March 6, 2012

How Carbon Dioxide Offsets and Other Policies Impact the Financial Feasibility for Anaerobic Digestion Systems on US Dairy Farms

Anaerobic digestion (AD) of livestock waste presents a potential technological solution to the challenges of renewable energy production, greenhouse gas mitigation, and livestock waste management. While AD systems have been commercially available for many years, they have not been widely adopted on U.S. livestock operations. Among livestock species, AD systems have been more rapidly adopted by dairy operations. According to the U.S. EPA’s AgSTAR program website, http://www.epa.gov/agstar/projects/index.html, in 2011 dairy operations accounted for 140 of the 171 active AD sites.

While the technology of AD is relatively well understood, it is not clear how many dairy farms could realistically be expected to adopt AD systems. As a result little is known about how much renewable energy could be created from AD systems installed on U.S. livestock operations or how much methane emissions associated with manure management on U.S. livestock operations could be reduced by adoption of AD systems. These are both critical questions as it is clear that government incentives would be required to encourage adoption of AD systems on a wide scale. The few analyses that have been undertaken to date have been developed from aggregate data and only considered a few of the many of the factors that will likely limit the deployment of this technology.

A variety of factors make dairy farms attractive candidates for AD. Dairy farms produce considerable amounts of waste and many of the operations confine livestock to barns where manure is collected and stored in anaerobic conditions. These manure handling systems could technically be converted to include an AD system and the installation of an AD system. Further, such an installation would likely result in a reduction in the amount of methane, an important greenhouse gas, that is emitted to the atmosphere. This is achieved when methane that is normally emitted to the atmosphere is captured and combusted.

Once biogas has been created by the AD system, a variety of options exist for converting the biogas to energy. Today, this is most commonly accomplished by combusting the biogas in an internal combustion engine which is used to power and electrical generator. The electricity can then be used to meet on-farm electrical needs and/or sold onto the power grid. Gloy and Dressler (2010) provide a more thorough description of the various energy conversion options and their potential benefits and challenges.

Although AD systems have many potential benefits, it is obvious from the small number of operating systems present in the U.S. that many hurdles to adoption exist. These include both technical feasibility as well as economic viability. For instance, it is clear that due to economies of scale, AD systems are more likely to be economically viable on larger dairy farms. Additionally, factors such as the current manure handling systems in place on the farm, the energy demands that are experienced by the farms, the farm’s plans to continue to operate into the future, and capital constraints faced by the farms all influence the likelihood that an AD system could be adopted by a dairy farm.

The purpose of this paper is to examine the viability of AD systems on U.S. dairy farms and produce and estimate of the potential for AD adoption that takes into consideration how a variety of constraints might impact AD adoption. In addition, this paper provides some insight into the potential methane emission reductions that could be achieved through the use of AD systems. Readers interested in a detailed analysis of the this issue should consult recent work by Gloy (2011) and Key and Sneeringer (2011) who develop estimates of aggregate supply curves for greenhouse gas emission reductions from AD systems.

The analysis makes use of the most comprehensive farm level data set available regarding the economic condition of U.S. dairy farms, the Economic Research Service’s Agricultural and Resource Management Survey, version 4 (ARMS). The ARMS survey contains detailed information on the production, financial and management characteristics of U.S. dairy farms. This study uses the 2005 special dairy costs and returns version of the ARMS to develop estimates of the potential for AD adoption on U.S. dairy farms.

The next section describes the various factors that influence the technical feasibility and economic viability of potential digester systems. Then previous estimates of the potential for AD on U.S. dairy farms are discussed. The data and methodology used to create the estimates is then presented and finally the results are developed and discussed.

Factors Influencing the Viability of AD Systems

There are several significant technical barriers that must be considered in developing an estimate of the potential for AD adoption on U.S. dairy farms. AD systems are designed to handle wet feedstocks with moisture content that is typically at least 85 percent. While the moisture content of excreted dairy manure is acceptable for AD systems, how the farms handle manure plays a role in determining the viability of AD systems. Farms that do not collect excreted manure, because animals are grazing or because animals are not kept in confinement, are unable to adopt an AD system. As a result, farms whose manure handling systems utilize lagoon or liquid slurry storage systems are typically the best candidates for AD systems.

Further, the inclusion of inorganic materials such as sand or dirt greatly reduces the feasibility of AD systems. If dirt or sand is not removed prior to digestion, it tends to settle out of suspension in the digestion tank and quickly fills the reactor. Once substantial amounts of inorganic material has settled in the digester it must be opened and cleaned, greatly reducing the amount of energy that the system generates. Thus, farms that bed with sand or farms that utilize a dry lot housing system are typically not good candidates for AD systems.

