Dry-surface foodborne pathogens under scrutiny at Purdue

Maintaining sanitary conditions without using water presents special challenges

During 2021 and 2022, national news reported on four infants being hospitalized and two dying after consuming infant formula tainted with Cronobacter sakazakii. The reports sparked the prolonged shutdown of a production plant that produced large quantities of the formula, leading to a monthslong nationwide shortage of infant formula.

The incident motivated Purdue University’s Haley Oliver to launch a project to improve the safety of low-moisture food-processing facilities. Oliver, a professor of food science, will collaborate with Old Dominion University’s Rishi Drolia on the project, which will target the C. sakazakii pathogen.

“It was a massive-scale food safety challenge that led to a food security challenge,” Oliver said.

Millions of infants were affected. Those in low-income households were hit especially hard. The incident magnified global food security issues that had already been aggravated by the COVID-19 pandemic. At issue are the foodborne pathogens that can form or become embedded under low-moisture conditions.

“We need to find practical solutions to controlling this organism in production environments that are challenging to clean and sanitize because these are dry products,” Oliver said. Adding water to a dry food-processing environment promotes bacterial growth, harmless and dangerous alike.

“Finding creative cleaning and sanitation solutions is key,” Oliver said. She and Drolia, who received his PhD in molecular and cellular biology at Purdue in 2018, will examine how cronobacter and associated organisms take up residence in a dry-surface biofilm environment. Their research is funded by the U.S. Department of Agriculture’s National Institute of Food and Agriculture.

When the organisms attach to the surface in a dry environment, they can pull moisture from their surroundings. As they do so, they may remain in a living but dormant state that can give rise to sporadic contamination events.

“It’s not a predictable thing, but if pieces of biofilm break off into the environment, it can result in contamination events,” Oliver said. The pathogens can also be difficult to detect because they are not consistently growing in the production environment.

Oliver and Drolia will conduct their tests in a laboratory environment in consultation with industry stakeholders. “We are seeking industry guidance from the production side but also the sanitation-solutions side,” she said.

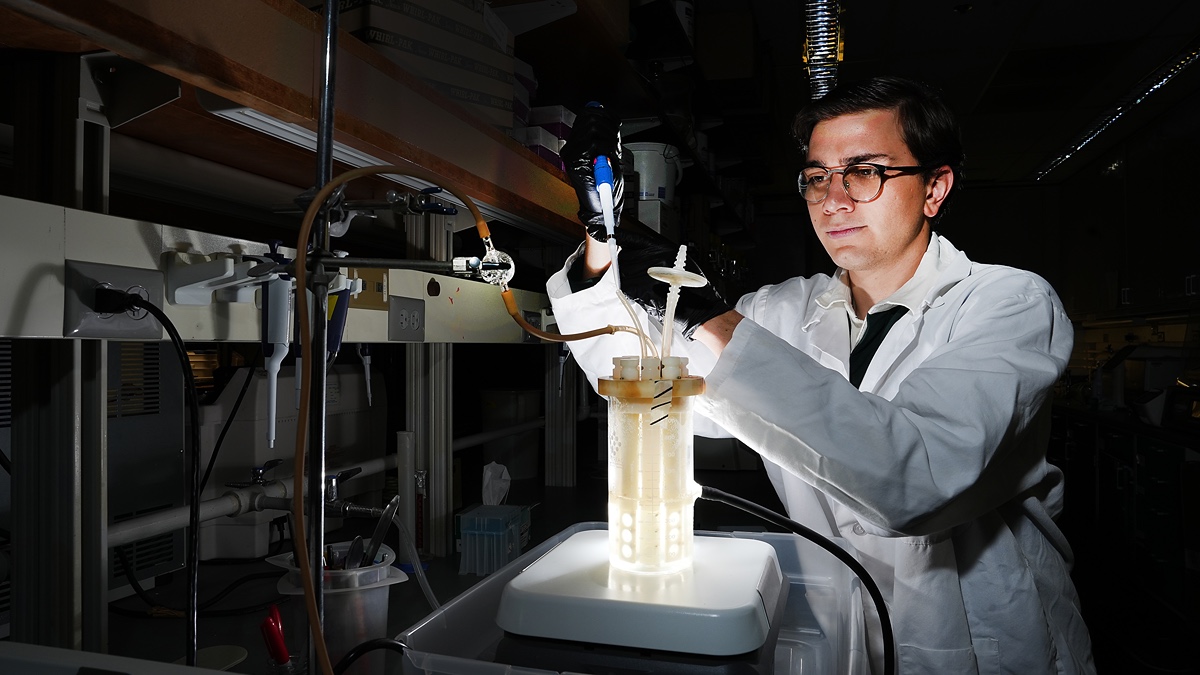

Drolia will handle the project’s microscopy imaging technology. Testing sanitizers or disinfectants typically require only one organism. Working with biofilm environments is different, however.

“We’re going to grow multiple organisms together. Rishi has an amazing microscopy skill set, so he can help us visualize how these organisms exist together in these lab-created biofilms,” Oliver said. “We know that some of the organisms survive better when pseudomonas is present.”

Pseudomonas, which can cause infections in humans, may help protect sakazakii pathogens. “We can find pseudomonas out in the wild. Are other organisms helping these pathogens set up residence or at least survive?” Oliver said.

The study also will include the listeria pathogen and salmonella.

“There’s a long list of food products that don’t support the growth of salmonella that can still be contaminated with it and subsequently cause disease,” Oliver said. “Even if it doesn’t have conditions to grow, it’s not dead. It’s like freezing food. It will stop the growth of organisms, but it doesn’t kill them.”

The researchers also will assess what genes C. sakazakii exploits to help it survive in dry food products and search for ways to inactivate or kill it.

“We’re bringing together multiple bacterial food safety challenges and our knowledge in sanitation and biofilms to work on a solution,” Oliver said.