away from the vehicle.

Setting the Caster. This adjustment has more to do with the steering mechanism than tire wear. Setting the caster means that when you have completed right and left turns, the vehicle will bring itself back straight.

Replacing, Repairing, Recycling, and Retreading

Paying for new tires, losing income from a truck or trailer sitting idle with a blown tire, or paying legal fees for an accident caused by faulty tires are just a few reasons why it is worth your time and expense to check air pressures and rotate tires.

But even the best-maintained tires eventually wear out and need to be replaced. One of the first indications that you need to replace a tire is the depth of its tread. New tires have treads that are 11/32 to 14/32 inch deep.

A tread reduced to 2/32 inch needs to be replaced. Each tire has a wear bar in the tread area that is set at the 2-32-inch mark. When the tread is lower than the wear bar, you need to take replace the tire right away. One way to measure tread depth is to use a tread gauge, which should be standard equipment on every vehicle (along with a tire pressure gauge).

Arrows point to wear bars.

You can also use a penny to measure tread depth. Insert the penny into the grooves that appear to be shallow. If the tread covers any part of Lincoln’s head, you have at least 2/32 inch of tread depth. If you drive a DOT-regulated vehicle, you need more than 2/32 inch of tread. Federal Department of Transportation (DOT) regulations indicate that steer tires on DOT-regulated vehicles must have a tread that is at least 4/32 inch deep. A quick reference for 4/32 inch is to use a quarter instead of a penny - if the tread covers any part of Washington’s head, then you have 4/32 inch or more of tread depth. But tread depth is only one to consider when deciding whether to replace a used tire. A tire can have plenty of tread left, but its age can become an issue.

Check tires for signs of aging, especially on equipment that you use infrequently.

Check tires for signs of aging, especially on equipment that you use infrequently. Sunlight, heat, and ozone can damage tires. Just like rubber hoses, sunlight can dry out rubber. Over time, the rubber experiences dry rot on the sidewalls. As the rubber continues to break down, the steel inside the tire is exposed to moisture and salts, which weaken the underlying reinforcement materials. Unlike the hard-and-fast tread depth criteria, there is no firm guideline for how old is too old for a tire. A rule of thumb is that you should replace any tire that was manufactured more than eight years ago, but always check with the manufacturer. You can tell how old a tire is by looking at the DOT identification on the tire. The last four digits tell when the tire was manufactured - the first two numbers are the week (1-52) and the last two numbers are the year. For example, 1013 is the tenth week of 2013 (early March).

Truck and trailer tires routinely carry heavier loads, so some experts suggest replacing them every three to five years. The reason is that tires can lose up to one-third of their strength during that time due to the excessive heat generated by continually carrying heavy loads. So changing those tires every four years may be more important than the tire’s tread depth or appearance.

This tire was made during week 50 of 2007.

This tire was made during week 50 of 2007.  This tire was made during week 42 of 2011.

This tire was made during week 42 of 2011.  Equipment can sit unused for months. While this tire may have plenty of tread, sunlight can degrade the rubber. Check tires and inflation pressures before putting equipment back on the road.

Equipment can sit unused for months. While this tire may have plenty of tread, sunlight can degrade the rubber. Check tires and inflation pressures before putting equipment back on the road.  Always replace dual tires in pairs. This keeps loads equal on each tire. A worn tire has a smaller circumference and height than a new tire.

Always replace dual tires in pairs. This keeps loads equal on each tire. A worn tire has a smaller circumference and height than a new tire. Repairs

Many tires with punctures in the tread (not the sidewall) can be repaired with confidence as long as the hole or damage is less than 1/4 inch. However, exercise good judgment. If a punctured tire has a tread that is at or near 2/32 inch (or is otherwise nearing the end of active life), then you should recycle rather than repair it. The correct method for repairing small punctures in tubeless tires is to put a plug in the puncture and apply a patch - both from inside the tire. A major advantage of applying the patch inside the tire is that it can be inspected for secondary damage. With so much at stake, you want to be certain the tire is plugged and patched, not just one or the other. Sidewall damage cannot be repaired. Once the strength capability of the tire has been compromised, it can’t be restored.

This photo shows a tire puncture.

