Nanocarrier research taps technology in Ag Alumni Seed Phenotyping Facility

T

he advantages of packaging a bioactive compound in a nanosized carrier have been proven in medicine for targeted drug delivery. Now Purdue researchers are studying nanocarriers for the delivery of agrochemicals to plants to reap equally important benefits — treating plant disease more effectively and reducing environmental impacts.

In medicine, nanotechnology can be used to increase the potency of the bioactive molecule and improves its uptake, which means less of the active ingredient can produce the same response. The goal in agriculture is similar, says Kurt Ristroph, assistant professor of agricultural and biological engineering. “If you can improve the utilization efficiency of these agrochemicals, maybe you can apply less mass and get the same protective quality.”

Ristroph’s lab develops nanomaterials and scalable nanoformulation processes for both medical and agricultural applications. In addition to formulating nanocarriers, his team evaluates their movement and efficacy in target systems.

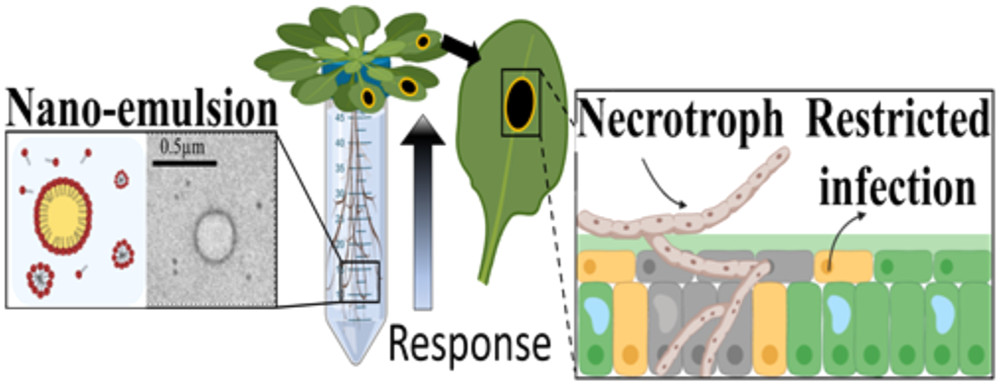

Hormesis-Inducing Essential Oil Nanodelivery System Protects Plants against Broad Host-Range Necrotrophs. Pablo Vega-Vásquez, Nathan S. Mosier, and Joseph Irudayaraj. ACS Nano 2021 15 (5), 8338-8349. DOI: 10.1021/acsnano.0c09759

Hormesis-Inducing Essential Oil Nanodelivery System Protects Plants against Broad Host-Range Necrotrophs. Pablo Vega-Vásquez, Nathan S. Mosier, and Joseph Irudayaraj. ACS Nano 2021 15 (5), 8338-8349. DOI: 10.1021/acsnano.0c09759 One such experiment consists of infecting the leaves of a model plant — mainly Arabidopsis thaliana and tomato — with a type of pathogen called a necrotroph. As the pathogen grows on a leaf over time, it kills the tissue around it.

Pablo Vega-Vasquez, a postdoctoral researcher in Ristroph’s lab, starts the experiment by preparing nanoparticles containing bioactive molecules and dosing plants on their leaves or roots. He then infects them with the pathogen.

Vega-Vasquez uses the multispectral capabilities of the Aris TopView Phenotyping System in the Ag Alumni Seed Phenotyping Facility to measure living tissue and dead tissue. This allows him to compare plants treated in various ways to non-treated plants by quantifying progress of the disease precisely and automatically. “That instrument was the core technology to assess how safe and how effective the treatments were — to quantifiably assess the effect of the treatment,” Vega-Vasquez says.

Aris Top-View Phenotyping System in the Ag Alumni Seed Phenotyping Facility at Purdue University.

Aris Top-View Phenotyping System in the Ag Alumni Seed Phenotyping Facility at Purdue University. The nanocarriers for this experiment are loaded with a metal tracer. After the plants are dosed and measured, Vega-Vasquez takes samples of different parts — leaf, stem sections, roots — and digests them with acids. He then uses mass spectrometry to determine the metal’s concentration in different tissues of the plant and map the final location of the particles after they have been dosed.

Knowing which of the treatments were most effective is a first step. Further experimentation will reveal what is occurring within the cells of the plant. “We have a different set of experiments to learn information from the plant using molecular analysis,” Vega-Vasquez says.

Nanotechnology in agriculture is still a relatively new area of research, so Ristroph borrows terms from the biomedical field to further explain the work.

“In the pharmaceutical world, ‘pharmacokinetics’ are what the body does to a drug — where the body sends it, what organs it ends up in, the cells it ends up associated with, and over what time scale,” he says. “‘Pharmacodynamics’ is what the drug does to the body — the biological effect the drug has on different systems.”

In translating nanocarrier technology from medicine to agriculture, much of Ristroph’s previous work would correspond to pharmacokinetics — where the nanoparticles go in plants, over what time scales and how much of them end up in the leaves, roots and stems.

“This experiment is starting to answer pharmacodynamic questions,” he says. “What is the bioactive we’re delivering doing to the plant? What is the biological effect?”

Both questions are important because growers want to know where the nanoparticles are going in the plant and if the treatment works. “We’re continuing to do a lot of nanoparticle tracking work,” Ristroph says, “but the next question is if the material we’re delivering is doing its job.”

The equipment in the phenotyping facility helps answer those kinds of questions, he adds.

Tomato plants used in the experiment were grown in Purdue's College of Agriculture Plant Growth Chamber Center.

Tomato plants used in the experiment were grown in Purdue's College of Agriculture Plant Growth Chamber Center. The two biggest challenges in adapting nanocarrier technology for use in agriculture are scale and safety, Ristroph says. Even in the pharma world, scaling up nanoforumulations has been successful commercially only a handful of times. The COVID vaccines, for example, were a success story in scalability and manufacturability.

“If you think about ag, your costs have to be very low,” he says. “From a science standpoint and also from an outreach standpoint, growers and regulators are much more interested in asking where these materials are moving in the plant and the environment. So tracking them around and showing that they’re safe is important and a major challenge. That’s some of what we’re doing.”