While many farms face some technical constraints that impact the potential for AD system adoption, almost all farms face significant economic hurdles to AD adoption. It is clear from previous research that AD systems tend to exhibit large economies of scale (Enahoro and Gloy; Gloy, 2011; Leuer, Hyde, and Richard). A major source for these economies of scale arises due to the fact that AD takes place in large containers or tanks whose construction costs are proportional to surface area and whose revenues are proportional to volume.

Additionally, the AD system requires active management for optimal production, and larger systems are more likely able to justify the managerial expertise necessary to achieve high levels of production. Finally, there are many other capital installation costs such as utility interconnection that have fixed cost elements which make them more suitable for installation on larger farms and prohibitively expensive for smaller operations. While there is no exact farm size at which AD systems become viable alternatives, many previous analyses assume that the system will handle the manure from at least 500 cows and larger farms are likely even more attractive candidates for system installation (Gloy and Dressler 2010).

In addition to the size necessary to achieve viability, there are a number of other economic realities that can significantly impact the potential profitability of AD systems. First, the energy price that the farm currently pays for its electricity and its level of demand is a critical element of potential profitability. Farms that face higher electrical prices will have a better chance at achieving AD system profitability because they are able to off-set higher retail electrical prices. Likewise, the price that the farm receives for any excess electricity sold back to the electrical grid also plays a key role in economic viability. As Gloy and Dressler point out, these factors tend to be very site specific because different utilities have different pricing policies for electricity purchased from AD system operators. Further, some utilities, utility regulators, and state and local governments offer incentives that are designed to enhance the economics of AD systems. An example of these incentives is the production incentives offered to AD systems by the New York State Energy Research and Development Authority (NYSERDA).

The economics of AD systems can be greatly enhanced with the inclusion of additional organic waste streams or substrates such as waste fats and oils. These waste streams sometimes generate “tipping fees” which are payments received by AD operators for taking the wastes. These substrates also often produce biogas which greatly increases the amount of energy that the system is capable of producing. A detailed discussion of these and other economic considerations is available in Enahoro and Gloy.

Finally, AD systems require a substantial capital outlays that will only be recaptured over an extended period of time. In other words, AD systems are long-term capital investments. This means that farms that adopt an AD system must expect to remain in operation for a considerable period of time in order to justify the capital outlay. Likewise, because many dairy farms are capital constrained, the availability of financing for the capital intensive AD projects is a significant economic barrier to AD system installation.

With respect to economic viability at current energy prices and capital requirements for AD systems, most AD systems exhibit marginal profitability at best (Gloy 2011). In fact, most AD systems are not economically viable without government incentives that encourage their adoption. However, the economics of AD systems can be enhanced with government policies such as enhanced electrical pricing, grants to reduce capital expenditures, and/or loan guarantees.

It is also possible that government incentives for AD adoption could be constructed around the idea of paying farmers for greenhouse gas (GHG) reductions achieved by reducing manure methane emissions. At times these incentives have been available in voluntary carbon markets like the Chicago Climate Exchange (CCX). At current carbon off-set prices the revenue stream that would be created by a typical AD system would be trivial. However, if AD systems were qualified to provide carbon off-sets to a larger regulated carbon market created through a cap and trade carbon regulations, the revenue stream might increase substantially.

In order to evaluate the potential impact that the sale of carbon off-sets might have on digester adoption, it is necessary to understand how many AD systems might qualify for carbon off-set credits. Under current rules for the CCX a farm qualifies for GHG emission reduction credits or off-sets if it utilizes a liquid slurry or anaerobic lagoon manure storage system. These systems create methane emissions because manure is stored in anaerobic conditions. However, the amount of methane generated by the manure storages is dependent on a variety of conditions such as temperatures and length of storage.

In summary, there are a variety of technical and economic constraints that should be taken into consideration when estimating the potential for AD adoption on U.S. dairy farms. The following analysis will incorporate many of these technical and economic constraints in assessing the potential for adoption on U.S. dairy farms. Important technical and economic constraints include appropriate animal housing and manure handling systems. Likewise, the farms should be of sufficient size so as to achieve economies of scale in the AD system. Additionally, the farm must have an expected life suitable for AD system payback and the farm must be in a financial condition that allows them to make the capital investment necessary to install the AD system.

