February 22, 2021

The Value of Data/Information and the Payoff of Precision Farming

by Mike Boehlje [1]

I. New Technologies of Modern-Day Crop Farming

Crop farming around the world is undergoing a profound technological transition. The management of production is moving toward more micro-management of production activities by individual field or location within a field driven by detailed and site-specific information about the environment and biological and economic factors that affect physical output (yield) and economic profitability as well as soil and water quality.

Increased use of monitoring technology will greatly expand the amount of information available regarding what affects plant growth and well-being. This will be made possible by innovations in sensors to use in monitoring and control systems, communication technologies and data analytics. In addition, greater understanding of how various growth and environmental factors interact to affect biological performance will be forthcoming. This understanding will then be designed into management systems which incorporate the optimum combinations of inputs and apply them at a micro or localized level. Precision farming in crop production includes the use of global positioning systems (GPS), yield monitors and variable rate application technology to more precisely apply crop inputs to enhance growth, lower cost and reduce environmental degradation.

Growing crops through precision production practices might be described as “biological manufacturing” — combining bio-nutritional technology, process control technology and sensing/measuring/monitoring technology to control and enhance productivity and plant growth. The critical linchpin among these “technology buckets” for successful execution is the data and information that can be continuously captured and utilized to manage the system and intervene in real time to control and enhance the growth process.

The transition of production agriculture from an industry that grows crops to one that biologically manufactures raw materials with specific attributes and characteristics for food and industrial use products is well underway. Three types of technology are critical in biological manufacturing:

- Biotechnology and nutritional technology,

- Monitoring/measuring and information technology, and

- Process control technology.

Biotechnology and nutritional technology

The focus of biotechnology and nutritional technology is to manipulate the growth and attribute development and deterioration process in plant production. An improved scientific base to understand how nutrition impacts not only plant growth but attribute development is providing additional capacity to manipulate and control that process. And biotechnology is advancing our capacity to control and manipulate plant growth and development including attribute composition (for example, starch or amino acid composition) through genetic manipulation. By combining nutritional and biotechnology concepts with mechanical and other technologies to control or adjust the growth environment (temperature, humidity and moisture, pest and disease infestation, etc.), the process control approach and thinking that is part of the assembly line used in mechanical manufacturing becomes closer to reality in biological manufacturing.

Monitoring/measuring and information technology

The focus of this technology is to trace the development and/or deterioration of attributes in the plant growth process, and to measure the impact of controllable and uncontrollable variables that are impacting that growth process. In crop production, yield monitors, global positioning systems (GPS), global information systems (GIS), satellite or aerial photography and imagery, weather monitoring and measuring systems, and plant and soil sensing systems are part of this technology. In future years, in-plant sensors to detect growth rates and disease characteristics may be part of such information and monitoring/measuring systems. And these systems will be tied to growth models to detect ways to improve growth performance, as well as to financial and physical performance accounting systems to monitor overall performance. The computer technology to manipulate the massive amounts of information is readily available; new monitoring/measuring technology including near-infrared (NIR) and electromagnetic scanning is now being developed to measure a broad spectrum of characteristics of the plant growth process.

Process control technology

The concept of process control technology is to intervene with the proper adjustments or controls that will close the gap any time actual performance of a process deviates from potential performance. Greenhouse production increasingly utilizes such technology to manipulate sunlight, humidity, temperature, and other characteristics of the plant growth environment. Irrigation systems are an example of this technology in field crop production; modern irrigation systems tied to weather stations and plant and soil sensors automatically turn irrigation systems on when moisture becomes a constraint to plant growth, and automatically turn the systems off when moisture levels are adequate for optimum growth. Variable rate application of fertilizer and chemicals and row shut-off technology are current examples of process control technology in rain-fed crop production. Modern precision planter technology that automatically adjusts seed placement, depth and soil coverage based on soil sensors is another example.

Combining real time monitoring/measuring technology and anytime intervention process control technology has the potential to generate significant benefits. Any-time intervention technology allows one to detect a problem when it occurs and real-time solve that problem rather than anticipate a possible problem and preemptively dispense control inputs that may be completely unnecessary (and thus costly) and possibly even harmful to the growth environment if that problem does not occur. For example, any-time intervention technology allows the detection of corn borers and the treatment of those borers once they meet an economic threshold, rather than spending funds and using materials in anticipation that a corn borer infestation might occur which are unneeded if the infestation does not reach an economic threshold during the growing season. A similar approach might be used to control weeds. Similar approaches to fertility management facilitate lower levels of pre-season fertilizer applications by enabling additional applications during the growing season as real-time sensing technology and drop-down nozzle attachments for high clearance sprayers enable split applications of fertilizer to be applied when needed. If such technology is developed, it may be less essential to use biotechnology to resist certain insects or larger than necessary fertilizer applications to insure the highest yield if growing conditions are exceptional.

It would be unrealistic to expect these process control and sensing technologies and methods to be as successful as they have been in industrial manufacturing in reducing variability and systemizing the processes of producing manufactured goods such as automobiles, computers or even chemicals and industrial goods. However, it is also unrealistic to ignore the potential of these technologies in reducing variability and obtaining more control over biological growth processes so as to increase efficiency, reduce costs, improve quality, minimize environmental impacts and in general more systematically produce biological based specific attribute food, feed, fuel and fiber raw materials. In essence, this is what the concepts of biological manufacturing are all about – to use monitoring/measuring, biological and nutritional manipulation and process control technologies to systematically manufacture food and industrial use products.

II. What is Information and How Does Data Become Valuable?

The Concepts

The concept of information means different things to different people. In this discussion, we will distinguish between three important concepts – 1) knowledge, 2) data, and 3) information.

Knowledge is the broad-based concepts, theories, principles and models that are necessary to understand a particular phenomena. Knowledge can be applied broadly across many sets of facts and circumstances or contexts. It is not data specific or unique, but helps one sort through the vast quantities of data available to determine what is relevant.

Data are more specific than knowledge; they frequently are individual numbers or observations. Data can be quantitative or qualitative in nature. At the extreme data is distinguishable from knowledge in that data is specific while knowledge is general. Clearly this clean distinction becomes fuzzy at times.

