GPS Based Guidance Systems for Farmers

December 12, 1999

PAER-1999-18

Jess Lowenberg-DeBoer, Professor

Introduction

Global Positioning System (GPS) guidance for ground based application equipment in agriculture is being adopted rapidly. Among other benefits, these systems help operators reduce skips and overlaps in applying fertilizer, pesticides and other inputs. In the last two years, use of the GPS guidance for ground equipment has gone from almost nothing to about 5% of all custom fertilizer and pesticide application equipment in the U.S. Crop producers are also starting to use the systems.

“It is our hottest item right now,” said Curtis Schaben, Ag Leader, Ames, Iowa. “Especially for larger operators, with large areas of drilled soybeans. Many already have GPS to use with yield monitors. They are looking for other GPS uses.” “We also sell a lot in Western Canada where fields are large and air seeders are popular. It can be very dusty there at seeding time and the GPS keeps them on track in the dust.”

GPS guidance systems can be used for all types of agricultural operations: planting, spraying, fertilizer spreading, tillage. Potentially, they replace the foam and disk marker systems now used to guide operations.

In its most basic form GPS guidance is a horizontal “lightbar” in a plastic case 12 to 18 inches long linked to a GPS receiver. The operator watches a bar of light. If the light is on the center line the machine is on target. If a bar of light extends to the left, the machine is off the swath to the left and needs to be corrected. If a bar of light extends to the right, the machine is off to the right. The lightbar can be mounted inside or outside of the cab. Similar GPS guidance systems have been used for aerial application since the early 1990s. While innovators in the use of GPS guidance for agriculture often have experience in using GPS for variable rate application and yield monitoring, GPS guidance is often used just to improve accuracy and speed of uniform application.

More advanced systems have a screen showing the swath of the machine as it moves through the field. Early models only allowed straight line parallel swaths, but now software is available for any contour. Areas covered with previous swaths are marked on the screen. These systems have the capacity to generate “as-applied” maps showing what part of the field was covered and the application pattern.

GPS vs. Foam Markers

GPS guidance potential advantages include:

– Accuracy at higher speeds.

-Works with spinner spreaders.

-Provides effective guidance over growing crops where foam falls between plants.

-Allows operation when visibility is poor.

-Less affected by weather.

-Has lower recurring costs.

-Reduces operator fatigue and eye strain.

-Has lower set up time.

-Is not affected by wind or boom bounce.

-Reduces chemical use, by reducing overlaps.

-As-applied maps can be generated.

-Reduces need to enter already sprayed areas.

GPS Guidance Cost

The most frequently mentioned dis-advantage of GPS guidance is the up-front cost which ranges from about $3000 for a farmer who already has a GPS to over $14,500 for a custom applicator. A basic system with GPS and lightbar can be purchased for about $7000. According to Azbell the biggest differences between the farmer and custom systems are speed, screen display and the ability to provide as-applied maps.

“Some of the cheaper GPS guidance units that you see advertised are slow. It is like using a computer with 286 chips,” Azbell said. “They are also strictly lightbar units, with no screen display or map making ability.”

Foam marker systems purchase prices range from $900 to $2,800. According to Azbell speed is also an issue in foam systems. The lower cost foam systems are slower and work ok when application is done with a tractor. Commercial applicators operating at 20 mph need more foam output than the lower cost systems can provide.

The useful life of the GPS units is hard to estimate because of the short period that they have been on the market, but Azbell said that he recommends that users try to recover costs in 3 years. Foam marker systems often last about 5 years or more, Azbell said “The GPS guidance system will work longer than three years, but by that time it will probably be obsolete.” Azbell said. “It will still do everything you originally wanted it to do, but something much better will be on the market.”

Cost/Benefit Examples

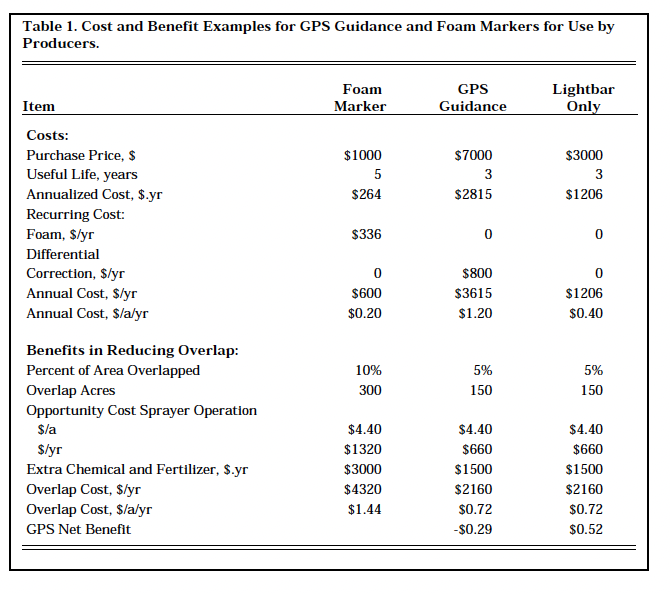

Cost and benefits vary widely depending on the crop, acreage covered, swathing accuracy achieved and other factors. Table 1 provides examples of GPS guidance costs and benefits for two scenarios: a producer buys a whole system including GPS and lightbar, and a producer who already has a GPS.

The examples show GPS guidance as increasing per acre costs. The per acre costs almost double for the producer who already has a GPS and for the producer starting from scratch guidance costs increase by a factor of six. This means that for many potential users the key to determining the profitability of GPS guidance is on the benefit side.

The benefits estimated in Table 1 focus on only the opportunity cost of sprayer operation and the cost of extra chemical and fertilizer. Azbell’s estimate of the percentage overlap is used, 10% with foam markers and 5% with GPS guidance. For simplicity the example assumes that the operators are very cautious and make only overlaps, no skips. The machine cost of overlaps is estimated at the custom rate, $4.40/a.

Table 1. Cost and Benefit Examples for GPS Guidance and Foam Markers for Use by Producers

The estimation of the economic impact of skips is complicated because the effect of crop yield varies by crop, the weed population and how long term weed seed bank effects are valued. A skip is much more costly in a higher value crop, such as sugar beet, potatoes, or seed crop, than it would be in bulk commodity corn, soybeans and wheat. If the skip occurs in a very clean field, the yield effect may be minimal, but in a heavily infested field the yield may drop to almost zero. Weed scientists suggest that the greatest eco-nomic effect of skips may be on creating a seed bank that will lead to management problems in future years.

This is a conservative estimate of GPS guidance benefits, which does not include many of the advantages outlined above, shows that for the producer who already owns a GPS, use of GPS guidance is profitable. In this example, the producer who does not own a GPS would need about 2000 acres to breakeven. Sensitivity testing shows that for the producer with a GPS, the breakeven acreage for the lightbar is only 600 a. Of course, relatively few 600 acre farmers already have GPS.