Calibrating For A Liquid Termiticide Application

Authors

Fred Whitford, Director, Purdue Pesticide Programs

Scott Robbins, Technical Services Manager, Action Pest Control

Aaron Kreider, Pesticide Investigator, Office of Indiana State Chemist

John Obermeyer, IPM Specialist, Purdue University

Kevin Leigh Smith, Continuing Lecturer and Communication Specialist, Purdue Agricultural Sciences Education and Communication

Table of Contents

Introduction 4

Advances in Termite Control Products 6

USDA Evaluation of Termiticides 8

A Professional Trade 10

Know and Understand the Label 13

A Graph To Determine Total Gallons of Solution Needed 15

Know the Equipment’s Gallons per Minute 15

Getting the Right Amount of Termiticide Mixed And Recirculated in the Tank 18

Get the Right Coverage 19

Complete Paperwork and Document Unusual Circumstances 22

Regulations to Remember 24

Conclusion 26

Acknowledgments 27

Disclaimer 27

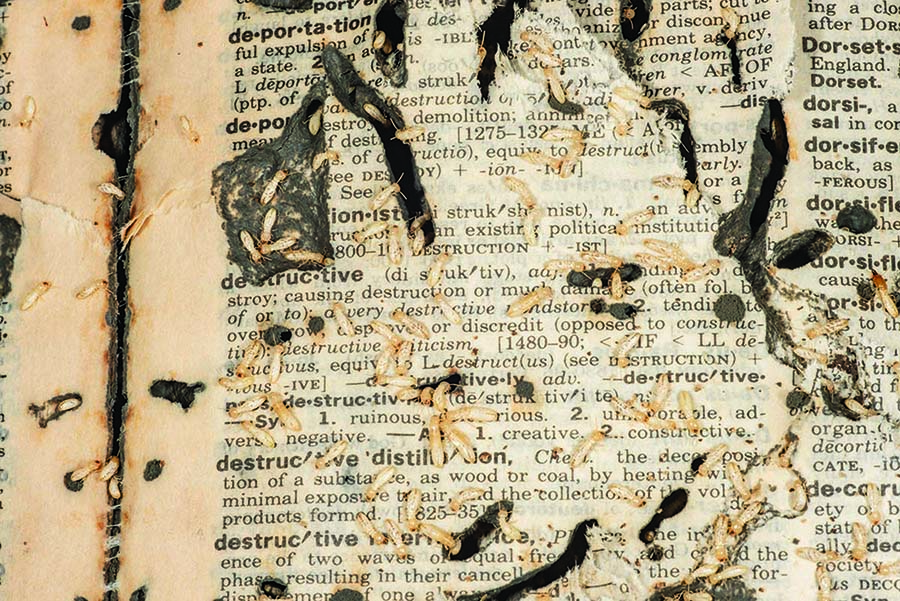

INTRODUCTION

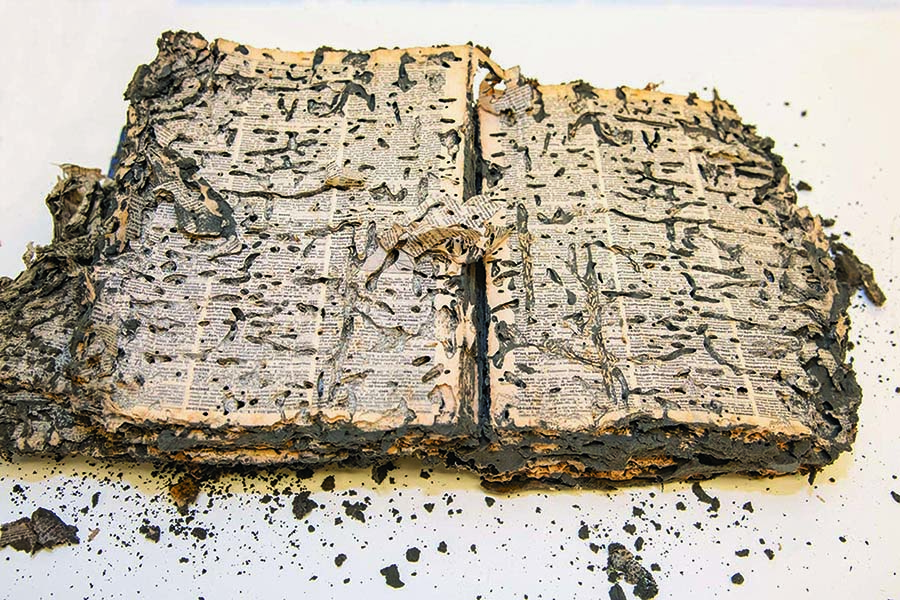

Pesticides can protect crop yields from plant pests, human health from mosquito-borne diseases, and pond ecosystems from the further spread of invasive weeds. One often overlooked (but important) benefit of pesticides is that they protect structures from the destruction caused by termites. Termites are necessary to any forested ecosystem. They break down dead plant material, which allows other organisms (including plants) to use the nutrients and mulch termites produce. So, they are, by far, beneficial insects. But as people began to build permanent wooden shelters, termites continued to seek this “dead” wood for nesting. Once they invade our habitats and establish, they become pests and need to be dealt with. Termites can cause a considerable amount of structural damage to a building before they are detected. Hidden damage under the floor boards, inside the framing of interior walls, or in the crawlspace can go undetected for years. By the time termites are “discovered” in a structure, the resident can become distraught and worried that the value of their home has been compromised.

This raises additional concerns about the financial cost: What will it cost to treat for termites? Will any repairs be required to maintain structural integrity? What will it cost to make structural repairs? The word “structure” does not truly cover what we are actually protecting when we get a call from a customer who suspects they have termites or uncovered termite damage. For many people, a home is the largest financial investment they will make in their lifetimes.

Beyond protecting their financial investment, there are other, equally important, reasons why people’s homes mean so much to them. Remember that the structure you are being paid to protect is someone’s home — the place they grew up, raised their children, earned a living from their home-based business, cared for their senior parents, and enjoyed retirement. Because of these emotional ties, homes represent much more than the concrete, wood, and metal from which they are built. Homeowners turn to pest management professionals (PMP) to rid these uninvited and unwanted insects from their homes. Why is this a job for a PMP and not a do-it-yourselfer? Most people realize they do not have the skill set, experience, products, or application equipment that professionals have access to for