Information is different from data or knowledge in two important dimensions: first, it is context specific, and second it is decision focused. In essence, if knowledge and data are combined and applied to a specific context (for example, a specific crop and parcel of land) and a specific decision (the proper level of fertilizer to apply to obtain a particular yield of a particular crop), they are transformed into valuable information. Data that is context specific and decision focused becomes information; information combined with knowledge results in improved decision making and better physical and financial performance.

Information has many attributes. It must be timely – appropriate to the decision context and not out-of-date. It must be technically accurate and scientifically sound. It must be objective and unbiased, and/or value judgments must be explicitly identified. It must be complete (as opposed to partial) so as to be useful in a decision, or its partial or incomplete nature must be clearly specified. It must be understandable – communicated in such a way that the user can comprehend it. And finally, it must be convenient – available when and where and at what time the user needs or wants it. These attributes will determine the value of information. The digital transformation of farming which is described in the Text Box has significantly enhanced these attributes and dramatically increased the value of information.

Accuracy/Resolution

As has been noted earlier, data becomes valuable as information as it becomes context specific and decision focused. This concept introduces the challenges of the accuracy or resolution associated with data. In crop production, data are becoming more unit or activity specific. Geographic information and mapping systems combined with GPS guidance systems are being used to increase the resolution and accuracy in evaluating soil productivity characteristics and crop growing conditions by location in the field and make appropriate fertilizer, chemical and other management input adjustments to increase yield or reduce cost. This site specificity results in the potential for more precise crop farming.

At the same time as our measuring and monitoring systems have the potential to become more site or unit specific and real time, the techniques for summarizing this data and converting it into decision focused information may not be keeping pace. Geo- referenced guidance linked to variable rate seed, fertilizer and pest control application systems has the potential to generate not just yield maps, but profit or operating margin maps that enable us to assess which locales (acres, parcels, grids, etc.) generate the highest returns. And this data analysis system could even project or simulate during the growing season the profit potential of additional within season variable rate applications of fertilizer or insect and weed control informed by real time sensing of the plant growth process.

Most standard farm accounting systems are driven by bottom-line, whole farm or enterprise financial results with significant lags in measurement. With increased capacity to measure and monitor the process of crop growth combined with increased emphasis on process control to increase efficiency and improve quality, more of the accounting/record keeping/data gathering activities must focus on process monitoring and measurement or activity accounting. This level of specificity and resolution is generally not yet part of standard accounting and data acquisition systems in agriculture – -but changes are coming.

A point of caution on this issue of accuracy and resolution. Some decisions require further refinement of accuracy and increased resolution; this is particularly the case with tactical decisions in the production and marketing area where there will be an increasing emphasis on process monitoring and control. Other decisions – particularly strategic decisions – may not require as much data specificity and resolution. One must be careful to not become immobilized in the decision-making process by too much data or too high a level of data specificity. And data gathering incurs a cost as well as a benefit. Thus, the level of data specificity must be matched to the decision that must be made, and the cost of gathering that data at an increased level of specificity or resolution must be compared to the benefits received.

When Should I Start Collecting Data?

Some argue that “I can’t waste my time collecting data that I’m not sure will be useful in making decisions; and when they show me it is useful, I will start to collect it.” That seems to be a reasonable argument, but it has a fatal flaw. Data that is available but not recorded is lost forever – for example it is virtually impossible to reconstruct yield data from different areas in a field if it is not collected and linked to a specific location when the crop is harvested. Once we had the technology to make variable rate applications to more accurately apply seed and fertilizer to locations in the field where it could have the most potential to increase yield, we needed yield maps to inform the variable rate decisions. If we had not yet collected the data to generate a yield map, we could start to do so to enable us to make more informed decisions in future years. But given the complexity and the high level of variability in crop production, one or two (or even three or four) year’s data observations doesn’t provide very accurate information to make agronomic management decisions. Science based decision making indicates that multiple observations are required to have the accuracy needed given the complexity and high level of variability in rain-fed crop production. And with the annual production cycles for crops like corn and soybeans, the number of observations one can collect is severely constrained even over a farmer’s lifetime. A missed observation lost forever is a high loss in long cycle-time crop production agriculture when data and information are an increasingly more important source of higher profitability and better financial success. Data must be collected and recorded when it is available – you can’t wait until it is proven to be useful!

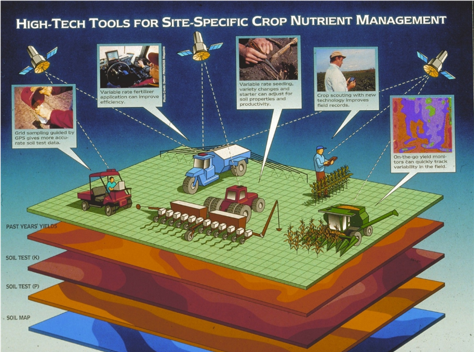

The Digital Transformation of FarmingThe use of digital technology in farming has evolved through a number of stages over the last 2-3 decades. During the 1990’s it was recognized that more accurate and timely data could be used to make better decisions. In one of the early reports on precision farming, Sonka and Coaldrake identified five interconnected geo-referenced data layers - - aerial, soil profile, NDVI, thermal, yield map - - that could be useful in understanding, documenting and manipulating the plant growth process and the relationship between inputs (sunlight, temperature, moisture, fertilizer, chemicals, etc.) and output (yield, attribute composition, water leaching, etc.) in crop production. (Figure 1).  Figure 1. High-Tech Tools for Site-Specific Crop Nutrient Management In the 1990s the information technology systems needed to collect and analyze that data were perceived to be more costly and difficult to implement than the data was worth in decision making. Improved communication and sensing technologies in the early 2000’s allowed better data analysis and communication within the farm as well as with suppliers and buyers, but information and communication technologies (ICT) as well as limited connective in rural areas continued to present cost and implementation challenges. Today the combination of cloud computing, artificial intelligence (AI), Big Data and the Internet of Things (IoT) technologies is breaking through the cost and effectiveness barriers to adoption, and we are in the early stages of a digital transformation in the farming sector. |

III. The Critical Role of Data/Information in Today’s Uncertain Business Climate

The business climate regularly presents challenges to the profitability and financial performance of even well managed crop forms. Given expectations that crop prices and farm incomes will periodically come under pressure, it is critical for farmers to “double down” on implementing the management strategies and practices to maintain or enhance profitability and reduce the prospects of reduced financial deterioration of their business. What are some of the strategies and practices that are critical to being “best in class”, irrespective of the business climate, to have the resiliency and agility to handle the kind of uncertainty farmers are currently facing?