Data and Method

This study relies upon a variety of data collected from the 2005 special dairy costs and returns of the USDA/ERS Agricultural Resource Management Survey (ARMS) version 4. The sample for the ARMS survey is developed from a complex survey sampling methodology designed to produce estimates that are statistically representative of the population of U.S. dairy farms that milk more than 10 cows in the 24 important dairy states in the U.S.1 The ARMS survey is administered by paid, professional enumerators. For the 2005 dairy costs and returns study, a total of 1,815 questionnaires were completed. Details of the survey and the methodology used to develop and collect results are available at http://www.ers.usda.gov/data/arms/.

The ARMS 2005 Dairy Production Practices and costs and Returns Report questionnaire contained a large number of questions about the characteristics and financial condition of U.S. dairy farms. These questions were used to develop estimates of the number of digesters that could potentially be developed in the U.S. dairy industry. Several different characteristics of the dairy operation were considered in developing the estimates. These included factors such as the farm size, characteristics of the manure handling and housing system, and financial condition. Each of these items is explained in detail in the following sections.

Farm Size

Because AD systems typically exhibit economies of scale, farm size is an important consideration in understanding the number of farms that could potentially adopt AD systems (Enahoro and Gloy; Leuer, Hyde, and Richard). The amount of manure that is available for the AD system is determined by the number of animals on the farm.

The ARMS survey contains information about the average number of dry and lactating milk cows on each farm. It does not directly ask farms to estimate the total annual manure production on the farm. Instead, it asks questions about the volume of different manure storage structures. In order to estimate the total manure production on the farm, the calculation in equation 1 was calculated for each farm.

(1) Manure = Ml * 365 * lactating + Md * 365 * dry

Where manure is the annual total quantity of manure produced by each farm, Ml is a parameter for the average daily pounds of manure produced by lactating cows, lactating is the average number of lactating cows, Md is a parameter for the average daily pounds of manure produced by dry cows, and dry is the average number of dry cows. In accordance with estimates produced by the ASAE, the parameters for manure production were set to 150 and 83 pounds per animal per day for lactating and dry cows respectively (ASAE). The estimates of total manure production are on an as excreted basis and include both feces and urine.

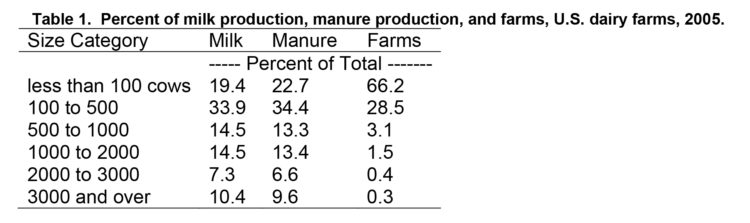

The structure of the dairy industry continues to undergo a shift toward larger operations (LaDue, Gloy, and Cuykendall; MacDonald and McBride). As a result, the nearly half of all of the milk and manure produced in the U.S. comes from the approximately 5.3 percent of dairy farms that milk in excess of 500 cows (Table 1).

While any size farm could technically install an AD system, it is likely that larger farms will find an AD system more economical. This study considers how herd size constraints of at least 500 cows, 1,000 cows, and 2,000 cows would impact the number of operations that might adopt an AD system. It is possible that incentives could be developed so as to make AD system installation on smaller operations economically viable. Likewise, technology could be developed that would allow digestion to be viable at smaller farm sizes. An estimate is also made assuming that there are no size restrictions to adoption of an AD system.

Housing and Manure Handling

The method that the farm uses to collect and store manure has an important impact on the potential feasibility of installing an AD system. First, if the animals spend considerable amounts of time grazing, collecting manure is not likely to be feasible. For this reason, all estimates of digesters excluded farms that were primarily grazing operations. Second, if manure is deposited in a dry lot system it is likely to dry and be contaminated with dirt and other foreign materials that make digestion problematic. Likewise, manure handled on a dry basis is unlikely to be of the appropriate moisture content for an AD system. Additionally, manure that is stored dry produces significantly fewer methane emissions than manure stored in anaerobic or slurry systems (US-EPA, 2009). If policy is designed to encourage digester installation on the basis of reducing methane emissions, it should be targeted toward systems that currently produce methane emissions from manure handling.

