Even Pre-COVID-19 pork packing plants were among cleanest facilities in the world

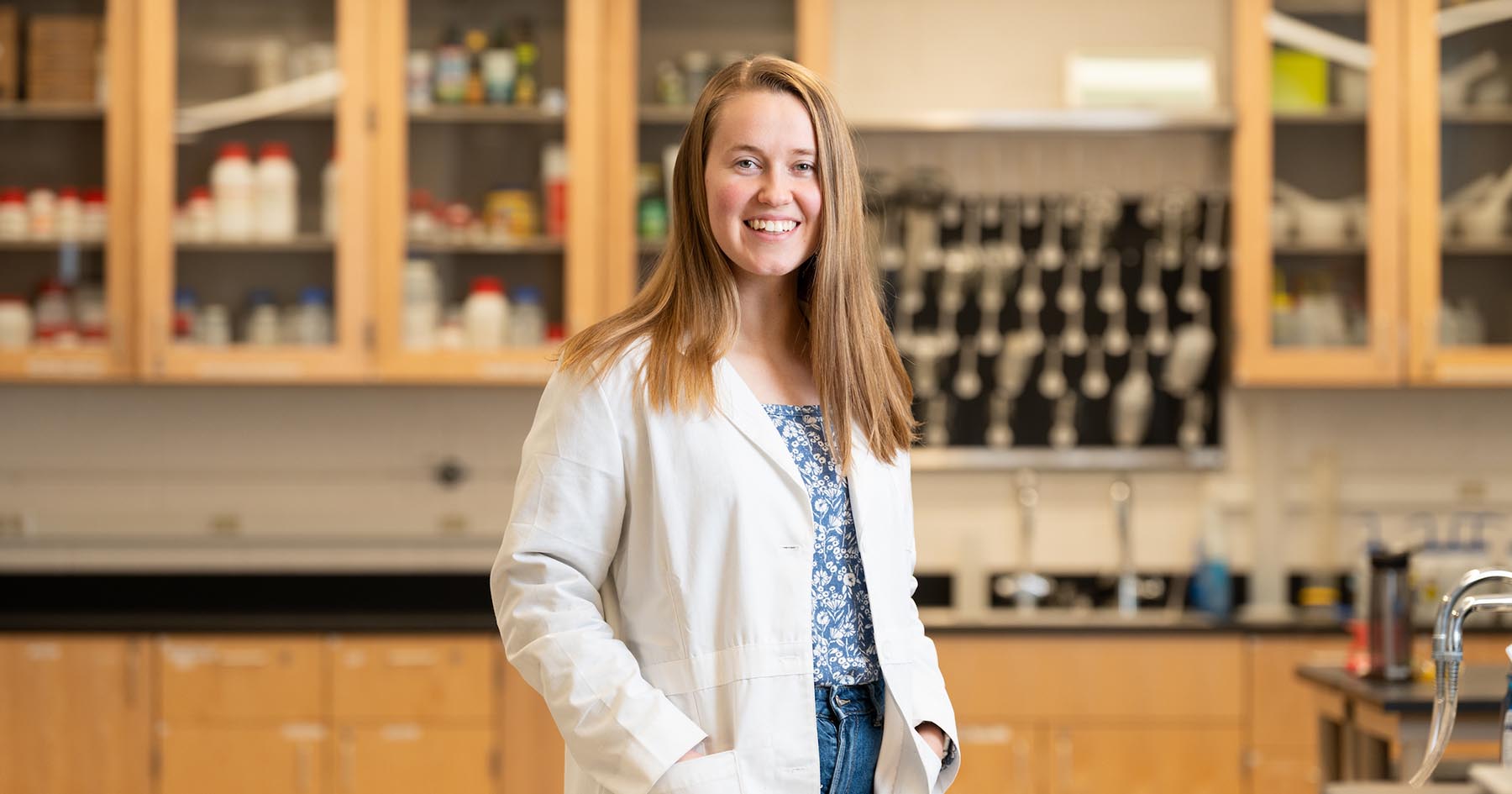

Meat packing plants, especially those in the pork industry, have been in the news recently due to outbreaks of COVID-19 among employees. Cramped quarters and a large number of occupants are ideal conditions for any virus to spread, Kara Stewart, animal sciences associate professor, said. Much of the coverage and discussion around meat packing plant closures, however, ignores a lesser known fact about these facilities: they are extremely clean and hygienic.

“These are already some of the cleanest facilities in the world, even before COVID-19,” Stewart said. “There are sometimes up to 2,000 people working in a large packing plant on an assembly line, similar to the automotive plants before robots. Workers also take breaks and eat lunch together. The virus is spreading because of an inability to be socially distant not because of a lack of cleanliness.”

As pork production plants begin opening, Stewart said industry leadership is taking extreme precautions to prevent these factories from becoming vectors again. These safety measures include working at a lower capacity, sometimes by 50 percent, to limit the plant’s population density. Also, instead of running multiple shifts most plants will run only one. Stations on the assembly line are now each separated by a Plexiglas barrier as are seats in lunch and break rooms. While the plants were closed they underwent a deep (deeper than usual) cleaning.

Additionally, Stewart said, plants in Indiana tested every employee before opening back up and continue to do compulsory, regular testing.

“It’s a very clean environment and now it’s even cleaner, so I think that says a lot about how aggressively this virus travels,” Stewart added.

From a consumer perspective, she continued, there isn’t much to worry about. It is well established that COVID-19 doesn’t survive well or for long on food products, including meat. Additionally, consumers shouldn’t worry about a supply of pork or meat.

“There is plenty of meat out there,” Stewart explained. “The shortages we are seeing are likely due to people buying larger quantities than normal and also the fact that the processing of meat needs to shift from restaurant ready products to store ready products. That doesn’t happen overnight.”

Stewart said the changes made at pork and other meat packing plants could remain in place for a while. Industry leaders and workers take their roles very seriously, she added. They know they serve an essential function in the nation’s food chain supply.

“I think they take it very seriously that they provide food for American families,” Stewart added. “They want to do this while keeping their employees safe. I actually think this is a really good example of people coming together from a lot of different areas to reach the common goal of reopening plants while keeping the employees safe.”