-

Improve Efficiency/Productivity

Without a doubt high efficiency and productivity are essential for success, even more so when prices and margins are under pressure. Doing everything you can to choose the right seed, fertility, pest control and other agronomic inputs and practices that will generate the best economic yield is essential – – remember that the highest physical yield is not the best if the cost to obtain additional bushels is higher than the value of those additional bushels. But given the uncertainty in weather and prices, it is difficult to be exactly correct in your agronomic decisions, so it is often better to over-apply than under-apply fertilizer in particular (but not too much!) to capture the yield potential that is available.

-

Intense Cost Control

In a commodity industry like crop farming, you have to be a low-cost producer to be successful in the long-run. So cost control is absolutely essential. Determining cost per unit of production (i.e. bushel of corn or soybeans) and detailing those costs by major category (for example, seed, fertilizer, chemicals, etc.) is one way to know which costs are the most important to focus on and attempt to reduce. One of the biggest cost categories is land cost. Rental payments on cash rented land have not adjusted down as much as most other input costs, and it is a difficult but important discussion to talk to your land owners and negotiate a lower rental rate. How long can you hold on to a rental property if you are losing money and expect to continue to do so? Maybe you could negotiate a flexible cash lease (a lower base payment per acre with an additional payment if prices or yields exceed a specified level), or a crop-share lease arrangement.

-

Improve Operations/Execution

Get it done right and in a timely fashion. In the manufacturing industries, this is known as “lean” production practices and procedures. Systemize the production processes by using check-lists and standard operating procedures (SOP’s) to make sure all the tasks necessary to produce a crop are done at the right time, the right order and the right way. Use the best data and information on field conditions and weather forecasts to schedule machine operations and sequencing of tillage, planting and harvesting operations by field and location. Expand the number of hours in the field per day and/or increase your workforce to get the most work accomplished in the suitable field days during the growing season. Maybe double or triple shift your field – work activities so you can operate as close as possible to 24 hours a day when field conditions allow you to do so. Use computer-based work flow scheduling procedures to plan your daily activities and have the capacity to quickly make the necessary adjustments when weather events or other interruptions such as equipment breakdowns disrupt your schedule. Details! Details! Details! Get it done right!

-

Manage Margins

Exactly determining profit margins is not easy when you don’t know what prices and/or yields will be, but it is still useful to estimate your profit margin, and more valuable to estimate it for different levels of prices and yields to determine the sensitivity of profit and cash flows to weather and market conditions. Determining potential margins per bushel of production requires estimates of costs per bushel which can also be useful in making marketing decisions. If product prices are above costs, maybe you should capture or lock in that margin/profit on some of your potential sales just in case market prices deteriorate in the future. And if you are projecting a negative margin and expect to lose money, it is important to know the size of the potential loss and develop a plan to make sure you can cover your financial commitments and not impede the survivability of the business.

-

Buy Right

Some businessmen say that the first and most important “marketing” decision they make is what inputs or raw materials they purchase and what they pay for them because that sets their cost structure. This is why most industrial manufacturing businesses have someone responsible for procurement – – buying right. And certainly, particularly in farming, you have more control over costs than you do over market prices, so time spent on making the best decision on “buying right” is critical to financial performance. Comparing potential suppliers’ offers just like one compares the prices offered by different product buyers is an important task in buying right. One common practice in the business world is to use a “spec sheet” to systemize and document those offers. And the spec sheet should include not just prices, but other features such as services included, performance guarantees or warranties, discounts if available, delivery conditions, information sources, contacts for complaint resolution, financing terms, etc.

-

Manage Operating Risk

Operating or business risk is the variability in the income generation and financial performance of the farm resulting from the variability in the prices, yield and costs that the farm business faces. Managing this risk can almost be a full time job. It involves choosing the right technology to reduce yield loss from weed and insect pests, from nutrient/fertility inadequacy or losses, seed that is not disease or weather resistant, equipment that is not reliable and subject to frequent breakdowns, etc. Operating risk can also result from marketing decisions that don’t recognize product price and basis volatility and input price increases. Choice of the government farm program options and the most appropriate crop insurance alternatives are important management strategies to manage operating risk, along with having the appropriate casualty and liability insurance program.

-

Debt/Capital Management

The capital structure of the business (the proportion of the assets financed with borrowed or lease funds compared to owner’s equity funds) is a critical source of financial risk. Common sense says a business has increased financial vulnerability as it relies on increased amounts of debt (and thus has a higher debt to asset ratio) to finance its activities. But there is more to it. Using short-term credit (an operating loan for example) to fund the purchase of a capital asset such as machinery or land can be a disaster if the operating line is reduced or not renewed in subsequent years. Loan repayment terms must be “matched” to the useful life of the asset so that earnings from using those assets can be used to service the debt. Lenders are interested not just in the total debt of a business, but the structure and repayment terms of that debt. And a premium is placed on the “liquidity” of the business as indicated by the amount of cash that will be generated during the normal business cycle from sales of products and inventories which will be available to make principle and interest payments on the debt. Lenders want a cushion or reserve in this “working capital” position so the scheduled payments can be made even if lower prices/yields or other factors reduce incomes or cash flows. Making the right choice to lengthen loan repayment terms, reduce capital expenditures, sell some underutilized assets to generate cash, use excess cash or negotiate a cash infusion from outside the business, or use some other strategy to respond if debt repayment problems are encountered is a difficult decision that is best avoided if possible by well developed debt/capital management plans.

-

Simplification/Automation

One way to improve the operations/execution process and the accuracy of getting everything “done right” is to simplify the processes as much as possible. Complexity creates confusion and results in mistakes. This doesn’t mean taking “short-cuts” and not doing the critical tasks correctly – – it means dropping the steps/activities that aren’t essential and making sure everyone is not just familiar with the SOP’s, but is actually using them to get the work done. And better yet, new precision farming technology (autonomous self-driving tractors, irrigation control systems, automated calibration of yield monitors, automated combine header and threshing controls, etc.) is increasingly making it possible to automate more and more farming activities.