controlling termite infestations. Termite treatments done well the first time offer peace-of-mind to homeowners that the first part of their problem is solved — that is, the termites are no longer in the home. A job well done lessens the potential of a reinfestation that would require additional treatments or possibly a damage claim from an unhappy customer. This publication describes the process for calibrating termite application equipment, so applicators apply the correct concentrations and volumes to structures based on product label instructions. This process is crucial for doing the job right and keeping customers happy and safe. By supplementing initial certification training with on-the-job experience, pest control operators can control termite infestations.

When termites infest an area, they may build mud tubes to protect themselves and avoid desiccation. Surface mud tubes are not always present in areas where termites are active.

Advances in Termite Control Products

Termiticides are a class of insecticides that have been proven to control termites. Termiticides and their application technologies have evolved over the past two decades to not only enhance control, but to provide greater flexibility, reliability, efficacy, and long-term protection.

In the past, the pest control industry relied on termiticides that repelled termites. This mode of action required applicators to place a chemical “envelope” under and around the structure. This strategy relied on a triple-barrier protection — applying termiticide inside the foundation; along the sides of the exterior foundation; and into block voids, porches, and abutting slabs after drilling into them. That triple-barrier prevented termites access to the structure.

More recently, nonrepellent termiticides have been introduced. These slow-acting products take advantage of termites’ foraging, grooming, and food-sharing habits to spread the termiticide’s active ingredient throughout the colony. These nonrepellent termiticides provided the industry with flexibility on how treatments are made. With these products, professional applicators can focus more on complete exterior perimeter treatments and spot treatments around areas of termite activity within the structure. Nonrepellent termiticides allowed less invasive (and thus, integrated pest management) approaches to termite control to expand. Having multiple approaches and products to control this pest benefits the industry as a whole, but it requires applicators’ commitment to continued education and attention to details.

USDA Evaluation of Termiticides

Unlike other pesticides, termiticides have to undergo significant efficacy testing and validation by a third-party government agency: the United States Department of Agriculture-Forest Service. The USDA has termiticide testing facilities in Mississippi, Arizona, Florida, and South Carolina. These multiple sites introduce environmental variations among the testing sites to allow USDA scientists to evaluate whether a termiticide’s effectiveness varies across geographical areas. For federal registration, the Environmental Protection Agency (EPA) requires termiticides to remain effective for a minimum of five years while not harming human health and the environment. Only then will the termiticide be granted an EPA registration number, which allows the manufacturer to begin marketing the product.

