Purdue researchers aim to make nutritious foods more accessible for consumers

Between busy work schedules, after school activities and household chores, it can be difficult to ensure we’re eating a balanced diet, creating a growing market for fortified and enriched foods.

Da Chen, assistant professor of food science, suggests that although protein powders, shakes and bars have been on store shelves for years, consumers sometimes avoid reaching for the “healthier” snack options due to concern about less appealing flavors and textures.

Chen, whose research focuses on protein-rich foods, explains that people tend to associate high-protein snacks with being “chalky” and “earthy.” Finding the balance between desirable flavor and texture can vary depending on the protein’s derivative, which is commonly either plant or whey-based.

“Whey proteins are typically used to create shakes, but not everyone finds that texture appealing,” Chen said. “In our research, we are working to create a ‘thinner mouthfeel’ on high protein shakes without taking away the high levels of nutrients.”

Obtaining protein from animal and plant sources also requires extensive energy, Chen explains, creating a larger carbon footprint for the industry. In a recent study, Chen’s lab identified a more sustainable method for producing plant protein-based fat replacers as food textural modifiers.

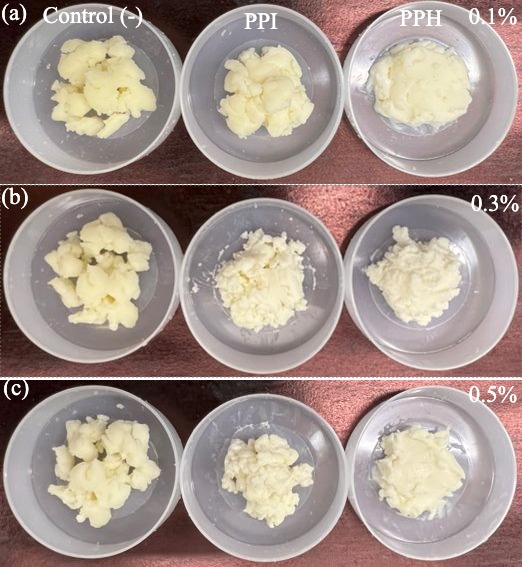

The researchers worked with fat-free cream cheese, a product that becomes stiff in production after removing the fat, making it difficult to spread. Fat replacers in dairy products like cream cheese are typically carbohydrate-based, resulting in a lower nutritional value. Chen’s lab sought to find a protein-based fat replacer to solve that problem.

From right to left, containers of cream cheese show the difference between the non-fat cream cheese base to increased percentages of fat replacer derived from protein, offering a softer texture. Photos provided by Da Chen.

From right to left, containers of cream cheese show the difference between the non-fat cream cheese base to increased percentages of fat replacer derived from protein, offering a softer texture. Photos provided by Da Chen.

“We found the addition of the fat replacement softened the cream cheese significantly with ideal heat softening capacity. The product contained more than 27 percent protein with negligible fat,” Chen said. “This study provided a cost and time efficient approach to develop plant protein-based fat replacement with improved sustainability.”

While this research shows the potential for modifying the textures of high-protein foods, Chen said finding ways to combat high prices for consumers will be the next struggle.

“The reason protein is expensive is because isolating animal and plant protein is time consuming and labor intensive,” he said. “If we want protein-rich foods to be more accessible for everyone, we have to find a way to simplify this process or find cheaper sources, thus bringing the price down.”

The high-protein foods market has continued to grow in recent years, with new and innovative products hitting store shelves each day. Chen said as consumers continue to monitor what they eat, researchers will continue to identify ways of crafting healthier, flavorful and more enjoyable snack options.

“The United States has about 40 percent of the high protein snack market across the globe because we care about what we eat,” Chen said. “We are a busy nation; people tend not to have time to cook nutritious food. Just because we are reaching for what is convenient, doesn’t mean it can’t be the healthier option, but we also want the healthier option to be the best tasting one.”