-

Do Fewer Things Better

Unfortunately many farmers suffer from the “jack of all trades, master of none” phenomena – – they do not have the time/energy to be “best in class” in everything they do, so aren’t as successful as they might be. A standard question asked by consultants who specialize in business management is what do you do better than anyone-else – – what is your core competency. Figure out what you are really good at and then focus on continually getting better at it over time. But what about those activities that need to get done but you don’t have the time/energy to do them? Hire or retain someone who specializes in that activity – – a standard practice for legal or accounting work. Maybe you need to do more “outsourcing” of other activities – – retain a crop consultant or a market advisory service, hire someone to custom spray your crops or transport the crop to the elevator. Focus on doing fewer things better.

-

Data Management

Just think about what your grandfather would say if he had all of the data and information that is now available to you to make farming decisions. Certainly, he would be concerned about “data overload” just like you are today, but the tools and techniques are increasingly available to sort through that data/information and make more informed and better decisions. No doubt you will need assistance in collecting the data and carefully analyzing it to sort-out false signals or noise from facts and true insight. But as we will discuss later, the payoff is there for time/energy/money spent on data management. One final comment. The lynch-pin and common denominator of all these strategies and practices is to have the most accurate data and information as well as the appropriate analytics and decision processes to make the right choices and implement the best strategies. Digitization of agriculture and the significant advances in the development of precision agriculture tools and techniques has enhanced our capacity to adopt strategies that will enhance resiliency and agility to respond in these increasingly uncertain times.

The increasing role that knowledge and information play in obtaining control of resources, increasing profits and reducing risk is occurring for two fundamental reasons. The first reason is the dramatic growth in knowledge of the chemical, biological and physical processes involved in agricultural production. This vast expansion in knowledge and understanding means that those who can sort through that knowledge and information and put it to work in a practical context have a better chance of success. Second, the “food business” has become an increasingly sophisticated and complex business in contrast to producing commodities as in the past. This increased complexity means that those with more knowledge and information about the detailed processes as well as how to combine those processes in a total system (i.e. a food chain approach) will have a comparative advantage. Whereas the physical resources of land, labor, and capital were the key determinants of financial success in the past, the role of knowledge and information will become more important in the future. Superior knowledge and information will enable producers to more successfully obtain the physical resources of land, labor, and capital and combine them in an efficient manner. Thus, the role of knowledge and information to success in the agricultural industry is more important today than ever before.

The Modern Global Farmer: Positioning For The FutureTom Farms, a very successful multi-generation family farm in northern Indiana, is an example of the modern 21st Century farming business. They describe their approach to farming as:

A critical component of Tom Farms’ success has been to identify, evaluate and adopt superior technology rapidly when the returns to that technology can be high. The farm uses GPS technology for field mapping, field management, RTK auto guidance, yield mapping, nutrient and pesticide application, soil testing on grids and tractor operation monitoring. In the transportation business, they use bar code tracking and geo-referenced placement. Using these technologies allows Tom Farms to successfully leverage the information to make better decisions that affect operational efficiencies and improve productivity and yields. In all cases, the focus is not on the technology itself, but on the value that can be added from using the technology. Plus, they always look for innovative ways to use the technology that others have not yet recognized. Kip says, “New technologies are implemented that provide information that reduces costs while making customers more aware of the products and services we are providing. We utilize sophisticated accounting to understand our various profit and costs centers.” That technology is evaluated within the broader scope of the business’ objectives. |