These photos show the ground board method of testing termiticides. A. First, researchers create a 5′ x 5′ plot. B. Then, they create a 2′ x 2′ plot within the larger one, which becomes the treatment area. C. The area is treated with the termiticide, and researchers place a piece of southern yellow pine in the center of the treated soil, holding it in place with a brick. “This weathered test is the ‘worst case scenario’ for a product,” said Dr. Thomas Shelton, USDA Forest Products Laboratory, Starkville, Mississippi. Photographs provided by Craig Bell, USDA FS FPL.

These photos show the concrete slab method of testing termiticides. A. Researchers apply termiticide in the metal frame. B. They place a vapor barrier over the treated soil. C. Next, they pour concrete around a PVC pipe that shows a block of southern yellow pine. D. A field test. Photographs provided by Craig Bell, USDA FS FPL.

A Professional Trade

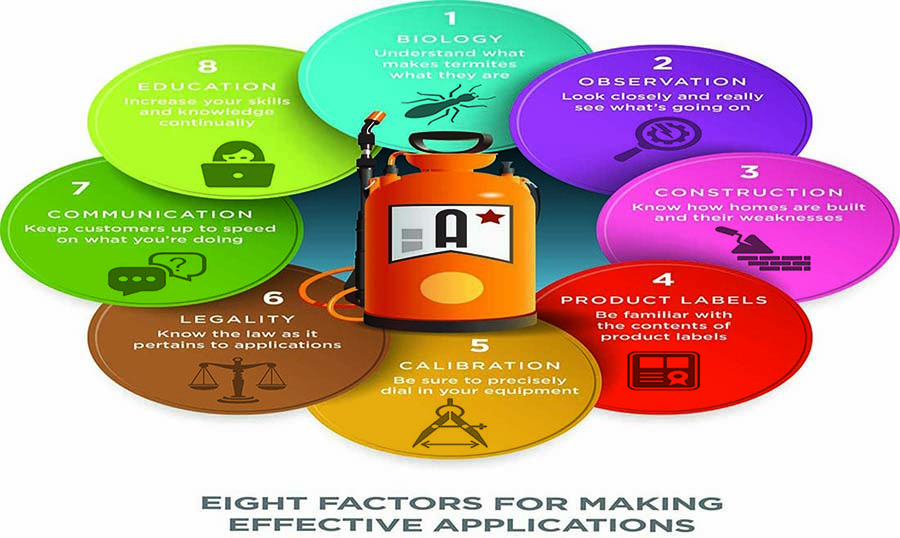

Working as a pest management professional is a trade that requires skills and experiences much like other specialized trades. In addition to acquiring state certification, effective applicators must:

• Communicate with customers

• Understand termite biology

• Demonstrate observation skills at the time of inspection and treatment

• Know home construction techniques

• Follow the termiticide product label

• Possess basic math skills

• Calibrate application equipment

• Adhere to federal and state laws and regulations

• Receive continued educational updates

Applicators first learn skills through on-the-job training, and then refine those skills with classroom work and educational programs. More important, termiticide applicators must continually upgrade their skills as products and practices change and improve.

Termiticide treatments can be applied preconstruction or postconstruction. Preconstruction treatments are preventative, and applied before builders pour the horizontal foundation or install the floor system over crawlspaces. This is an ideal time to make this application, because applicators have access to the entire area that the house will be built over — nothing is hidden. Applicators often must make multiple trips to the job site to work around the construction schedule and inclement weather. Applicators complete the pretreatment with a final perimeter application after the construction crew makes the final soil grade around the home.

Postconstruction treatments are curative and applied when someone finds termites or signs of termite activity in or near a structure. Postconstruction treatments are complex and made more difficult by the fact that applicators have to think about access points that can’t readily be seen or reached. This is why knowing how structures are built becomes critical to the long-term success of these curative termiticide treatments.

Postconstruction applications occur after the structure’s foundation is poured.

In addition to wearing the required personal protective equipment, applicators should be sure to wear hearing protection.

While there are different approaches for preconstruction and postconstruction treatments, both rely on thorough exterior perimeter treatments to maximize contact with the random foraging behavior of subterranean termites. There are general steps for applying liquid termiticides that can lead to long-term success in protecting homes and other structures:

• Understand the product’s label

• Measure the dimensions of the home to determine gallons needed for the job

• Know the equipment flow rate

• Properly mix and recirculate the termiticide in the tank

• Determine the total amount of product used to ensure proper application rates

• Document all aspects of the treatment

Know and Understand the Label

A product’s label is the guide for using the product effectively and legally, getting the job done correctly the first time, eliminating treatment failures, and reducing potential damage claims by customers. A warning up front: The labels for all termiticides are complex and require time to read, understand, and put into practice what should (and should not) be done when making a treatment. Termiticide labels will include three key pieces of application information.

