Shweta Singh and Team receives $3 million grant to explore zero-waste sustainable pharmaceutical manufacturing

Purdue University researchers have received a $3 million grant from the National Science Foundation to help the pharmaceutical industry cost-effectively achieve zero waste in its manufacturing operations.

The pharmaceutical industry today generates large amounts of unused medicines and toxic wastes, reducing profits and degrading the environment.

“It’s a waste problem that causes economic, social and environmentally negative impact,” said project leader Shweta Singh, associate professor of Agricultural and Biological Engineering and Environmental and Ecological Engineering. Health problems also result when discarded antibiotics get back into the food chain, increasing antibiotic resistance.

Similar challenges confront other manufacturing industries, including battery and plastic production. “Our project is focused on creating a large-scale framework and cyberinfrastructure that can help manufacturing networks to perform more sustainably,” Singh said. “We’ll start our proof of concept with the pharmaceutical industry given its high impact on the American manufacturing system during COVID.”

Moving toward a circular economy by reusing resources can reduce the need for extracting new raw materials while also reducing the flow of waste into the environment. But cost poses a challenge to shifting the pharmaceutical industry away from its linear model of “take, make, and dispose” toward a “circular” model.

“If there is an additional cost, where do we get the incentives to do it?” Singh asked. “There are no algorithms that can help industries do it in the most resilient way. Everyone wants to transition to a circular economy paradigm in manufacturing. No one knows how and what will be the consequences of such a transition. That’s what we are fundamentally focusing on to create knowledge and tools for a sustainable transition to a circular economy.”

Singh’s team also will work with industry partners in the project to help develop and test the proposed algorithms and cyber infrastructure.

Singh’s project collaborators are Gintaras Reklaitis, the Burton and Kathryn Gedge Distinguished Professor of Chemical Engineering; X. Carol Song, chief scientist at the Rosen Center for Advanced Computing; Zoltan Nagy, the Arvind Varma Professor of Chemical Engineering; and Vaneet Aggarwal, professor of industrial engineering.

The project builds on a computational method that Singh and Purdue ABE Ph.D. alumnus Gargeya Vunnava invented for testing new recycling and waste reduction options across industry sectors. They tested their method and tool by showing how to create a circular economy by reusing livestock and industrial wastes in the agro-based manufacturing network such as food and biobased energy production in Illinois.

Shweta Singh, associate professor of agricultural and biological engineering at Purdue University, will adapt a circular economy design computational tool that she co-invented for application to the pharmaceutical industry. (Purdue University photo/Tom Campbell)

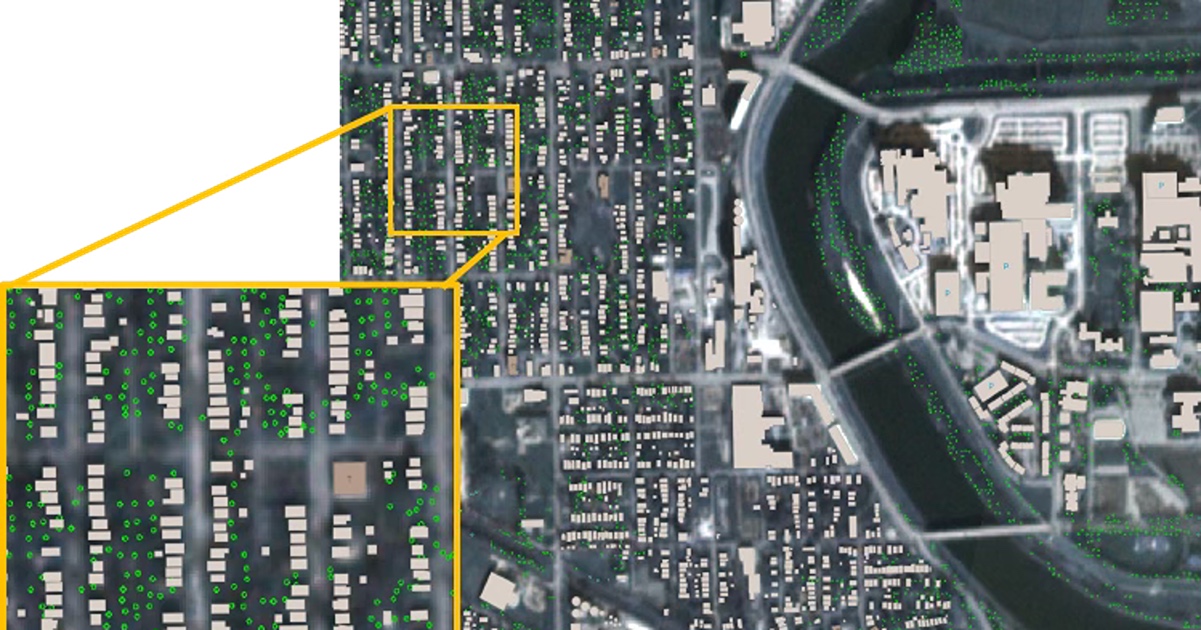

Shweta Singh, associate professor of agricultural and biological engineering at Purdue University, will adapt a circular economy design computational tool that she co-invented for application to the pharmaceutical industry. (Purdue University photo/Tom Campbell) Singh will expand the method’s capabilities for circular manufacturing in the pharmaceutical industry by incorporating digital twin models of future modular manufacturing. She will collaborate with Song on transferring the capabilities to a cloud-based platform dedicated to pharma manufacturing and made available to academics and industries using Purdue’s MyGeoHub capabilities.

“The cyberinfrastructure will be a computational tool based on a digital twin of the whole manufacturing system,” Singh explained. “Then we can do simulations to understand the right process and scale to incorporate for sustainable manufacturing.” The new processes will be developed in Reklaitis’ and Nagy’s labs. They run an experimental facility that will serve as a pilot plant to test and optimize the new recycling process. This will provide a foundational process change to restructure the linear supply chains to a circular one.

Singh and Aggarwal will develop a pricing algorithm for reusing and recycling waste medicines for manufacturing. They also will collaborate with Pradeep Chintagunta of the University of Chicago’s Booth School of Business to explore strategies that could help move market behavior toward waste reuse.

“One great challenge is that this new paradigm of circular manufacturing or circular supply chain will require new skills and workforce development,” Singh said. Her project will pursue multiple strategies to meet the need. These strategies will include establishing a Computational Lab to prepare graduate students for the future of manufacturing. They’ll learn process development and process modeling. They’ll also learn macro-scale modeling principles and about designing a zero-waste industrial network,” she said.

The Summer Undergraduate Research Fellowship (SURF) program will recruit students from underrepresented groups via Purdue’s Women in Engineering Program and the university’s partnerships with Historically Black Colleges and Universities. Purdue’s collaborations with Ivy Tech Community College will offer further opportunities for training the manufacturing professionals of the future.

Together with the university’s Biotechnology Innovation and Regulatory Science program led by Kari Clase, professor of Agricultural and Biological Engineering, and the Office of Professional Practice, the project will offer training through student internships and workshops for industrial stakeholders.

A novel aspect of the project will be a web-based data science hub for citizen participation. The hub will address the logistical challenges, possibly through a special app that offers participation incentives, presented by recycling materials from the consumer arena. The findings could have implications for battery recycling and other industries.

“It is an ambitious and challenging project,” Singh said. “It’s education, research, and prototype development for future manufacturing, all tied together.”