IV. The Adoption of Precision Agriculture Technology

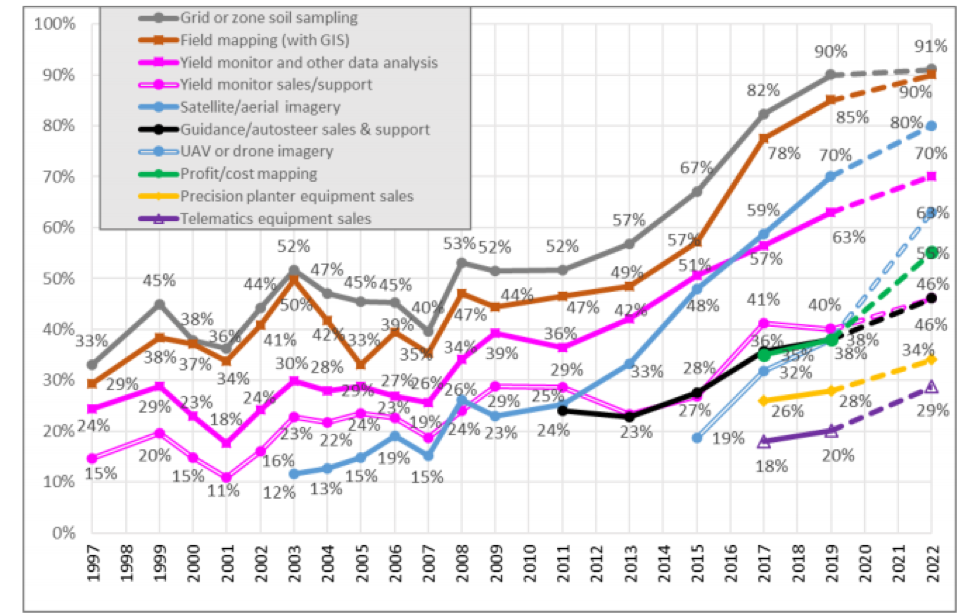

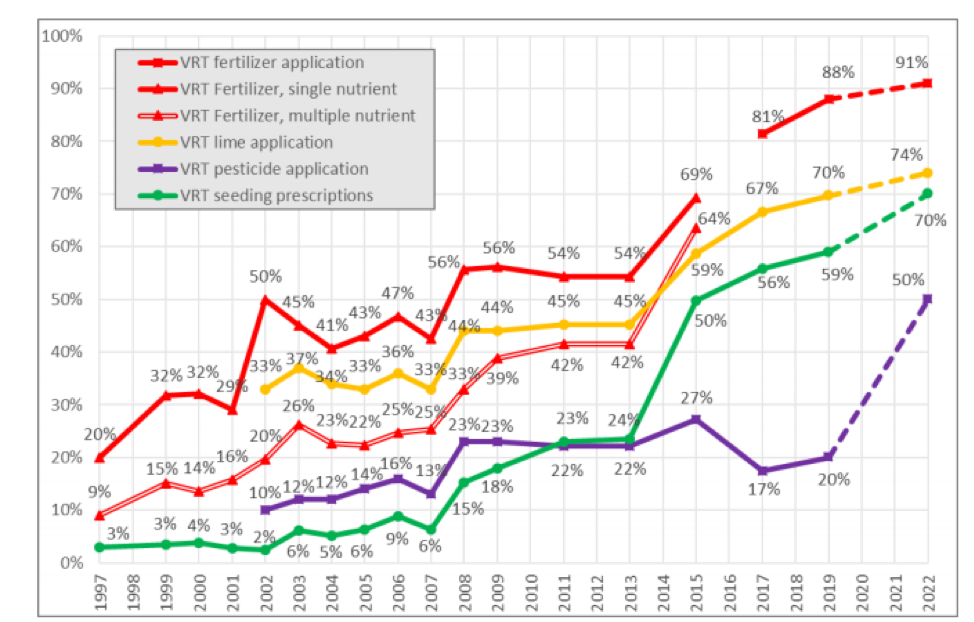

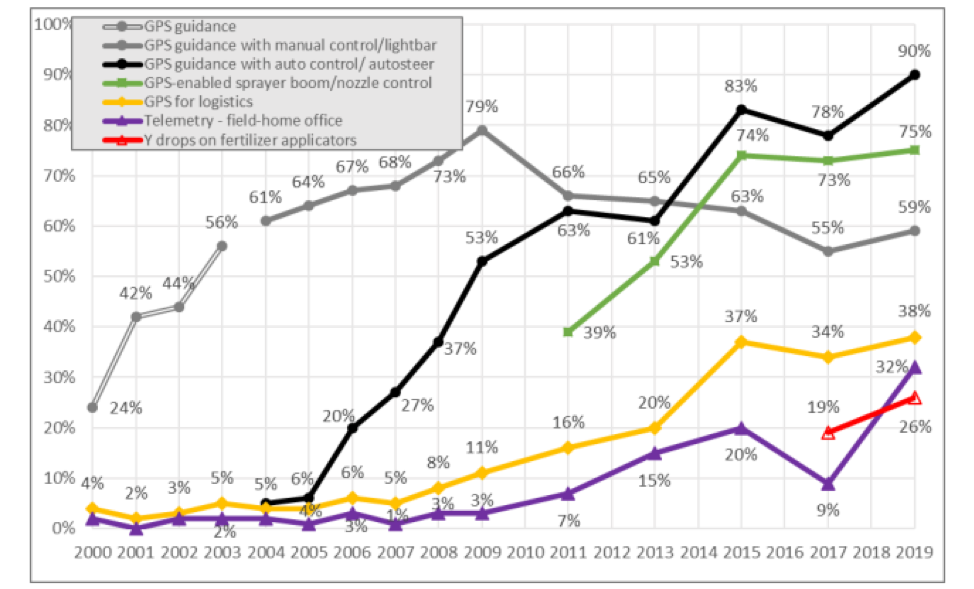

So, what is the current status of the availability and use of precision agriculture technology and information systems? A 2019 survey of ag retailers provides a useful perspective (Erickson and Lowenberg DeBoer). This survey of precision farming technology adoption was initiated in 1997, so it provides a historical perspective of the development over time of precision farming technology adoption as well as some evidence of future challenges and opportunities. A total of 165 dealers responded to the 2019 survey. Figure 2 summarizes the sensing-based precision farming service offerings since 1997 and expectations for increased offerings by 2022. The availability of service offerings increased relatively slowly for the first 10 or so years, but since the year 2010 it has accelerated so that by 2019 grid/zone soil sampling, satellite aerial vehicle imaging and yield mapping services are now at offering levels of approximately 70-90% of dealers, more than double their levels two decades ago. Variable rate application services for fertilizer and lime, and prescriptions for seeding and pesticides have been introduced and are expected to increase at a rapid pace (Figure 3). GPS based guidance and auto control systems have been adopted at a more rapid pace since the late 1990’s and are finding new uses in automation and telemetry enabling improved process control (Figure 4).

A 2019 survey of 800 commercial farmers (1000 acres or larger in size) by Purdue’s Center for Commercial Agriculture provides further insight on issues of precision agriculture technology adoption and data analysis and utilization. Results indicate that a large proportion of farmers with 2000 or more operated acres collect yield monitor (approximately 75%), soil sample (approximately 85%) and imagery (close to 90%) data. This data has the highest influence on fertilizer decisions, seeding rate decisions and drainage decisions. And the respondents appear to be very satisfied with the results – 72% report a positive yield impact from data-driven seeding rate decisions; 81% from fertilizer decisions and 85% from drainage decisions. Collecting data from all three sources results in even more satisfaction with the results than if only one data stream is collected. As to data management practices, 47% of the farms collecting data use one or more data software products/services; 63% of farmers with 5000 acres or more use at least one data software product/service. In terms of data sharing, over 70% share their farm data with at least one service provider. And farmers who subscribe to a data software platform or share their data with an outside service provider are much more “highly influenced” by the data in their seeding and fertility decisions than those who collect data but do not use a platform or share their data.

Lowenberg-DeBoer and Erickson have provided an excellent review of the research that has been done internationally on the adoption of precision agriculture technology (Lowenberg-DeBoer and Erickson, 2019). Quoting from their work:

“Rapid adoption of some PA technologies worldwide: GNSS guidance and associated technologies like sprayer boom control and planter row or section shutoffs are becoming standard practice for mechanized agriculture. They are being adopted as fast as any agricultural technology in recent memory, just as fast as GM seed and over a wider area because GNSS guidance has not faced the regulatory hurdles and political/social concern that has restricted use of GMs in some parts of the world.” Page 14

“Slow adoption of VRT: The main reason for perceiving that PA adoption is slow is that PA is sometimes thought of as strictly VRT. In spite of the fact that VRT fertilizer was part of classic PA introduced commercially in North America in the early 1990s, adoption at the regional level rarely exceeds 20% of farms. This level of adoption suggests that farmers like the idea of VRT and are trying it, but are not convinced of its value. The VRT adoption estimates for specific groups of farmers may exceed 50% and approach the standard practice level. High VRT adoption estimates also occur because survey sampling is not representative. For example, farmers attending a PA workshop or a farm technology show may be self-selecting for PA interest and consequently a high percentage of them may have tried VRT.” Page 14

Their perspective is that:

“Historians of the future may look back and realize that the VRT equipment and services marketed starting in the early 1990s were a useful first step, but not the last word in spatial management of crop inputs. A new wave of technology may be required to apply the right input, at the right place, at the right time, and in the right manner. For example, it may require robots equipped with AI doing individual plant management.” Page 15

Figure 2. Dealer offering of precision services over time, sensing technologies. 2022 are projections.