1. Product Rates

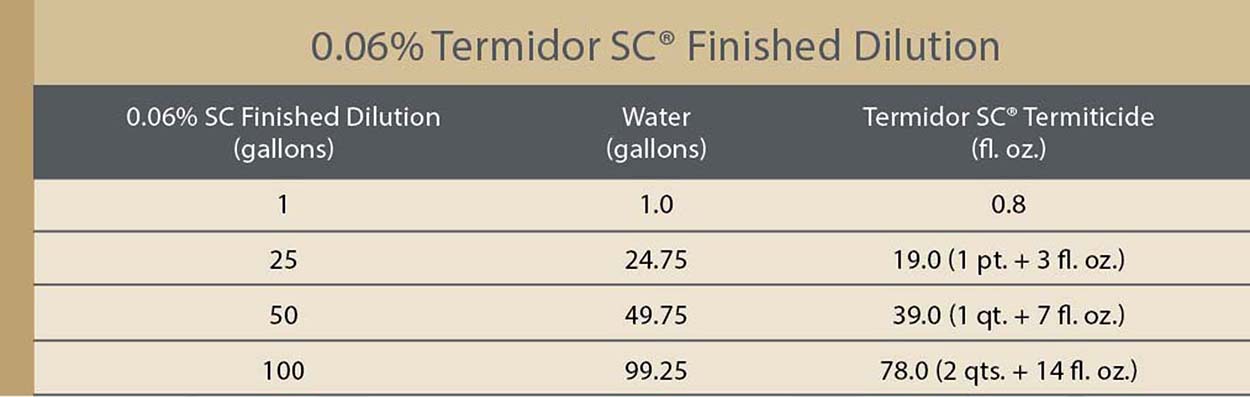

Some products have variable application rates based on the concentrations required for the finished solutions. For instance, one product label provides tables to mix the product for a 0.03 percent, 0.06 percent, 0.09 percent, and 0.125 percent solution. The concentration required depends on the severity of the termite infestation and other factors like soil moisture content.

Dilution rates also vary based on the particular active ingredient in the selected termiticide. A competitive product provides dilution rates of 0.25 percent or 0.125 percent. Another label may set the concentration target at 0.05 percent or 0.1 percent. Make certain you know the product, and settle on the percentage of active ingredient to determine how much termiticide you need to mix in your tank.

2. Volume

The total volume of termiticide that gets applied can also vary depending on the product’s label. Examples include a finished spray solution with a rate of 4 gallons per 10 linear feet x depth to footer (in feet), which has been the industry standard for decades. Some newer product labels specify a rate of 2 gallons per 10 linear feet x 2-foot minimum depth. Still other products may allow less water to be applied when the soil is at or near saturation, when there is a potential for runoff, or there is a sump pump or well near the application site. If you need to use less water, the label will direct you to increase the concentration of the product.

3. Mixing Procedures

Proper mixing procedures vary by product. Most labels say to fill a tank 1/4- to 1/3- full of water, and then start agitation. Next, add the correct amount of the termiticide to the tank before filling the remainder of the tank with water. It is important that the product gets recirculated by placing the treating tool at the opening of the tank and spraying back into the tank. This will thoroughly mix the product in the tank and throughout the application hose. This way, what comes out of the injector rod or spray gun is the same concentration from the beginning to the end of the application.