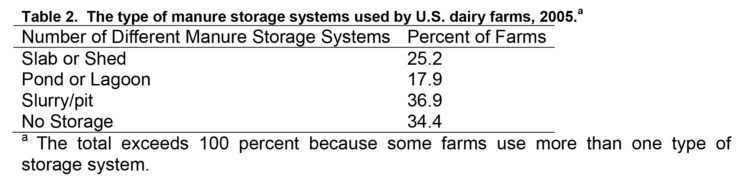

Farms with manure handling systems that would be conducive to AD system installation were determined by examining the type of manure storage systems used by the farm. The ARMS survey asks respondents to identify the various types of manure storages on the farm. Table 2 shows the percentage of farms with various types of manure storages on their farms. Because some farms have multiple types of storages, the total percentage of farms does not add to 100. The second most common type of storage is for farms that have no storage system (34.4 percent). This includes farms that spread manure daily or graze their herds.

Farms with pond or lagoon or slurry/pit systems were identified as possible candidates for AD systems. The types of storage that are appropriate for AD systems are slurry based systems or lagoon systems. Either one of these or both of these systems are present on approximately 55 percent of dairy farms.

Information about the type of manure storage on the farm was used to estimate the carbon dioxide equivalent (CO2e) emissions of the farm from manure in metric tons. The estimates were developed by characterizing the overall manure handling system as an anaerobic lagoon based system, a slurry/pit system, or neither. The Chicago Climate Exchange (CCX) uses these classifications and the state the farm is located to determine the potential methane emissions from manure under its ex ante approach to calculated emission reduction associated with methane destruction (Chicago Climate Exchange). These calculations are part of the process that the CCX uses to calculate offsets for agricultural methane collection and combustion.

The procedure used to estimate the methane emissions for each farm follows the ex-ante procedure and parameter estimates developed by the CCX. As such, the approach used is to identify farms with either a slurry/pit system or an anaerobic lagoon based system. Once these are identified the CCX methane emission factors for each state and the number of dairy cows on the farm are used to calculate the total CO2e methane emissions for the farm. The procedure used in this paper does not consider dairy animals other than cows. To the extent that animals identified in ARMS as milking cows are actually heifers, this approach would overestimate methane emissions from the farm. However, it should be noted that CCX makes no distinction between lactating and dry dairy cows. Because the manure production from lactating animals is nearly twice that of dry animals, the CCX protocol likely overestimates methane emissions as well.

Additionally, when a farm has both pit/slurry systems and anaerobic systems, the CCX protocol would require that the emissions be calculated accordingly. The approach in this paper is to use the estimate from anaerobic lagoons when both types of storages are available. This was done because it was not possible to accurately determine the relative proportion of manure held in the various storages. As such, the process in the paper will likely overestimate methane emissions from manure handling. In total, the methane emissions estimates are believed to be as accurate as can be possible with the level of data that is available at the national level.

Specifically, methane emissions are estimated for each farm according to equation 2.

(2) Manure EmissionsS,T = EFS,TCows

Where Manure EmissionsS,T is the carbon dioxide equivalent emissions of methane in metric tons/farm/year for a farm in state S with manure storage type T, T is the type of manure storage (either anaerobic lagoon or slurry/pit), EFS,T is the emission factor for each state and type of manure storage in metric tons of CO2e per cow per year, and Cows is the average number of dairy cows on the farm. The emissions factors (EFS,T) are taken from the Chicago Climate Exchange protocols for agricultural methane gas projects.

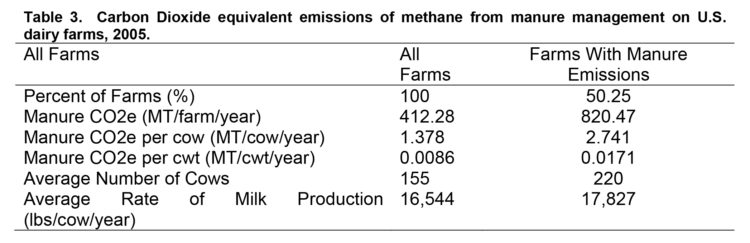

The installation of an AD system should enable the farm to significantly reduce the methane emissions associated with manure management. In order to determine the potential methane emission reduction that could be achieved by AD installation the calculation procedure in equation 2 was used to estimate the CO2e methane emissions from manure for U.S. dairy farms (Table 3).

Based upon the manure storage structures present on the farm approximately half of the dairy farms generate methane emissions from manure storages. Considering all farms, including those with no estimated methane emissions from manure storages, the average dairy farm in the U.S. generates 412 metric tons of CO2e methane emissions from their manure storage. Considering only farms that generate emissions, the average CO2e manure methane emission climbs to 820 MT per farm. For farms with manure emissions, each hundred weight of milk production produces roughly 0.0171 MT’s of CO2e methane emissions. As one can see, the typical farm with manure methane emissions is larger than average and has a higher average rate of milk production per cow per year.