Figure 3. Dealer offerings of precision services over time, variable rate technologies. Starting at 2017 the survey stopped asking separately about single and multiple fertilizer applications. 2022 are projections.

Figure 4. Use of precision technology over time by retailers, automated technologies.

Finally, as to the profitability of adopting precision agriculture technology, early studies indicated that the returns are modest – – for example a 2% increase in net returns for using soil and yield maps, automated guidance systems and variable input applications (Schimmelpfennig, J., of Ag and Applied Economics, 2018). Survey responses from soybean farmers suggest benefits of $10 – $20 per acre through the use of digital agriculture tools (Fulton, et.al, Digital Agriculture Tools to Support Soybean Production Final Report, United Soybean Board, 2017).

A more recent exploratory study of use of digital technology in farming used a detailed interview survey of a small sample (10) of farmers who are recognized as early adopters of precision farming technology to obtain their estimates of the costs and benefits of approximately 25 individual precision farming tools or practices (Pope and Sonka, 2020). Categories of tools and practices included:

- “Legacy Control Systems” (e.g., yield monitors and auto steer)

- “Mapping”

- “Agronomic/Fertility Systems” (e.g., gird/zone soil mapping, variable rate technology, sensors)

- “Monitoring Systems” (e.g., drones or aerial imagery)

- “Decision Support Technologies” (e.g., analytics, management systems)

The perceived average net benefit was almost $90 per acre, and the benefit cost ratio averaged 9.7 to 1. These results suggest a much higher payoff of precision farming than previous studies. This higher payoff is a result of the whole-farm systems benefits of the interactions among individual tools and technologies which results in a new way of farming. As reflected by the specific interview responses of the participants in this study, the payoff of adopting precision farming technologies is well beyond the cost savings and efficiency gains of specific farming practices. It is the “system” benefits of a new way of farming – the interactions among the practices that compound or multiple the benefits of individual practices or technologies and enable the implementation of a more systematic way of farming — systemic whole-farm benefits. These systemic whole-farm benefits are reflected in the insights from the farmer interviews reported in that study:

- Understanding rainfall events – knowing when to go to the field

- Knowing what is going on with different hybrids within the field

- Deciding when to cull cash rented fields

- Documentation for crop insurance claims, lenders, landlords, buyers

- Facilitates on-farm research

- Leads to savings in machinery investment and costs

- Provides data for benchmarking with other farmers

- Enables savings in labor costs

- Has made farming easier and less stressful

V. The Pay-off of Precision Farming

Precision farming has the potential to have profound impacts on the agricultural production/distribution system. What is the payoff of precision farming – for the producer, for the value chain, and for the environment and society as a whole?

For the Producer

-

Cost Reduction/Efficiency Improvement Increases

The improved measurement of soil characteristics and weather patterns that is part of precision farming has the most direct and obvious payoff in terms of cost reductions and efficiency increases from more accurate use of inputs such as fertilizer, seed, chemicals and other inputs and the systematic measurement of the impacts of these inputs on yield and profitability. In essence, precision farming is one step closer to the manufacturing mentality of production agriculture. Precision farming combined with creative ways to schedule and sequence machinery use including 24 hour-per-day operations, moving equipment among sites and deployment based on weather patterns has the potential to increase machinery utilization and lower per acre machinery and equipment costs as well

-

Value Enhanced Differentiated Products

Part of production agriculture is expected to move from commodity to differentiated product production. One dimension of that differentiation may be the production process itself – – for example the use of chemicals during only certain stages of the plant growth process. For some markets such as organic, products cannot be produced using inorganic chemicals, and some processors and food companies want to trace the sourcing of crop products to specific locations/fields with detailed documentation of production processes. With more specificity required in the raw material to meet qualified supplier requirements, increased measurement and monitoring of both the growth process and the end product will be important for quality control and compliance. In fact, precision farming in its broader context of measuring, monitoring and controlling the plant growth process is expected to have more payoff in differentiated product production rather than commodity product production because it has the potential to not only lower cost but to simultaneously enhance revenue by producing a higher valued product.

-

Span of Control

A key concern in crop operations is the perceived and, in many cases, real limit on size of operation because of the difficulty of monitoring progress and performance on large geographically dispersed acreages. The fundamental argument is that if plant growth processes can only be monitored by people with unique skills and those resources are costly or expensive to train, the monitoring process limits the span of control to what one individual (or at least a few) can oversee personally. If electronic monitoring systems can be developed that monitoring the processes of plant growth (whether it be machinery operations or the growth process of the crop or the level of infestation of insects or weeds), fewer human resources are needed for this task and generally larger scale is possible. An analogy is the transformation from the labor-intensive corn processing or feed milling plants of the past to the electronically controlled and monitored plants and mills of today with computer-based monitoring and control systems and fewer employees producing significantly more output. Crop production can and will move more and more in that direction with improved electronic monitoring and control systems, which expands the span of control.

-

Reduced Downtime/Better Capacity Utilization

A critical determinant of productivity in crop production is timely operations – getting the planting completed in a timely fashion for optimal growth and harvest completed before harsh winter weather occurs. Delays due to unanticipated breakdowns can be very costly. Telematics that inform preventative maintenance can be very useful in reducing the prospects of a breakdown – and GPS guidance can extend the hours of operating during the critical planting and harvesting seasons. Precision planting technology which enables more accurate seed placement at higher travel speeds increases the number of acres that can be planted per hour. In some cases, higher accomplishment rates and extended hours of operation per day can enable farmers to operate more acres with the same equipment or the same number of acres with a smaller machinery line.