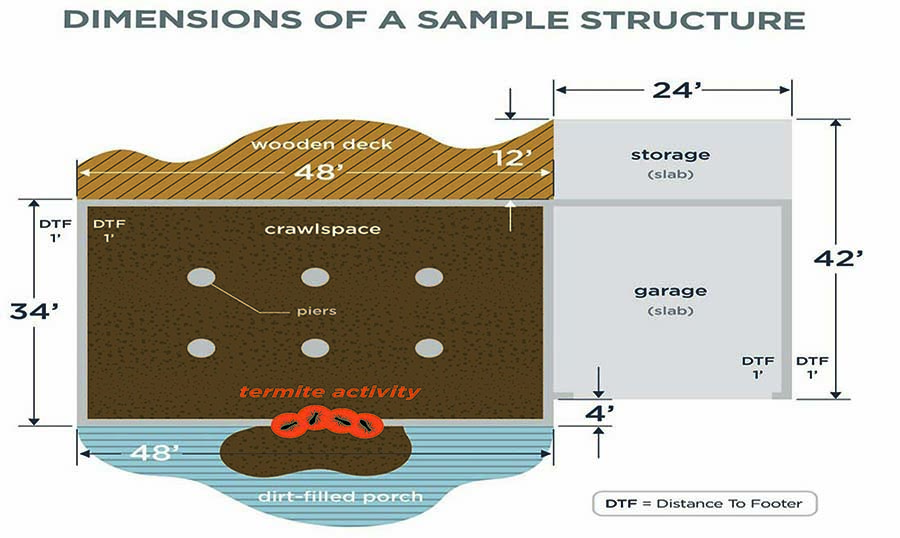

A Graph to Determine Total Gallons of Solution Needed

Most termiticide products require applicators to know the outer linear measurement and the depth of footer to determine how much termiticide will be needed to treat the structure. The graph should indicate on each section of exterior wall the length of the wall and the depth of footer. For instance, a wall is 20 feet long and the footer is 3 feet deep. If the application rate calls for 4 gallons per 10 linear feet x depth of footer, this area will require an application of 24 gallons of solution. By adding up the gallons used for each section, applicators can calculate the total amount of product they need for the entire structure (see Doing the Math illustrations, pages 19-21).

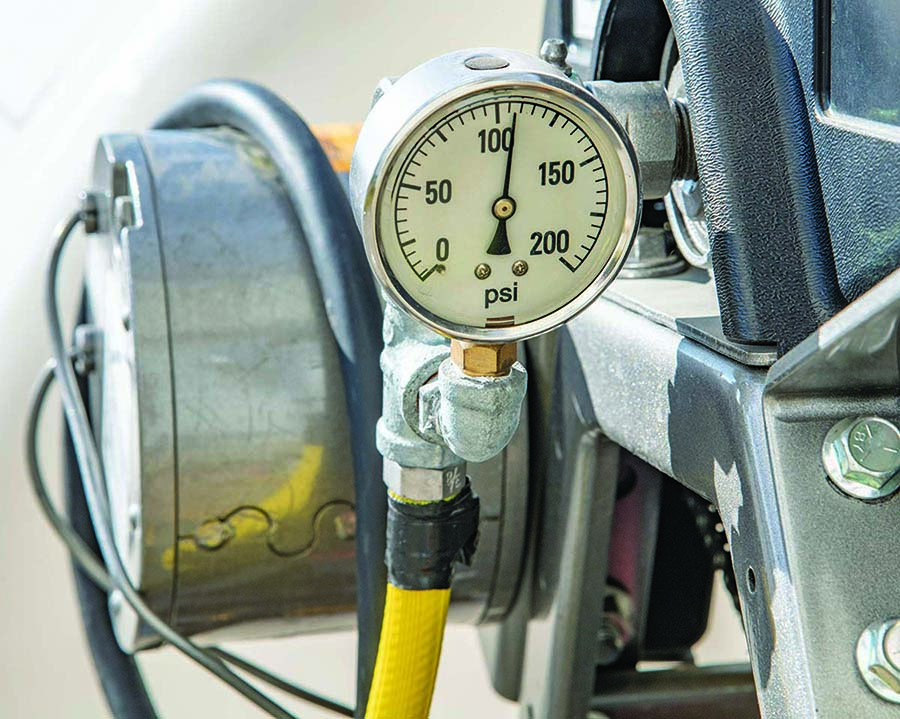

Know the Equipment’s Gallons per Minute

The normal target flow for most termite application rigs is 2 gallons per minute. To check your flow rate, all you need is a bucket with graduated gallon measurements and a stopwatch. To determine flow, dispense the liquid from your injector rod or gun in the graduated bucket for one minute — you can also collect the liquid for 30 seconds and multiply the amount by 2. Alternatively, you can use a stopwatch to see how long your termiticide rig takes to apply one gallon.

Changes Require Recalibration

Remember that you must calibrate your equipment any time you make any repairs or replacements to the pump or hoses, or if you use a different product.

Note the pump’s pressure at the start of collecting. If the rate is more or less than 2 gallons per minute, adjust the pump pressure. The lower the pressure, the less flow and vice versa — so, increasing the pressure increases the product flow. Continue adjusting the pressure until the attachments are each putting out 2 gallons per minute.