In order to provide some context with which to understand the CO2e emission levels one can compare them to some more basic activities. For instance, the U.S. EPA (2005) estimates that the typical passenger vehicle in the U.S. generates greenhouse gas emissions of 5.5 MT of CO2e annually. In other words, considering farms with manure methane emissions, the average U.S. dairy farm has manure methane emissions equivalent to 149 passenger vehicles. Likewise, the EPA estimates that roughly 4 MT of CO2e per person per year are emitted from U.S. homes, making the average CO2e emissions from manure equivalent to roughly 205 U.S. homes. Clearly, these comparisons are only intended to be illustrative as a dairy farm is a business with substantial economic activity.

Financial Condition

Because AD systems require substantial amounts of capital, the financial condition of the farm will play a key role in system adoption. The major capital expenditures associated with an AD system include construction of the AD reactor, the electrical generator (or other energy conversion device), and modifications to the existing manure handling system. While there is little publically available data regarding the magnitude of these costs, several studies have estimated these expenses for feasibility studies and the estimates of capital costs have varied widely.

For example, Enahoro and Gloy examine installation of an AD system on a 1,000 cow New York farm and use studies from the Cornell Manure Management Program estimate capital expenses at $940 per cow. They also note that the US-EPA’s FarmWare AD evaluation tool produces a capital expense estimate for the same system of $788 per cow. Continuing with the large disparity in capital budgets for AD systems, Lazrus and Rudstrom estimate capital costs at roughly $530 per cow for an 800 cow system in Minnesota. Reflecting the economies of scale described earlier, Leuer, Hyde and Richard estimate that the capital costs at $1,608 and $887 per cow for 500 and 2000 cow installations respectively.

Kramer reports the capital costs for several AD systems noting a range of installed costs of $417 to $763 per head. Additionally, Kramer notes that simple covered lagoon digesters can be installed at substantially lower cost, from $57 to $78 per head. Ultimately, the capital cost of an AD system is dependent upon the type of digester installed and producing an exact estimate applicable to all digesters is not realistic. However, it is clear from previous studies that the digester is a substantial capital investment and one should consider whether dairy farms are in a position to make such an investment.

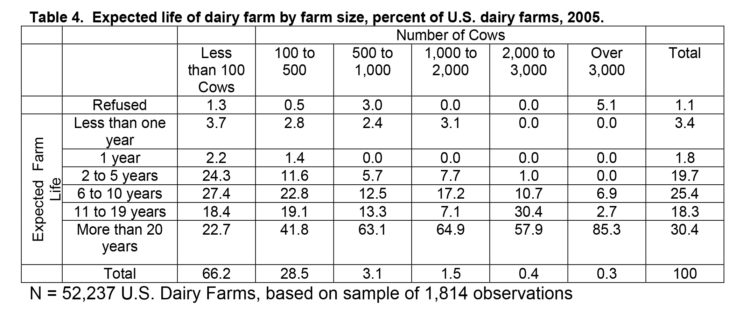

A number of measures were calculated in order to assess how financial condition would influence the likelihood that a farm would be able to adopt an AD system. Because the payoff to an AD system occurs over a relatively long period of time, it is important to consider how long the farm plans to operate. Table 4 shows the expected operating life of U.S. dairy farms by herd size. Over 20 percent of all U.S. dairy farms plan to operate for less than 6 additional years. These farms would be unlikely to adopt an AD system because it is unlikely that they would receive enough financial benefits to justify adoption. Slightly more than 30 percent of all operations expect to operate for more than 20 years. As one would expect, the data in the table also indicate that as opposed to farms with fewer than 500 cows, a much greater proportion of larger farms expect to have a lifespan in excess of 20 years.

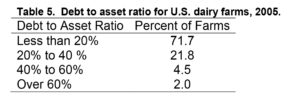

In addition to expectations about operating lifespan, one should also consider the financial condition of the dairy farms when examining the potential for AD adoption. Farms with substantial debt and poor cash flow are unlikely to have the financial capacity necessary to make the significant investment that would be required to install and AD system. Table 5 shows how the proportion of assets financed with debt (debt to asset ratio) in 2005. Farms with greater proportions of existing debt are less likely to be able to adopt as they are more financial constrained.