-

Risk Reduction

No matter how good they are, people can and do make mistakes. Precision agriculture technology combined with automation reduces the chances of a mistake. GPS based auto- guidance combined with row shut-off technology reduces overlap in chemical or seed application. Seed monitors reduce the chances of skips or other inaccuracies in seed placement. Yield monitors provide the data for more accurate selection of fertility and chemical programs, which combined with variable rate application technology, reduce the risk of making an incorrect variety or weed control selection in subsequent years. And more timely planting and harvesting using precision farming technologies reduces the risk of yield reductions from unpredictable weather events.

-

Landlord/Supplier and Buyer Relationships

One of the most important business relationships a farmer has is with the land owners who rent him/her their property. Keeping the land owner (or the management company that has been retained by the landowner to oversee this arrangement) informed of the farming activities that are occurring on their property, the progress of the growing crop and the management and cultural practices that are being used by the operator to maintain or improve the productivity of the property strengths and deepens this critical relationship. The data and information generated through use of precision farming tools and techniques enhances communication with the land owner/farm manager well beyond the pictures and phone calls typically used in the past. Communication with other suppliers such as lenders and agronomic input and farm equipment suppliers is also enhanced by the additional detail that can be provided to solve problems or assess issues. And in a similar vein, data/information useful to more effectively communicate with buyers concerning crop progress and/or production practices or problems can also enhance the “preferred supplier” relationship that more and more farmers want to have with their product purchasers.

-

Enhanced Property Value

Finally, a longer-term payoff of adopting precision farming practices is improved productivity and soil health and thus value of the land. Farm land values are heavily dependent on productivity as reflected by yield, and in today’s and tomorrow’s agriculture yield is more and more impacted by data driven investments in land improvements. In the past these improvements have been primarily in the form of investments in drainage, land clearing, terraces and contour tillage, waterways, etc., but in recent years they have included the adoption of management practices that improve fundamental characteristics of the soil such as microbial activity, water-holding capacity, acidity, organic matter, compaction, soil tilth, etc. The use of management practices informed by improved sensing technology and data analytics that document the long-term yield response of 4R (right source, right rate, right time, right place) applications of agronomic inputs, soil conserving tillage techniques, cover crops, lime application, etc., have demonstrated the productivity benefits of improved soil health. Just to illustrate, one of the most common and well-recognized data driven precision agriculture soil health investments is lime applications to increase soil pH which enhances root growth and nutrient uptake.

So how specifically does this show up in a direct payoff to farmers? One way to think about and actually document the payoff is to measure the additional value of farmland that results from using precision agriculture tools and techniques. A common way of measuring farmland productivity in the Midwest is the CSR (Corn Suitability Rating) – – a soil productivity index driven primarily by fundamental soil characteristics (texture, tilth, water-holding capacity, etc.) or soil types, and less so by current and past farming practices. Precision agriculture documentation can help us understand how more informed data driven decisions on tillage, fertility, chemical use, seed selection, and planting and harvesting operations can enhance the natural productivity of the soil (compared to properties with the same CSR rating where these practices are not used), thus creating additional value that can be captured not only by higher yields and profitability during the years the owner is farming the land, but also in the value of that land when it is eventually sold or a higher rental rate when rented to a tenant. In essence, land farmed with precision farming practices has the potential to be more productive over a lifetime and consequently has higher value – – it is worth more to the property owner as well as to society.

For the Value Chain

-

Food Safety

One of the most difficult risks for a food processing firm to manage is the potential of contamination in raw materials. And for a branded-product food company, a food safety scare can be disastrous. The improved measurement and monitoring of the soil preparation, growth, harvesting, storage and handling, and processing processes that have the potential to be part of precision farming in the future will enable trace-back from end-user through the production/distribution chain which is the only secure method of guaranteeing food safety. If food safety concerns continue to increase and consumers demand more documentation that food products are in fact safe, precision farming has the potential to become one of the most effective ways of providing that documentation and reducing the risk of food contamination.

-

Sustainability

A growing number of food processors and retailers are responding to the “sustainability” concerns of their customers by requiring their suppliers to meet what they have specified as sustainability criteria, and document their sustainability practices. For example, General Mills has indicated that by 2020 it expects to source close to 100% of its commodity raw materials (for example corn, wheat and rice for breakfast cereals) from fields that meet their sustainability criteria, and they expect to be able to trace the source of raw materials for their products to specific farms and fields. Some food retailers have or are considering adding a “sustainability” label to their food products much like the nutrition label that they currently carry. These “trust your food” initiatives are expected to expand. Precision farming provides the capability to execute and document the sustainability practices increasingly required to be a “qualified supplier” in a more demanding supply chain.

-

Traceability

Not unrelated to the increasing concerns of food consumers about food safety and sustainability is the issue of traceability and the chain of custody. If there is a food safety issue or contamination of a food product, consumers as well as food companies and government officials are eager to quickly uncover the source and take mitigating action. Tracking and tracing at the farm gate level to uncover sources of contaminant is significantly enhanced with precision farming tools that have recorded the use of specific agronomic and production practices. Likewise, similar documentation can be used to verify that sustainability criteria have been met, or what adjustments might be needed to maintain “qualified supplier” status.

For the Environment

-

Reduced Fertilizer and Chemical Leaching and Runoff

More precise applications of fertilizer and insect and weed control in terms of location, timing and amount to better match plant needs should reduce leaching and runoff into ground and surface water and the resulting deterioration of water quality. Undoubtedly this potential exists, but what if the precision farming recommendations are for the highest application rates on the soils closest to a stream or waterway or with a shallow water table and heavy rains occur shortly after application. Precision farming has the potential to reduce environmental degradation of water sources, but we need to monitor and measure this phenomena to be sure we are obtaining the expected results.

-

Conserving Irrigation Water

In some locations in the US, particularly in the Southern Plains, the availability of water for irrigation purposes is declining because utilization and draw-downs exceed recharge rates for underground as well as surface water sources. Use of precision farming technology to manage irrigation systems by applying water at the needed amount at the right location and the right time has been shown to significantly increase efficiency and effectiveness of irrigation, and thus conserve increasingly scarce water resources.