This photo shows a tire puncture.  The photo demonstrate installing a patch and plug at the same time.

The photo demonstrate installing a patch and plug at the same time.  The photo demonstrate installing a patch and plug at the same time.

The photo demonstrate installing a patch and plug at the same time.  The photo demonstrate installing a patch and plug at the same time.

The photo demonstrate installing a patch and plug at the same time.  The photo demonstrate installing a patch and plug at the same time.

The photo demonstrate installing a patch and plug at the same time.  When you can see cords in the sidewall, then you know the tire needs replacing. Sidewalls with this kind of damage are beyond repair.

When you can see cords in the sidewall, then you know the tire needs replacing. Sidewalls with this kind of damage are beyond repair.  When you can see cords in the sidewall, then you know the tire needs replacing. Sidewalls with this kind of damage are beyond repair.

When you can see cords in the sidewall, then you know the tire needs replacing. Sidewalls with this kind of damage are beyond repair.  When you can see cords in the sidewall, then you know the tire needs replacing. Sidewalls with this kind of damage are beyond repair.

When you can see cords in the sidewall, then you know the tire needs replacing. Sidewalls with this kind of damage are beyond repair.  Sidewall damage can be difficult to assess.

Sidewall damage can be difficult to assess.  Sidewall damage can be difficult to assess. This tire has surface damage only, which

is not serious.

Sidewall damage can be difficult to assess. This tire has surface damage only, which

is not serious.  The tire shows wear, but it is only cosmetic. The thing to consider here may be the age of the tires rather than their wear or treads.

The tire shows wear, but it is only cosmetic. The thing to consider here may be the age of the tires rather than their wear or treads.  The tire shows wear, but it is only cosmetic. The thing to consider here may be the age of the tires rather than their wear or treads.

The tire shows wear, but it is only cosmetic. The thing to consider here may be the age of the tires rather than their wear or treads.  The cap is coming off this retread.

The cap is coming off this retread.  The inner tread areas have dry rot, which will affect the tire’s overall integrity. Dry rot is a common problem on equipment that has very specific uses. The equipment is used just a few times per year, so the tires never wear out, but they will crack from age and rot.

The inner tread areas have dry rot, which will affect the tire’s overall integrity. Dry rot is a common problem on equipment that has very specific uses. The equipment is used just a few times per year, so the tires never wear out, but they will crack from age and rot. Tire Retreads

A retread tire is one that has a new layer of tread placed over the original tire’s core or casing. A retread tire is not necessarily inferior to a new one. The quality of a retread depends on the retreading process that is used, the age of the casing, the tire’s original construction, and how many repairs have been made to it. Because a retread uses the same casing, the carrying capacity remains the same as the original tire.

Many people believe retreads are not as safe as new tires. Perhaps they believe so because they assume that most of the discarded treads they see along the highway originated from retreaded tires. Studies have shown that less than half the tire remnants found along roadsides are from retread tires (John Woodrooffe and Oliver Page, Roadside Alligators and the UMTRI Tire Debris Survey, 2008). The evidence shows that most of the tire remnants you see along the road came from tires that were running at pressures that were too low for the weights they were carrying — whether a tire was an original or a retread. Retreads may not be a viable option for some, but the lower cost of retread tires is very attractive for others.

When a Tire Fails

If a tire fails while you’re driving, you may hear a loud noise, feel a sudden vibration, or have the vehicle suddenly pull to one side. When a tire fails, try to maintain your speed until you can gain control of the vehicle.

Do not slam on your brakes; instead, take your foot off the accelerator and come to a gradual stop. As the vehicle slows down, look for a safe place to pull over, and get as far off the road or shoulder as possible. Next, consider whether you are going to replace the flat tire yourself or will pay for roadside assistance. You may even have insurance for events like this. If you change the flat yourself, make sure the vehicle is on solid and level ground. Turn your warning lights on, and set reflective triangles on the side of the road (if you have them). Pay attention to traffic, especially if the wheel is on the same side of the vehicle as the road.