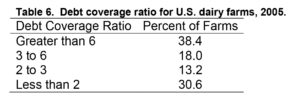

The debt coverage ratio was calculated in order to measure the cash flow generation of U.S. dairy farms relative to their debt servicing requirements (Table 6). The debt coverage ratio is a measure of the farm’s cash flow position and describes how well the farm produces cash flow to service its debts. Here, larger values indicate larger amounts of cash flow relative to debt servicing requirements, placing the farm operation in a more comfortable financial position. Slightly over half of the farms had a debt coverage ratio in excess of 3 meaning that they had cash flow sufficient to cover their debt service requirements 3 times over.

Criteria for Digester Adoption

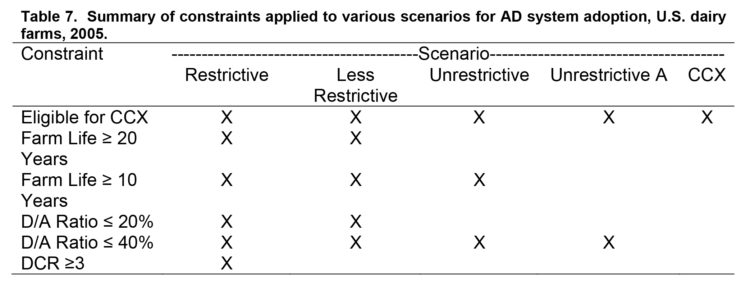

The various criteria discussed above were used to construct a variety of constraints that were used to evaluate the potential adoption of AD systems on U.S. dairy farms. Five different scenarios were developed ranging from restrictive to just identifying farms that would be eligible for manure methane reductions by installing an AD system under CCX rules (Table 7). After the application of the constraints for each scenario, the number of farms eligible to adopt AD systems were identified and the manure methane emissions associated with these farms were calculated.

In order for a farm to be able to adopt an AD in the restrictive scenario, the farm must be eligible for CCX (store manure in slurry or anaerobic conditions), expect to operate for at least 20 years, have a debt to asset ratio less than 20%, and a debt coverage ratio (DCR) greater than 3. The less restrictive scenario relaxes the debt coverage ratio requirement and only focuses on the debt to asset ratio. This was done because the debt coverage ratio can vary substantially from year to year and some farms in very sound financial condition could easily experience a year in which the debt coverage ratio was less than 3.

The first unrestrictive scenario requires that the farm be eligible for CCX, expects to operate for at least 10 years, and have a debt to asset ratio less than 40%. This scenario identifies farms in relatively strong financial condition and farms that expect to operate for a considerable period of time. The scenario labeled unrestrictive A eliminates the condition that the farm plans to operate for at least 10 years. The final scenario, CCX, considers only whether farms store manure in anaerobic conditions.

Results

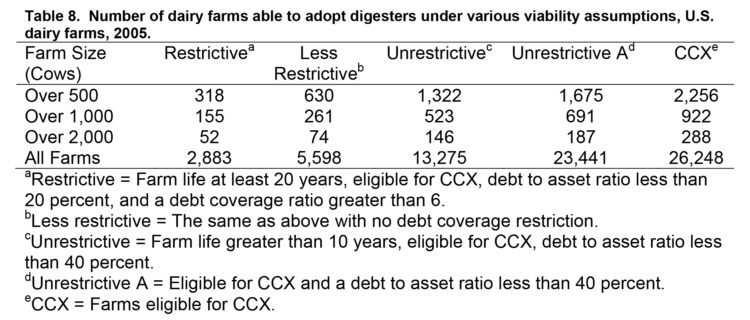

The scenarios in Table 7 were applied to the 2005 ARMS dairy data. The results indicate the number of farms able to adopt AD systems under various constraints (Table 8). Here, one can see that if no farm size constraints are considered and the least restrictive constraint set is applied, anaerobic manure storage (CCX), nearly 26,248 could technically reduce manure methane emissions through the installation of an AD system (final column of Table 8). However, one can see that most of these farms are smaller in size. If only farms over 500 cows are considered under the anaerobic storage requirement, the number of potential farms drops to 2,256 farms.

As one applies more restrictive assumptions about the characteristics required for adoption, the number of farms able to adopt an AD system declines rapidly. For instance, under the most restrictive assumptions and assuming that a 500 cow farm is the minimum efficient scale for an AD system only 318 farms would be good candidates for AD systems. In other words, the number of AD systems currently installed on U.S. dairy farms is about one third of the total potential. If one were to assume that any size farm could adopt, then the potential number would increase to 2,883 farms.