Record the operational pressures separately for each of the application tools to ensure that the equipment is putting out 2 gallons per minute. Refer to the specific pressures for each tool when you use them, then set the correct pressure before starting the treatment. Inline flow meters are also available for some termite rigs, but they may require calibration. You should also routinely calibrate these meters using this simple method to verify their accuracy.

Getting the Right Amount of Termiticide Mixed And Recirculated in the Tank

Termiticide product labels indicate how much product must be used to get the desired tank concentration based on the amount of water used to dilute the termiticide.

Using a table from the Termidor SC® label, assume you want to use the 0.06 percent finished dilution rate. Based on the graph (measurement) and accompanying table, the job will take 400 gallons of finished product. Let’s say you have a 200-gallon tank. The table indicates that for each 100 gallons of water you will add 78 fluid ounces of product, so 200 gallons will require 156 ounces of product, or about 1.2 gallons. It will take you two full tanks to complete the application

Get the Right Coverage

You have calibrated your equipment to apply 2 gallons per minute, and the tank has the right termiticide concentration in it. The last step is to actually apply the termiticide to the structure.

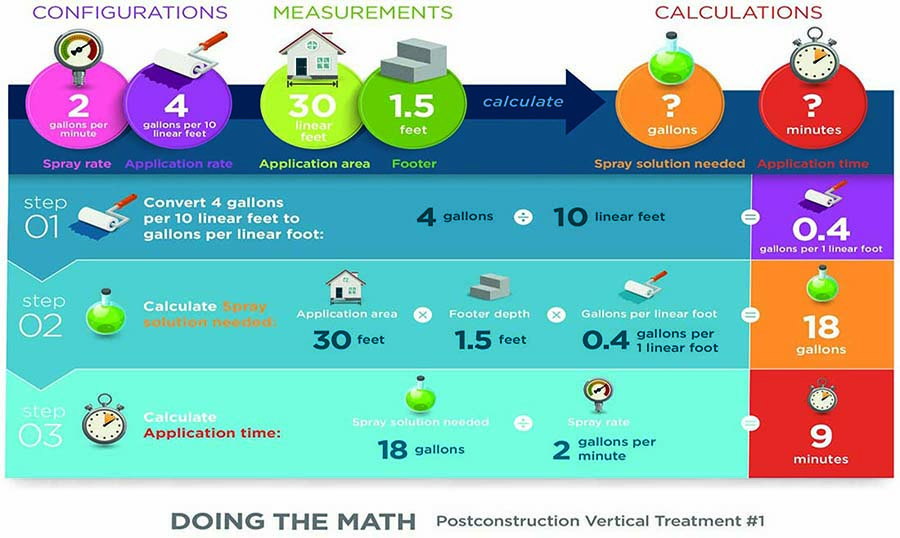

Example: A Postconstruction Vertical Treatment

Let’s say you decide to use a rate of 4 gallons of finished dilution per 10 linear feet per foot of footer’s depth. Assume you are treating the length of a section of a house that is 30 feet long and the depth of footer is 1.5 feet (see calculations below).

How many gallons of finished product will be required for this section? If the application equipment is calibrated at 2 gallons per minute, how many minutes does the applicator need to treat the 30-foot section? Since we know that we need to apply 18 gallons at a rate of 2 gallons per minute, we can determine that it will take 9 minutes to make the application (18 gallons divided by 2 gallons per minute).