Several manufacturers offer aerosol cans that have material in them that will stop small leaks and add air to the tire at the same time. These products (such as Fix-A-Flat®) are an alternative to changing a flat on the road, but be sure to match the product with the size of tire that you have. Remember: only use these products in an emergency and as a temporary fix. You still need to get the tire properly repaired or replaced. After you use one of these products, it’s a good idea to stop at the nearest service center to check the air pressure. When you repair or replace a tire treated with an aerosol product, tell the mechanic which one you used. Some aerosols may be flammable and could injure the person who repairs it. Other products require mechanics to clean the product from the tire’s interior.

A separated steel belt caused the bubble in this tire. The bubble could be a defect, or it could have been caused by hitting a solid object that damaged the steel belt or inner liner and allowed air to migrate into the body of the tire.

Tire Disposal

Disposing of tires properly is important. It is easy to leave them with your dealer when you have them replaced. Tire dealers arrange for most tires to be picked up and recycled into consumer products. Recycling tires makes good environmental sense considering how many tires are replaced annually. It’s not a good idea to keep old tires lying around. Water accumulates in tires that are stockpiled around buildings. These water-filled tires become breeding sites for mosquitoes that are a nuisance and carry disease. Recycling old tires takes them out of the landfills where they take up space, and allows the rubber to be reused.

DOT Regulations

The United States Department of Transportation (DOT) has some regulatory inspection power regarding tires. State officers can inspect tires as part of routine vehicle inspections. Officers will examine tires to see if they might have contributed to an accident.

DOT regulations state:

• A tire cannot be used if the poly or belt material is exposed on the tread or sidewall.

• The tread depth on the front wheels of a bus, truck, or tractor-trailer must be at least 4/32 inch. For all other tires, the minimum tread depth is 2/32 inch.

• Tires cannot carry more weight than what the sidewall allows.

• Tires shall not be operated below the cold inflation pressure that is specified for the load being carried on the road.

The tire belt material is exposed on the tread or sidewall.

The tire belt material is exposed on the tread or sidewall.

Legal and Civil Liabilities

All owners, operators, and fleet managers are obligated to put safe vehicles, trailers, and agricultural implements on the highway. A blown tire that injures someone or leads to environmental contamination can lead to serious insurance claims and liability repercussions. Running on bald, underinflated, or mismatched tires can lead to serious accidents, which can lead to civil and criminal charges against the driver, farmer, or business owner.

If someone is killed, investigators will examine all aspects of the crash, including tires and rims. A vehicle using a tire marked “Temporary Use” for everyday use will create a serious and significant liability if it is involved in an accident. When prosecutors can link a crash fatality to a bad tire, it can be a slam-dunk case. Why risk injuring someone and being legally responsible in court?

Continuing to drive a trailer or truck with wheels in poor condition (such as missing lug nuts) can lead to criminal and civil charges against the driver for knowingly continuing to drive a vehicle or pull a trailer with serious defects.

Worn tires, underinflated tires, missing lug nuts, or extra heavy loads can cause a tire to fail. Having all of them together on the same tire guarantees a disaster - it’s not a question of if this tire will fail, but when.

Conclusion

You usually don’t have to drive very far along the highway to find tire remnants. We usually don’t give the rubbish a second thought. But what happened to those tires for them to end up as litter on the highway? Were they underinflated, overloaded, bald, mismatched, or just worn out?

However, we do take notice when our own tires go flat or tread separations cause our equipment to stop. Whatever plans or appointments you had must wait until you can repair or replace the damaged tire. And it’s more than just inconvenient if that blown tire caused a crash — especially if someone is killed. Most of us have read, heard about, or seen accidents caused after a driver lost control of a vehicle after a tire separation. And if you think about it, all that’s between you and the person in front, back, or to the side of you are the tires.

We expect tires to stop quickly, deal with inclement weather, and often carry heavy loads. Tires will meet our expectations as long as we follow a few simple rules: buy tires that meet your needs, keep the tires inflated, keep them balanced and rotated, and replace them when needed. Doing these few simple things will protect your investment, help prevent crashes, and keep everyone around you safer. Knowing how to read tire specifications allows you to compare products that are similar in construction and design. These are important factors to consider about tires that go beyond price, appearance, or warranty. Before you select or buy your next set of truck, trailer, or implement tires, know how you will use the tires, what weights they will carry, and on what types of roads they travel.

Our goal is that you have learned enough about tires to work with your sales professional to select the best tires for your needs.