Overall, several important findings can be derived from these results. First, the role of farm size is critical in determining the number of farms that could potentially adopt an AD system. As the minimum farm size increase, the number of potential AD systems declines rapidly. These results indicate that if one hopes to achieve widespread adoption of AD systems that it is important to develop technology that can be applied on smaller dairy farms.

Second, the financial and operating characteristics of the farms are critical considerations in AD adoption. While there are 2,256 farms over 500 cows that store manure in anaerobic conditions, many are unlikely to adopt because they either do not expect to remain in operation much longer or their financial condition is such that they would be unlikely to adopt an AD system at this time. This means that either the profitability of AD systems will have to be improved greatly to encourage adoption and/or financing incentives or grants will likely be required for broader adoption.

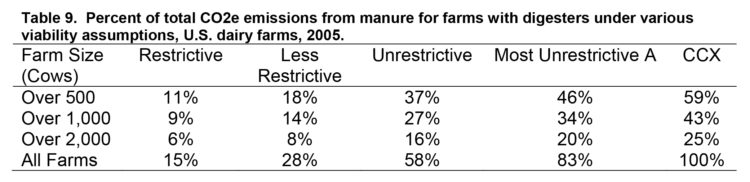

Once the number of farms able to adopt AD systems were determined, it was possible to calculate how adoption of digesters on these farms would influence the total amount of CO2e emissions from manure storages (Table 9). The calculations in Table 9 were completed using the methane emission factors developed by the CCX. These factors include only methane that would normally be emitted from these storages, not the amount of methane that would be produced by the AD systems.

The results show that even with only a modest adoption of AD systems, it is possible to achieve relatively significant reductions in the amount of methane produced by U.S. dairy farms. For instance, even under the most restrictive assumptions, nearly 15 percent of the manure methane emissions of the U.S. dairy sector could be reduced through the adoption of AD systems on only 2,883 dairy farms. If only farms over 500 cows were to adopt under the most restrictive constraints, nearly 11% of the methane emissions could be eliminated.

The results indicate that technical and financial constraints are likely to be a barrier to widespread adoption of AD systems. Economic constraints related to the financial condition of the dairy farms, greatly reduce the number of farms that are able to adopt systems. If these constraints were lessened through either grants or increased returns to AD systems, it is possible that substantial amounts of the manure methane emissions of the sector could be reduced. These incentives would allow one to move to the right in Tables 8 and 9 where larger numbers of farms were able to adopt, and greater amounts of manure methane emissions captured.

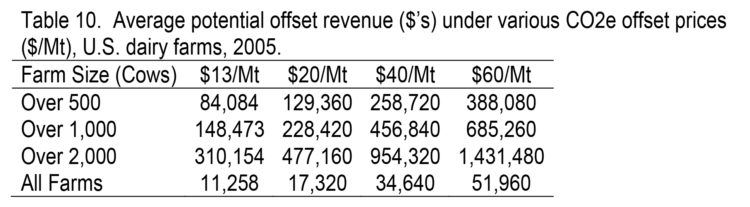

One method in which this could be accomplished would be to compensate dairy producers for methane emission reductions produced by AD systems. Here, the question becomes how would various price levels for CO2e emission reductions influence adoption?2 While the analysis of that question in detail is beyond the scope of this paper, it is possible to illustrate how different carbon prices would influence the revenue generated by the AD system. Table 10 shows the potential CO2e offset revenue that would be generated at different carbon offset prices.

These results indicate that under different carbon prices offset revenues could provide a substantial revenue stream for some dairy farms. The more thorough analysis of this issue in Gloy (2011) indicates that roughly 2,300 farms would be able to economically justify AD adoption at offset prices between $10 and $20 per Mt. Further, he found that a price of $20 per Mt for CO2e offsets would results in approximately a 60% reduction of manure methane emissions from 2005 levels.

Summary

Anaerobic digestion (AD) systems provide a number of potential benefits for dairy farmers and society in general. However, their adoption has been slowed by a number of economic and technical constraints. This article illustrated how several technical and financial constraints influences the potential adoption of AD systems. If more farms are to adopt AD systems, it will be necessary to improve the economics of AD systems on smaller farms, and/or improve the financial incentives associated with adoption.

One possible approach is to provide greater financial grants to ease the capital constraints associated with AD adoption. This would allow more farms to adopt AD systems. In addition, providing a price for manure methane emission reductions would improve the economics of AD adoption, although relatively high prices are likely required to make AD widely adopted.