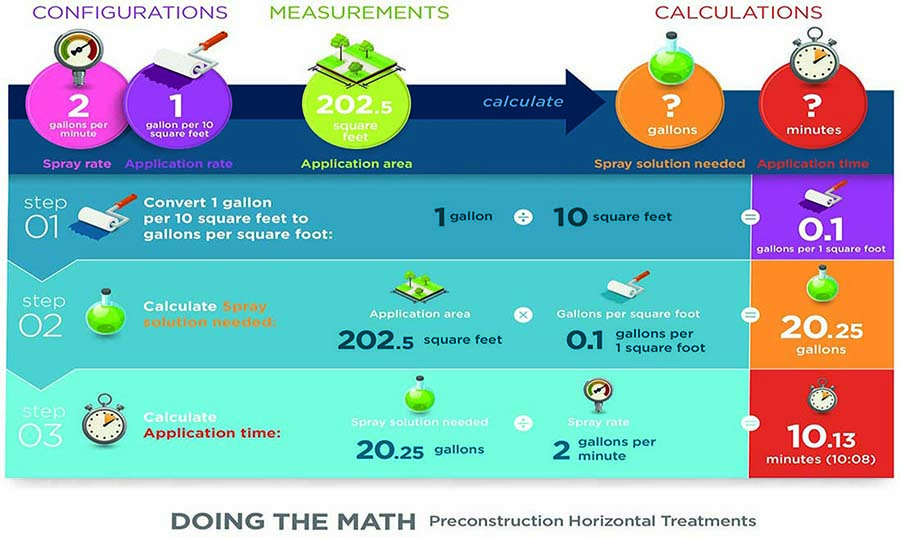

Example: A Preconstruction Horizontal Treatment

Now let’s say you decide to use a rate of 1 gallon of finished dilution per 10 square feet in the open space. Assume the area to treat is 202.5 square feet (see calculations below).

How many gallons of finished product will be required to treat this area with 1 gallon per 10 square feet? How long does the applicator need to treat the area with the spray gun?

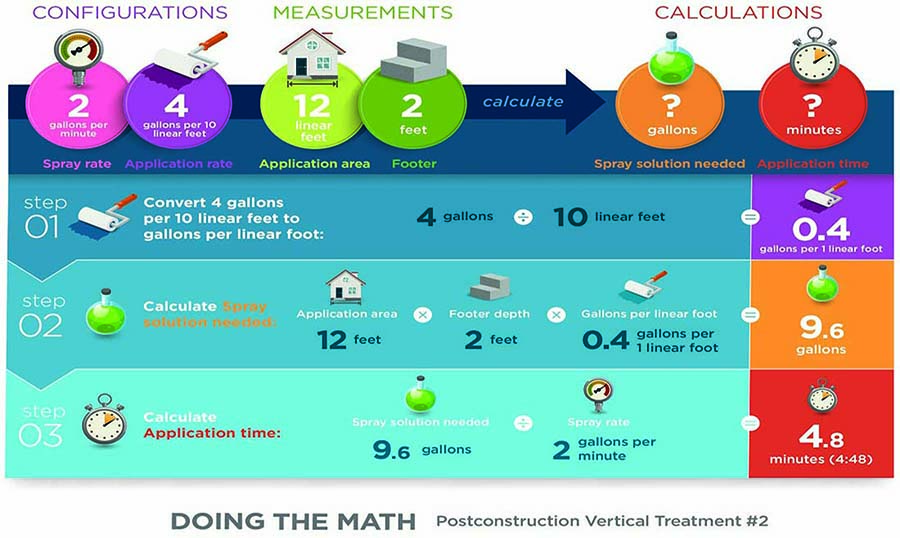

Work through the following problem to see if you understand how the numbers are calculated for an outside vertical wall on a postconstruction vertical application (see calculations below).

• The outside wall measured at 12 linear feet

• The depth to footer was measured at 2 feet

• The application rate is 4 gallons per 10 linear feet

• This treatment area will require 9.6 gallons of spray solution

• The application equipment applies 2 gallons per minute, so it will take 4 minutes and 48 seconds to make the application

No matter what application equipment you use, you still need complete coverage to form a termiticide barrier. When you use a trenching rod to perform vertical applications, make sure you’ve adequately dug the trench to contain all the product that you apply. This will ensure that the product stays where it will perform at its best.

As you are trenching, raise and lower the trenching rod to ensure that you push the product into the entire soil profile that you are treating. As you are rodding, push the soil that you removed back into the trench to ensure that it is also adequately treated.

It is much easier to make sure you get 100 percent coverage when you use a spray gun for horizontal applications, because you can completely see the area being treated. If there are building foundations (such as pillars or block walls) concentrate the product at the bases of these foundations where they meet the ground.

Complete Paperwork and Document Unusual Circumstances

There is no such thing as having too much documentation. The more documentation that is associated with the termite job, the better the communication with customers before, during, and after the applications will be. In addition to creating accurate graphs with structural dimensions and areas of termite activity, keep track of the volumes you apply by adding up how much was applied to each section (along a foundation wall, for example). Your total should be nearly equal to the target gallons estimated at the beginning of the job. Another way to roughly calculate is to add up the number of finished gallons used by the number of tanks you emptied during the application process. You need to record the total amount as part of the treatment documentation.

The Office of Indiana State Chemist requires a Termite Control Customer Disclosure Form if there are any deviations in the label application rates or procedures from normal application as required by the product label. You can find this form on the OISC website (oisc.purdue.edu), and it is the only disclosure form that can be used.