-

Comprehensive Nutrient Management

In many states and locales, concerns about soil and water (or even air) degradation in rural areas has resulted in pressures to regulate and restrict the application of inorganic and organic (manure and animal waste) fertilizer. Some states/locales are contemplating or requiring comprehensive nutrient management plans to reduce the environmental footprint of crop production. Precision farming tools and technologies can be very effective in developing and implementing those plans that in many cases will not only reduce the potential of environmental degradation, but also lower costs by more efficiently and effectively using fertilizer (including animal waste) inputs.

VI. What Are the New Precision Farming Developments

Significant advancements in precision farming technology have been made in the last few years. And given the increased interest in and commitment by venture capital funders and innovators/entrepreneurs to enhancing the “digitization of everything” in the food production and distribution industry, the development of new tools and technologies should continue at an accelerated pace. What should we be watching to monitor the new advances in precision farming? Here is a partial list:

- Better understanding of the fundamental drivers/determinants/constraints of plant growth and the specific structure and parameters of the underlying growth process.

- Improved technologies to more accurately real-time measure/sense/monitor that growth process.

- Better understanding of how frequently and at what level of granularity (by acre, field, parcel, etc.) to monitor and manage the production process.

- Improvement in the accuracy in measuring outputs (yield, production) and inputs (seed, nutrition, chemicals, tillage, etc.) of crop production processes.

- Further advances in the application and process control technologies that can be used in real-time to manage and intervene in order to enhance plant growth.

- A better understanding and control of the accuracy of “application” technology (seed and fertilizer placement, spray patterns and dosage, tank or batch composition and concentration, etc.)

- A better understanding of the challenges and opportunities of data aggregation and sharing needed to obtain essential insights in crop production.

- Increased availability of broadband connectivity in rural areas to enable faster and more accurate data transmission and communication.

- Advances in data security systems and resolution of issues concerning privacy and data sharing between farmers and their business partners in the value chain.

- Further advances in cloud computing, artificial intelligence (AI), Big Data, and the Internet of Things (IoT) technologies that will accelerate the digital transformation of the farming sector.

As we develop technologies and tools to expand the toolkit for precision farming and digitization systems and platforms to enhance farmer’s profit margins as well as create value for the value chain and society as a whole, the farming sector will be increasingly transformed from “growing stuff” to biological manufacturing.

___

[1]Financial assistance to complete this work was provided by John Deere Corporation—this acknowledgment does not imply endorsement of their precision agriculture product/service offerings or those of any other company or entity. Review comments provided by Michael Langemeier, Purdue University are greatly appreciated.

References and Other Resources

Center for Food and Agricultural Business, “Data and Data Analytical Themes Report” 2019 National Conference, Purdue University, 2020. Internet site: https://agribusiness.purdue.edu/research/2019-themes-report/download/

Centrec Consulting Group, LLC, “Use of On-Farm Digital Technologies”, United Soybean Board, 2020.

Erickson,B., Lowenberg-Deboer, J., and Bradford,J. “2017 Precision Agriculture Dealership Survey” Department of Agricultural Economics and Agronomy, Purdue University, Internet site: https://agribusiness.purdue.edu/wp-content/uploads/2019/07/croplife-purdue-2017-precision-dealer-survey-report.pdf.

Erickson, B., Lowenberg-Deboer, J., “2019 Precision Agriculture Dealership Survey”, Department of Agricultural Economics and Agronomy, Purdue University, 2020. Internet site: https://ag.purdue.edu/digital-ag-resources/wp-content/uploads/2020/03/2019-CropLife-Purdue-Precision-Survey-Report-4-Mar-2020-1.pdf

Fernandez-Cornejo,J., S.G. Daberkow, and W.D. McBride. “Decomposing the Size Effect on the Adoption of Innovations: Agrobiotechnology and Precision Agriculture.” AgBio Forum 4,2 (2001): 124-36.

Fulton, et.al., “Digital Agriculture Tools to Support Soybean Production Final Report”, United Soybean Board, 2017.

Lowenberg-DeBoer, J., and Erickson, B., “Setting the Record Straight on Precision Agriculture Adoption”, Published in Agron. J. 111:1-18 (2019).

Pope, Micah and Steve Sonka, “Quantifying the Economic Benefits of On-Farm Digital Technologies, Farmdoc Daily, 3/7/2020. Internet site: https://farmdocdaily.illinois.edu/2020/03/quantifying-the-economic-benefits-of-on-farm-digital-technologies.html

Schimmelpfennig, D., 2016, October. “Farm Profits and the Adoption of Precision Agriculture.” USDA-ERS, Economic Research Report, Number 217.

Schimmelpfennig, D., 2018. “Crop Production Costs, Profits, and Ecosystem Stewardship with Precision Agriculture.” Journal of Agricultural and Applied Economics. 50(1):81-103.

Schrimpf, Paul. 2018. “Taking Measure of the Precision Agriculture Program: 6 Key Observations.” Internet site: https://www.precisionag.com/market-watch/taking-measure-of-the-precision-agriculture-program-6-key-observations/

Shockley, J.M., C. Dillon, and T. Stombaugh. 2011. “A Whole Farm Analysis of the Influence of Auto-Steer Navigation on Net Returns, Risk, and Production Practices.” Journal of Agricultural and Applied Economics43(1):57-75.

Shockley, J.M., C. Dillon, and T. Stombaugh. 2012. “The Influence of Auto-Steer on Machinery Selection and Land Acquisitions.” Journal of the American Society of Farm Managers and Rural Appraisers, Pages 1-7.

Sonka, S., and Y.-T., Cheng. “Precision Agriculture: Not the Same as Big Data But…” farmdoc daily (5):206, Department of Agricultural and Consumer Economics, University of Illinois at Urbana-Champaign, November 5, 2015.Permalink: http://farmdocdaily.illinois.edu/2015/11/precision-agriculture-not-the-same-as-big-data.html

Thompson, N.M., C. Bir, D.A. Widmar, and J.R. Mintert. 2019. “Farmer Perceptions of Precision Agriculture Technology Benefits.” Journal of Agricultural and Applied Economics 51:142-163.

TAGS:

TEAM LINKS:

RELATED RESOURCES

UPCOMING EVENTS

We are taking a short break, but please plan to join us at one of our future programs that is a little farther in the future.