One of the biggest problems facing biorefinery operations is the flow of biomass into and throughout facilities. Lignocellulosic biomass, often made up of post-harvest agricultural materials such as corn stover and soybean hulls, often accumulates and compacts while moving through augers, forcing costly shutdowns for cleaning and repairs.

A team led by Purdue University scientists will receive a $1.8 million grant from the U.S. Department of Energy’s Bioenergy Technologies Office to solve that problem. Researchers from Purdue’s Departments of Agricultural and Biological Engineering, Mechanical Engineering, Materials Engineering, Discovery Park Energy Center, the Laboratory of Renewable Resources Engineering (LORRE), and the Center for Particulate Products and Processes (CP3) will work with scientists from Argonne National Laboratory and Idaho National Laboratory, as well as industry partners Forest Concepts and AdvanceBio Systems.

The goal is to transform solid biomass into a slurry that can act more like a liquid flowing freely through material transportation systems in biorefineries. To do that, the researchers will create models to predict the physical properties - particle shape, size and surface charge - necessary for a liquid-like flow of solid materials.

“We plan to use these models to create regime maps for robust operation, which would tell engineers and operators how to adjust screw feeder and reactor operating parameters given measured biomass characteristics so that the inlet portion of the biorefinery can operate without difficulty,” said Carl Wassgren, a Purdue professor of mechanical engineering and director of the CP3.

From there, scientists will develop methods for modifying the biomass to meet the models’ specifications, changing particle size, shape and charge.

“We’ll use small amounts of enzymes to reduce particle size and some surface characteristics so that they become moveable as a fluid with the same amount of moisture,” said Michael Ladisch, the project’s principal investigator, Purdue distinguished professor of agricultural and biological engineering, and director of LORRE. “Materials handling issues are very important in being able to scale up technology for converting cellulosic materials into ethanol. These advances will give biorefineries the tools to overcome one of the most difficult logistical issues they all face.”

Researchers will start with corn stover, but Ladisch said the work could be the foundation to develop similar technology for other biomass products, including wood chips, soybean hulls, wheat straw and sugarcane in the future. The funding, which will amount to $2.3 million total with cost share from partners, will cover three years. The team’s co-principal investigators include: Nathan Mosier, a professor in Purdue’s Department of Agricultural and Biological Engineering, Pankaj Sharma, managing director of the Discovery Park Energy Center, and David Thompson, a distinguished staff engineer at the Idaho National Laboratory. Other Purdue faculty and staff involved are: Eduardo Ximenes, bioprocess research scientist at LORRE, Kingsly Ambrose, assistant professor of agricultural and biological engineering, Abigail Engelberth, assistant professor of agricultural and biological engineering, and environmental and ecological engineering, Kendra Erk, assistant professor of materials engineering, Marcial Gonzalez, assistant professor of mechanical engineering and Klein Ileleji, associate professor of agricultural & biological engineering.

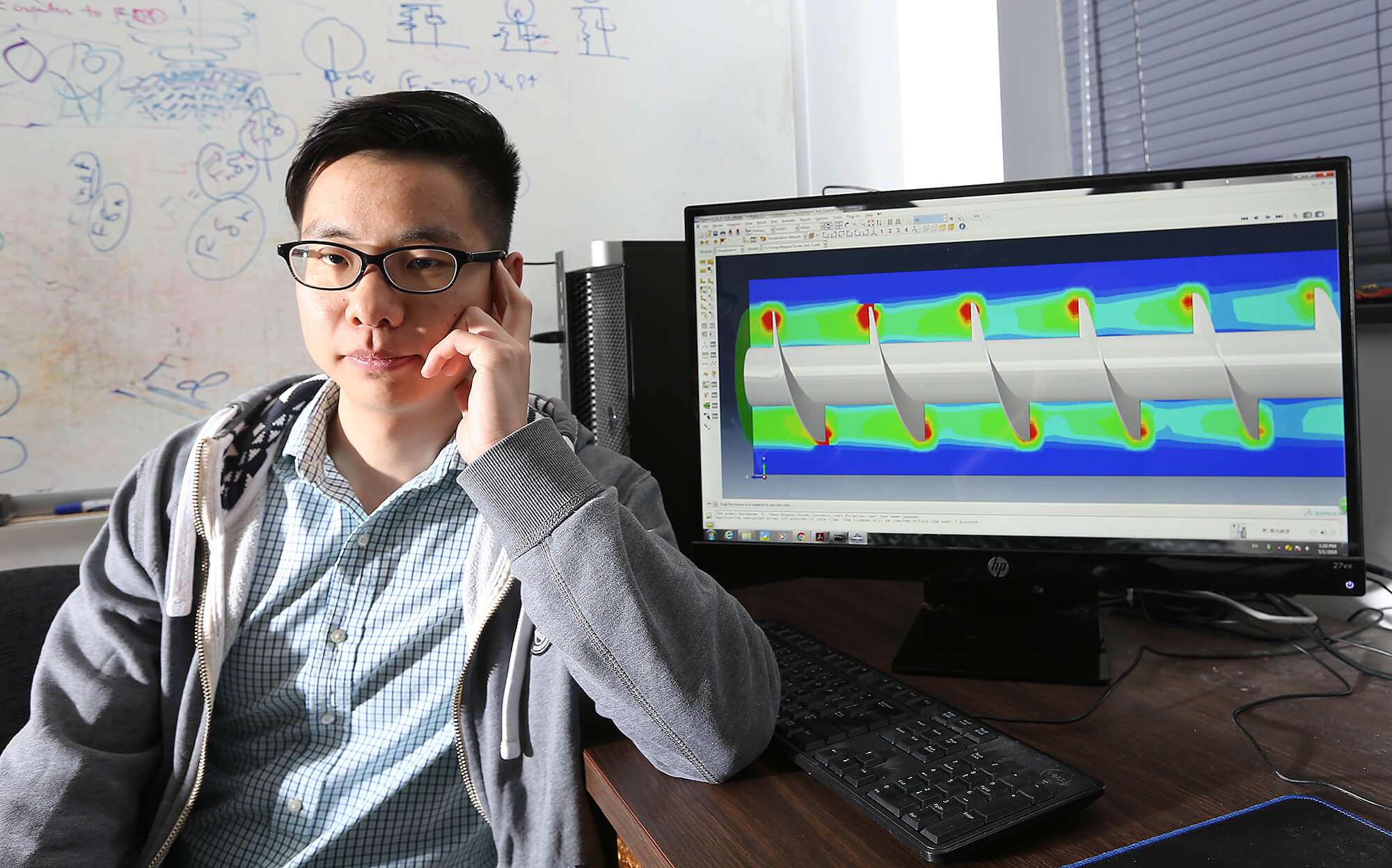

Yu Liu, a mechanical engineering doctoral student working with Carl Wassgren and Marcial Gonzalez, works on computer simulation of biomass particle movement through a screw conveyor. His research will contribute to solving biorefinery blockage issues as part of a $1.8 million Department of Energy grant to Purdue. (Purdue Ag Communication photo/Tom Campbell)

Yu Liu, a mechanical engineering doctoral student working with Carl Wassgren and Marcial Gonzalez, works on computer simulation of biomass particle movement through a screw conveyor. His research will contribute to solving biorefinery blockage issues as part of a $1.8 million Department of Energy grant to Purdue. (Purdue Ag Communication photo/Tom Campbell)