Document the Unusual

There will be times that you must use less than the labeled volumes of a termiticide, or where parts of the job cannot be done according to label specifications. Such situations might include times when:

• The soil is saturated

• The basement foundations are leaking

• Other runoff concerns exist

• There are loose electrical wires

• The sewer is leaking

• The crawlspace is inaccessible

Termiticide labels might indicate that you cannot apply a termiticide to saturated soil.

You absolutely need to thoroughly document and denote on your paperwork any deviation from the label. Consider taking photographs as part of the documentation. In Indiana, if the actual application deviates from procedures described on the product label, then homeowners and applicators need to sign disclosure waivers when the jobs are done. This way, everyone is on the same page. The waiver form is available on the OISC website (oisc.purdue.edu)

Regulations to Remember

When performing termiticide applications, the paperwork is as important as the product that you put into the tank. There are multiple regulatory requirements that applicators often overlook. For preconstruction applications, applicators must notify the OISC at least three hours before the application takes place. The notification form is on the OISC website (oisc.purdue.edu). Applicators are required to keep termiticide application records for five years and the records must contain the following:

• Contract/service ticket

• Diagram of structure

• Structure dimensions

• Depth of footer

• Treatment specifications for soil liquids (trenching, broadcast, hollow block)

• Product EPA Registration Number

• Product dilution rate

• Certified applicator name and credential number or the certified supervisor and registered technician name and credential number

• Treatment date(s)

Preconstruction applications require applicators to remain aware of construction processes and to not rely on contractors to notify you of construction progress. Applicators are responsible for portions of the application that do not get performed and they must disclose those areas to the customer. OISC allows applicators a 10 percent margin of error rate. This margin of error means that applicators may be 10 percent above or below the desired total application rates.

Conclusion

Treating structures for termites is an ever-evolving field, and pest management professionals need to continually update themselves about changes in products, application techniques, construction techniques, and regulations. All of these things are constantly changing. It is in the best interest of pest control companies to provide effective and professional service to their clients. If they make applications correctly, customers will be adequately protected and not see an immediate return of termites. In turn, this will ultimately strengthen your business’ reputation and increase service calls as word spreads of your company’s professionalism. This is why applicators must keep up with changes in the industry, so they can provide customers with the best service possible. One thing is as true today as it was 40 years ago: Applicators need to follow termiticide label changes as closely as possible. This is especially true for getting the right mixture applied in the right volume in the right places. Doing the right things will allow you to not only get control of the termite infestation, but offer your customers peace of mind that the termites have been eliminated from one of their more prized possessions.

ACKNOWLEDGMENTS

Thanks to Dawn Minns for graphic design, Adduci Studios for illustrations, Craig Bell (USDA-Forest Service) for photos, and Orkin for photos. Thanks also to the following individuals who provided valuable comments and suggestions that improved this publication:

Doug Foster, Burt’s Termite and Pest Control

Bob Hanstra, Reliable Pest Control

Tim Kaforke, Veseris

Jay Kelly, Office of Indiana State Chemist

DISCLAIMER

This publication is intended for educational purposes only. The authors’ views have not been approved by any government agency, business, or individual and cannot be construed as representing a perspective other than that of the authors. The publication is distributed with the understanding that the authors are not rendering legal or other professional advice to the reader, and that the information contained herein should not be regarded or relied upon as a substitute for professional consultation. The use of information contained herein constitutes an agreement to hold the authors, companies or reviewers harmless for liability, damage, or expense incurred as a result of reference to or reliance upon the information provided. Mention of a proprietary product or service does not constitute an endorsement by the authors or their employers. Descriptions of specific situations are included only as hypothetical case studies to assist readers of this publication, and are not intended to represent any actual person, business entity, or situation. Reference in this publication to any specific commercial product, process, or service, or the use of any trade, firm, or corporation name is for general informational purposes only and does not constitute an endorsement, recommendation, or certification of any kind by Purdue University. Individuals using such products assume responsibility that the product is used in a way intended by the manufacturer and misuse is neither endorsed nor condoned by the authors nor the manufacturer.

Reference in this publication to any specific commercial product, process, or service, or the use of any trade, firm, or corporation name is for general informational purposes only and does not constitute an endorsement, recommendation, or certification of any kind by Purdue Extension. Individuals using such products assume responsibility for their use in accordance with current directions of the manufacturer.

Find out more at THE EDUCATION STORE edustore.purdue.edu

An Equal Access/Equal Opportunity University September 2021