Given the economic concentration in the dairy industry, it is possible to achieve a large reduction in the manure methane emissions of the sector by installing digesters on a relatively small number of the largest U.S. dairy farms. For instance, manure methane emissions could be reduced by nearly 25% with the installation of AD systems on less than 1% of U.S. dairy farms. However, it is very important to realize that many of these farms would require substantial financial assistance in order to justify adoption.

1 The states covered by the survey are AZ, CA, FL, GA, ID, IL, IN, IA, KY, ME, MI, MN, MO, NM, NY, OH, OR, PA, TN, TX, VT, VA, WA, WI

2 For a detailed analysis of this question, readers should consult Gloy (2011) where a thorough analysis with a supply curve which shows how digester adoption varies with carbon offset prices is presented.

References

ASAE. “Manure Production and Characteristics.” American Society of Agricultural Engineers, St. Joseph, MI, March 2005, ASAE D384.2.

Chicago Climate Exchange. Agricultural Methane Gas Project Guidelines.” Chicago Climate Exchange. Available at: http://www.chicagoclimatex.com/docs/offsets/Agriculture_Methane_Protocol.pdf.

Enahoro, D.K. and B.A. Gloy. “Economic Analysis of Anaerobic Digestion Systems and the Financial Incentives provided by the New York State Renewable Portfolio Standard (RPS) Customer-Sited Tier (CST) Anaerobic Digester Gas (ADG)-to-Electricity Program.” Extension Bulletin 4 (2008). 23 pages. Department of Applied Economics and Management, Cornell University.

Gloy, B.A. “The Potential Supply of Carbon Dioxide Offsets from the Anaerobic Digestion of Dairy Waste in the United States.” Applied Economic Perspectives and Policy, 33:1(2011):59-78.

Gloy, B.A. “Creating Renewable Energy from Livestock Waste: Overcoming Barriers to Adoption.” Extension Bulletin 2 (2008). 17 pages. Department of Applied Economics and Management, Cornell University.

Gloy, B.A. and J.B. Dressler. “Financial Barriers to the Adoption of Anaerobic Digestion on U.S. Livestock Operations.” Agricultural Finance Review, 70:2(2010):157-168.

Key, N. D. and S.E. Sneeringer. “Climate Change Policy and the Adoption of Methane Digesters on Livestock Operations,” Economic Research Report 102758, 2011, United States Department of Agriculture, Economic Research Service.

Leuer, E.R., J. Hyde, and T.L. Richard. “Investing in Methane Digesters on Pennsylvania Dairy Farms: Implications of Scale Economies and Environmental Programs.” Agricultural and Resource Economics Review 37/2 (October 2008): 188–203.

LaDue, E.L., B. A. Gloy, and C. Cuykendall. “Future Structure of the Dairy Industry: Historical Trends, Projections, and Issues.” Research Bulletin 01(2003). 60 pages. Department of Applied Economics and Management, Cornell University.

MacDonald, J.M. and W.D. McBride. 2009. “The Transformation of U.S. Livestock Agriculture: Scale, Efficiency, and Risks.” Information Bulletin No.43. Economic Research Service, U.S. Department of Agriculture.

United States, Environmental Protection Agency. 2006. “Market Opportunities for Biogas Recovery Systems A Guide to Identifying Candidates for On-Farm and Centralized Systems.” EPA-430-8-06-004www.epa.gov/agstar.

US-EPA. 2005. “Greenhouse Gas Emissions from a Typical Passenger Vehicle.” United States, Environmental Protection Agency, Office of Transportation and Air Quality, Washington, D.C., EPA420-F-05-004.

US-EPA. 2006a. “AgStar Digest.” United States, Environmental Protection Agency, Office of Air and Radiation , Washington, D.C., Winter 2006.

US-EPA. 2006b. “Market Opportunities for Biogas Recovery Systems A Guide to Identifying Candidates for On-Farm and Centralized Systems.” United States, Environmental Protection Agency. EPA-430-8-06-004www.epa.gov/agstar.

US-EPA. 2009. “Inventory of U.S. Greenhouse Gas Emissions and Sinks: 1990-2007.” United States, Environmental Protection Agency. EPA-430-R-09-004.

TAGS:

TEAM LINKS:

RELATED RESOURCES

UPCOMING EVENTS

We are taking a short break, but please plan to join us at one of our future programs that is a little farther in the future.